C-C type interlocking steel pipe pile cofferdam and construction method

A steel pipe pile and locking technology, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of poor water-stopping effect, poor adhesion of the yin and yang lock joints, etc., and achieves easy control of construction quality. , Eliminate the effect of embedded restraint, easy to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

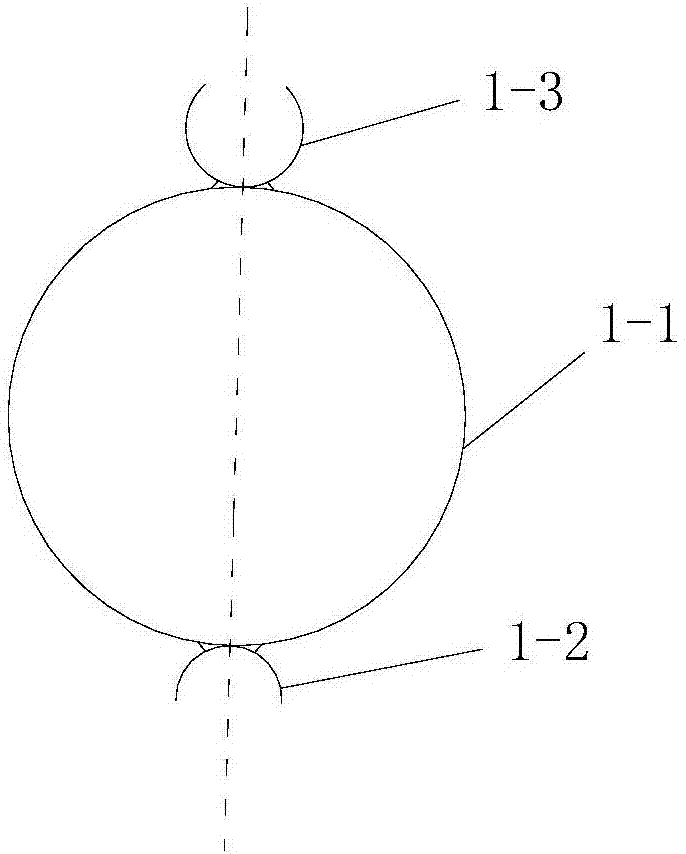

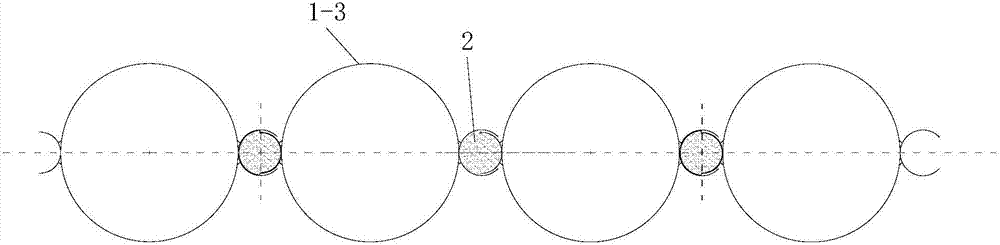

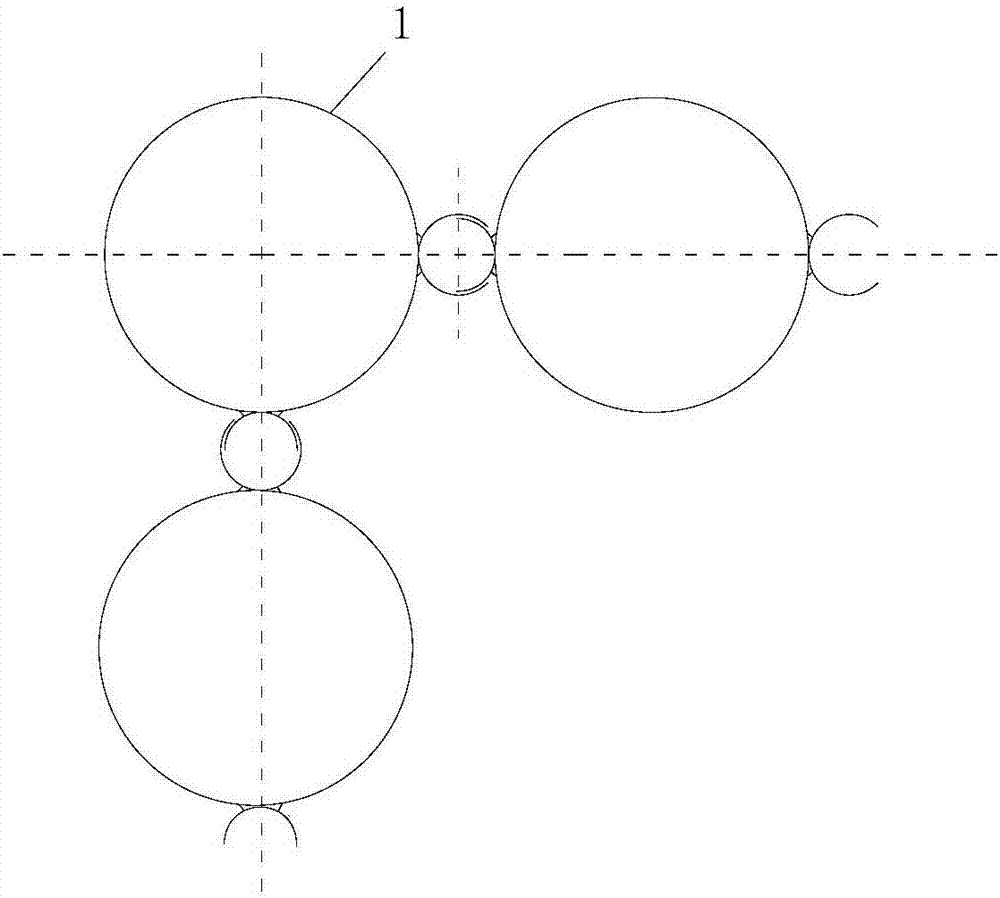

[0047] Such as figure 1 , figure 2 and image 3 As shown, a C-C type lock steel pipe pile cofferdam according to the present invention is surrounded by a plurality of C-C type lock steel pipe piles 1 closely connected in sequence, and a plurality of C-C type lock steel pipe piles 1 The structures are the same and they are all arranged vertically; each of the C-C type locking steel pipe piles 1 includes a vertical steel pipe 1-1 and a male lock 1-1 arranged on the outside of the vertical steel pipe 1-1 2 and the female lock 1-3, the male lock 1-2 and the female lock 1-3 are C-shaped and both are arranged along the central axis of the vertical steel pipe 1-1; two adjacent The vertical steel pipes 1-1 are all connected by a lock structure composed of a male lock 1-2 and a female lock 1-3 buckled on the outside of the male lock 1-2; Figure 4 As shown, each of the lock structures is densely filled by the lock filling structure 2, and the lock filling structure 2 includes a clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com