Pi-shaped concrete pile

A concrete pile and concrete technology, which is applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve the problems of small pile diameter limitation, soil erosion, complicated construction, etc., and achieve the effect of ensuring connection strength and water-stopping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

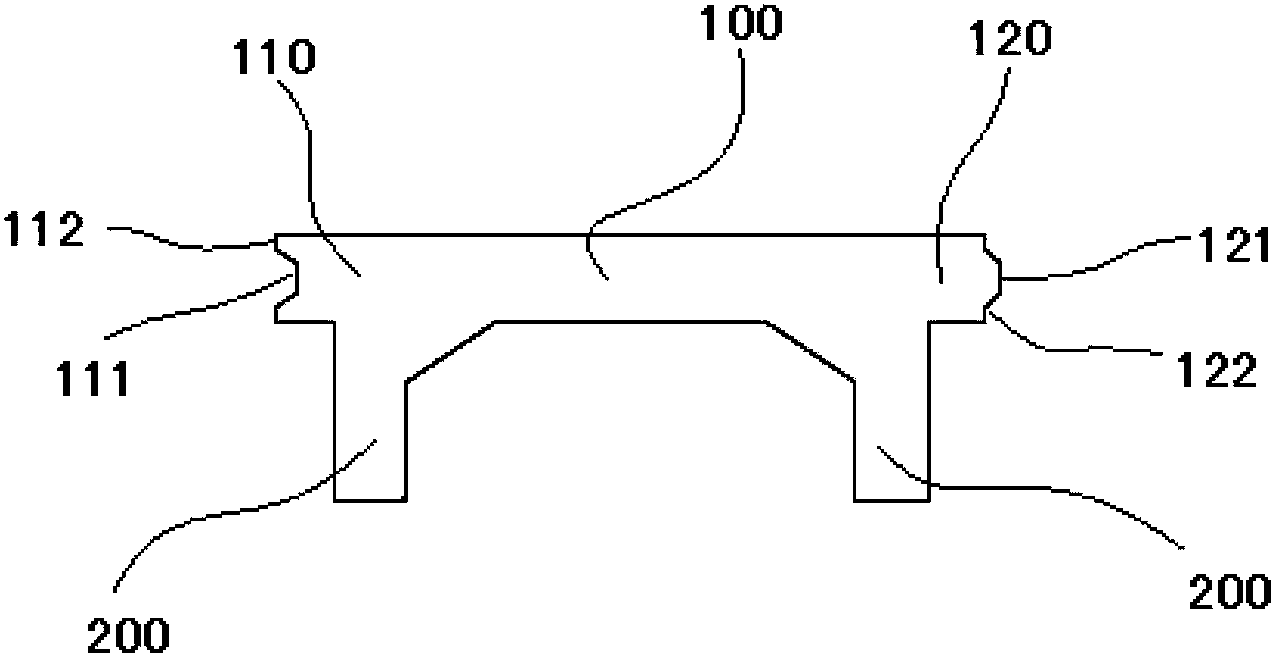

[0029] see figure 1 and figure 2 As shown, a π-shaped concrete pile of the present invention is made of high-performance concrete, active powder concrete or fiber concrete. Since the concrete has a considerable difference from the steel plate in terms of mechanical strength and post-processing, it can adopt The structure and shape are just one of the differences between the present invention and the existing steel sheet piles.

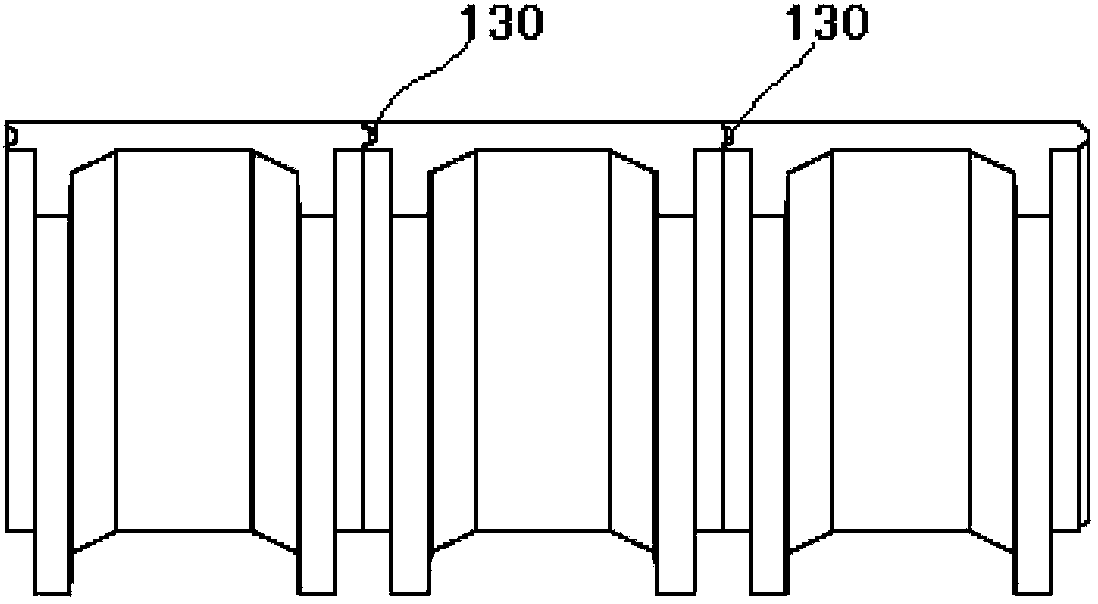

[0030] The π-shaped concrete pile of the present invention includes a pile body with a cross section of π shape, which can also be described as a double T shape; The two sides of the crossbeam 100 have a first connection part 110 and a second connection part 120 that play a connecting role, and there is a gap between the mating surfaces of the first connection part 110 and the second connection part 120 that abut against each other in shape. 130 , pouring concrete slurry into the gap 130 , filling water-stop rubber strips or setting sealing material...

Embodiment 2

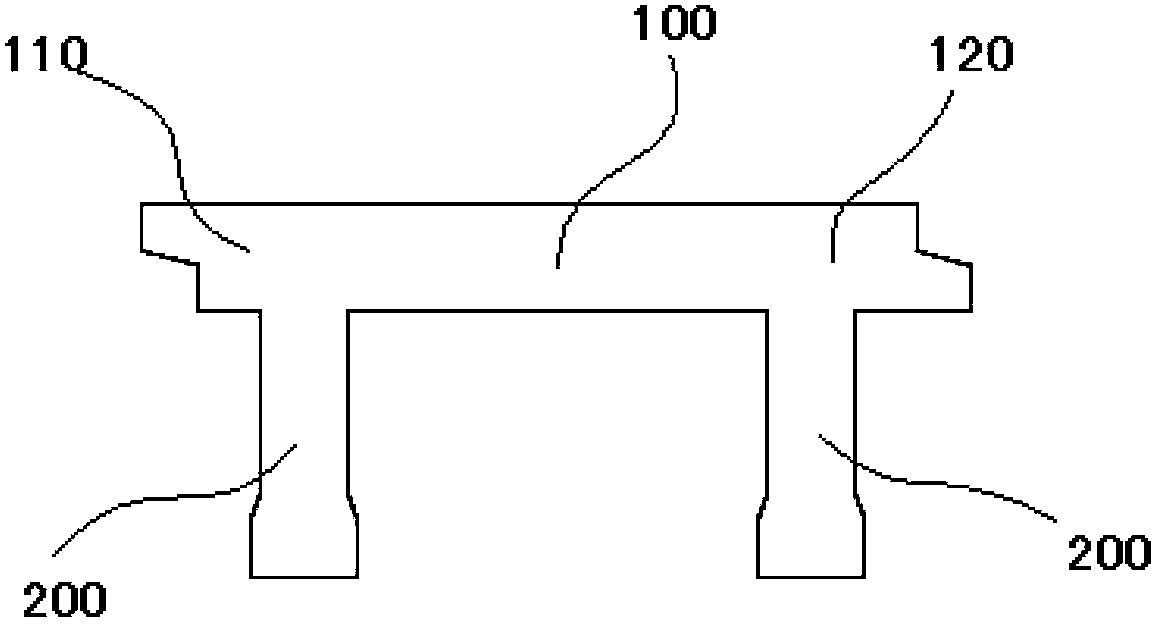

[0034] see image 3 and Figure 4 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1, the difference is that the first connecting portion 110 and the second connecting portion 120 on both sides of the beam have a wedge-shaped structure that fits against each other; and the legs 200 The end has a thicker enlarged structure, which can better play the role of locking and fixing the pile body.

Embodiment 3

[0036] see Figure 5 and Figure 6 As shown, the structure of embodiment 3 and embodiment 1 is basically the same, the difference is that the bottom of the leg 200 of the π-shaped concrete pile in embodiment 3 is provided with a bending section 210, and the end of the bending section 210 has two sides with the beam 100. The first connecting part 110 and the second connecting part 120 act on the same connecting parts, that is, the connecting structure 220 of the left leg and the connecting structure 230 of the right leg; when the π-shaped concrete pile forms an enclosure structure such as a continuous wall, the A closed gap 240 is formed between the beam 200 and the crossbeam 100, and concrete grout may be poured into the gap 240 or filled with water-stop rubber strips or other sealing materials; Water effects and connection strength.

[0037] see Figure 7 and Figure 8 As shown, as a deformed structure of the π-shaped concrete pile in Embodiment 1, the first connecting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com