Method for supporting bored filling pile driven by stirring pile in foundation pit, group pit and middle pit

A technology of bored cast-in-place piles and mixing piles is applied in excavation, sheet pile wall, foundation structure engineering and other directions to ensure the safety of excavation and structural construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

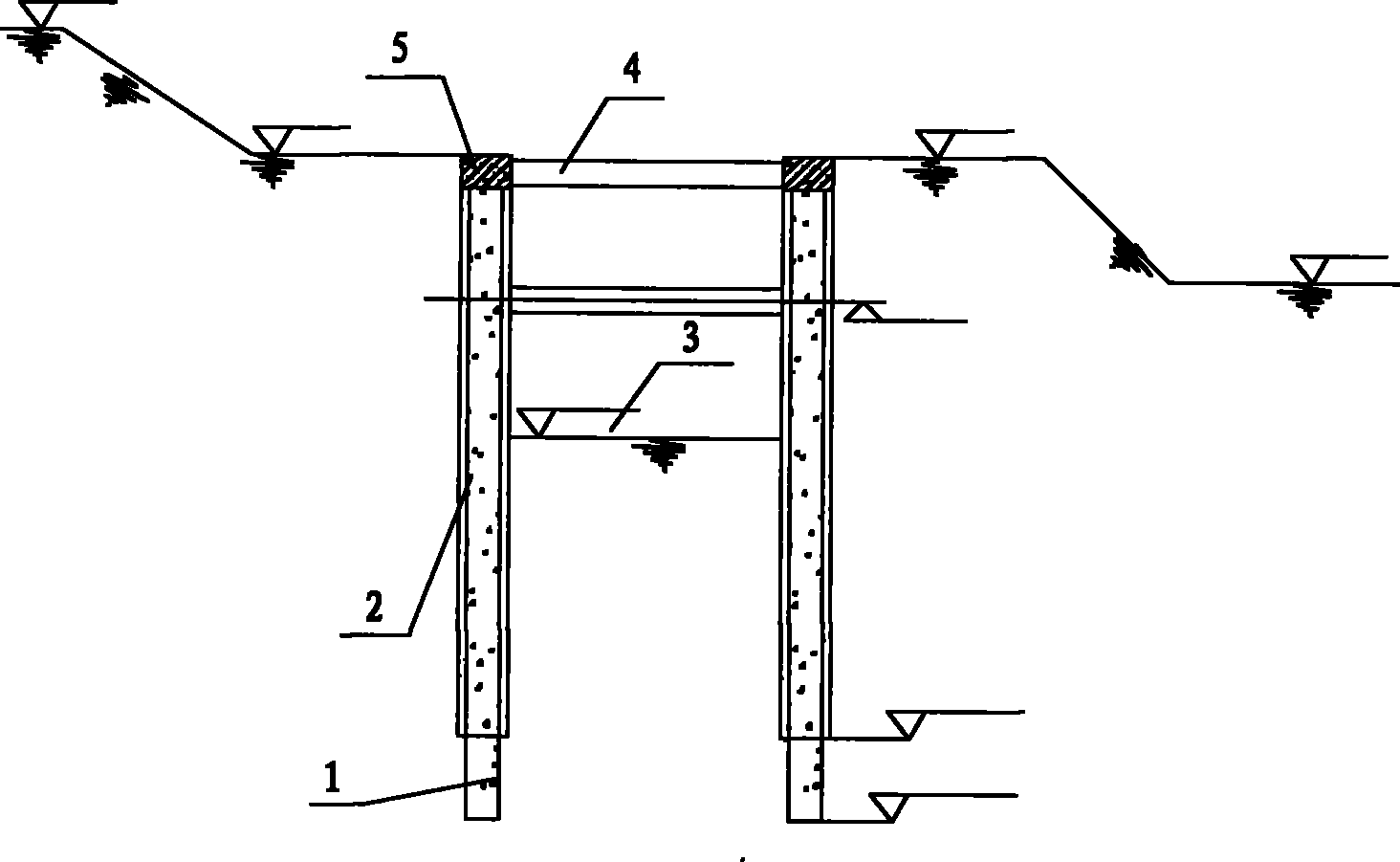

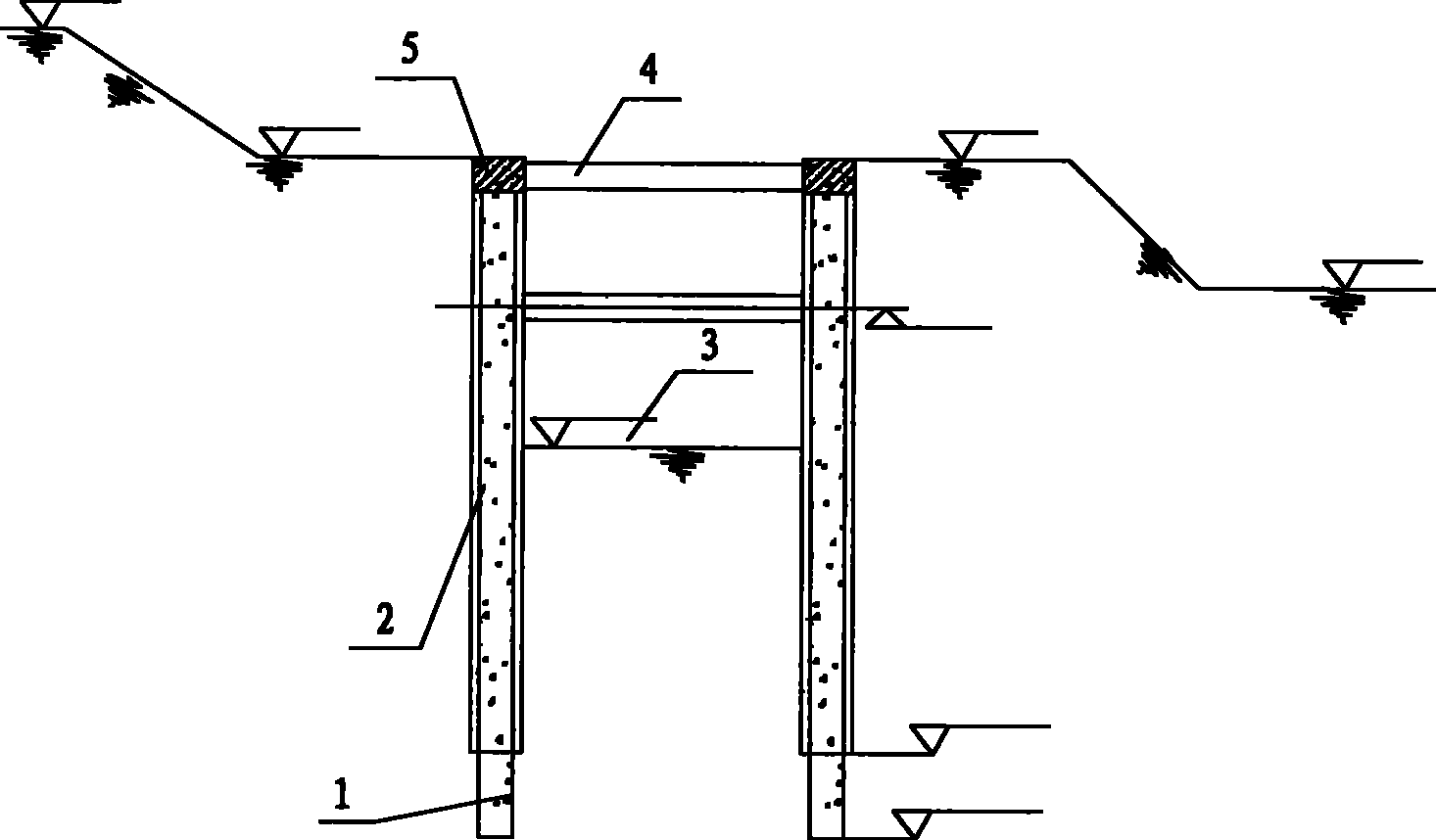

[0014] Such as figure 1 As shown, the hole-in-pit mixing pile sleeve of the present invention drills the bored pile supporting method and comprises the following steps,

[0015] Step 1. In the case of the natural floor before the excavation of the deep foundation pit group 3, carry out the support construction of 2 sets of drilling piles 1 with mixing piles, and the parts of the mixing pile 2 and the casting pile 1 are solidified with ordinary Portland cement NG soil curing agent or NG new soil curing agent, the amount of curing agent for retaining wall support is 10% to 18%, and the mixing pile is used. The water-cement ratio of the slurry is 0.5-0.55, and the construction interval time of the adjacent piles in the overlapping construction of the mixing pile 2 shall not exceed 6-12 hours;

[0016] The above-mentioned empty mixing part of the composite pile refers to the part of the composite pile of the mixing pile 2 and the cast-in-place pile 1 without the pile body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com