Construction method used after tunnel integral type collapse

A construction method and integrated technology, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problem of high cost of pipe shed, and achieve the effect of reducing construction safety risks, significant economic benefits, construction accuracy and construction control.

Active Publication Date: 2017-09-15

DATANG LINZHOU THERMAL POWER CO LTD

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Pipe sheds are more expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

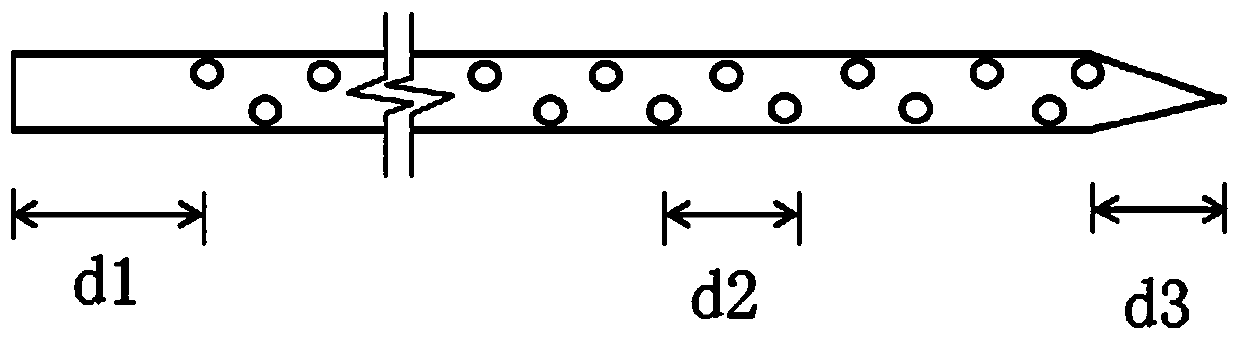

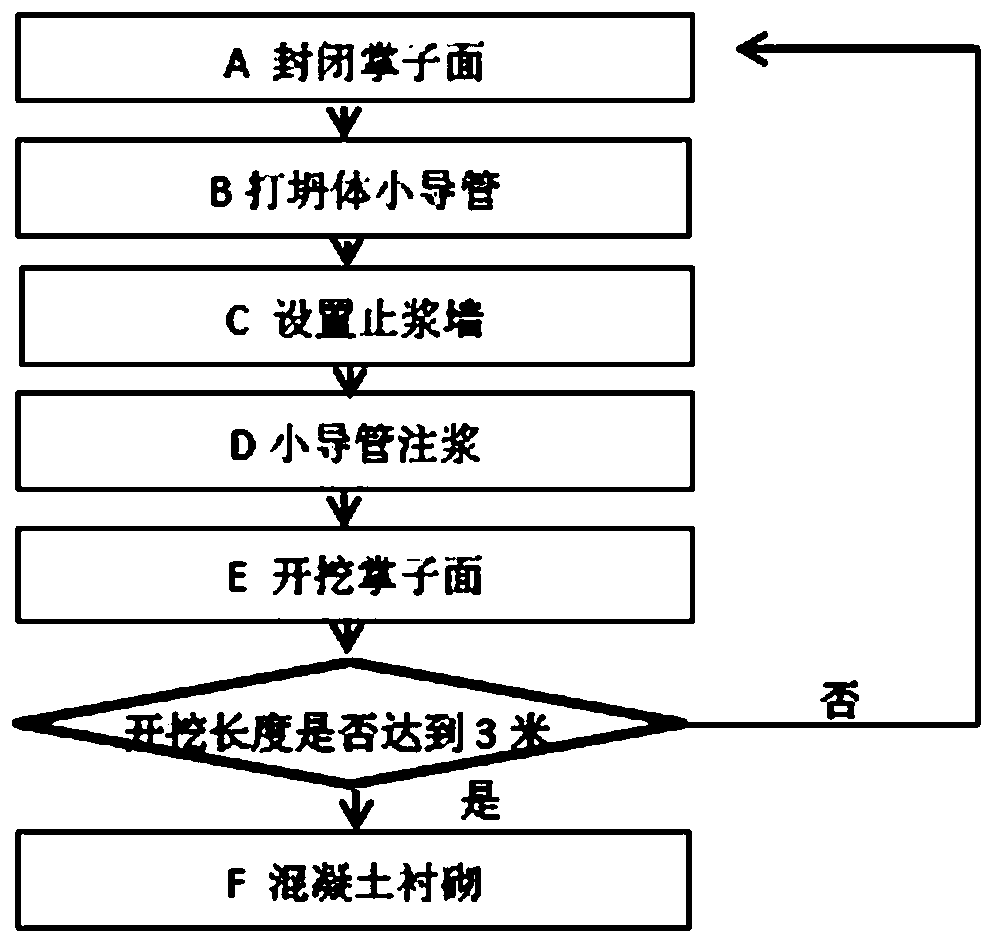

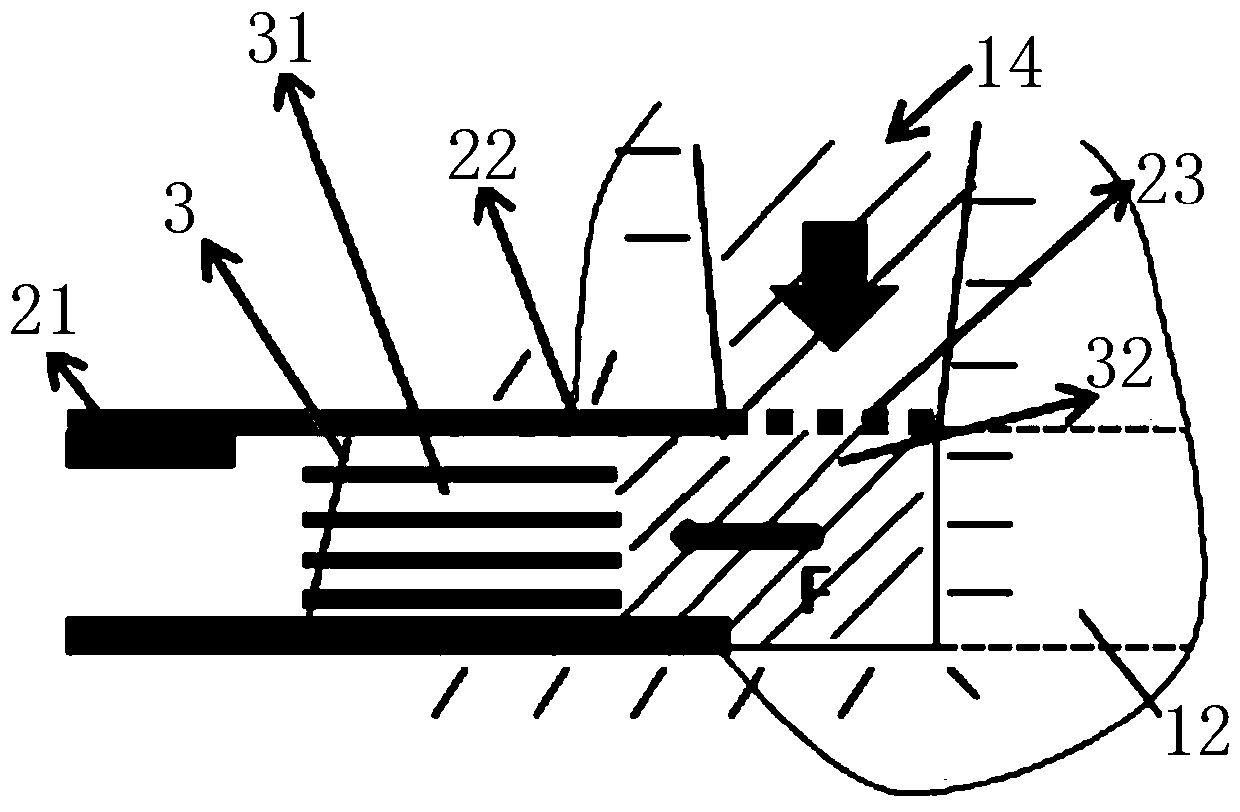

The invention provides a construction method used for tunnel integral type collapse. A collapsed tunnel is divided into two sections in the tunneling direction, the first section is an impacting area, and the second section is a collapsing area; a first support is complete in the impacting area, only a tunnel face collapsing part is subjected to treatment, and tunnel surrounding rocks are not subjected to treatment; and part of a first support in the collapsing area is damaged, and tunnel surrounding rocks and a tunnel face collapsing part are both subjected to treatment. Compared with the prior art, the construction method used for tunnel integral type collapse has the beneficial effects that (1) advanced small guiding pipes at the top of a tunnel and I-shaped steel arching frames are ingeniously combined, so that the advanced small guiding pipes form a structure similar to a pipe shed, and the supporting capacity is strengthened; and (2) collapsing part small guiding pipes are densely hit on tunnel faces to enable the tunnel face collapsing parts to be concreted, the collapsing part small guiding pipes and surrounding rock soil form a stone body, and thus the capacity of resisting the tunnel top collapsing load and impacting load is strengthened.

Description

A construction method after integral collapse of tunnel technical field The invention relates to a construction method for tunnel engineering. Background technique The length of diversion tunnels for thermal power units in power plants is generally more than several thousand meters long. The tunnel body structure is designed in the shape of a 2.5m×3m city gate, and the entrance and exit sections are excavated at the same time. The groundwater activity in culverts is generally weak, but due to faults, fault water may exist, and water inrush may occur in some sections of the cave. Moreover, due to the large permeability coefficient and strong permeability of the surrounding rock, short-term water seepage and gushing may occur in rainy seasons. If the surrounding rock is Quaternary alluvial, alluvial cohesive soil with gravel and other loose accumulations, there will be fault zones in the underlying bedrock, intersecting the tunnel line at a large angle. The surrounding ro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21D9/14E21D9/00E21D11/10E21D11/18E21D20/00

CPCE21D9/001E21D9/002E21D9/14E21D11/10E21D11/107E21D11/18E21D20/00

Inventor 王晓进胡振国靳振东董国瑞王会明孙东明

Owner DATANG LINZHOU THERMAL POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com