Sealing device for slurry shield starting of water-rich sand layer and sealing control method for starting

A mud-water shield and water-rich sand layer technology, which is applied to earthwork drilling, mining equipment, tunnels, etc., can solve problems such as high risk and poor effectiveness of the initial sealing device, to eliminate sand gushing, improve sealing effect, simplify The effect of the originating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

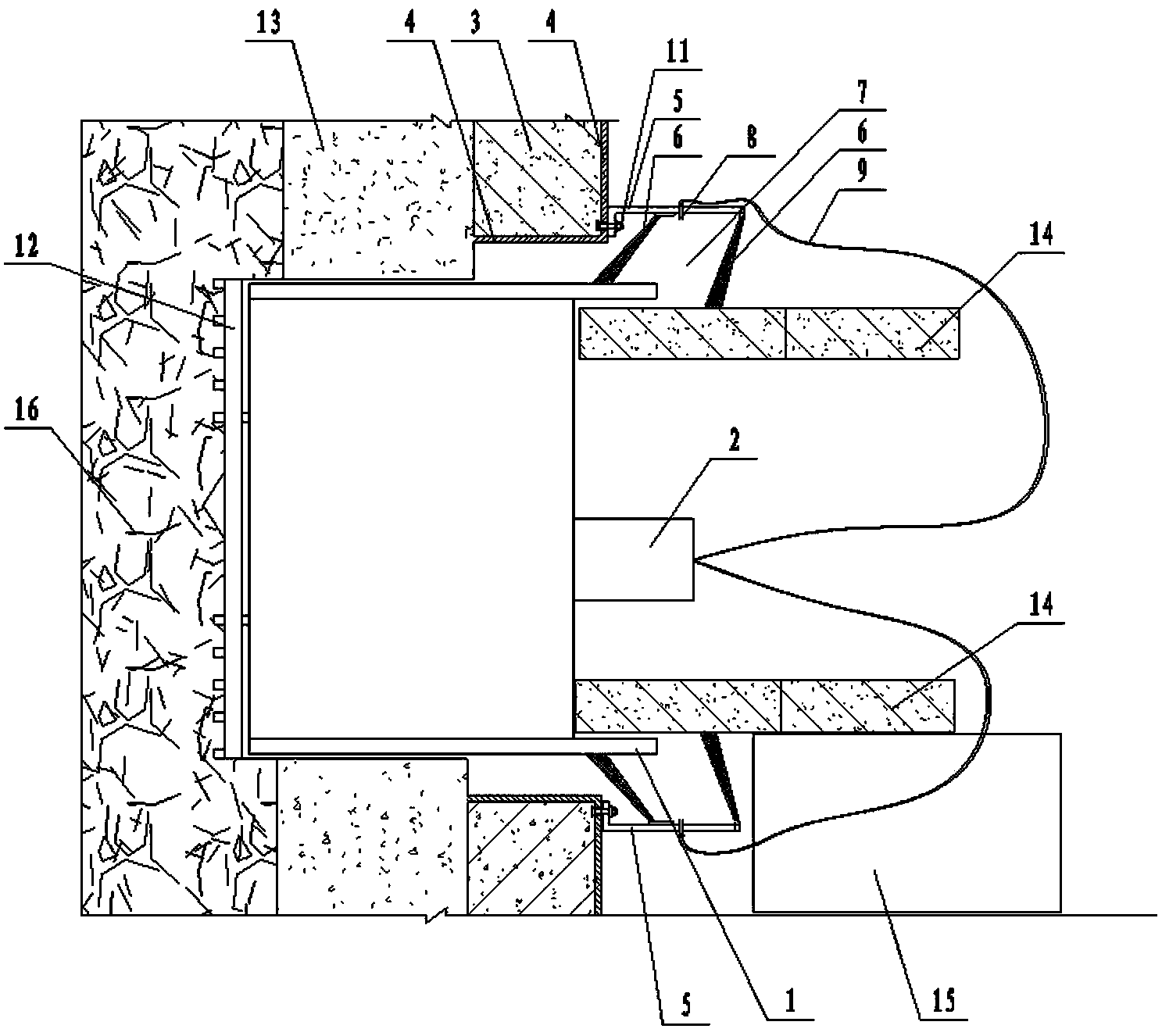

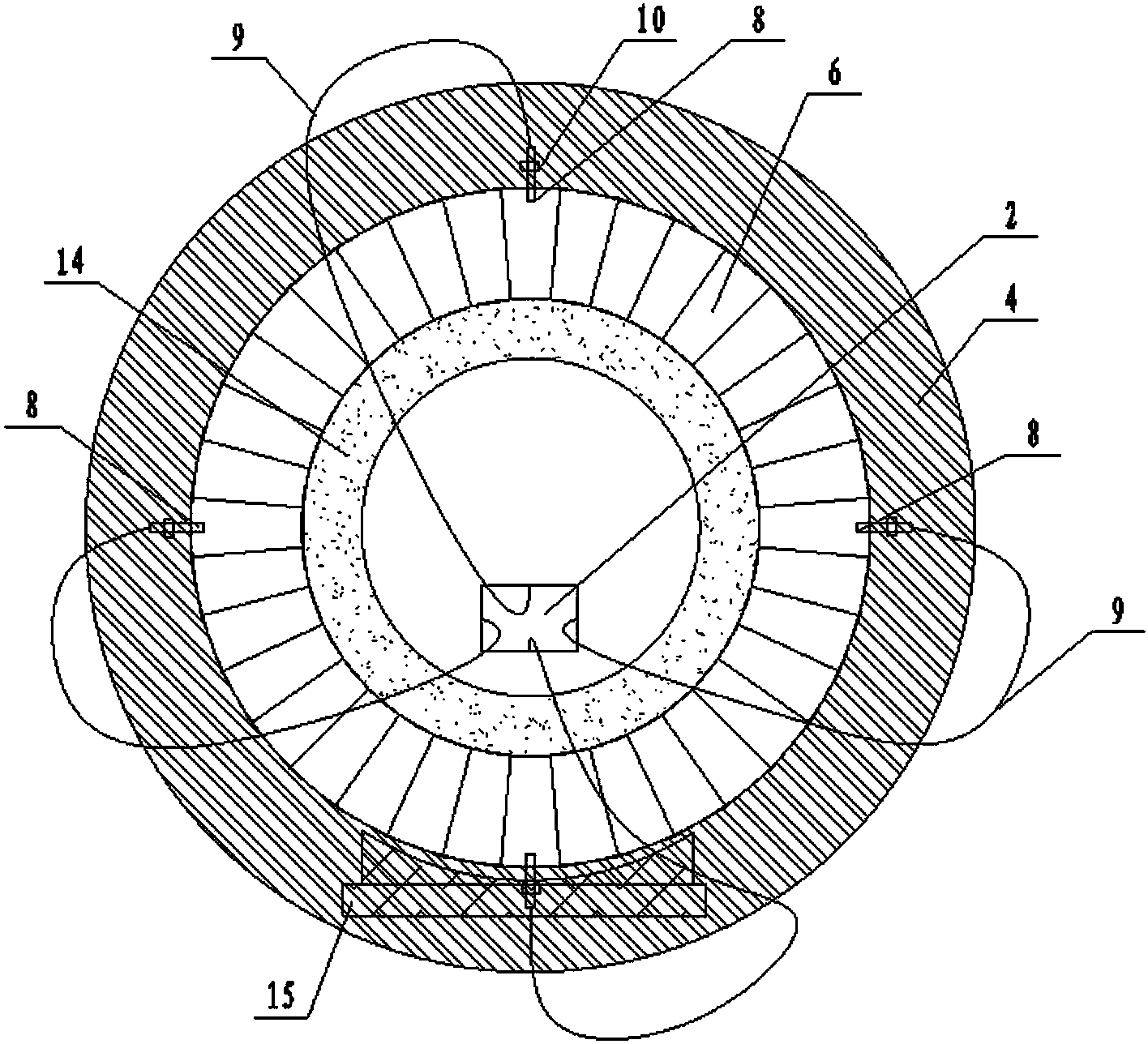

[0022] A starting sealing device for mud water shield in rich water sand layer, such as figure 1 , 2 As shown, it includes a grease distribution valve 2 installed on the grease injection pipe of the shield tail 1 of the shield machine, and an external steel ring 5 fixed on the main structure of the station 3 outside the steel ring 4 of the entrance door. Two external steel rings are provided on the inner circumference The steel wire brushes 6 sealed with the shield machine respectively, a grease filling gap 7 is reserved between the two wire brushes, and grease injection holes 8 are provided on the outer steel ring and located between the two wire brushes. Each grease injection hole The grease injection pipe 9 is connected with the grease distribution valve, and each grease injection pipe is equipped with a gate valve 10.

[0023] The initial sealing control method of the mud water shield in the water-rich sand layer includes the following steps:

[0024] Step 1. Grease distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com