Shallow-buried tunnel section construction method

A construction method and technology for shallow buried tunnels, applied in tunnels, earthwork drilling, infrastructure engineering, etc., can solve the problem that shield tunneling method cannot be fully utilized for rapid construction, shield machine is frequently turned around and disassembled, and is not suitable for shield tunneling method construction and other issues, to reduce construction safety risks, reduce construction technical difficulty, and achieve the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

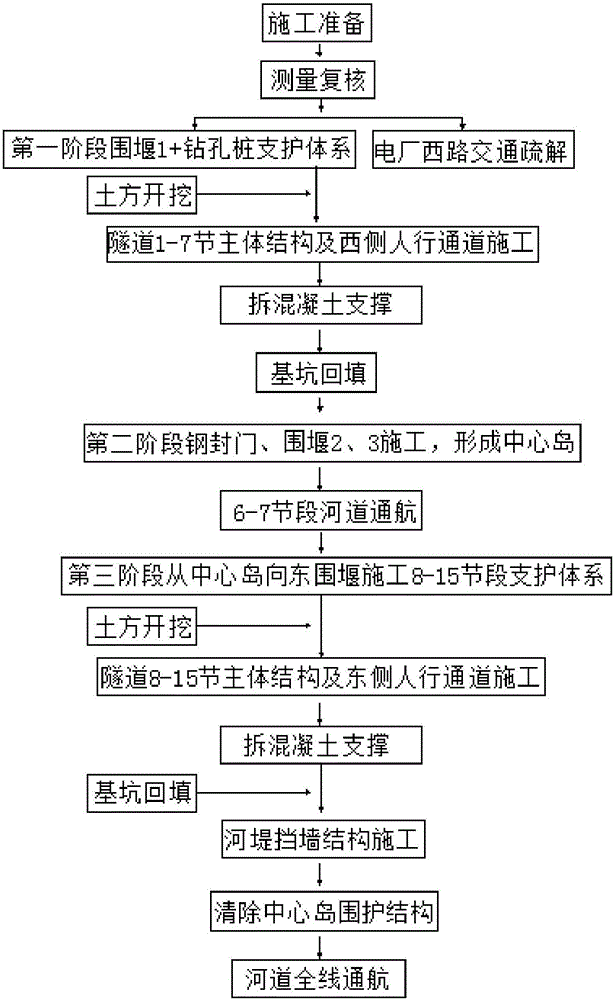

Method used

Image

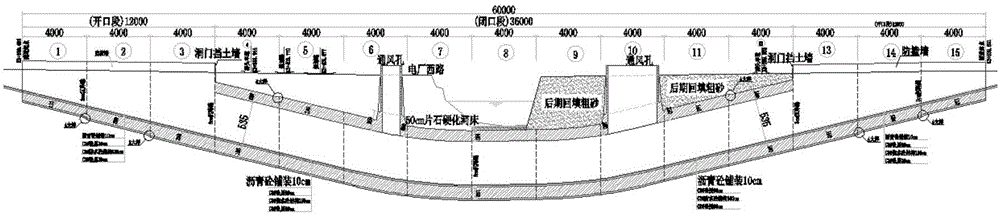

Examples

Embodiment

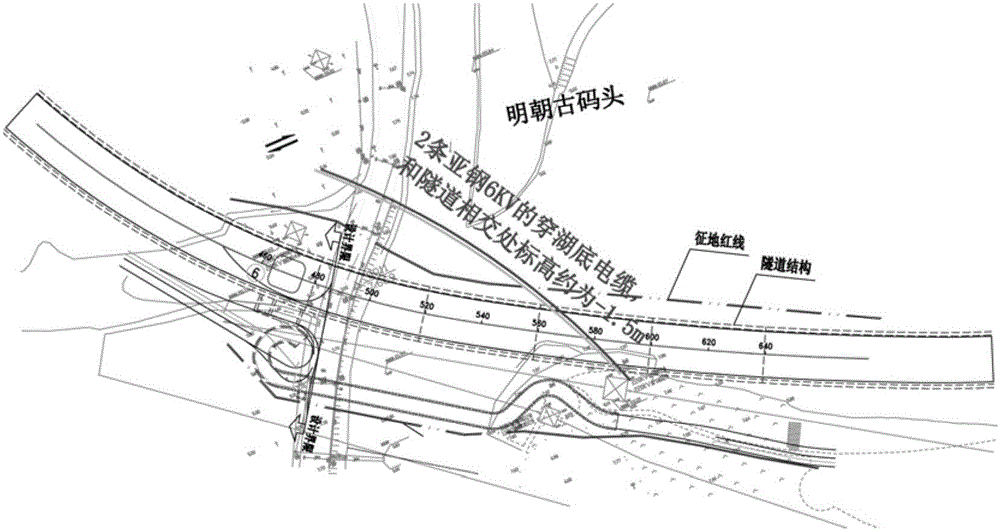

[0046] 1. Introduction to the implementation project

[0047] The embodiment of the present invention is located at Gangqian Road (South Petrochemical Road-Kaikai Avenue). The Nanhai Temple section of the Gangqian Road project passes near Miaotou Village. The south side of the line is Huangpu Power Plant, and the north is the famous Nanhai Temple. The Nanhai Temple was originally a temple on the coast of the South China Sea to worship the God of the South China Sea. Over time, the sedimentation carried by the Pearl River has caused the coastline to move southward, and the temple has a certain distance from the coastline. The current situation is that the bay near the temple has degenerated into a lake (belonging to the Pearl River system). The lake is about 400 meters long and 200 meters wide. The total area of the lake is about 80,000 square meters. The South China Sea Temple is located on a peninsula jutting into the lake. Pineapple Lake is connected to the vast South Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com