Secondary vertical rotation construction method of long-span steel pipe arch bridge

A technology for steel pipe arch bridges and construction methods, applied to arch bridges, bridges, bridge materials, etc., can solve problems such as difficulty in installation and placement, prominent safety problems, and difficulty in ensuring weld quality, so as to ensure project quality, improve construction efficiency, The effect of reducing construction safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

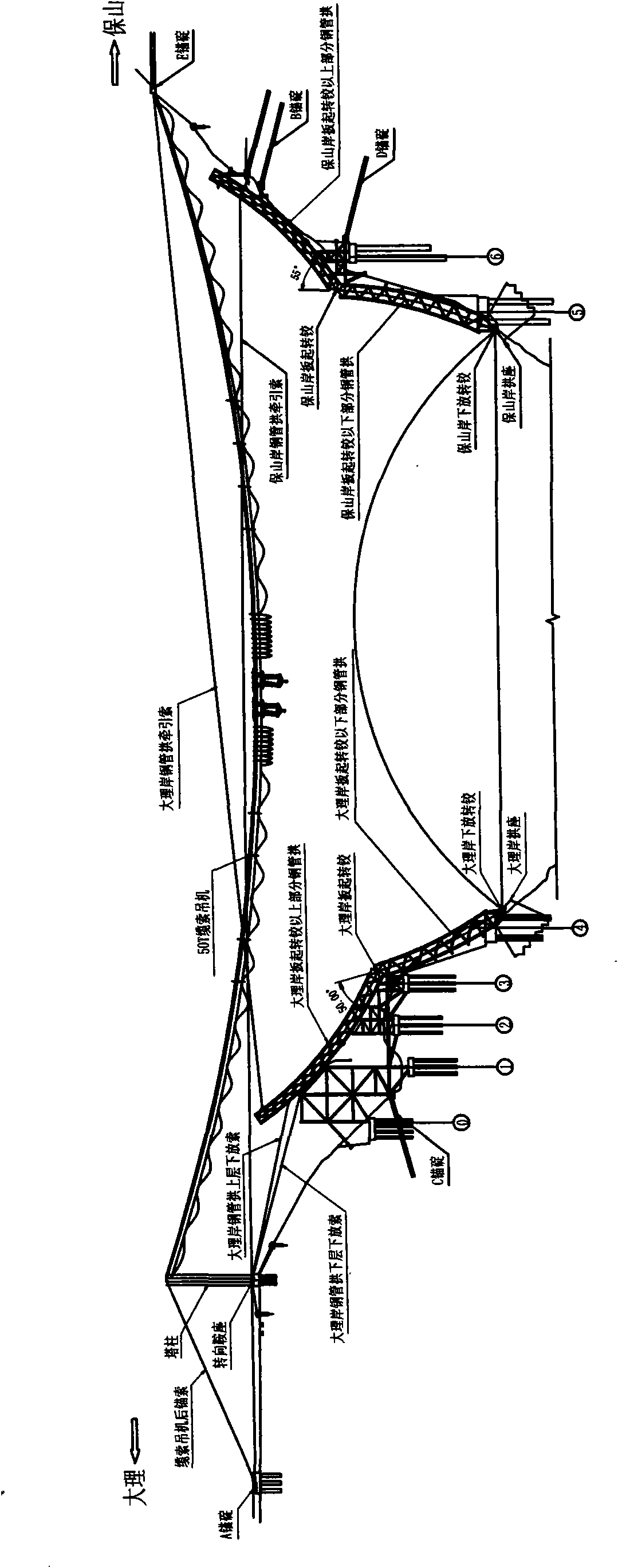

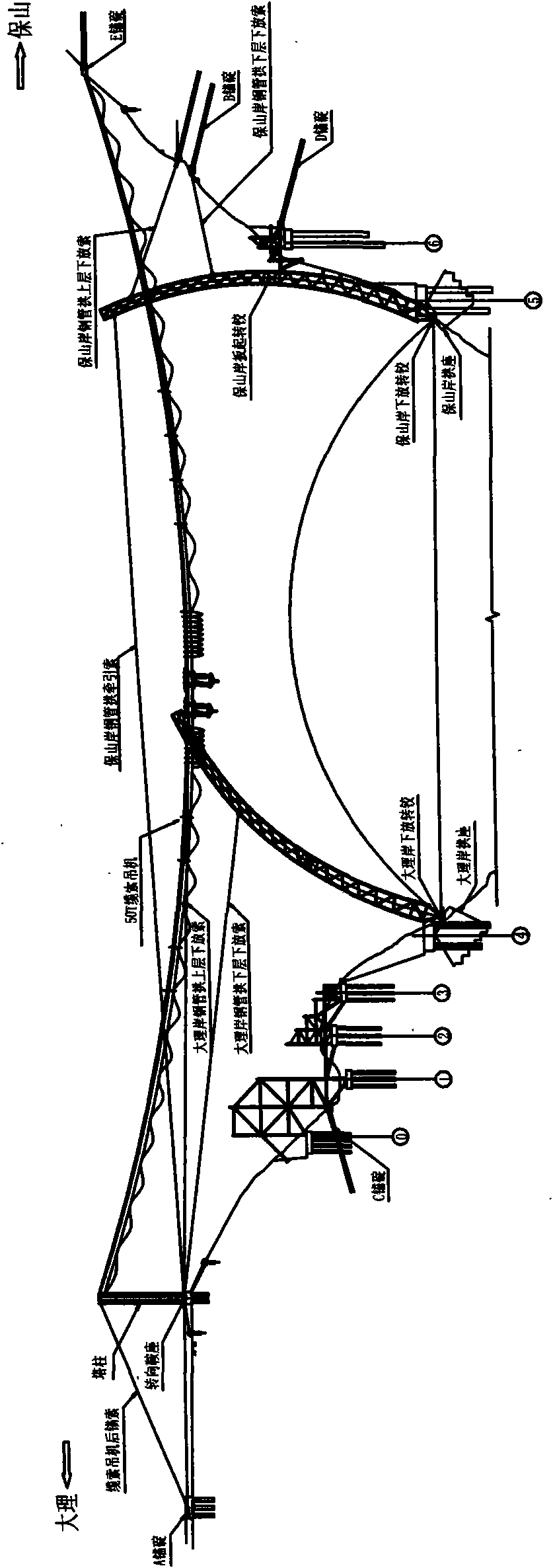

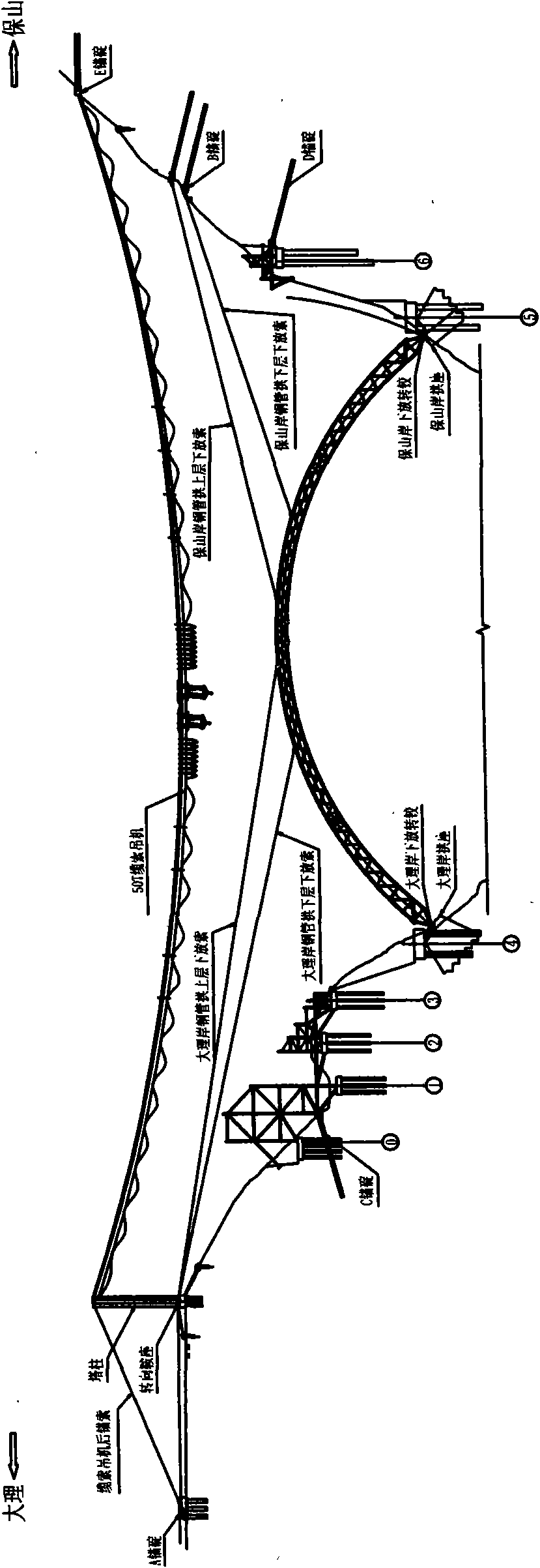

[0018] Example: Secondary vertical rotation construction of Lancang River super long-span steel pipe arch bridge

[0019] 1. Program overview:

[0020] The steel pipe arch is manufactured in the factory, transported to the bridge site by railway and road, and the construction support is installed along the mountain on both sides of the bridge site, and assembled on the support with a 50t cable crane. First lift up the part of the steel pipe arch on the lifting hinge to complete the connection of the half-span steel pipe arch, then turn it vertically downwards and close it to complete the installation and construction of the steel pipe arch.

[0021] 2. Implementation steps:

[0022] (1) Manufacture and transportation of steel pipe arches:

[0023] Restricted by road transportation conditions, the steel pipe arch steel pipe is divided into 6-11m sections, transported by car to the vicinity of platform 0# of the Dali Bank of the bridge, installed by a 50t cable crane, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com