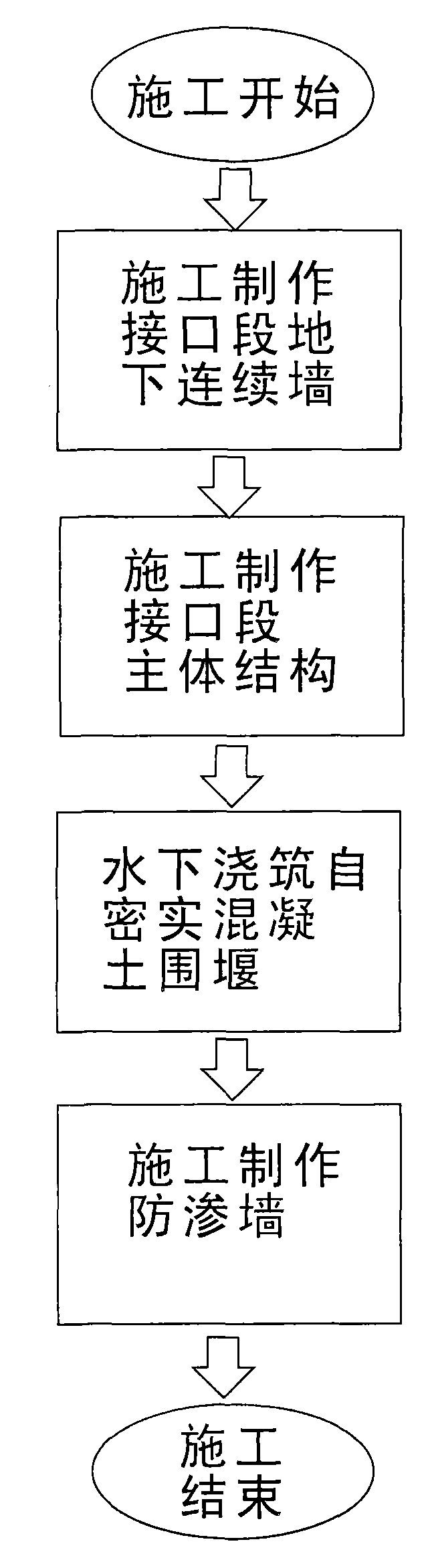

Method for constructing seepage prevention system of secondary cofferdam for immersed tube tunnel

A construction method and technology of immersed tunnel, applied in the field of construction engineering, can solve the problems of unpredictable hoisting operation accuracy, damage to blocks, block collision, etc., and achieve strong controllability of hoisting operation, low safety risk, and processing site. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

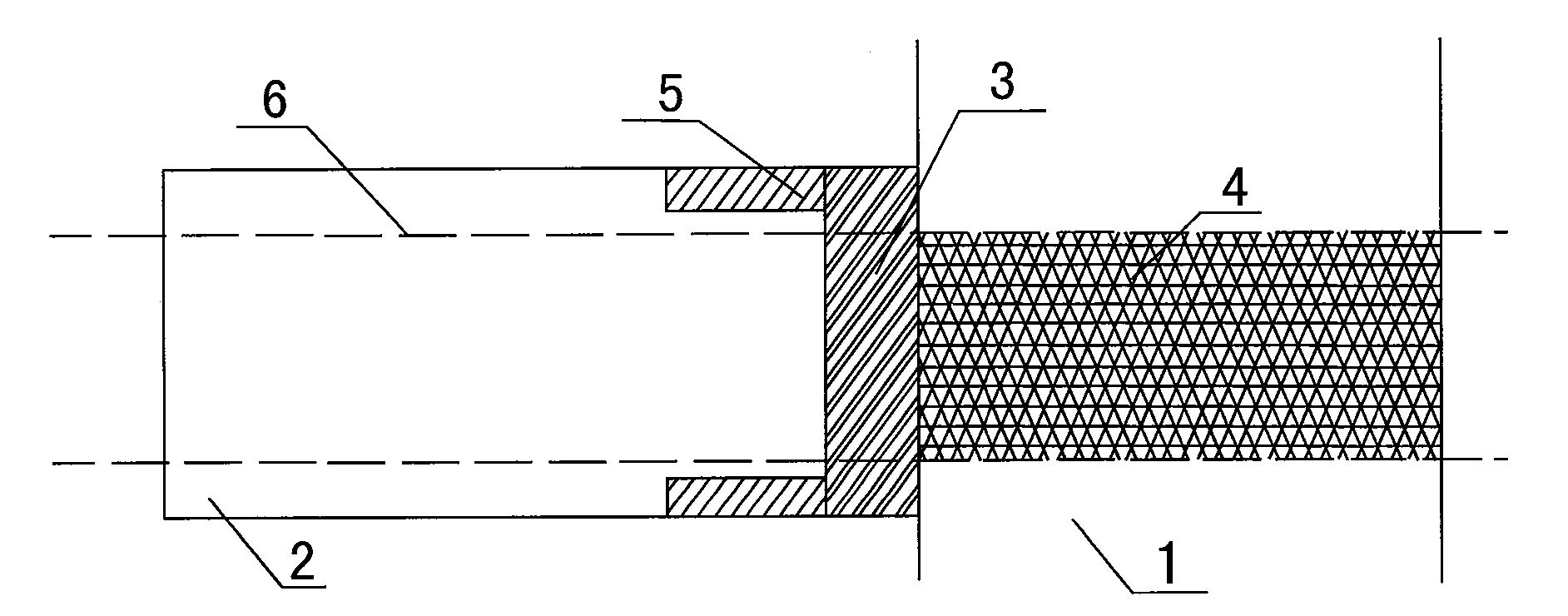

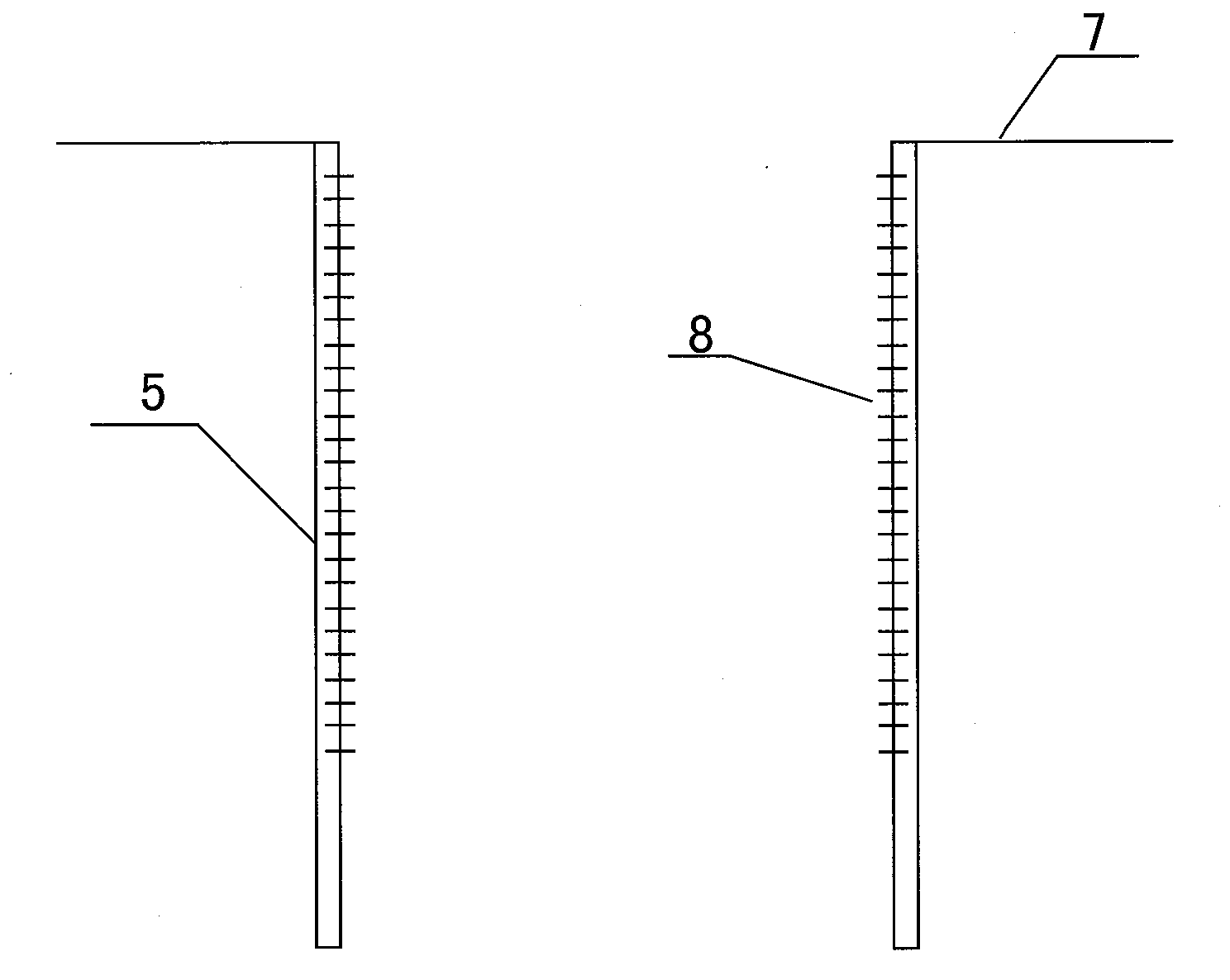

[0054] Such as figure 1 , figure 2 , image 3 As shown, before excavating the foundation pit, the underground diaphragm wall 5 of reinforced concrete structure is firstly constructed as the enclosure structure of the foundation pit. Wall 5 is constructed directly from the ground. The main process is: first use a hydraulic grab bucket excavator to form a groove, process the steel cage as a whole on site, use a crane to hoist the steel cage into the dug groove, and finally pour concrete that meets the design requirements Excavate the interface section after the construction of the interface section diaphragm wall 5 is completed. After excavating to the design elevation, pre-embed the connecting steel bars 8 in the exposed diaphragm wall, which is the construction of the main structure 11 of the interface section and the construction of the secondary cofferdam 18. Prepare.

[0055] In the underground diaphragm wall 5 of the interface section described in construction, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com