Method for preventing sinking of hole opening protective cylinder of slurry retaining wall hole forming cast-in-place pile

A technology of hole casing and mud wall protection, which is applied in excavation, construction, foundation structure engineering, etc., and can solve problems such as quality defects of cast-in-situ piles, self-heavy reinforcement cages, and increased uplifting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

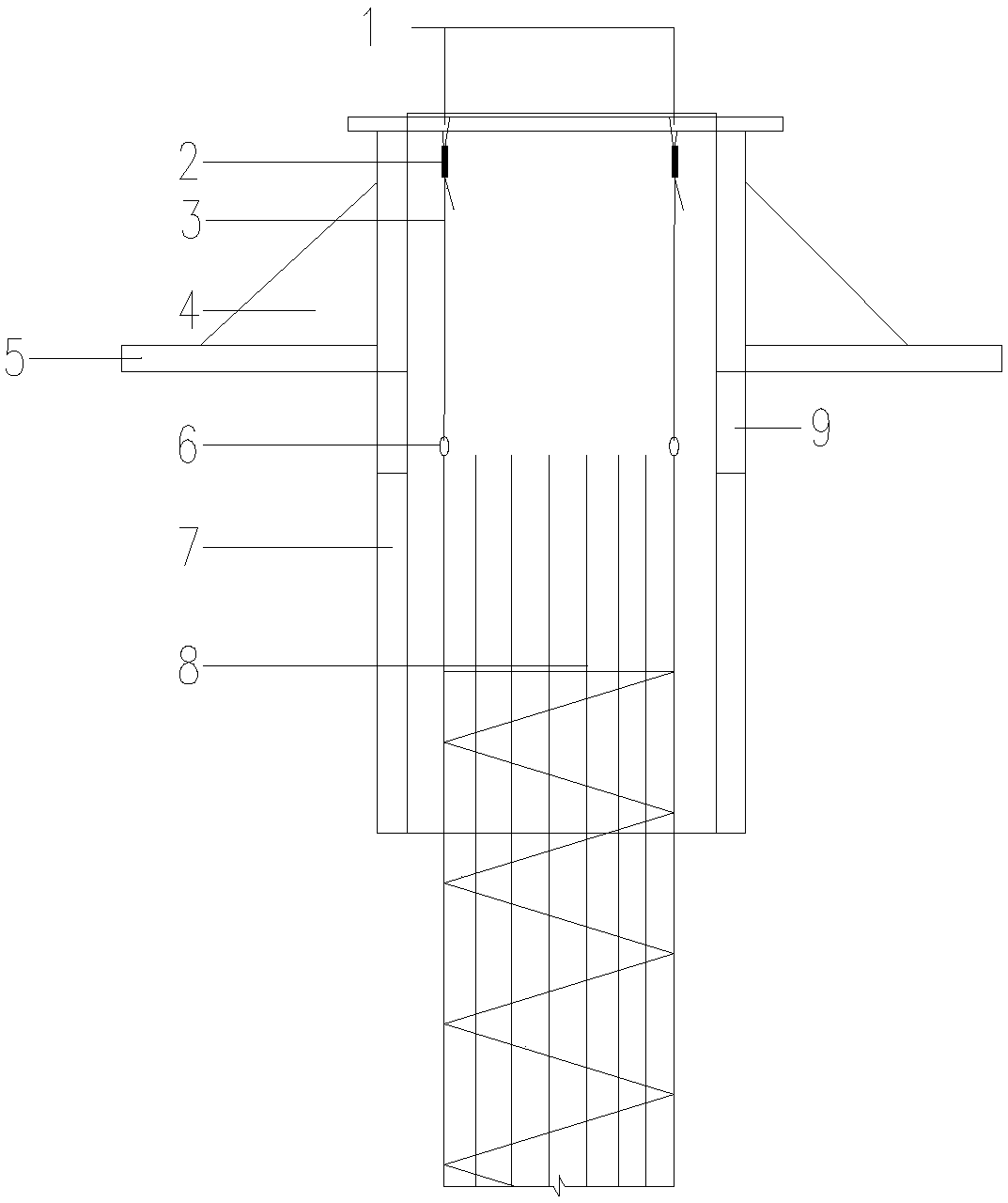

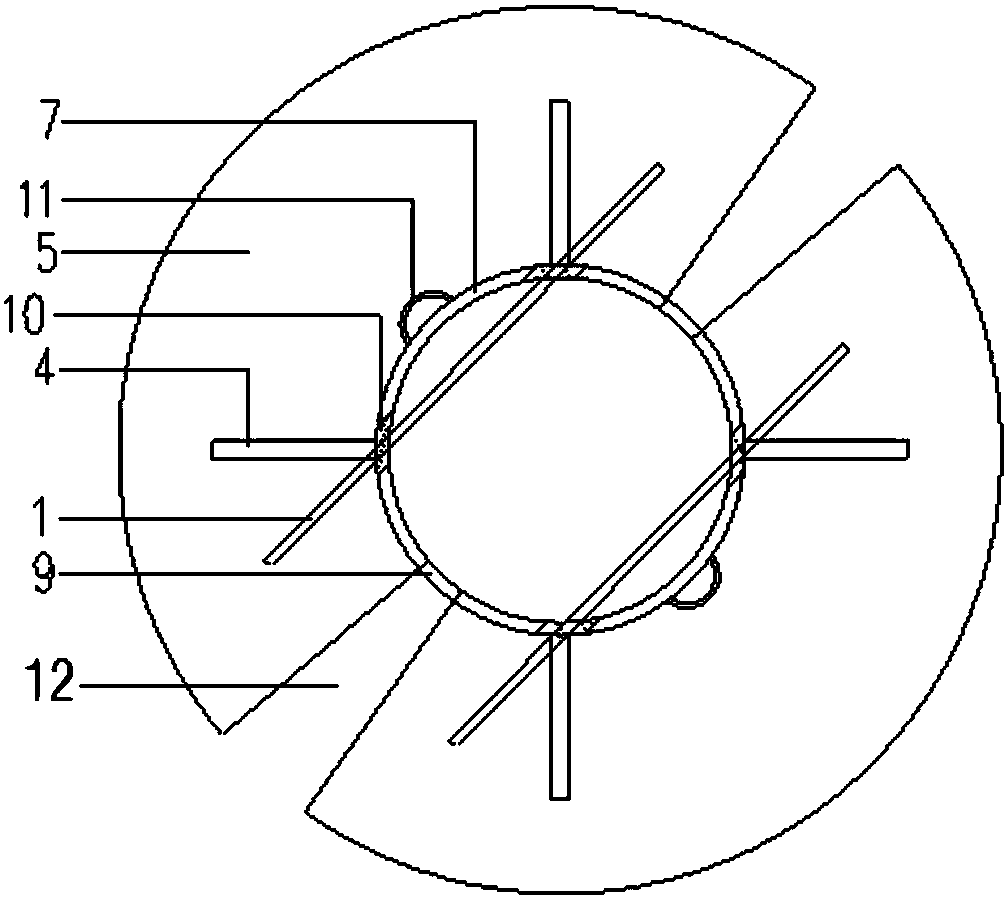

[0022] A method for preventing the sinking of an orifice casing by a mud retaining wall-forming cast-in-place pile designed by the present invention, the specific process is as follows: the anti-sinking orifice casing 7 is mainly made of a steel plate to form an orifice casing, and then the casing wall The upper part is vertically welded with two circular-arc steel plates as the casing flange 5, leaving a gap between the two casing flanges 5 for the overflow channel 12, and then vertically welding the casing wing ring and the casing wall with four triangular The reinforcing plate 4 makes the casing and the soil surface form a supporting surface through the casing flange 7, thereby limiting the sinking of the casing 7 of the orifice, and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com