Method for pre-damping thermal blasting demolition of concrete in to-be-dismantled area of frame structure

A frame structure and concrete technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems of inability to remove stirrups and longitudinal reinforcement cutting, inability to directly use reinforced concrete demolition work, and inability to separate concrete and steel skeletons To achieve the effect of shortening the demolition period, improving the demolition efficiency, and reducing the generation of waste and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: Use the method of the present invention to dismantle the cast-in-place reinforced concrete frame structure building.

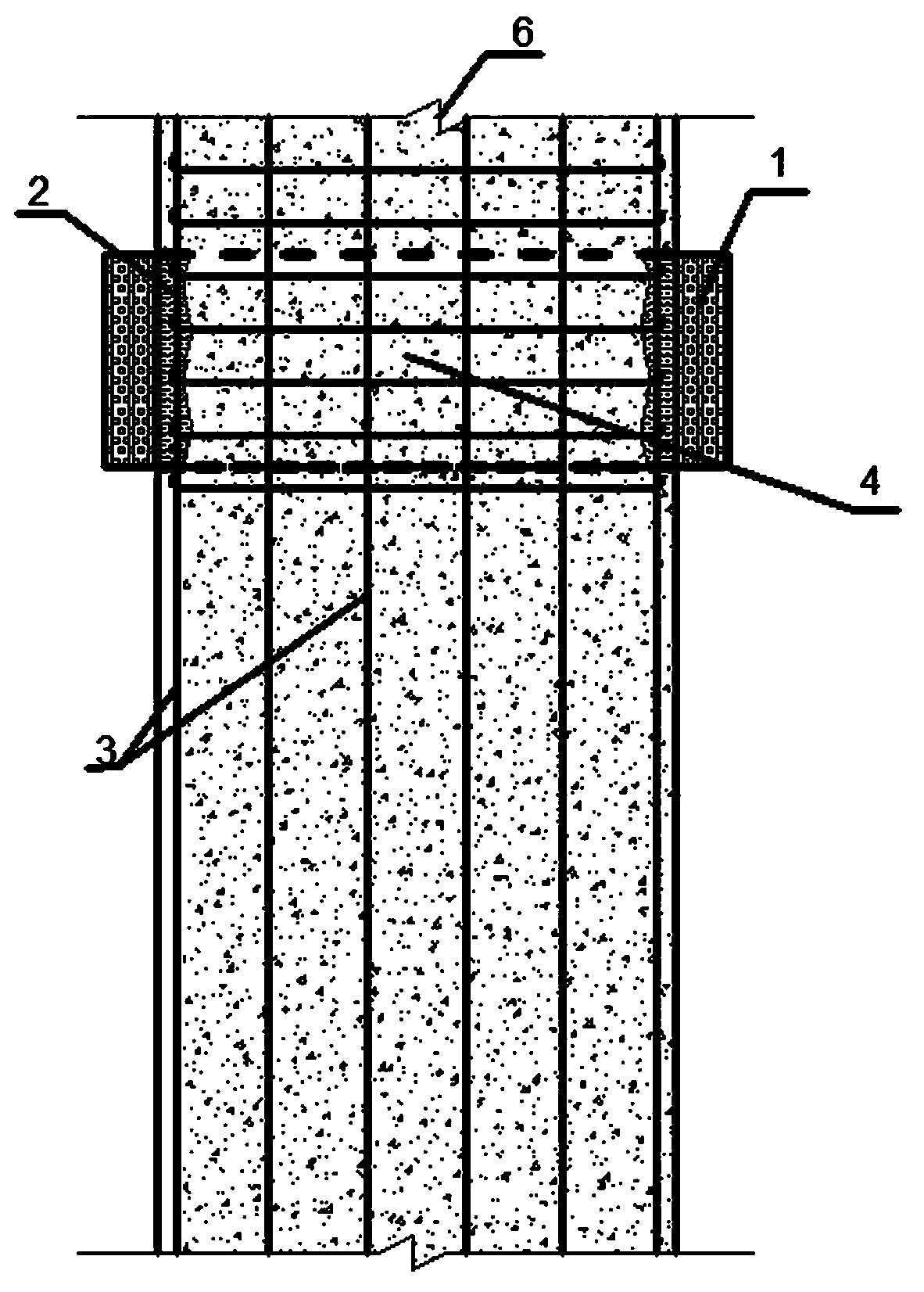

[0033] Step 1. Remove all walls, doors, windows and other non-load-bearing parts of the cast-in-place reinforced concrete frame structure building to be dismantled, leaving only the space force skeleton composed of beams, floors, and column load-bearing components.

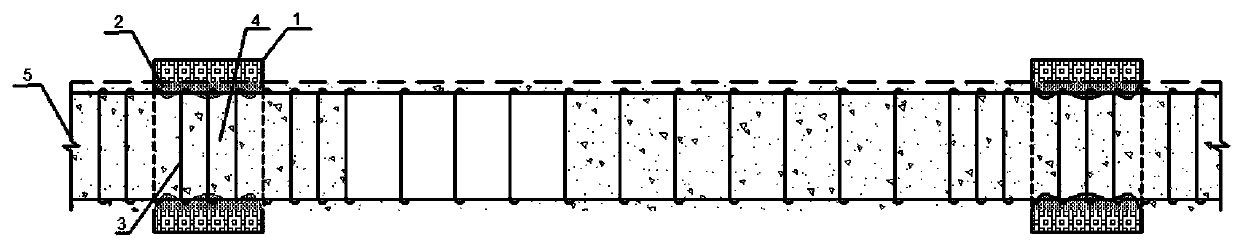

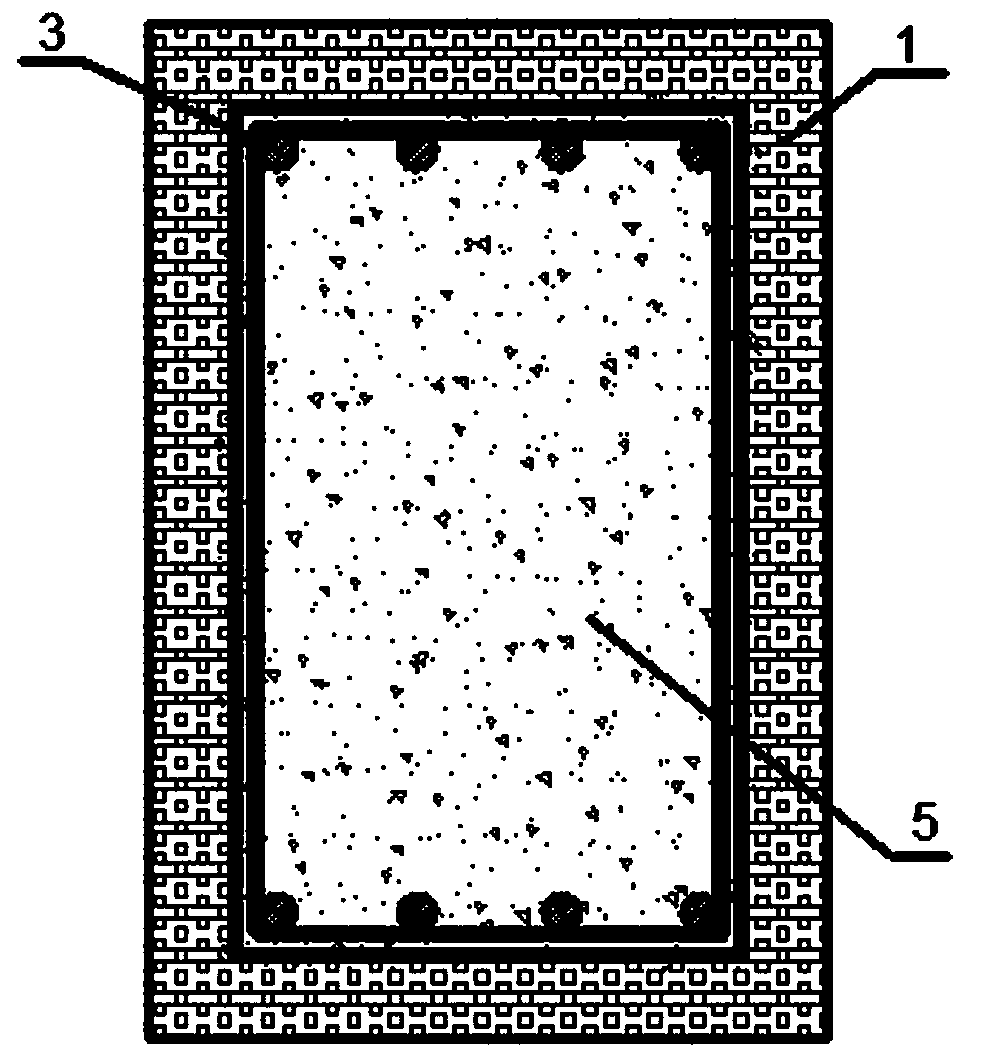

[0034] The width direction of the house is set as the main force direction of the horizontal load, which is called the transverse direction, and the length direction perpendicular to it is recorded as the longitudinal direction. The entire space force skeleton is divided into several transverse frames and longitudinal connecting beams with flanges And secondary beams and slabs with flanges. The transverse frame is composed of several frame columns and beams between each frame column, the longitudinal connecting beams are horizontal connecting beams between adjacent transverse fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com