7.63m Coke Oven Feeding Platform Reinforcement Method

A platform and coke oven technology, applied in coke ovens, coke oven bricklaying operations, charging devices, etc., can solve problems such as inconvenience, lack of load-bearing function, and inability of masonry to protect finished products, and achieve convenient production, The effect of simple bracket structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

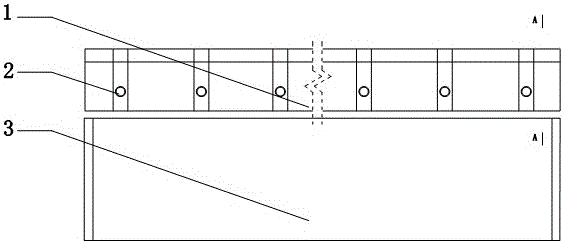

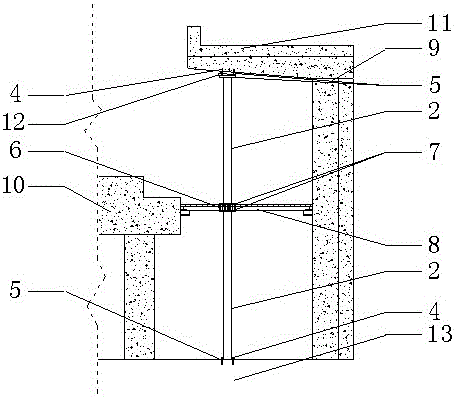

[0024] see now figure 1 , figure 1 It is the 7m platform reinforcement plane layout diagram of the embodiment of the 7.63m coke oven charging platform of the present invention, figure 2 yes figure 1 A-A sectional view in . As shown in the figure, the 7.63m coke oven charging platform includes a platform support wall 9 and a furnace body 10, the 7m platform support wall 9 includes a support portion perpendicular to the foundation 13 and a 7m platform 11, and the 7m platform passes through its lower part The slanted beam is supported by a support portion perpendicular to the foundation 13, the furnace body 10 includes a vertical support portion and an end portion of the furnace body, and the reinforcement method for a 7.63m coke oven charging platform is characterized in that it includes the following steps:

[0025] a. Provide a connecting seat

[0026] The connecting seat is made of upper and lower two steel plates and a reinforced strong plate between them. The connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com