Emblem type self-insulation cavity wall and manufacture method thereof

A self-insulation, empty bucket technology, applied in the direction of insulation, walls, building components, etc., can solve the problems of energy consumption, environmental pollution, low comfort, etc., to achieve excellent thermal insulation effect, broad application and development prospects, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

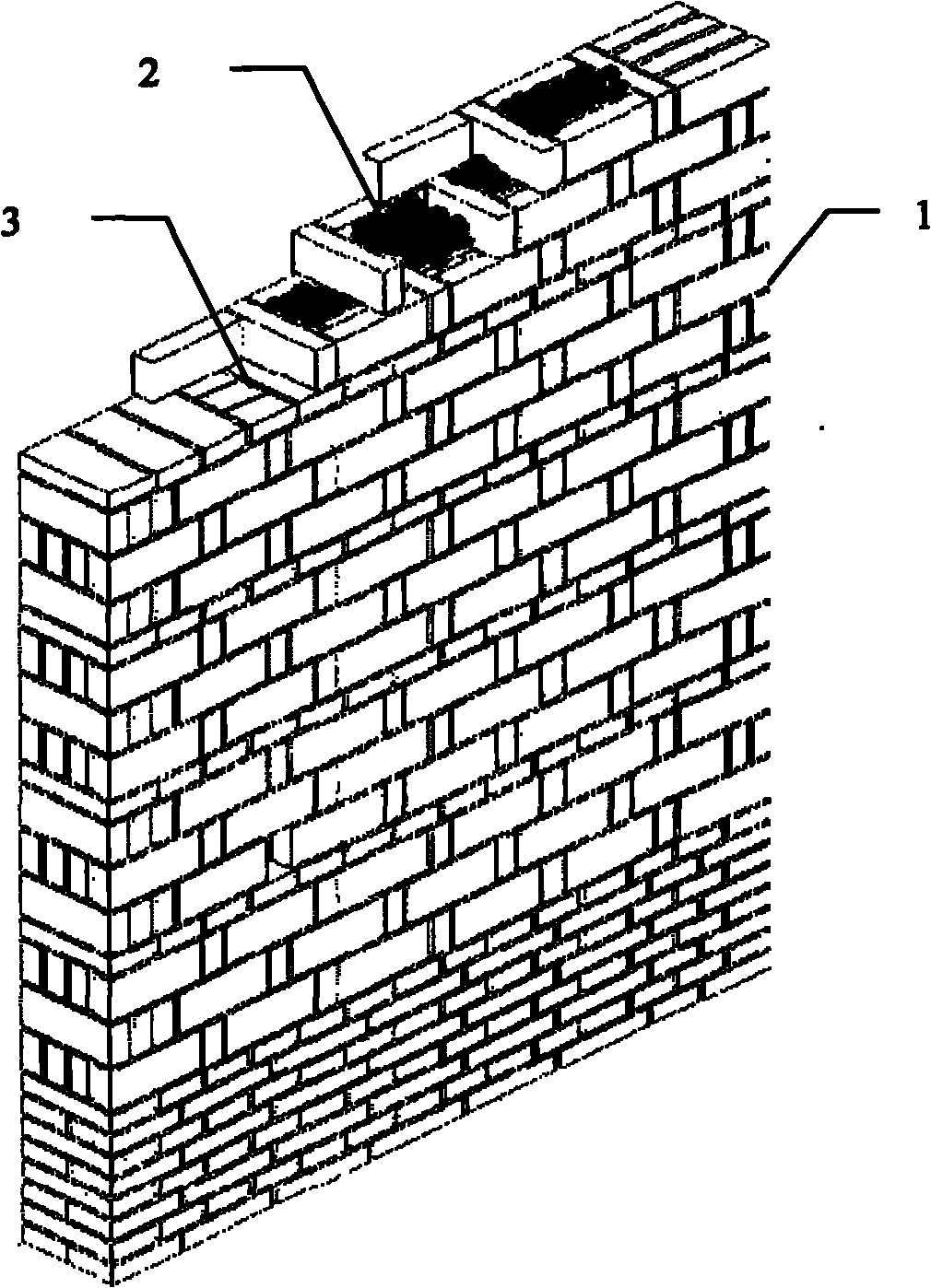

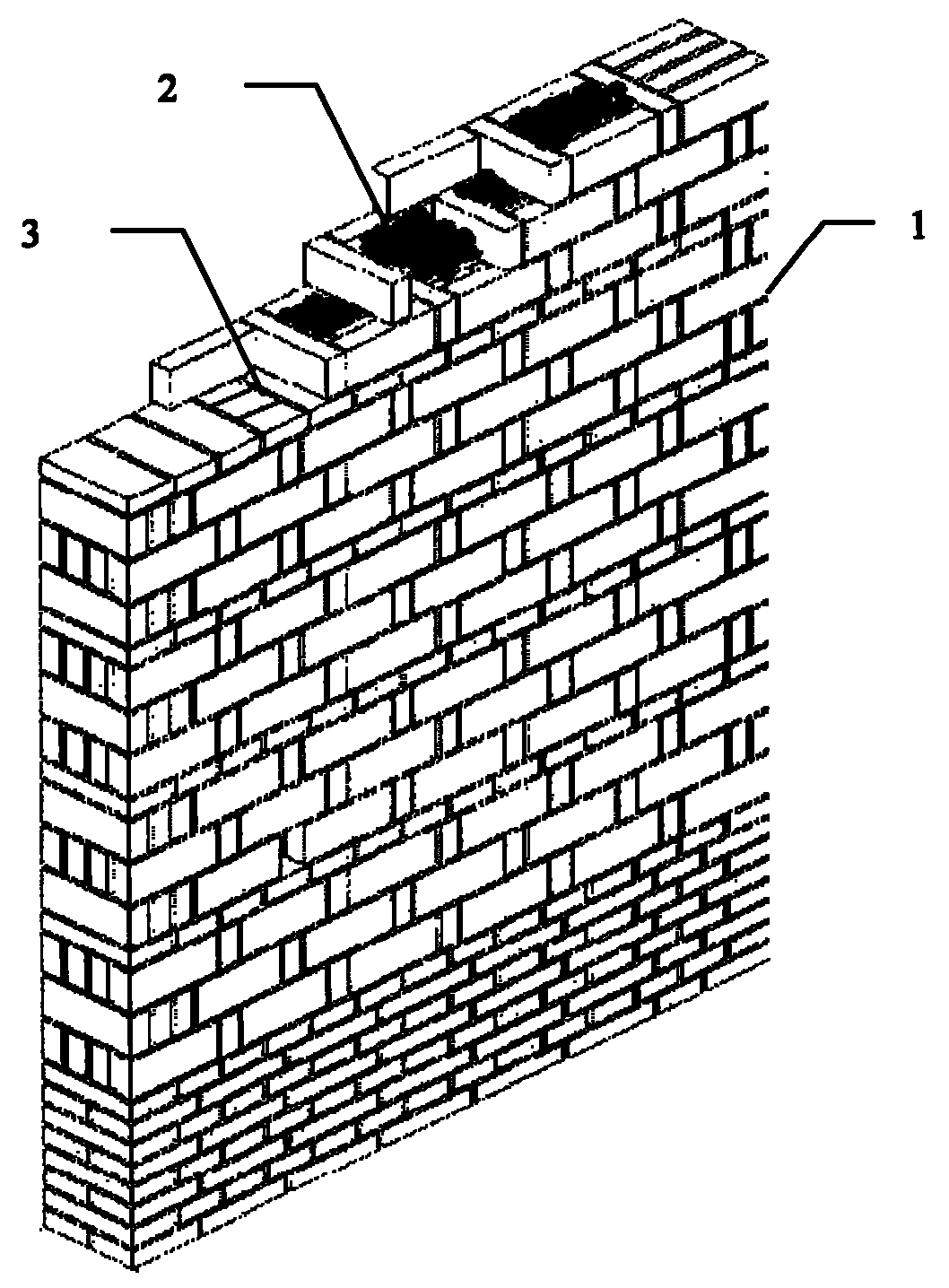

[0018] The cement brick commonly used in Anhui is used as the masonry material, and the yellow mud is used as the binder. The wall is built according to the Hui-style empty bucket masonry method, and an integral connection is formed by reserving a cavity in the same-level sleeping brick layer. The empty bucket wall; by adding fly ash and mine tailings and other industrial waste residues into the cement matrix, using protein foaming agent to foam, and mixing the cement paste and foaming agent evenly to form an ultra-light porous thermal insulation cement base Filling slurry, the specific formula is as follows; pour the filling slurry from the upper entrance of the wall to the empty bucket part, and form an integral self-insulating wall with the empty bucket wall, and test its insulation insulation under natural conditions for 7 days. thermal performance.

[0019] Raw materials: PII42.5 Portland cement, Class II fly ash industrial waste, protein foaming agent, water glass coagul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com