Permanent plate pile underground structure and construction method thereof

A technology of underground structure and construction method, applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve problems such as damage and poor water-stop effect, and achieve the effects of improving earthquake resistance, saving construction costs, and optimizing internal structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

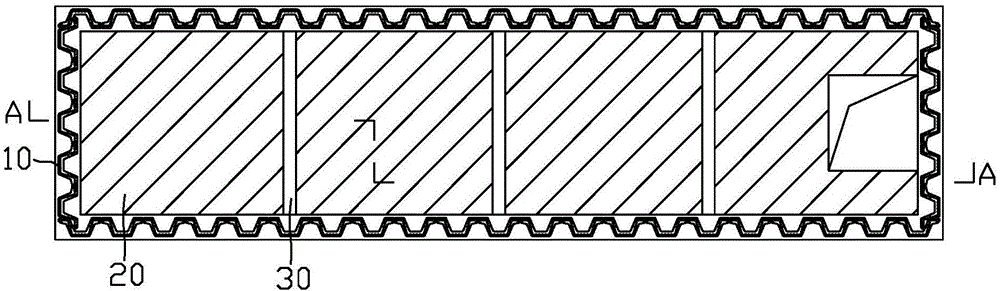

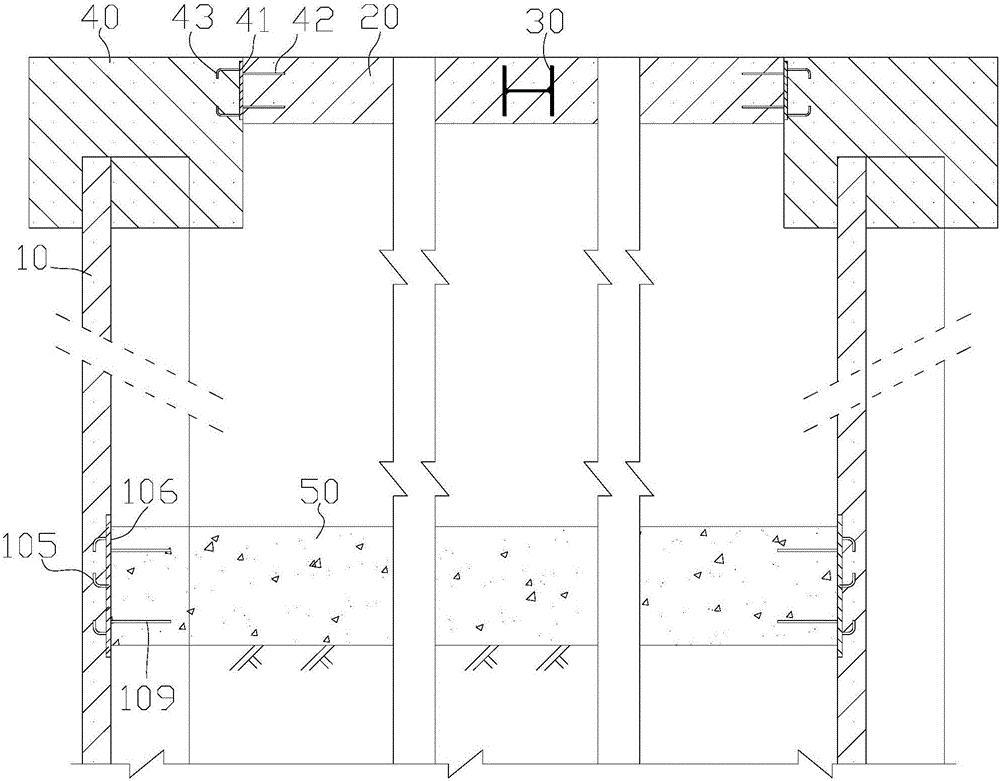

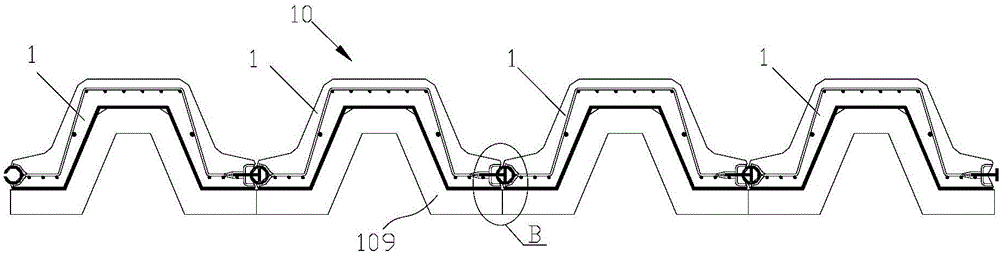

[0042] see figure 1 , figure 2 and image 3 , a permanent sheet pile underground structure, comprising:

[0043] A sheet pile wall 10 formed of interconnected reinforced concrete corrugated sheet piles 1 as the outer wall of the permanent sheet pile underground structure; a crown beam 40 arranged on top of the sheet pile wall 10; supported on The horizontal support beam 30 on the inner side of the crown beam 40; the roof 20 with the horizontal support beam 30 as a structural beam; the reinforced concrete bottom plate 50 connected to the inner side of the sheet pile wall 10;

[0044] The sheet pile wall 10 is the support structure of the foundation pit of the permanent sheet pile underground structure; the crown beam 40 and the horizontal support beam 30 are the crown beam and the support system of the foundation pit of the permanent sheet pile underground structure. Horizontal support beams.

[0045] In this embodiment, the horizontal support beam is a steel beam made of ...

Embodiment 2

[0056] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the opening direction of the groove of the main body of the reinforced concrete corrugated sheet pile faces the direction outside the foundation pit, please refer to Figure 6 , Figure 6 It is a schematic diagram of a sheet pile wall 60 forming an underground structure using a reinforced concrete wave sheet pile 6, wherein the opening direction of the groove of the main body of the reinforced concrete wave sheet pile 6 faces the direction outside the foundation pit. The structure of reinforced concrete wave sheet pile 6 is similar to that of reinforced concrete wave sheet pile 1, see Figure 7 The reinforced concrete wave sheet pile 6 includes a main body 601 with a U-shaped cross section. The main body 601 is a reinforced concrete structure, which is specifically formed by concrete 602 and stirrups 603 and longitudinal bars 604 wrapped inside the concrete 602. A part...

Embodiment 3

[0064] This embodiment is a construction method for constructing the permanent sheet pile underground structure described in Embodiment 1, which specifically includes the following steps:

[0065] (1) Please refer to Figure 9 In step a, the guide groove 71 is excavated along the edge of the foundation pit to be excavated, Figure 9 The middle mark 200 represents the ground;

[0066] (2) See Figure 9 In the b step, the reinforced concrete corrugated sheet pile is sunk and reaches the set depth, so that the adjacent reinforced concrete corrugated sheet piles are engaged with each other to form the sheet pile wall 10; the reinforced concrete corrugated sheet pile used in this embodiment is Figure 4 The shown reinforced concrete corrugated sheet pile 1, the specific structure of the reinforced concrete corrugated sheet pile 1 please refer to Figure 4 And the description in embodiment 1, no longer repeat;

[0067] A steel pre-embedded slab is provided on the inner side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com