Few-circulation sling graded tension construction method of concrete self-anchored suspension bridge

A technology of self-anchored suspension bridge and construction method, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., to achieve the effects of shortening the construction period, reducing construction costs, and reducing the number of times of repeated tensioning and saddle pushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

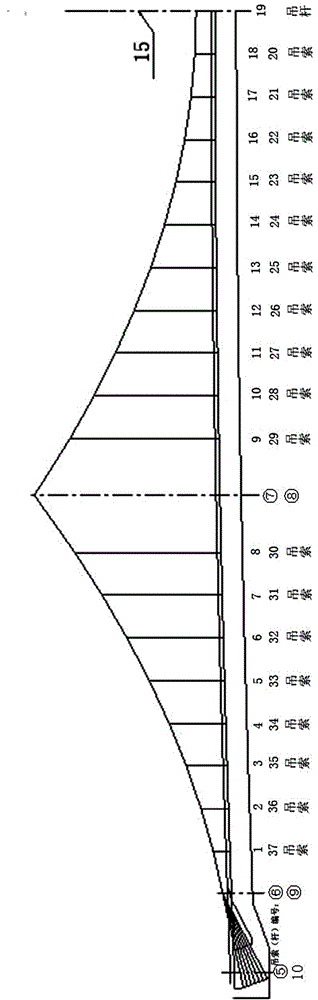

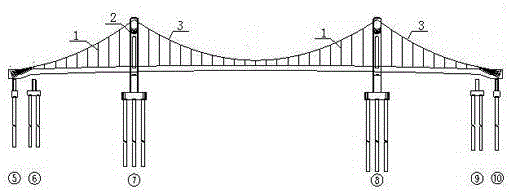

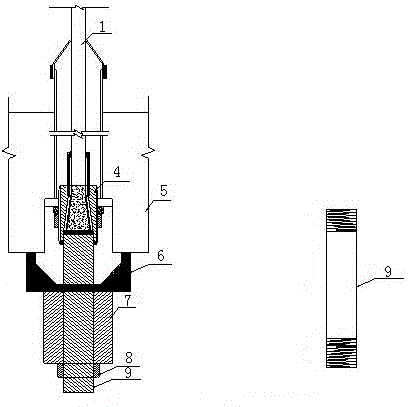

[0032] Hongkou Bridge (such as figure 1 (shown) is located in Hongkou Town, Liyang City, the main bridge is a double-tower self-anchored suspension bridge, and the span layout is: (10+42+102+42+10=206) m. The theoretical sag of the main span main cable (3) is 17m, and the theoretical sag ratio is 1:6; the theoretical sag of the side span main cable (3) is 2.838m, the theoretical span is 42m, and the theoretical sag ratio is 1:14.799. There are 4 main towers (2) in the whole bridge, and the height of the main towers (2) is 31.4m. The main girder has a total length of 207.4m and a width of 38m. There are 2 main cables (3) in the whole bridge, and each main cable (3) contains 37 parallel steel wire strands, and each strand contains 91-φ4.8mm galvanized high-strength steel wires, which are vertically arranged into a pointed regular hexagon . The distance between the suspension cables along the bridge direction is 4.5m, there are 21 suspension points in the middle span, 8 suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com