Patents

Literature

68results about How to "Save processing space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

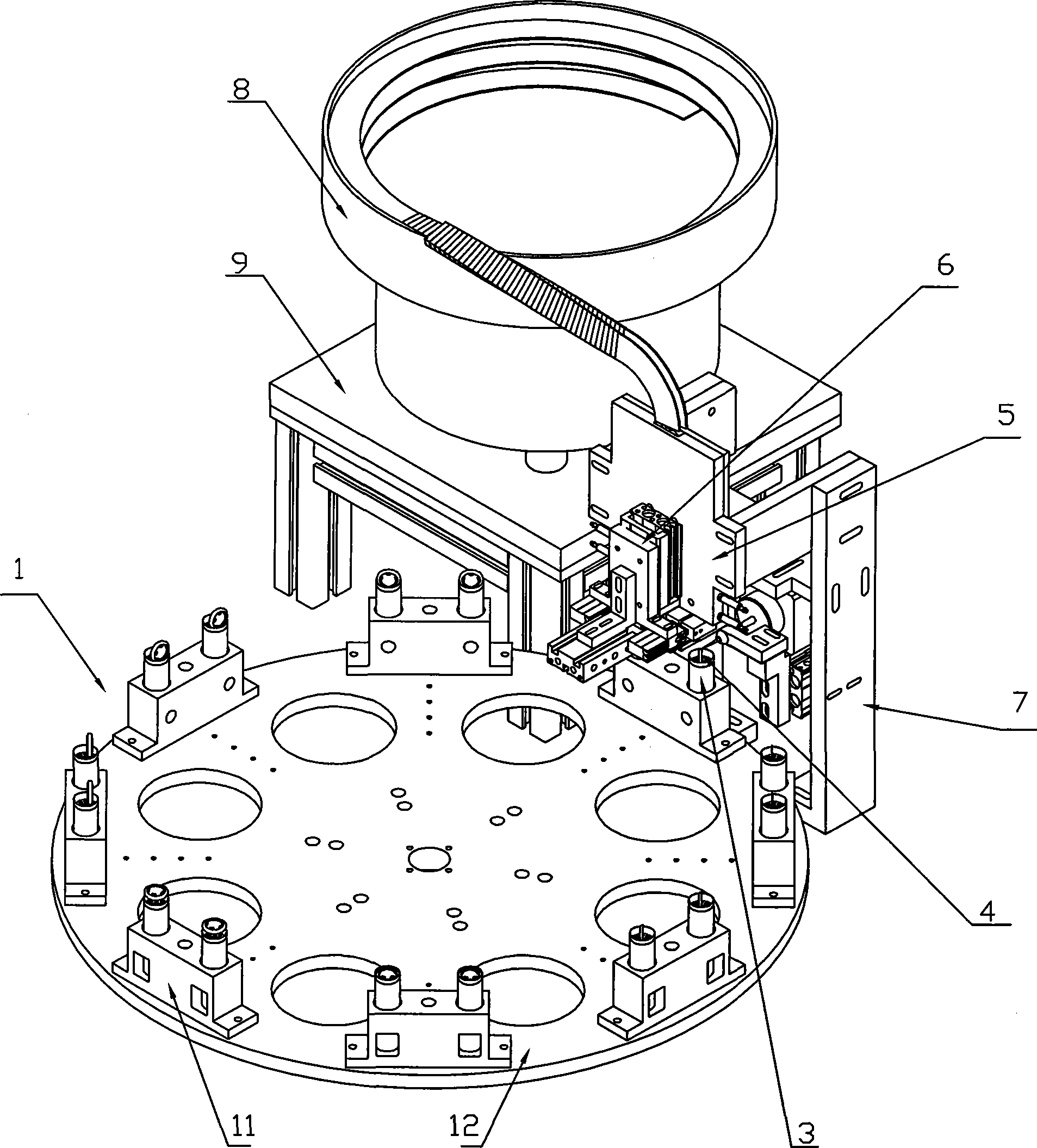

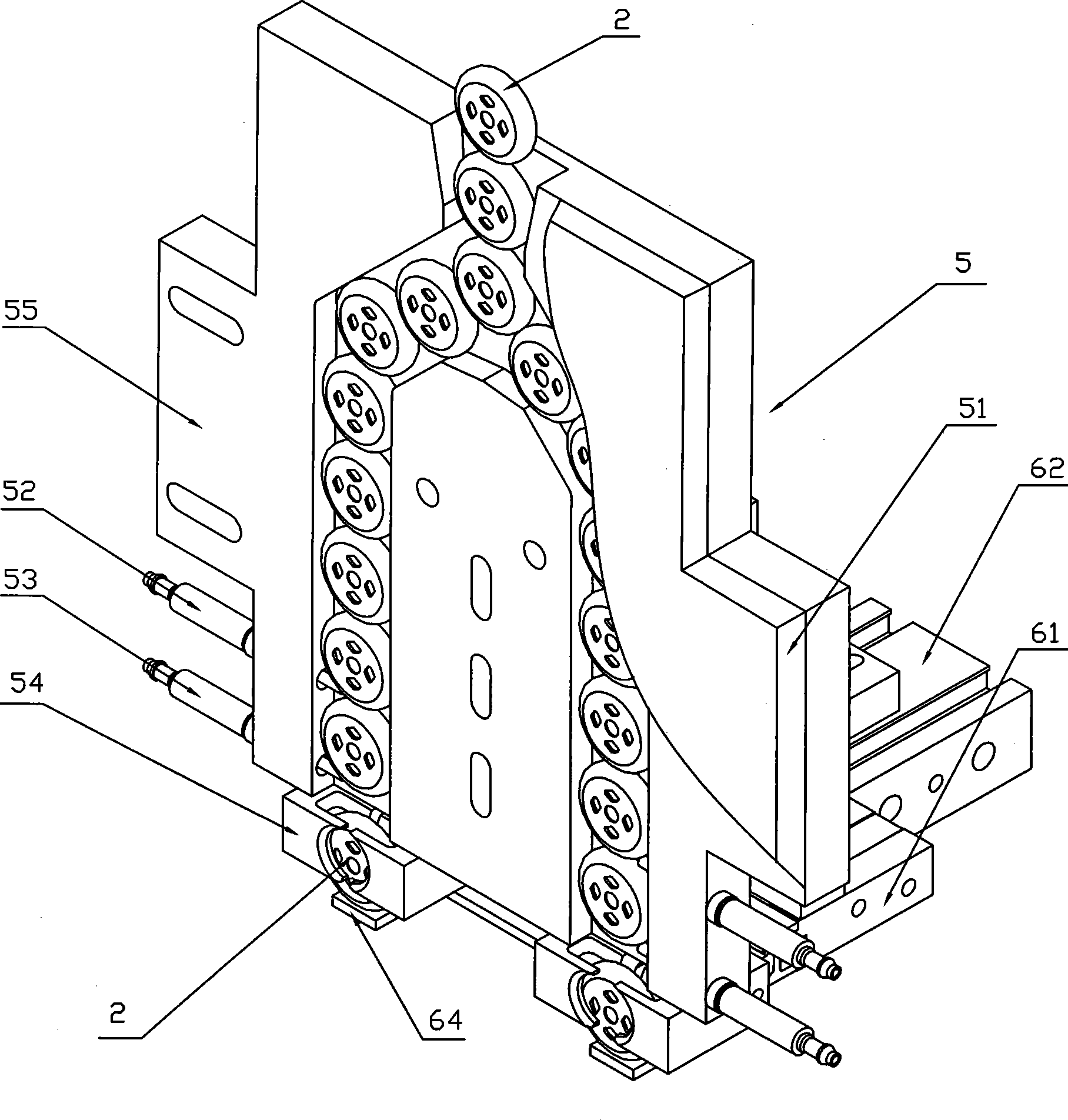

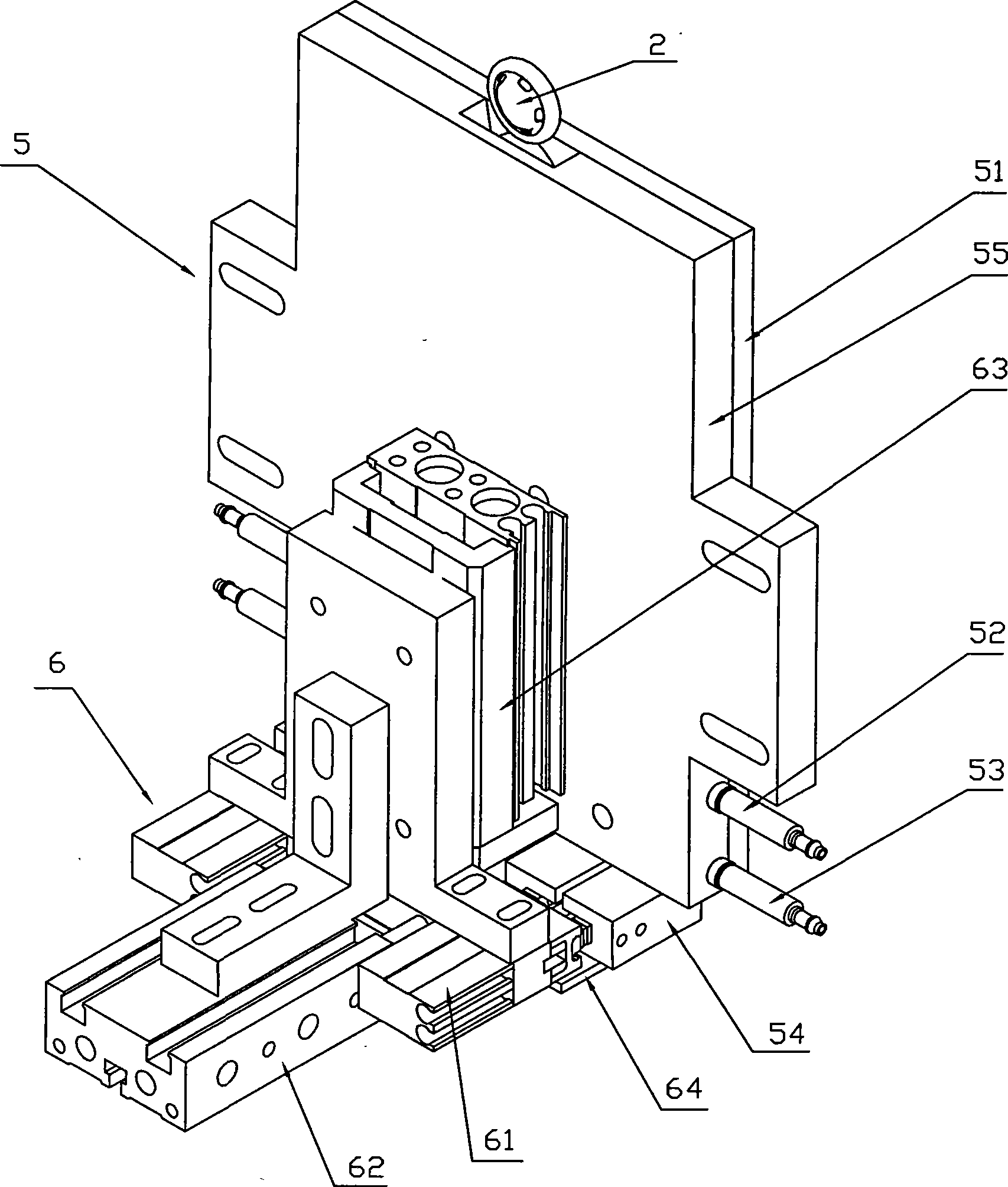

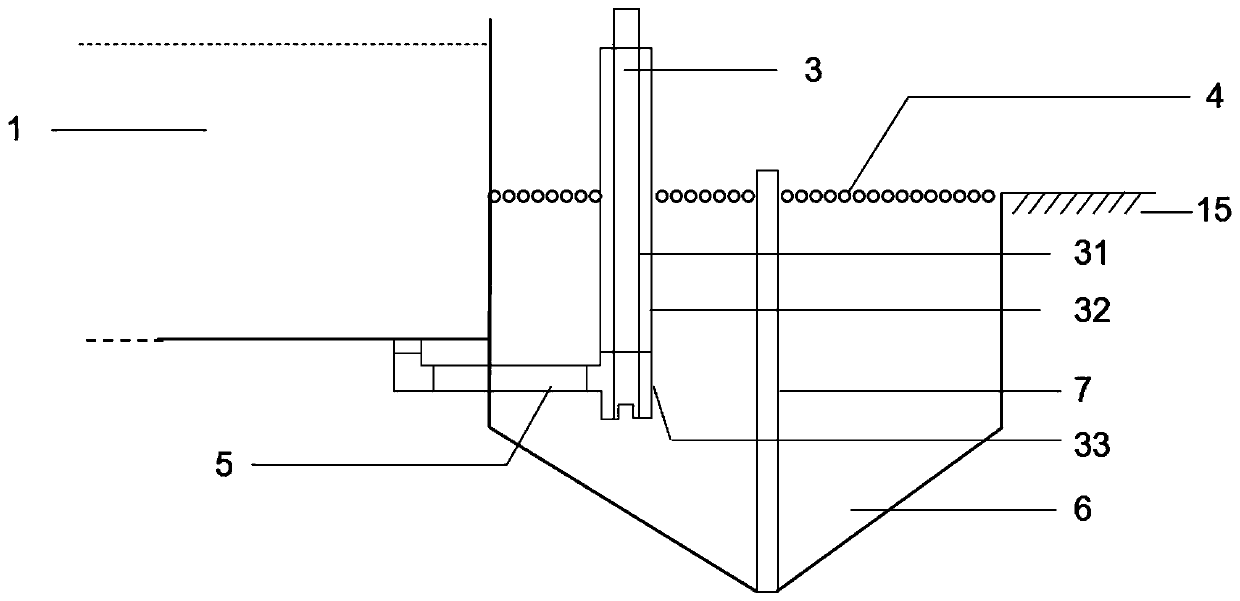

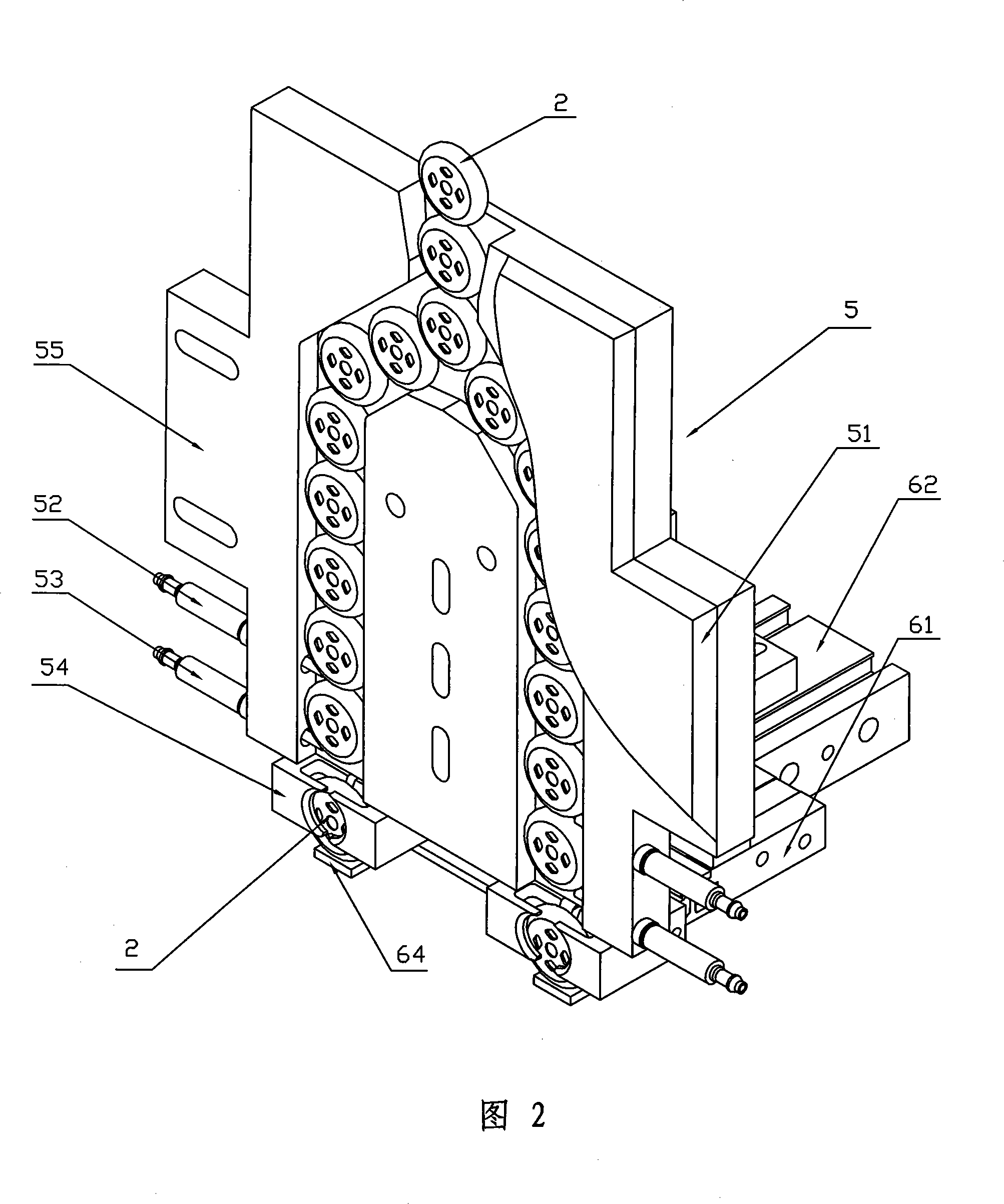

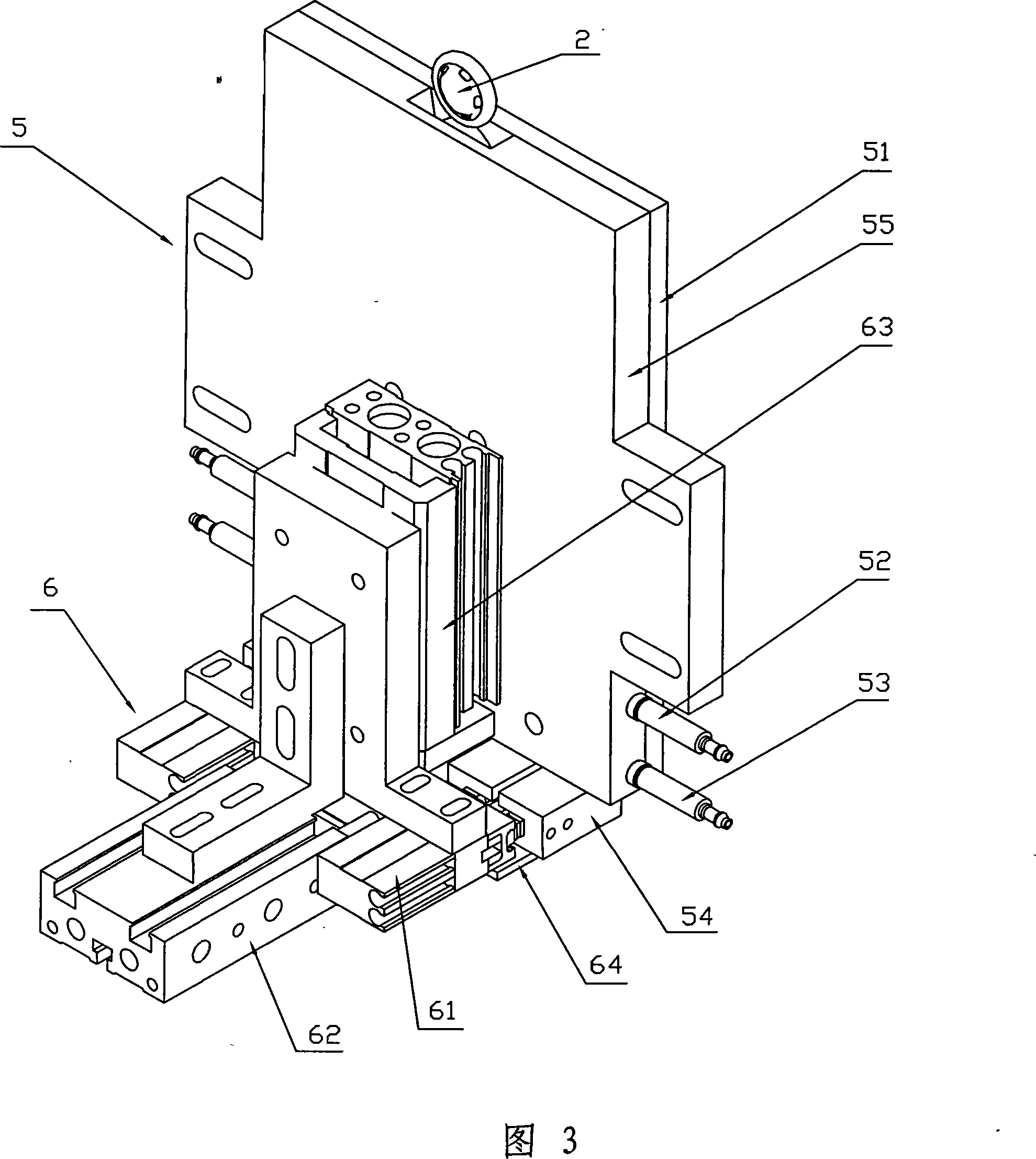

Spot welding device for battery cap and tab

ActiveCN101434008ASimple structureCompact structureWelding/soldering/cutting articlesMetal working apparatusControl systemSpot welding

The invention relates to a cell cover and polar ear spot welding device, which comprises a cell feeding mechanism which can send cells to be processed into spot welding stations, a cover guiding mechanism which can lead in covers and automatically and progressively arrange the covers in order, a cover feeding mechanism which accommodates the covers sent by the cover guiding mechanism and sends the covers into the spot welding stations, a laser spot welding mechanism which welds the cell covers and cell polar ears sent into the welding stations, and a control system which can control the motion of various mechanisms, wherein the cover feeding mechanism and the cover guiding mechanism are in matched connection and arranged above the cell feeding mechanism, so that the covers contact upper polar ears of the cells; the laser spot welding mechanism is positioned aside the cell feeding mechanism; and a laser emitting center of the laser spot welding mechanism is in the same line with the contact points of the covers and the upper polar ears of the cells. The invention provides a laser spot welding processing apparatus which can automatically send the cylindrical cells and the covers into the welding stations and perform spot welding connection on the upper polar ears of the cells and the covers.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

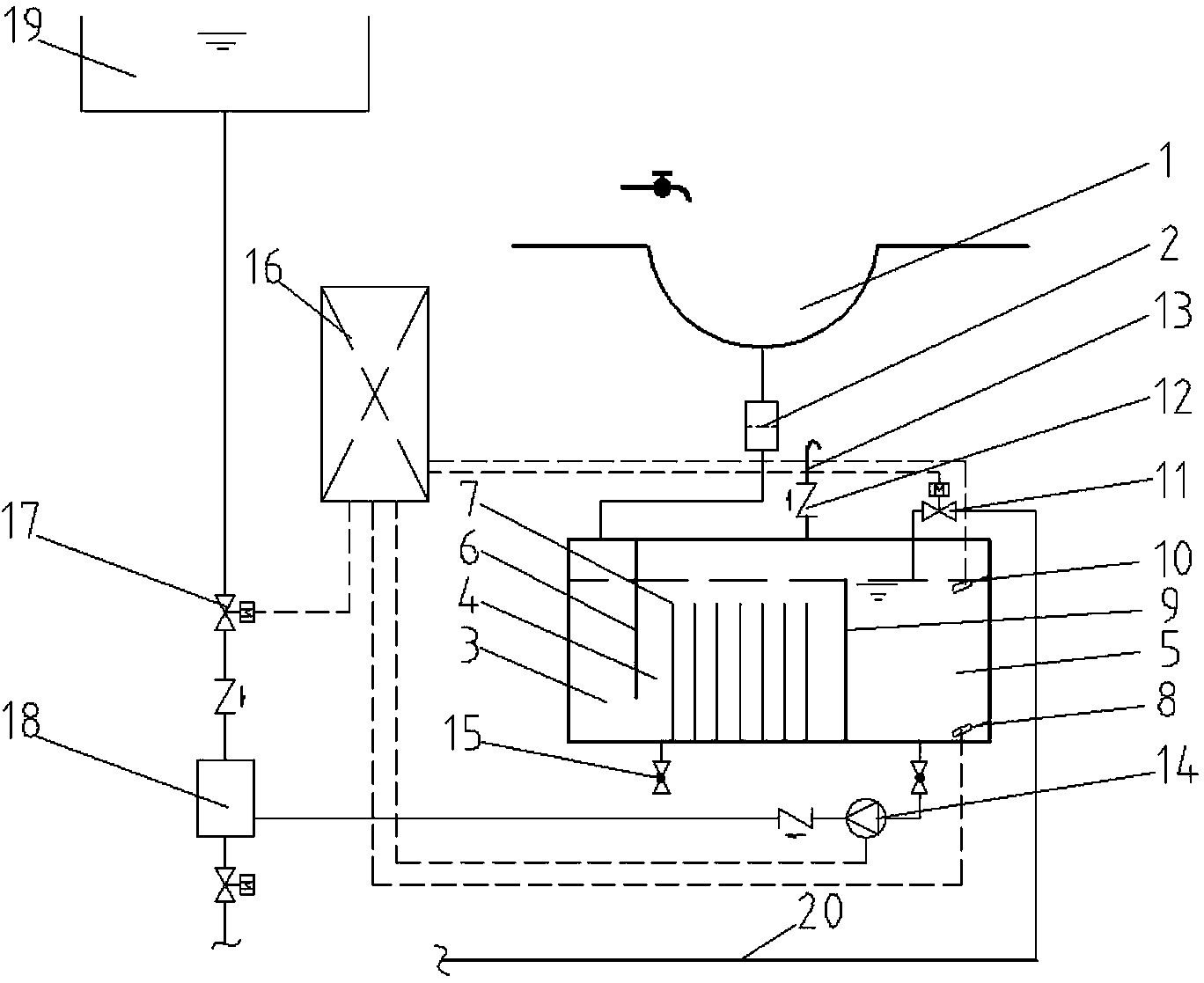

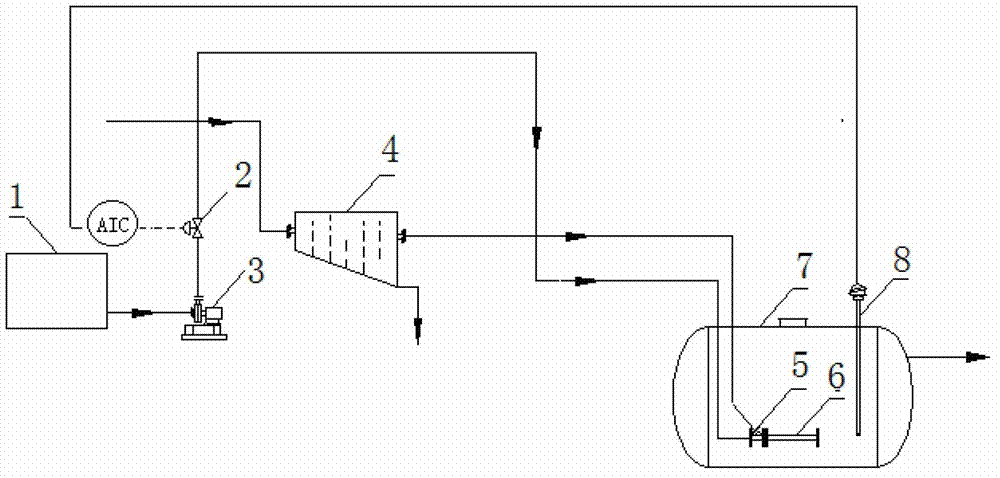

Train washing water treatment and reuse method and device

ActiveCN103612643AReduce the frequency of standing by for water replenishmentReduce loadDomestic plumbingSanitationFlocculationParticulates

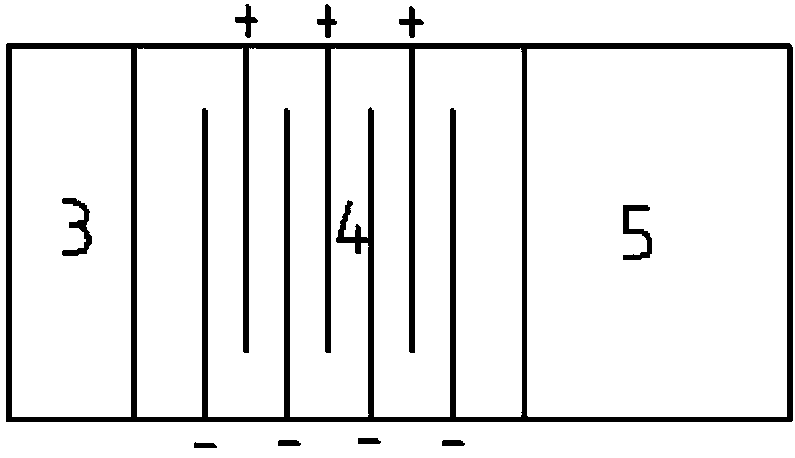

The invention discloses a train washing water treatment and reuse method. After large particulate matters in drained water of a washing basin are removed through a mesh filter, the drained water is collected into a water inflow buffer area, returns via the bottom of a baffle, flows into an electrolytic oxidation area in a plug-flow type flow state and flows through internal electrolytic pole plates in the electrolytic oxidation area in a plug flow state of returning back and forth, and washing water is purified via single action or multiple collaborative actions of electrolytic oxidation, electrolytic floatation and electrolytic flocculation; the water subjected to electrolytic purification overflows to a produced water collection area from the upper portion of another baffle, and water in the produced water collection area is pumped into a flushing water pressurizing tank in real time via a reuse water pump for flushing. Meanwhile, the invention further discloses a device of the method. By the method and the device, water is saved by more than 50%, load of an on-board water tank can be reduced effectively, frequency that a train stops at a station for water supplementation is reduced, and contradiction of water supply and water consumption of the train is solved.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

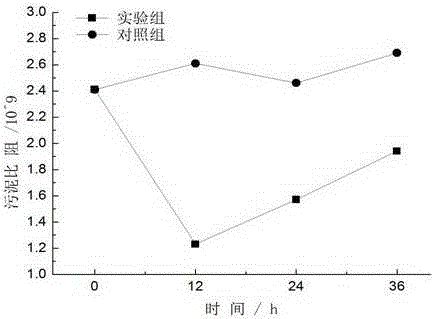

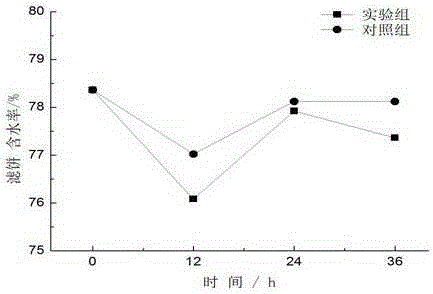

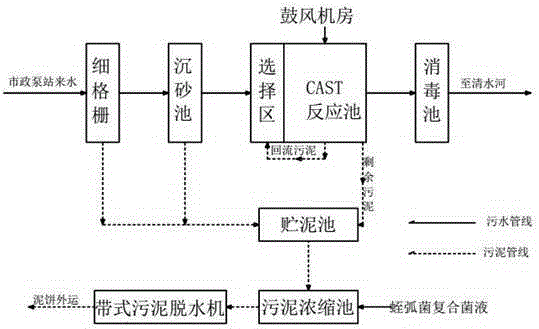

Biological wall-breaking method for improving sludge dewatering performance

ActiveCN105254155AImprove dehydration and weight loss performanceImprove dehydration effectSludge treatment by de-watering/drying/thickeningSludge processingMicroorganismReduction treatment

The invention relates to a biological wall-breaking method for improving sludge dewatering performance, and belongs to the technical field of sludge treatment. According to the method, the phagocytosis characteristic that bdellovibrio can widely and effectively decompose Gram-negative bacteria is sufficiently utilized, bdellovibrio is combined with other microorganisms to prepare bdellovibrio complex microbial inoculants which are applied to the treatment process of excess sludge of the biological treatment process of a municipal wastewater treatment plant so that the dewatering performance of treated sludge can be improved by 30% or higher after subsequent plate frame press filtering or centrifugal dewatering or other physical treatment, and therefore the sludge reduction efficiency is improved. The method treats remaining sludge of the municipal wastewater biological treatment process, is little in device investment, easy to operate, safe, free of pollution and low in energy consumption, and has good economic benefits and environment benefits, and a new method for municipal sludge biological dewatering reduction treatment is developed.

Owner:余冉 +2

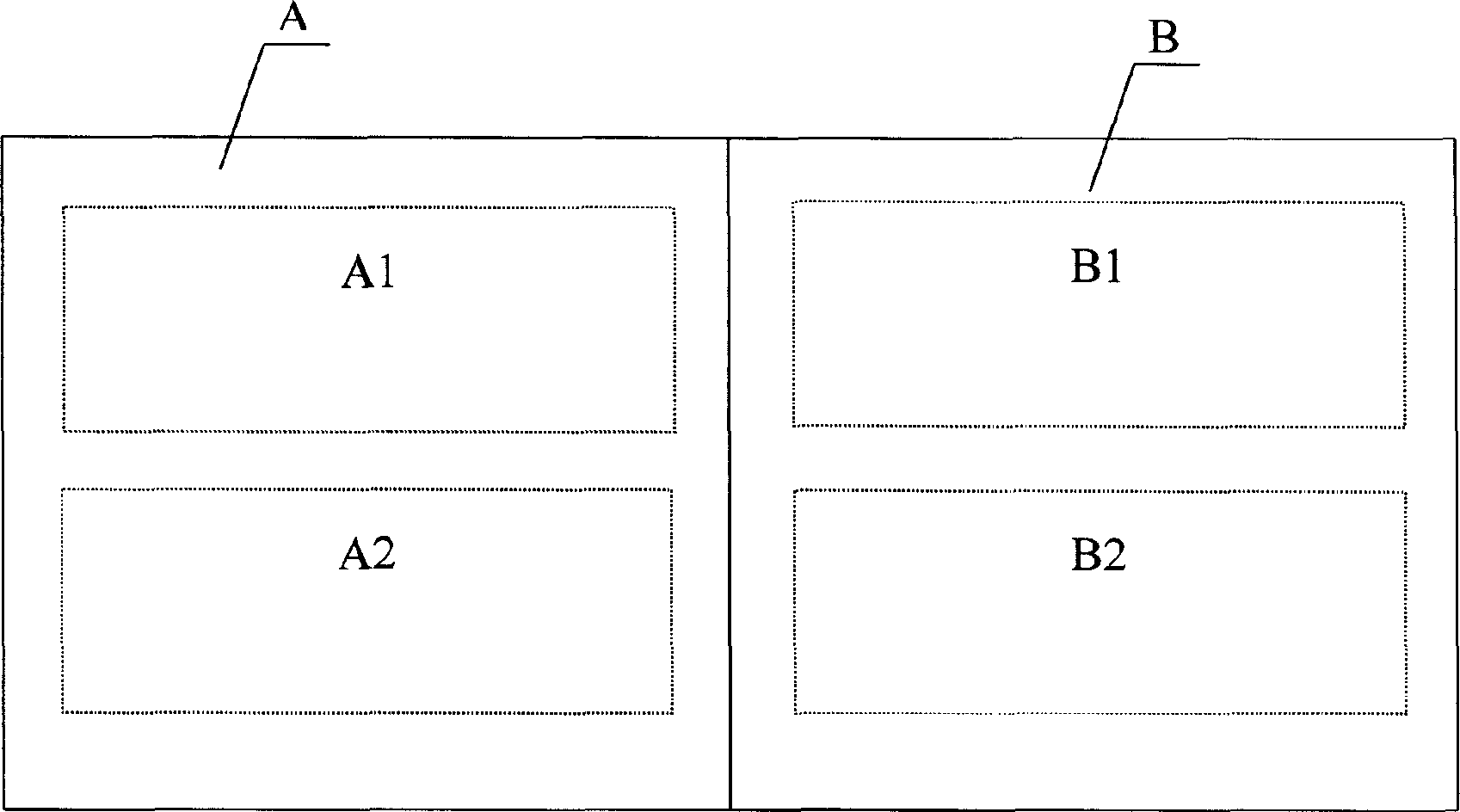

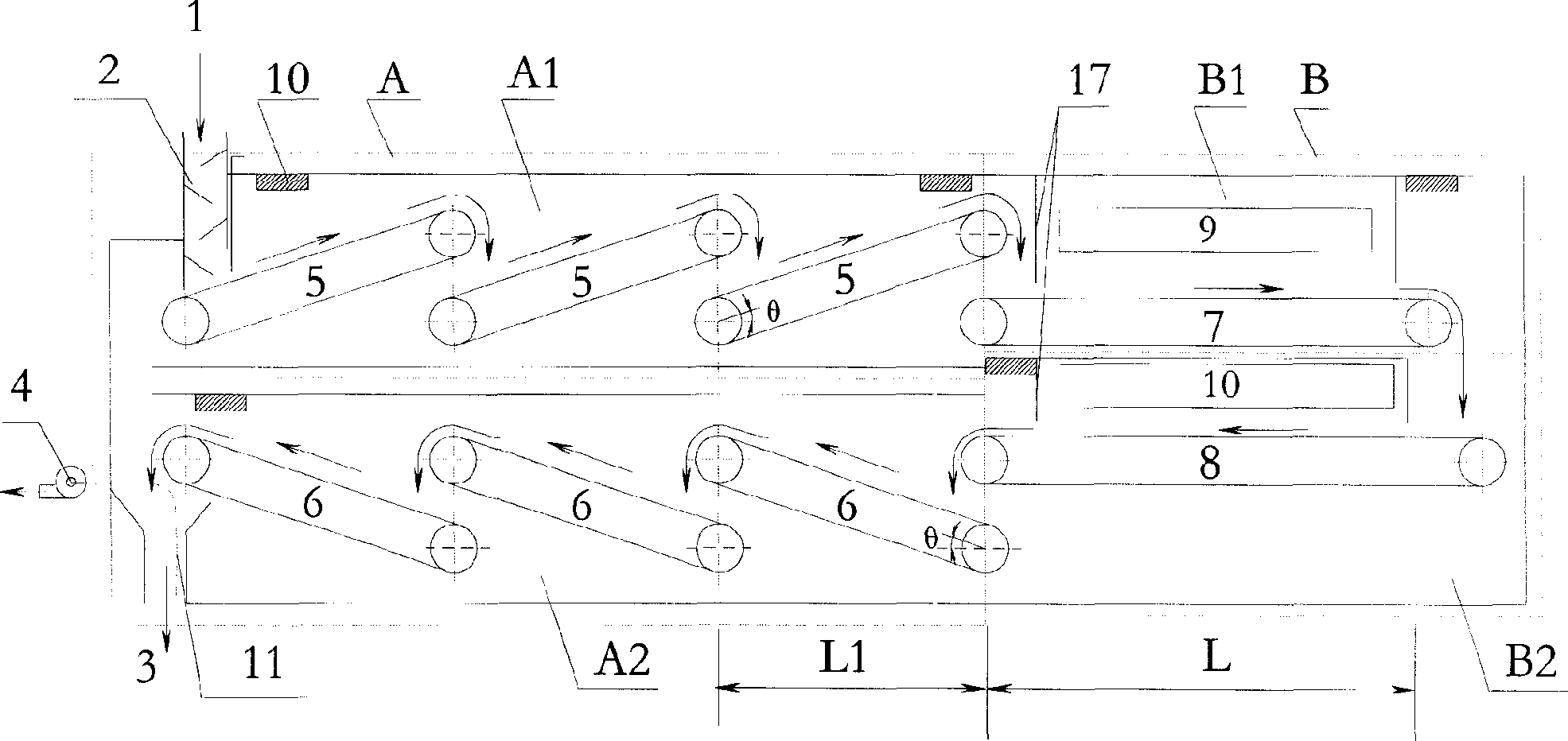

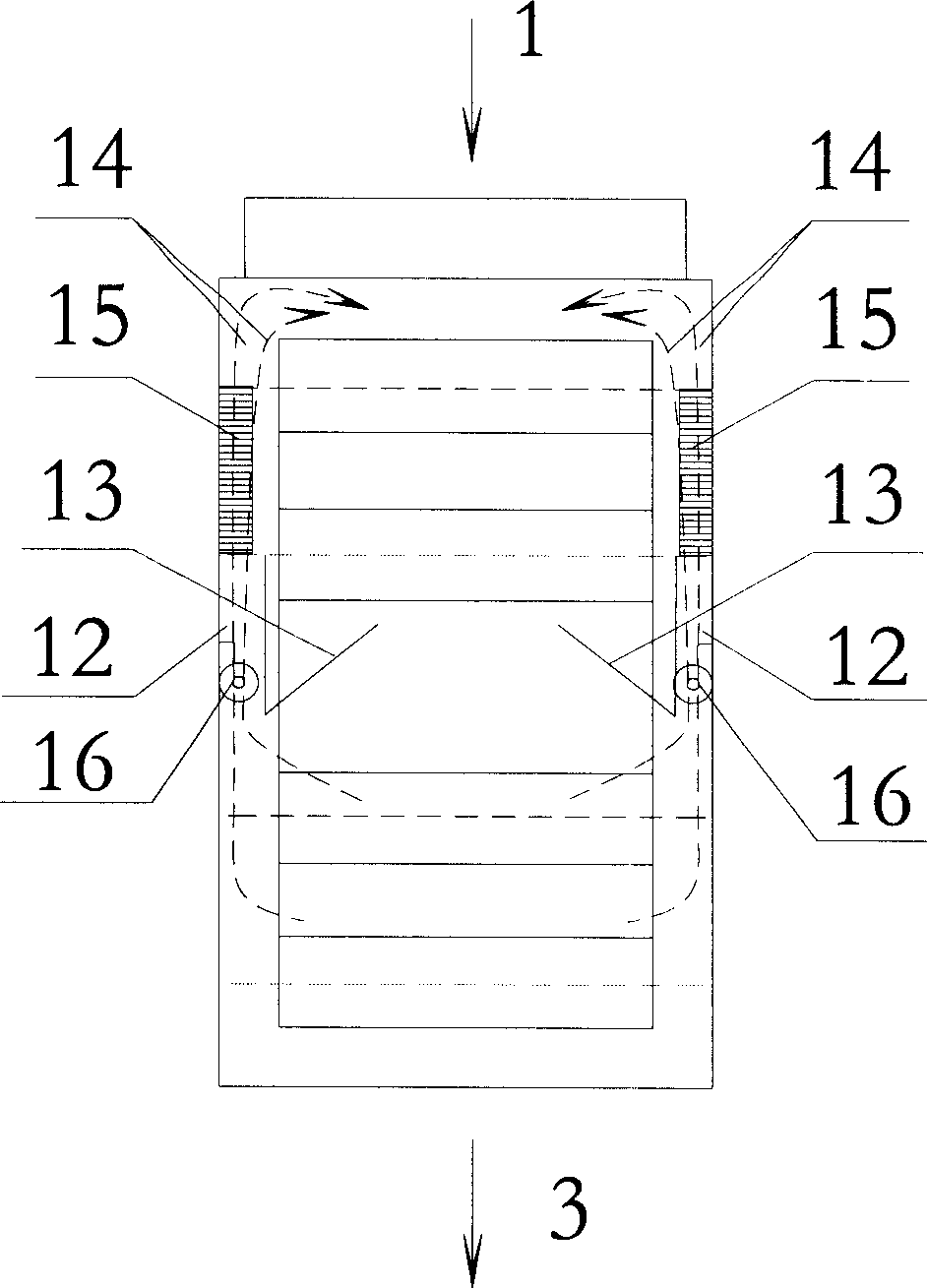

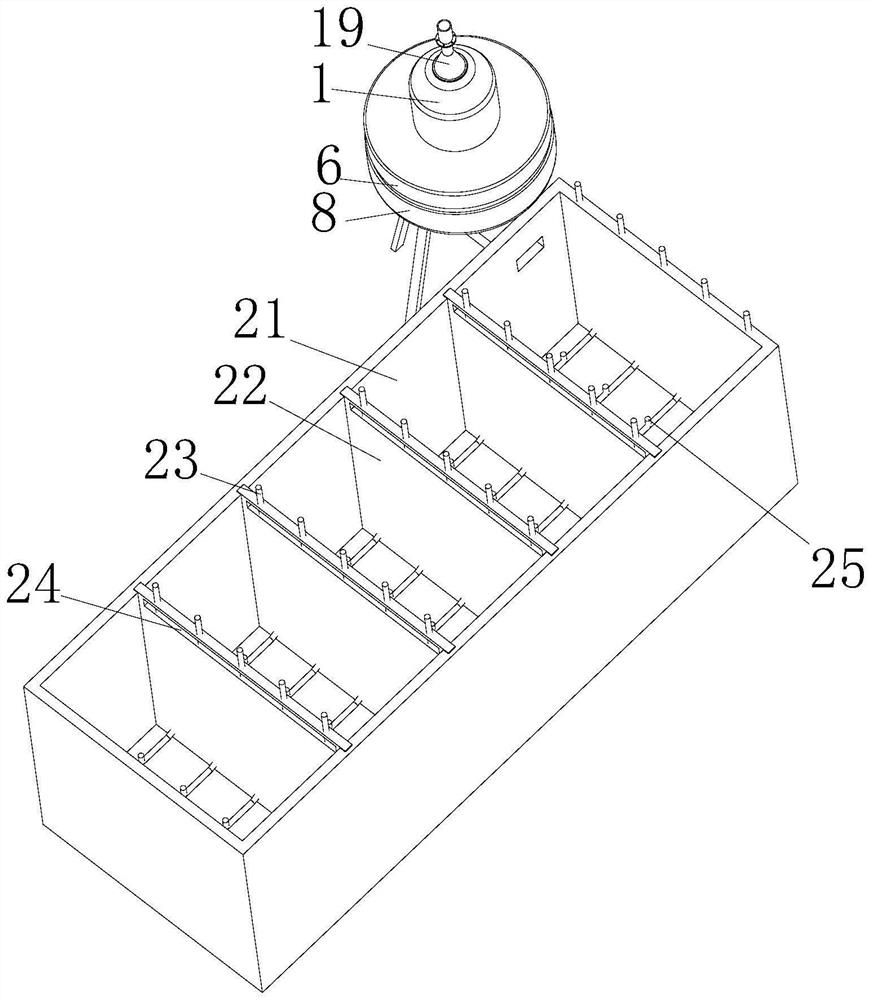

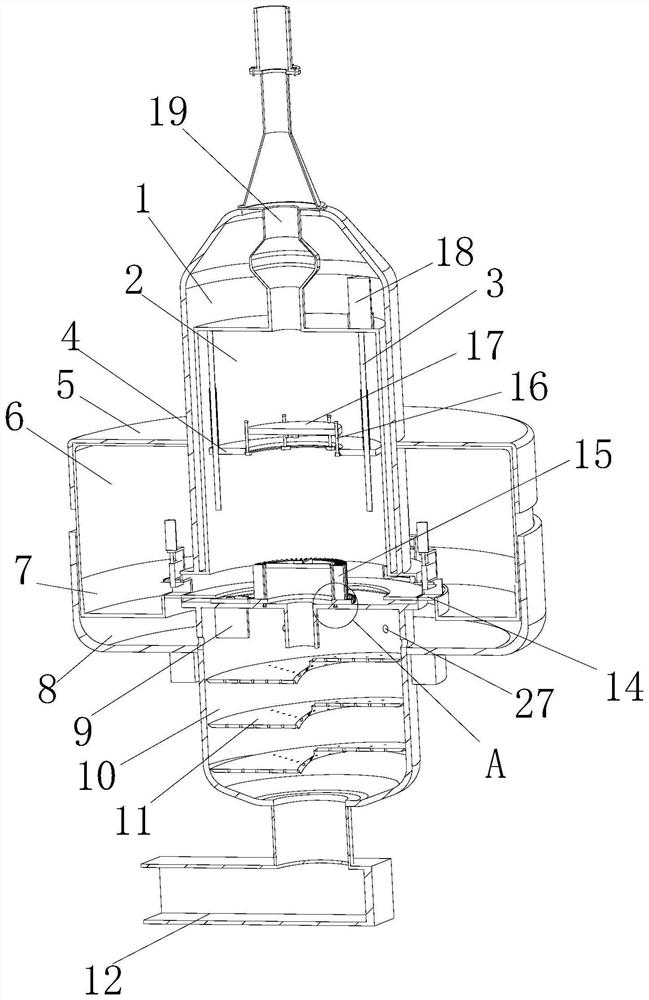

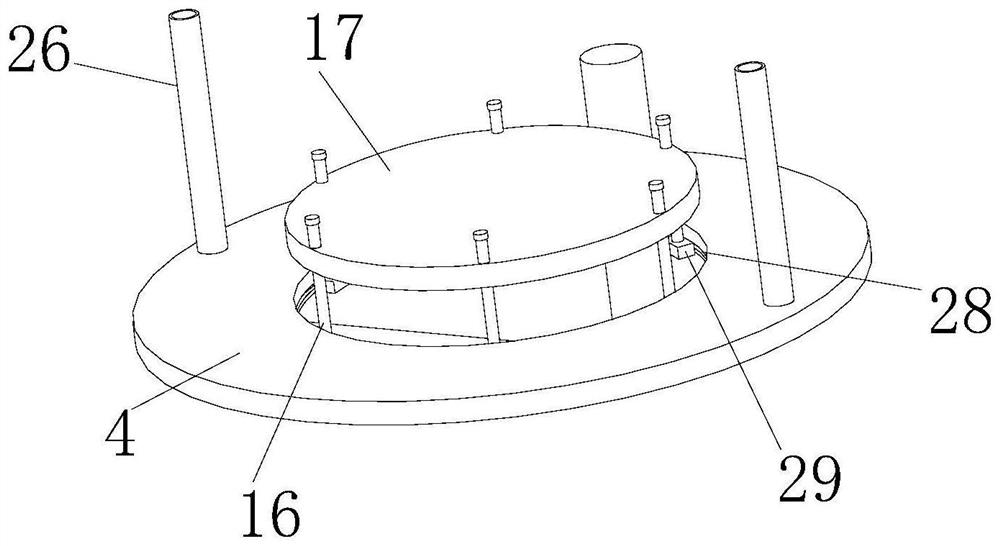

Energy-saving type grain microwave insect preventing and mould-proof method and special equipment

InactiveCN1813550AIncrease the venueIncrease Microwave TimeFood processingSeed preservation by irradiation/electric treatmentEngineeringMicrowave irradiation

The present invention relates to an energy-saving type pests-resisting mould-proofing treatment method for grains and its special-purpose equipment. Said invention includes the microwave irradiation-cooling treatment steps, and is characterized by that it includes the steps of preheating, microwave irradiation, cooling and heat exchange, in which the heat exchange is implemented in unit A for preheating and cooling and the microwave irradiation is implement in unit B, and between unit A and unit B ac closed channel is connected. Besides, said invention also provides its working principle and operation method.

Owner:HUAZHONG AGRI UNIV

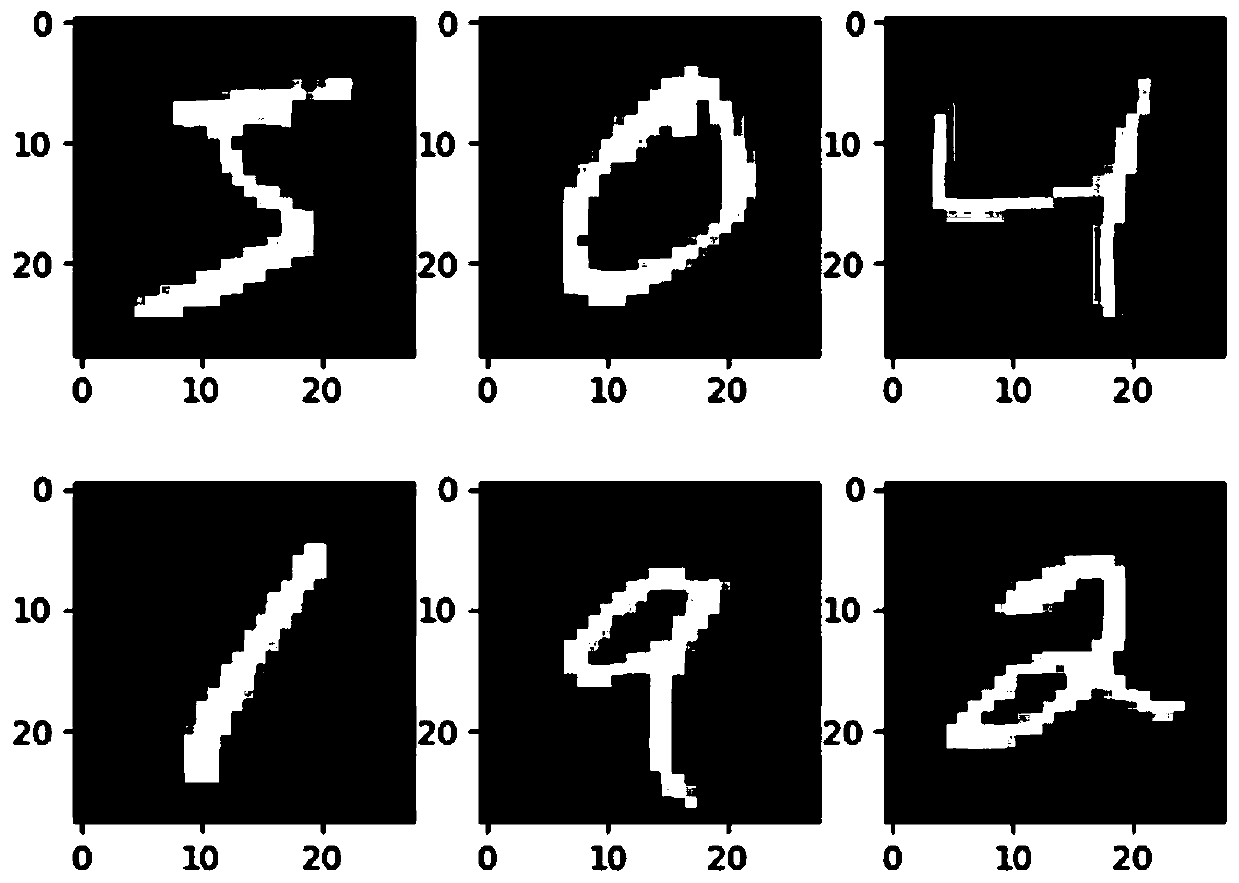

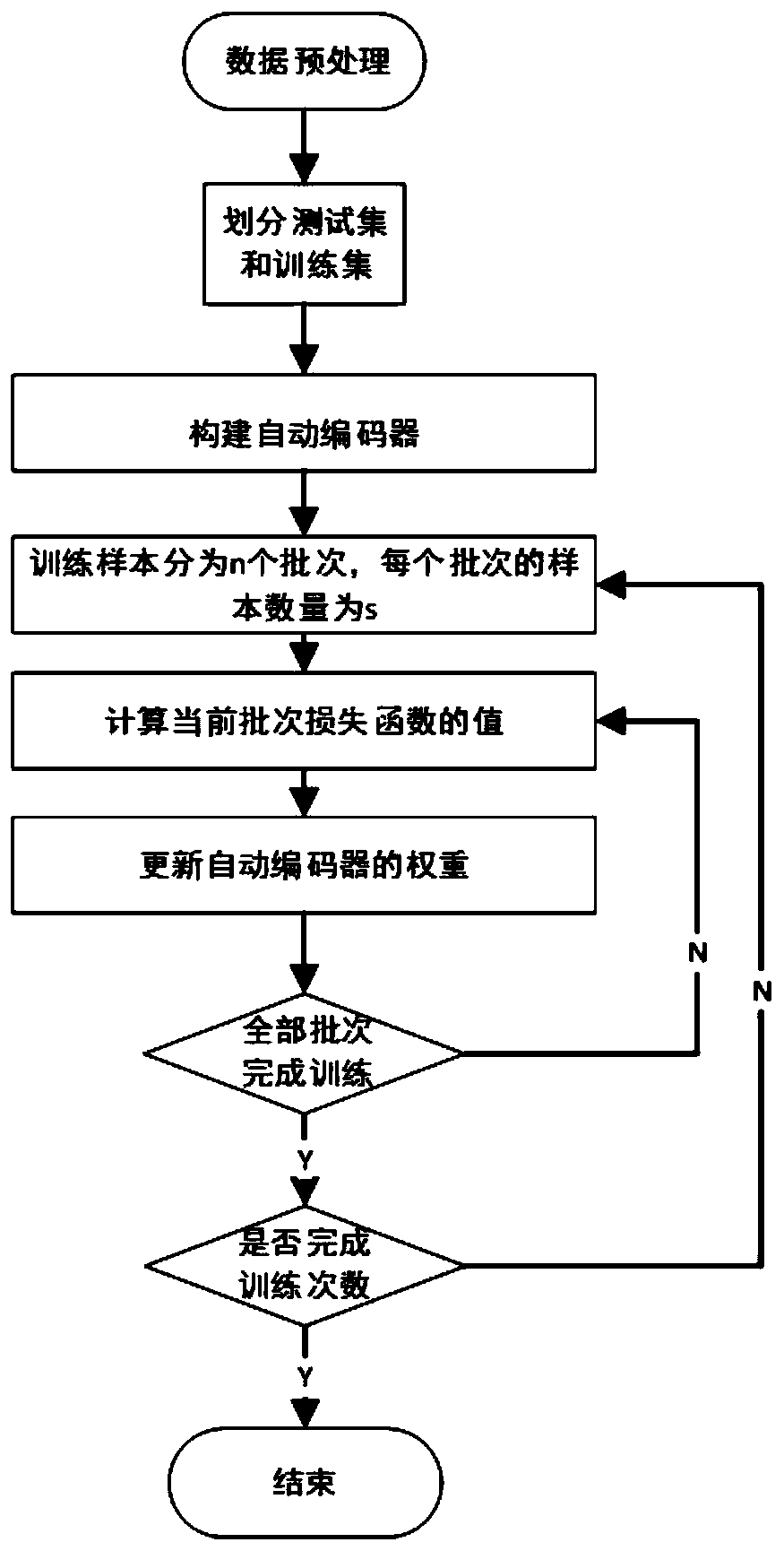

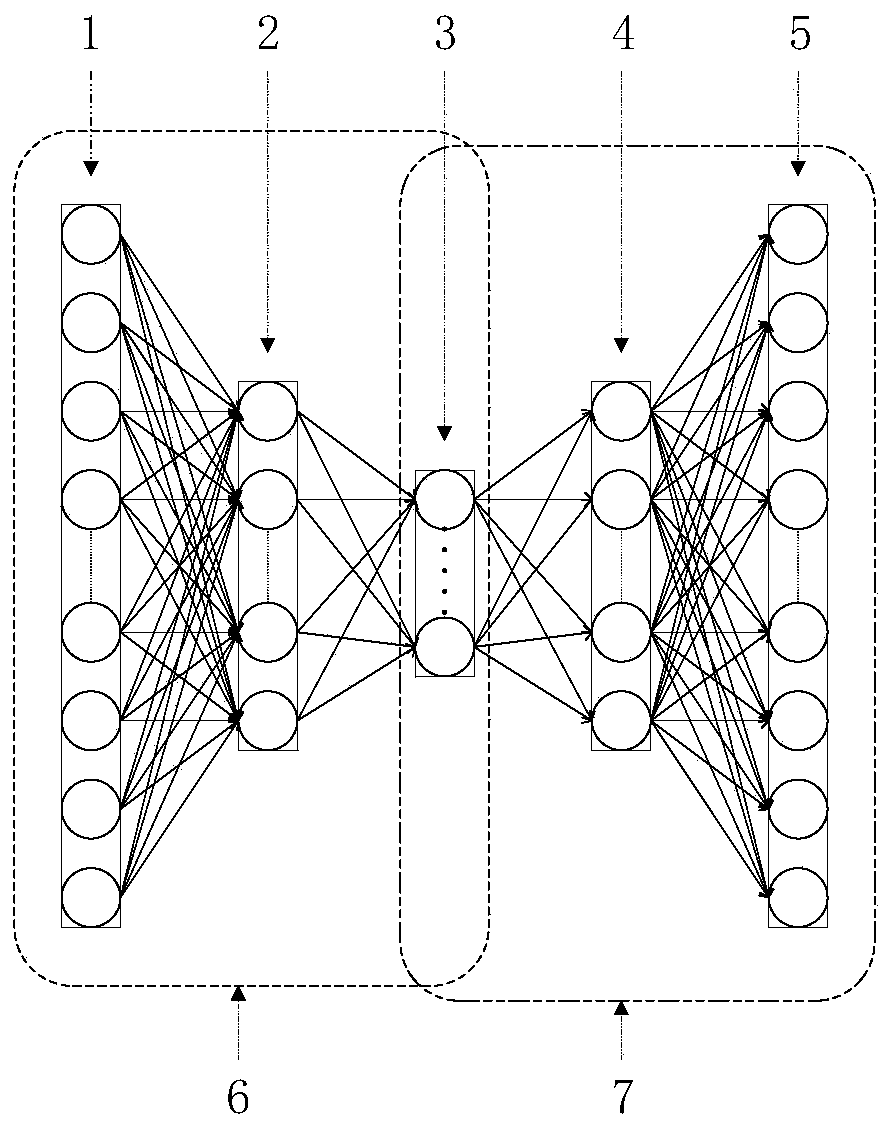

Distance-preserving and dimension-reducing method for data containing missing data

PendingCN110852366AKeeping distance hasEasy to handleCharacter and pattern recognitionNeural architecturesMissing dataAlgorithm

The invention discloses a distance-preserving and dimension-reducing method for data containing missing data, and relates to the technical field of data processing. According to the data distance-preserving and dimension-reducing method, the missing part in the original data does not participate in the calculation of the loss function of the automatic encoder through the missing data matrix, so that the automatic encoder can process the dimensionality reduction containing the missing data, and the influence of the missing data on the automatic encoder is avoided; meanwhile, the strong automatic learning capability of the automatic encoder is used; the complex nonlinear relationship between the original data can be effectively captured; and the weight matrix of the encoder in the loss function is updated through constraint, so that the dimension reduction processing has distance preserving performance, the distribution information of the original high-dimensional data is reserved for the low-dimensional data after dimension reduction to the maximum extent, subsequent data processing is facilitated, and the data processing time and space are saved.

Owner:HUNAN UNIV

Depth processing method of cyanogen-containing waste water

ActiveCN102491487ASave spaceReagents are simpleWater/sewage treatment by ion-exchangeWater/sewage treatment by oxidationChemistryMunicipal sewage

The invention discloses a depth processing method of cyanogen-containing waste water. The method comprises the following step of treating the cyanogen-containing waste water with chlorine oxidizing agent generating hypochlorite and anion exchange resin. The method is specifically one of the following modes: 1. mixing well the cyanogen-containing waste water and the chlorine oxidizing agent generating hypochlorite and treating the mixture with the anion exchange resin; 2. treating the cyanogen-containing waste water with anion exchange resin loaded with hypochlorite. The method needs no equalizing tank, oxidation reaction tank or filtering treatment, greatly saves sewage treatment place and effectively treats total cyanide in the cyanogen-containing waste water to realize stable and standard reached discharge and satisfy industrial water quality in municipal sewage regeneration and utilization.

Owner:EAST CHINA UNIV OF SCI & TECH +1

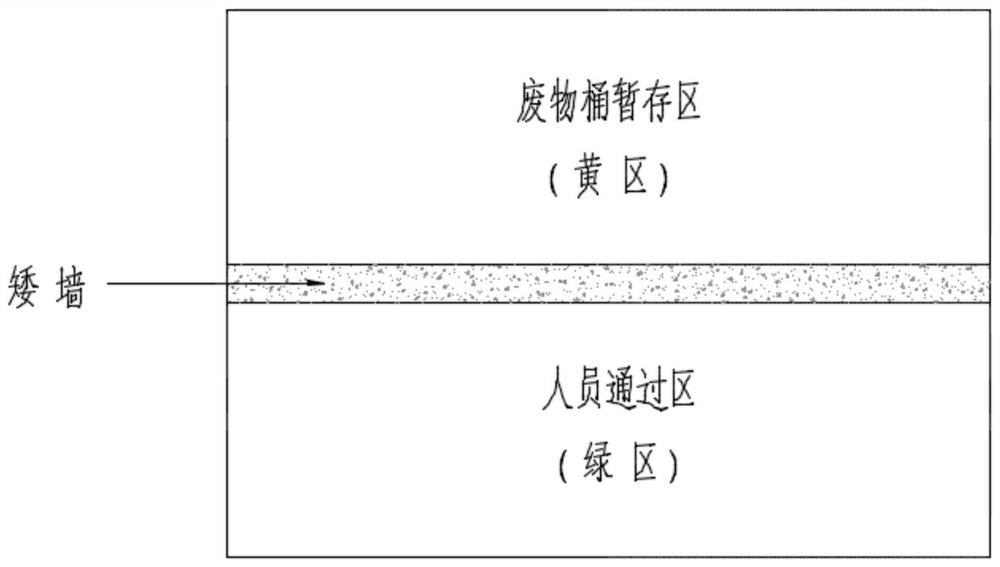

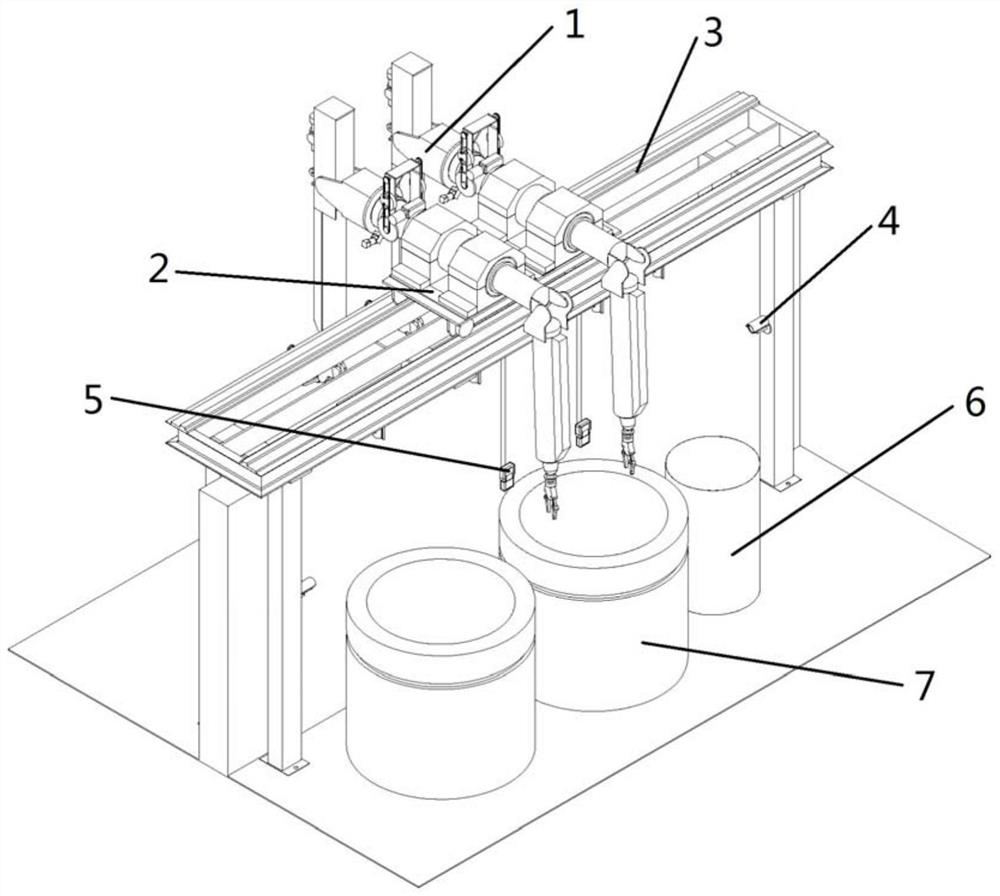

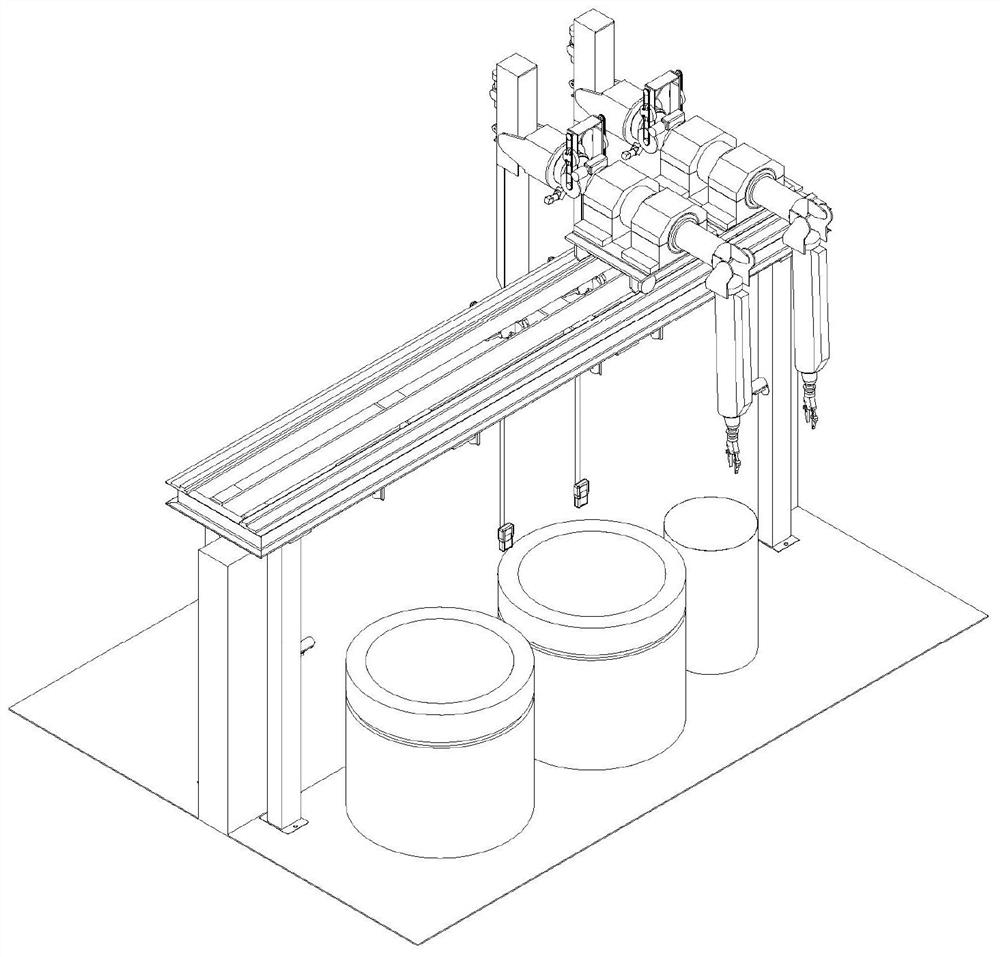

Movable radioactive waste sorting device and using method thereof

PendingCN111617974AIncrease flexibilityWide applicabilitySolid waste disposalSortingProcess engineeringRadioactive waste

The invention discloses a movable radioactive waste sorting device and a using method thereof. The device comprises a mounting platform mounted at the top of a low shielding wall; railways are arranged on the mounting platform in the length direction; a trolley which can slide along the railways is arranged on the railways; two manipulators are mounted on the trolley side by side; clamp forceps ofthe manipulators are located in a radioactive waste storage area located inside the low shielding wall; and a dosage measurement instrument and a video system are further mounted on an inside wall surface of the low shielding wall. According to the sorting device disclosed by the invention, the mounting platform is connected to supporting vertical posts by bolts; when other radioactive waste storage areas need sorting, the platform can be detached quickly; the overall sorting device is moved to the low shielding wall of the radioactive waste storage area for performing sorting work; and a detachable structure is high in flexibility, wide in applicability, and convenient to mount and detach, and facilitates transportation and adjustment.

Owner:QINGDAO DONGKA ENVIRONMENTAL PROTECTION ENG TECH +1

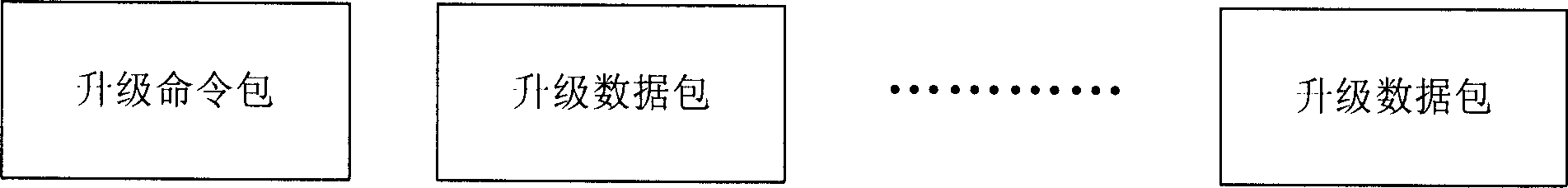

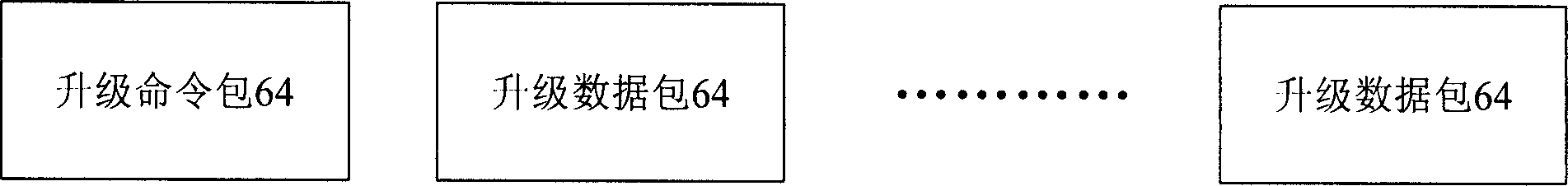

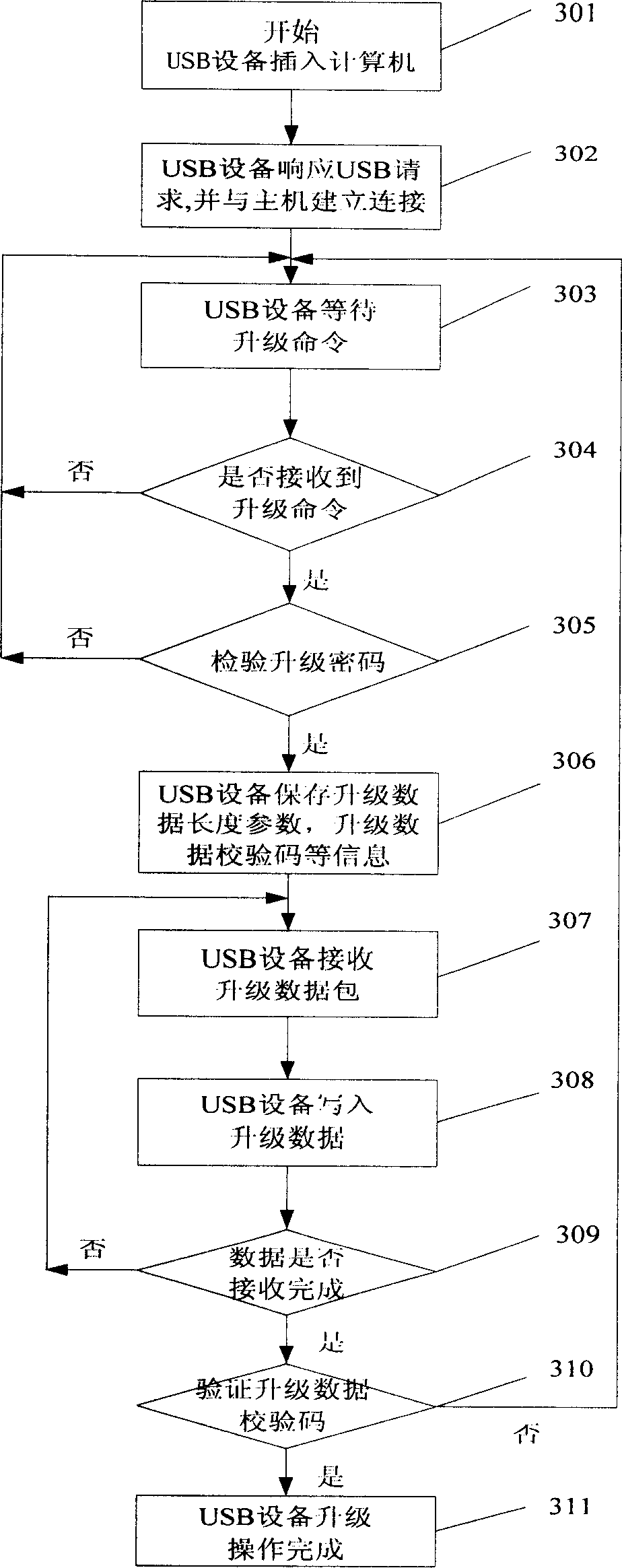

Online updating method for USB device when communication protocol constrained

ActiveCN1866228ASave spaceImprove efficiencyElectric digital data processingNetwork packetCommunications protocol

The disclosed on-line upgrade method for USB device comprises: packing upgrade data into command package and data package with length aligned to FLASH USB physical partition respectively by upper computer to send to USB device, writing the received upgrade data into hardware to complete the process. This invention saves time and space, and more convenient to user even the communication protocol is limited.

Owner:FEITIAN TECHNOLOGIES

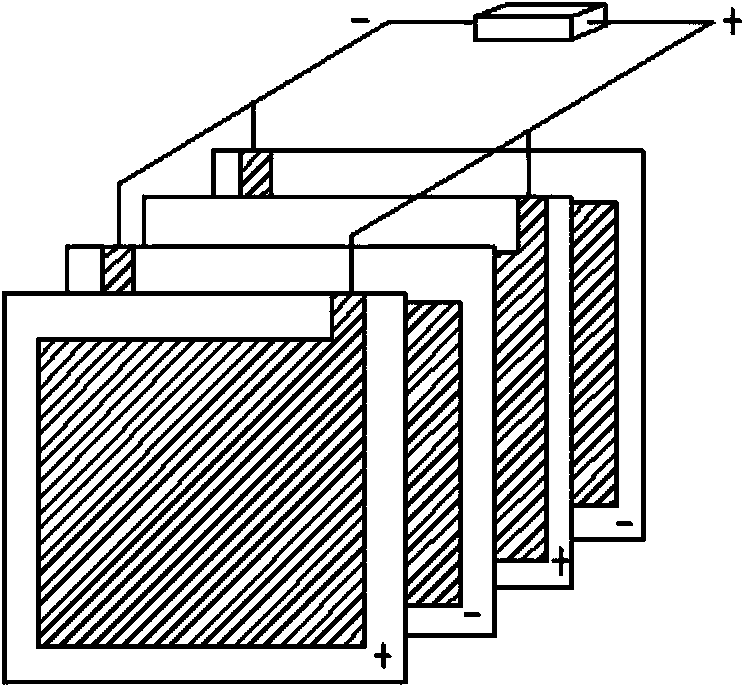

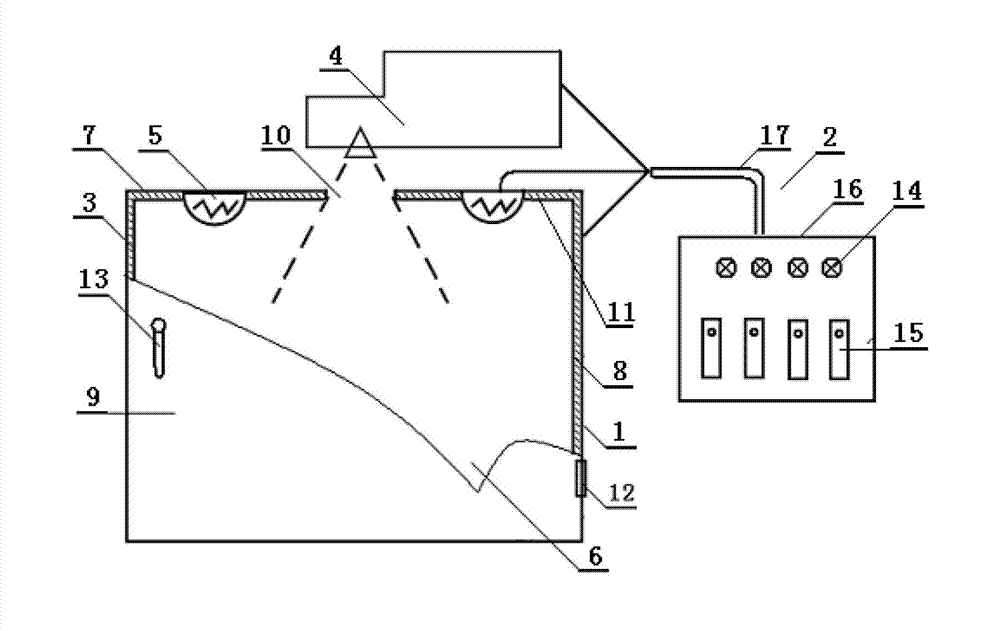

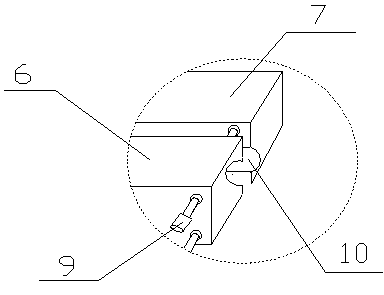

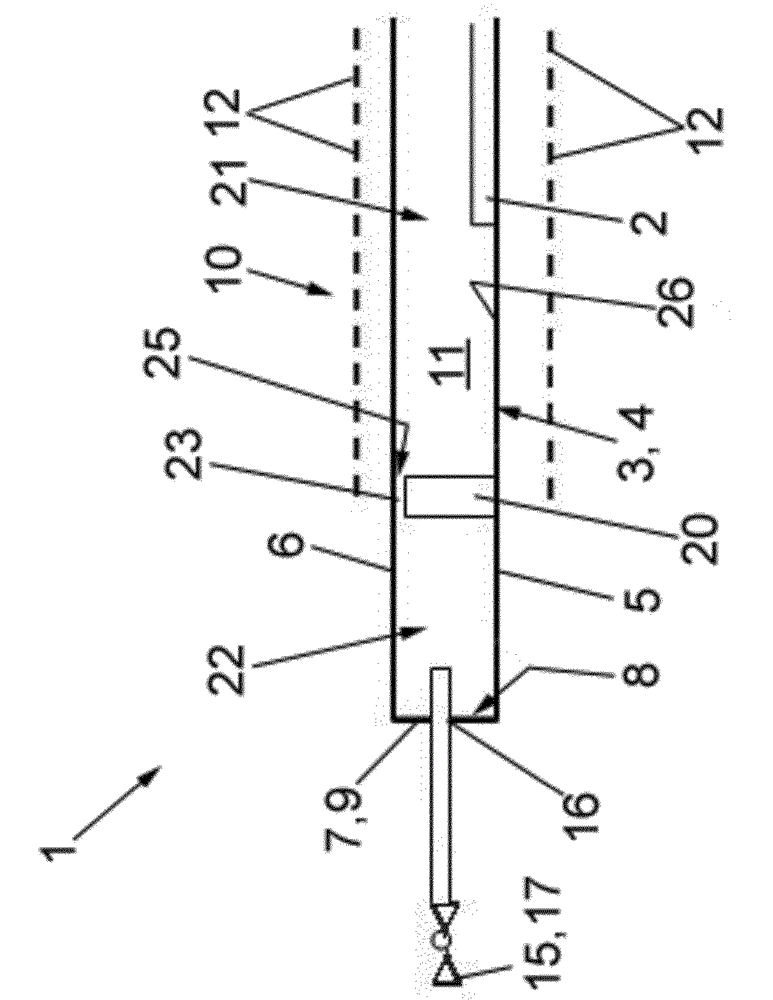

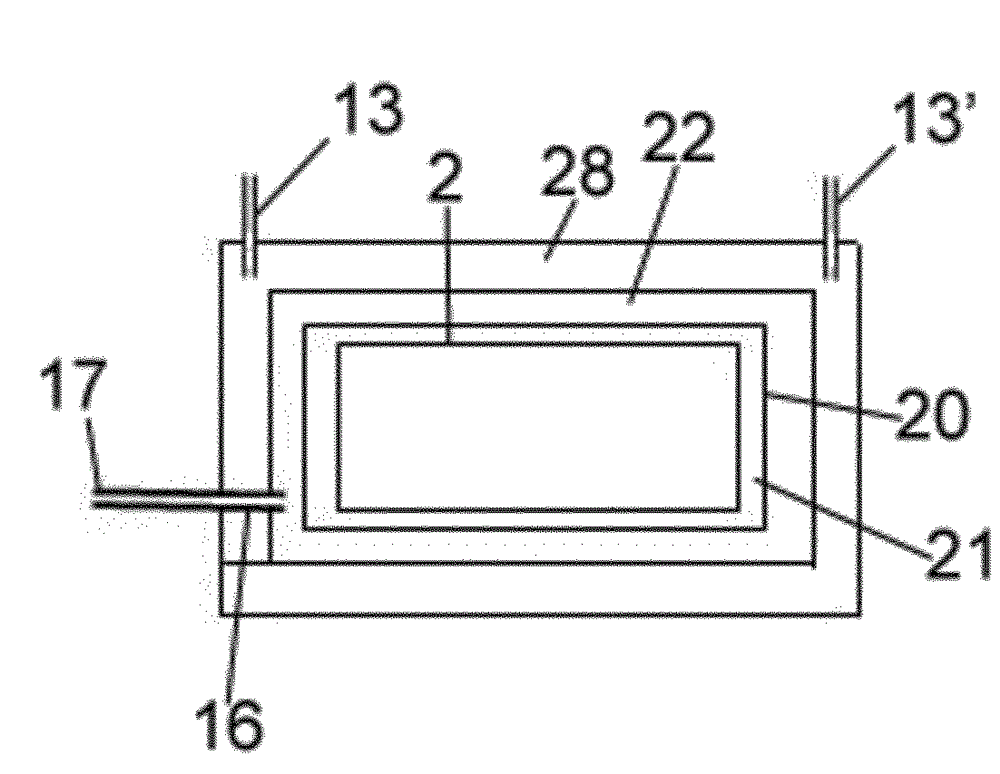

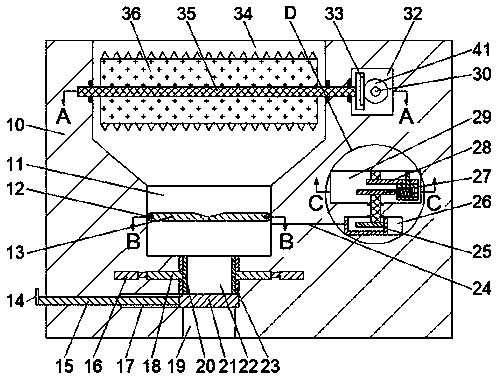

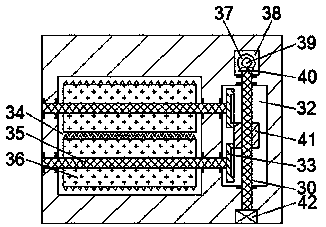

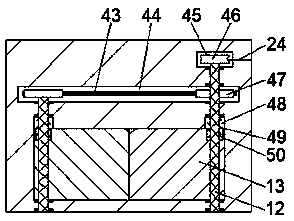

Method and device for treating in-vitro blood

ActiveCN102861104ASave processing spaceReduce processing timeMammal material medical ingredientsBlood disorderImmunocompetencePhotosens

The invention relates to a method and a device for treating in-vitro blood. The device consists of a lead comprehensive treatment box and an electric and control part, wherein an irradiation cavity is arranged in the treatment box; a front bin gate is arranged outside the treatment box; and an upper top plate is provided with an X-ray incidence window, an X-ray tube and a halogen lamp. During operation, an in-vitro blood sample with methylene blue photosensitizer and to be treated is arranged in the irradiation cavity; the X-ray tube and the halogen lamp can be started to operate after the front bin gate is closed; the X ray is emitted downward through the incidence window and irradiates the blood sample; the halogen light directly irradiates the blood sample; and the irradiation treatment of killing virus in the blood sample and the methylene blue chemical treatment of killing lymphocyte with immunocompetence are carried out simultaneously on the in-vitro blood in the same treatment cavity with high efficiency, high quality and low cost. Two processes for substep chambered single treatment are carried out in the same cavity, so that the treatment space is effectively compressed, the treatment time is shortened, the treatment cost is reduced, the treatment quality is improved, and strong practicability is ensured.

Owner:UNITED WELL BIOTECH SHANGHAI CO LTD

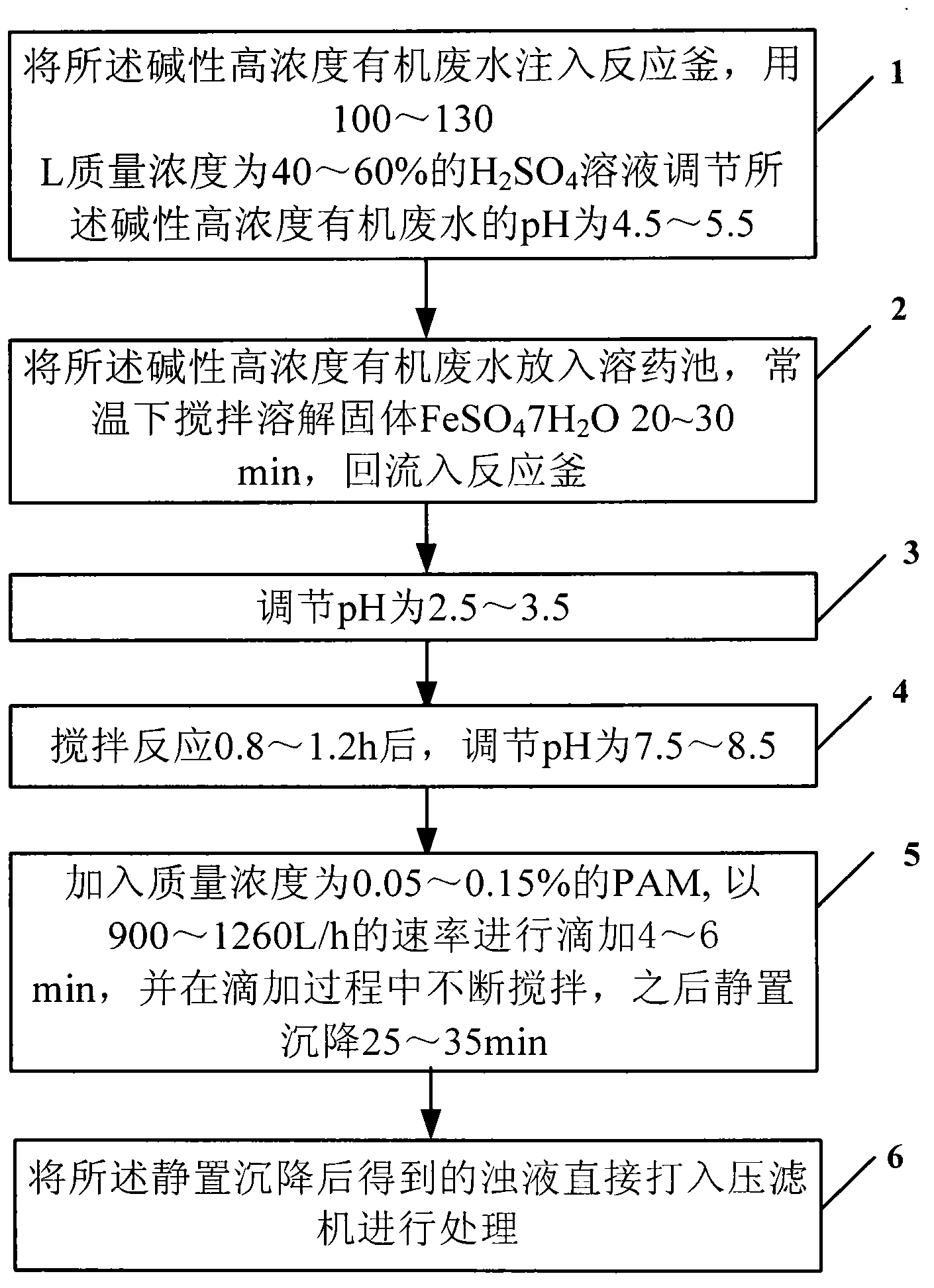

Method for treating alkali high-concentration organic waste water by using Fenton process

InactiveCN102838229ALow costReduce usageWater contaminantsMultistage water/sewage treatmentHigh concentrationWastewater

The invention provides a method for treating alkali high-concentration organic waste water by using a Fenton process. The method comprises the following steps of: injecting the alkali high-concentration organic waste water into a reaction kettle, and adjusting the pH value of the alkali high-concentration organic waste water to 4.5-5.5 by using 40-60% of H2SO4 with the mass concentration of 100-130L; draining the alkali high-concentration organic waste water in a medical dissolving pond, stirring and dissolving solid FeSO4.7H2O2 at 25-35 DEG C for 20-30min, and reflowing to the reaction kettle; adjusting the pH value to 2.5-3.5; stirring and reacting for 0.8-1.2h, and adjusting the pH value to 7.5-8.5; adding PAM (polyacrylamide) with the mass concentration of 0.05-0.15%, dropping with the rate of 900-1260L / h for 4-6min, stirring continuously, and then standing and settling for 25-35min; directly pumping the turbid solution obtained after the standing and settling treatments in a filter press for later treatment. With the adoption of the method, the consumption of tap water is reduced and the medical dissolving time is shortened.

Owner:青岛海安生物环保有限公司

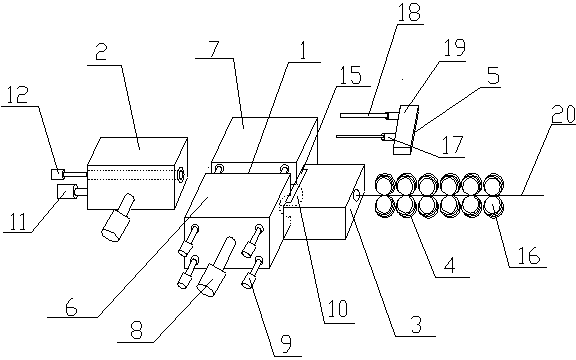

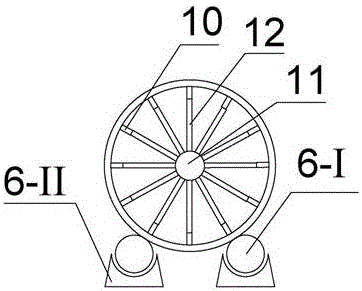

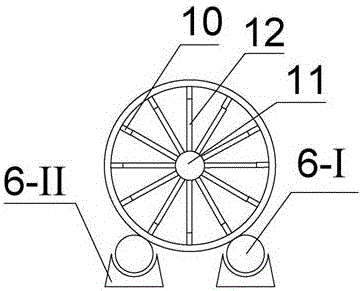

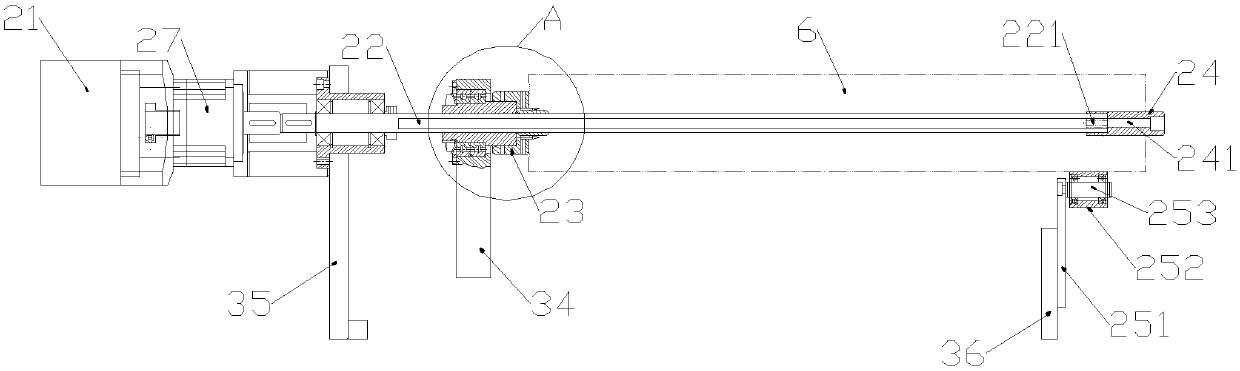

Automatic pier head equipment of automobile hollow lifting hooks

ActiveCN103522065AGuaranteed forming effectReasonable structureOther manufacturing equipments/toolsHandling devicesPipe fittingEngineering

The invention provides automatic pier head equipment of automobile hollow lifting hooks. The automatic pier head equipment of the automobile hollow lifting hooks comprises a positioning device, a forming device, a guide cutting-off device, a round broaching device and a conveying device, wherein the forming device is arranged at the left side of the positioning device, the guide cutting-off device is arranged at the right side of the positioning device, the round broaching device is arranged at the right side of the guide cutting-off device, and the conveying device is arranged at the back of the guide cutting-off device. The automatic pier head equipment of the automobile hollow lifting hooks is reasonable in structure, can effectively, rapidly and automatically complete the whole machining process from automatic feeding of the automobile hollow lifting hooks to material receding of pier heads, accurately processes pipe fittings to be machined, is simple in machining working procedure, guarantees the forming effect of the hollow lifting hooks, adopts automation machining, reduces manual operation, saves machining cost, and improves work efficiency.

Owner:安徽振华汽车部件有限责任公司

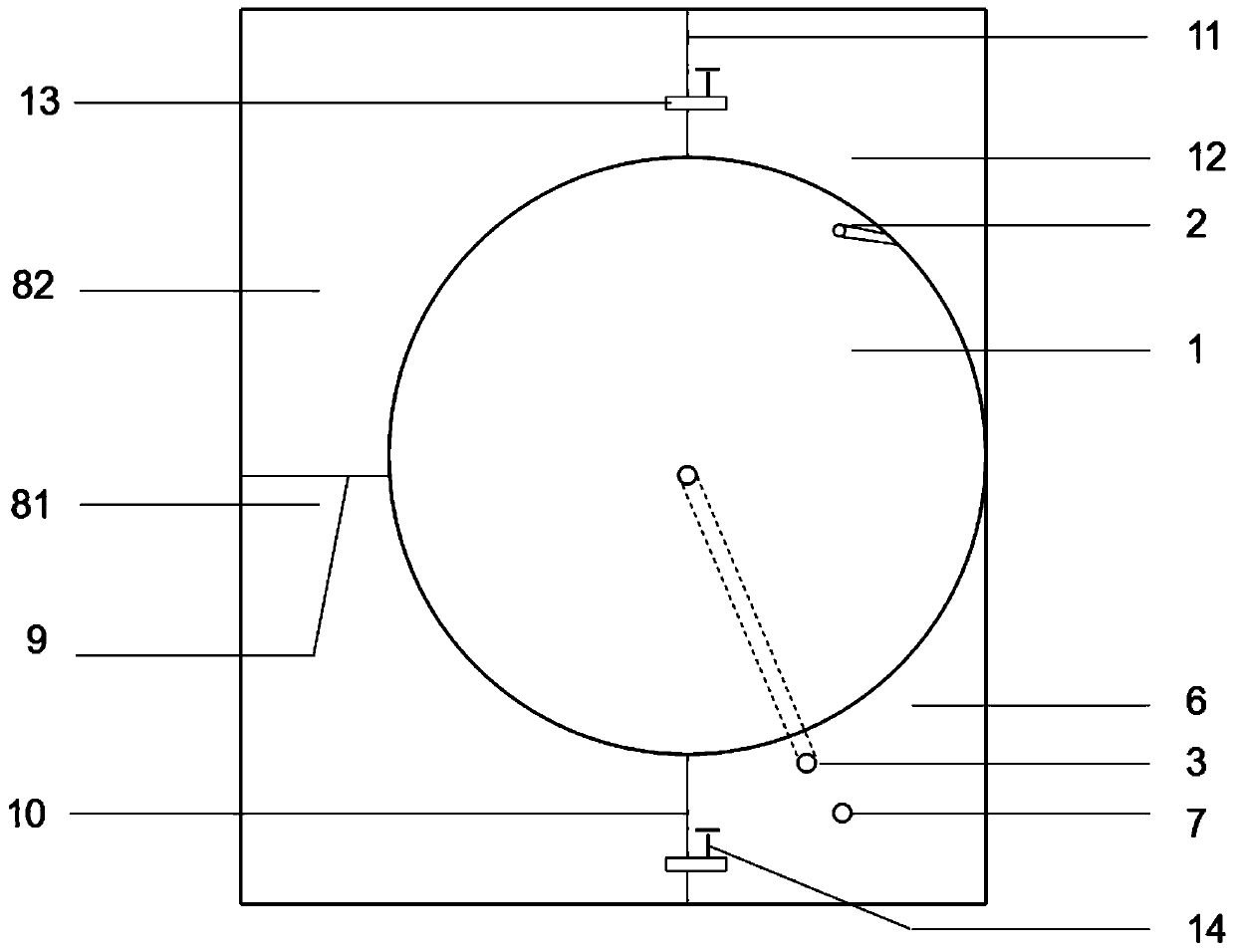

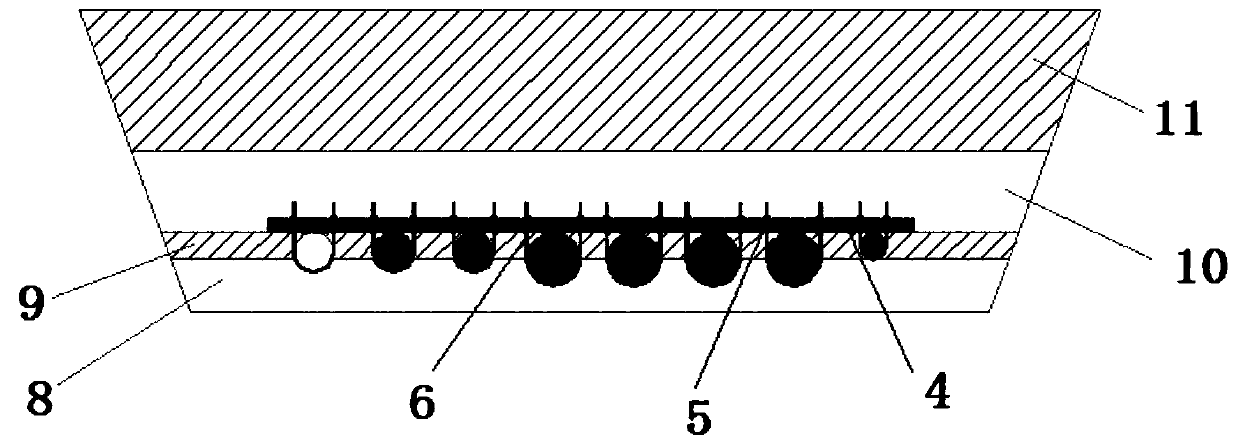

Circulating water culture system for single-pond culture of penaeus vannamei boone and operation method

InactiveCN111204928ASave processing spaceAvoid the chance of mutual infectionWater treatment parameter controlWater/sewage treatment by irradiationParticulatesWater treatment system

The invention relates to a circulating water culture system for single-pond culture of penaeus vannamei boone and an operation method, and belongs to the field of aquatic facilities. The circulating water culture system comprises a culture unit and a water treatment unit, and the water treatment unit comprises a particulate matter precipitation removal unit, a biological treatment unit and an ultraviolet disinfection unit. The water treatment unit is arranged under the ground around the culture unit, the upper edge of the water treatment unit is flush with the ground, and grids capable of being taken and placed freely are laid on the water treatment unit. Culture wastewater in the culture unit sequentially enters the particulate matter precipitation removal unit, the biological treatment unit and the ultraviolet disinfection unit after being discharged, and seawater subjected to ultraviolet disinfection is pumped into the culture unit again. According to the invention, a single culturepond is taken as a system unit, water circulation and water treatment are independently carried out, and the problem of cross infection among different culture ponds is avoided; and the water circulation and water treatment system is located under the periphery of the culture pond, so that the culture space is saved, and convenience is provided for operations such as feeding and observation of single-pond culture.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

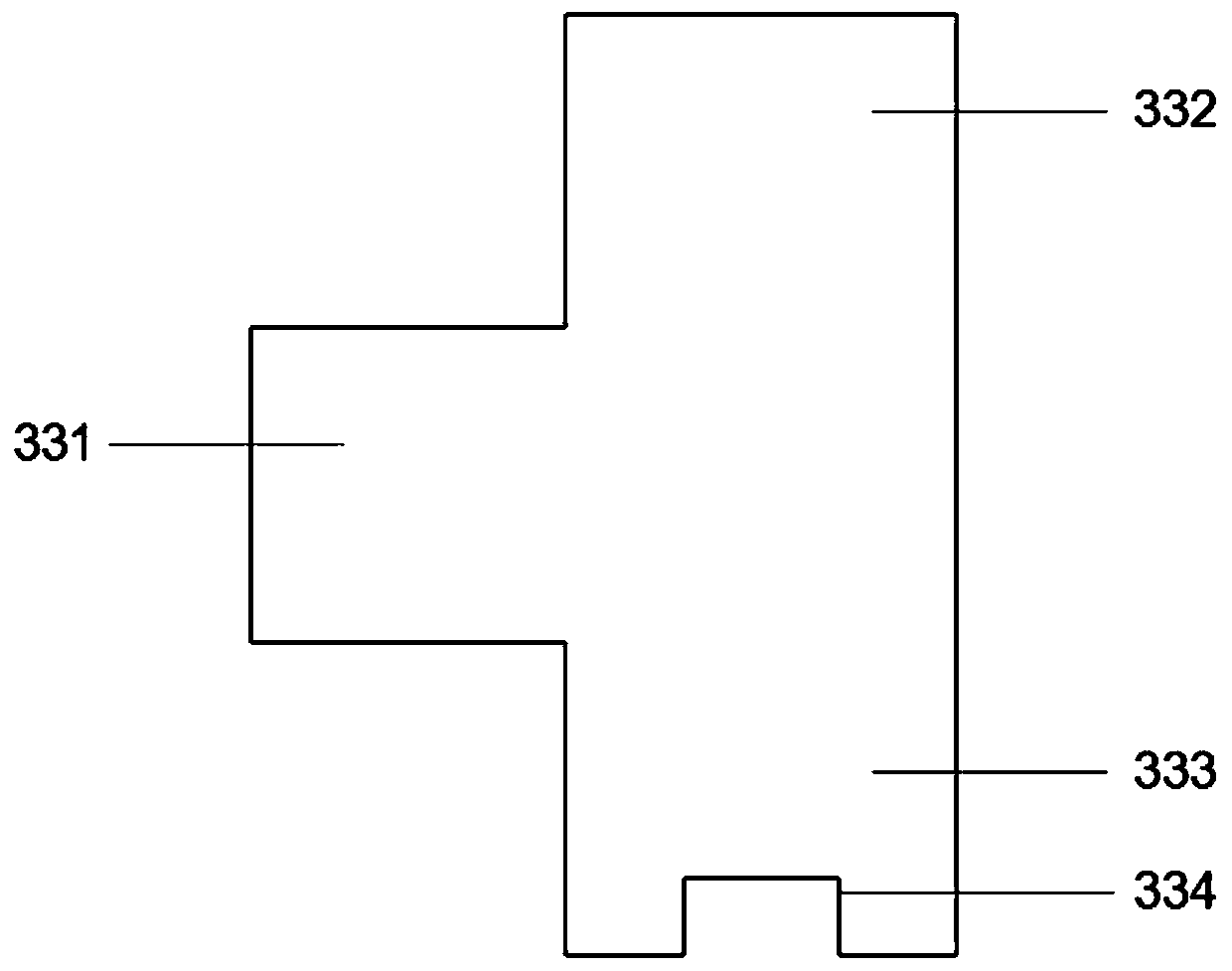

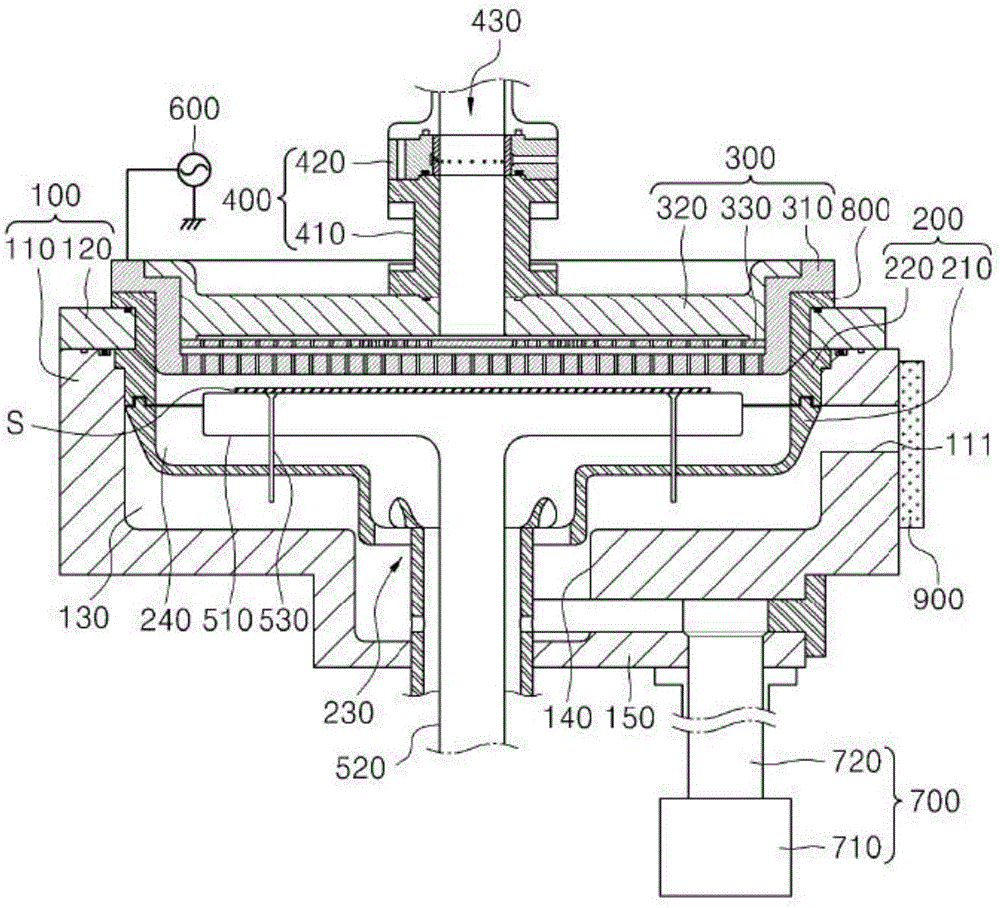

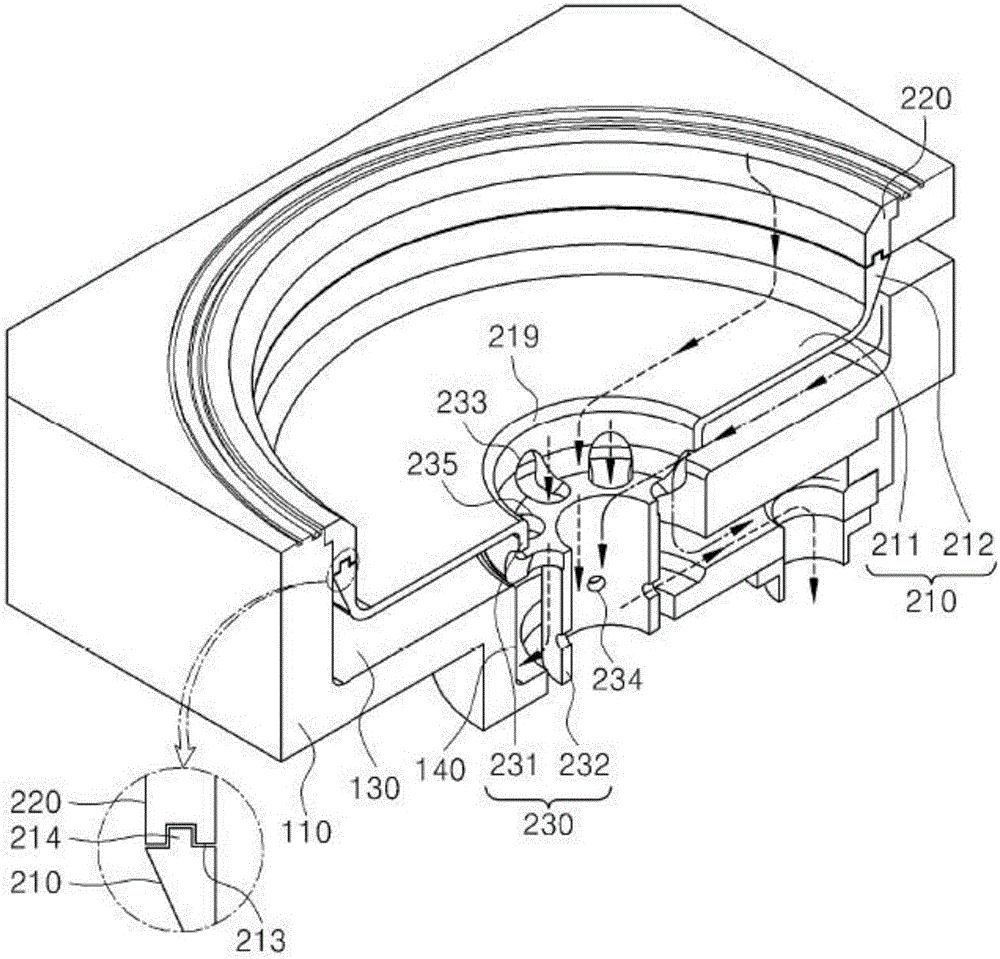

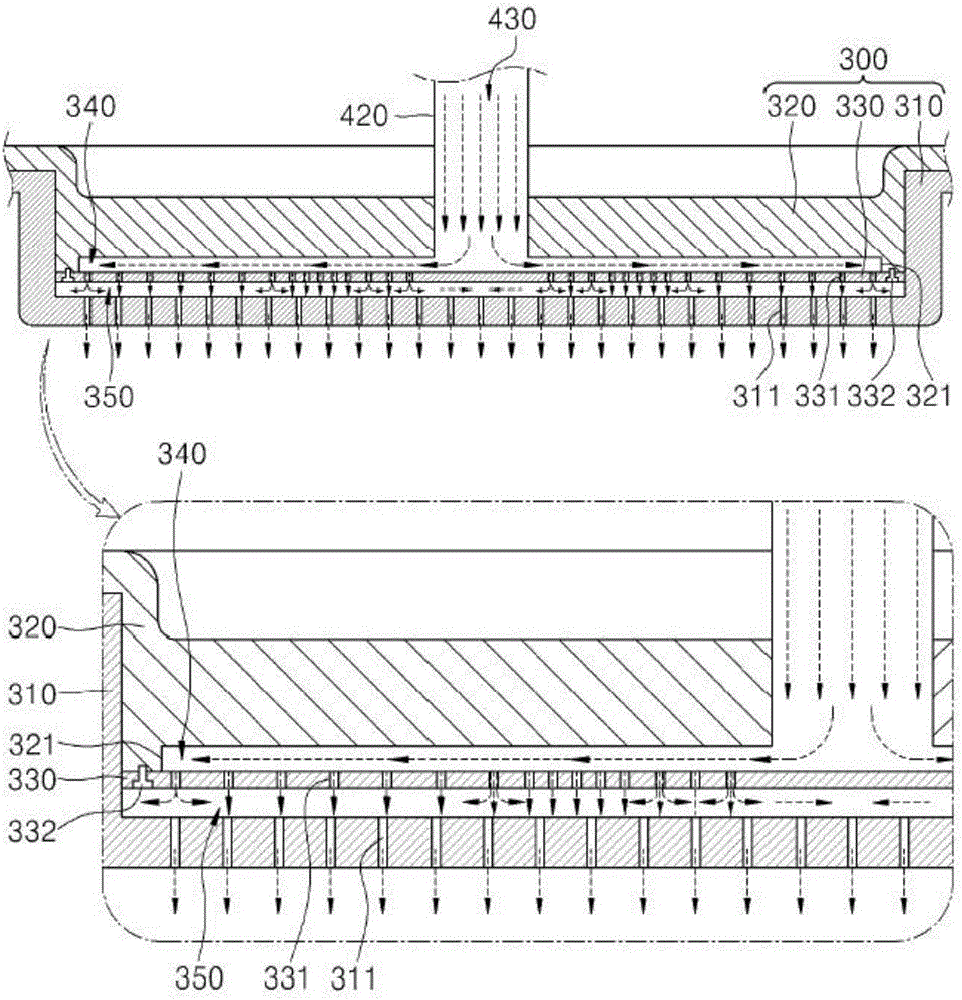

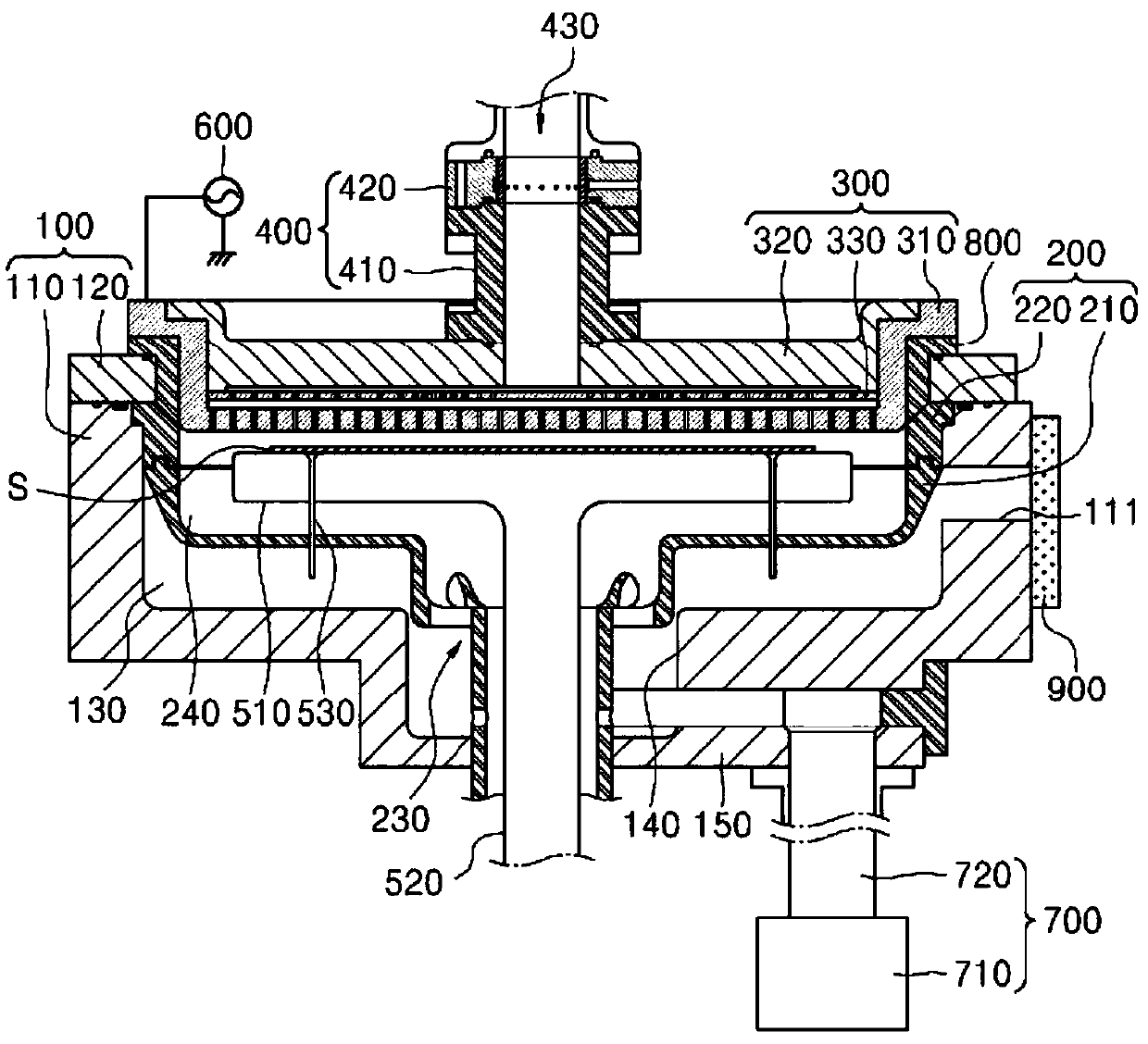

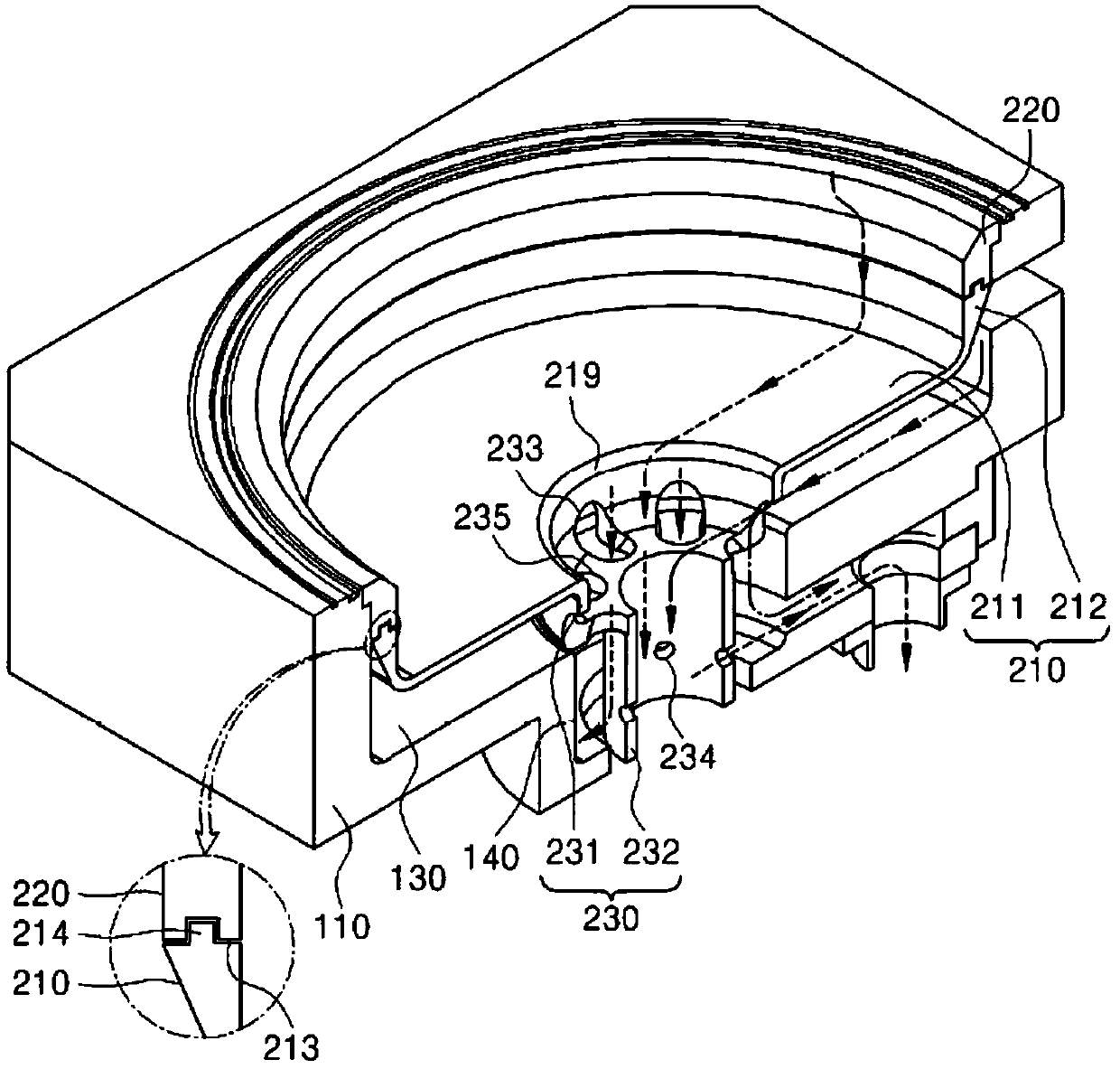

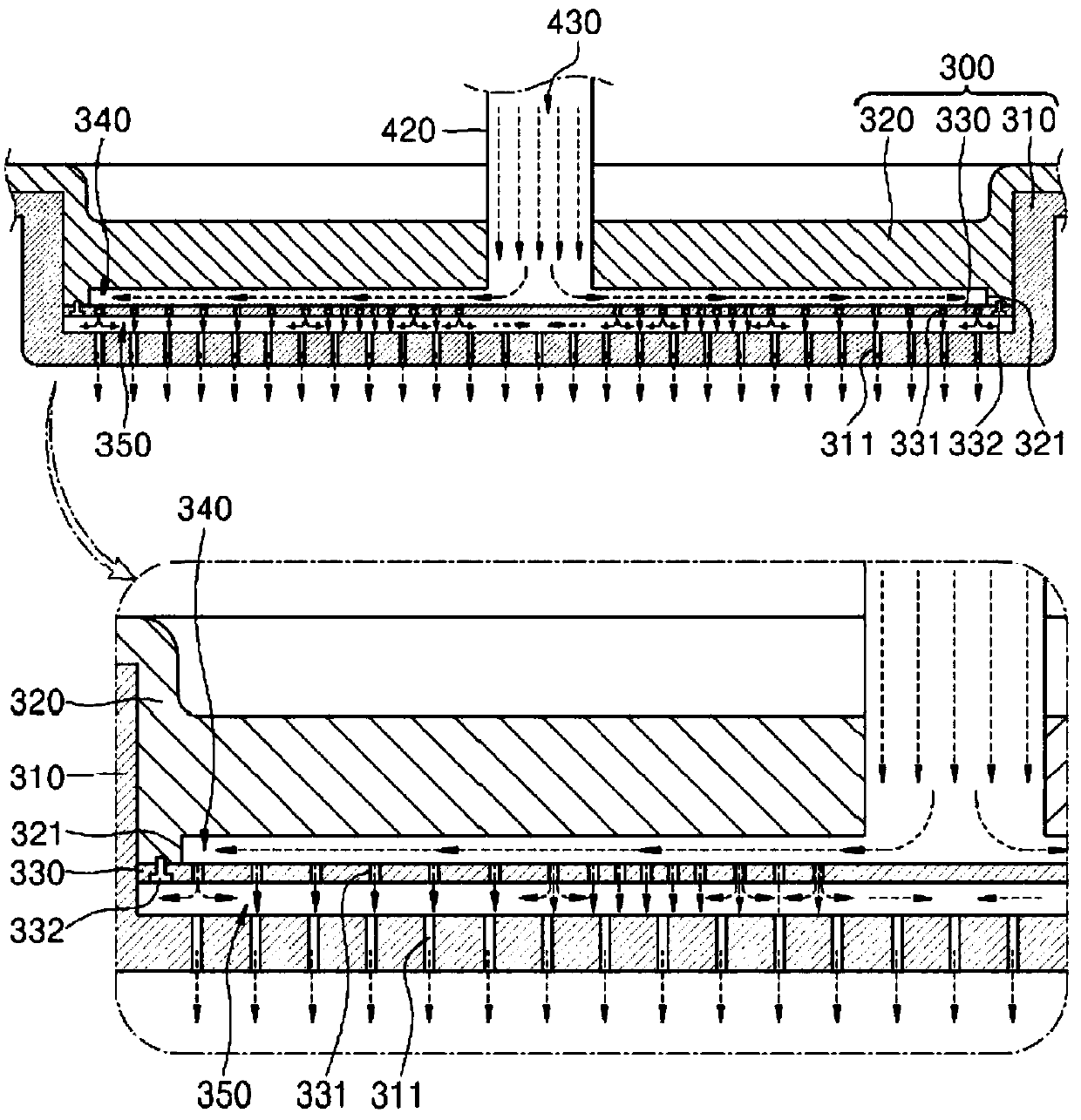

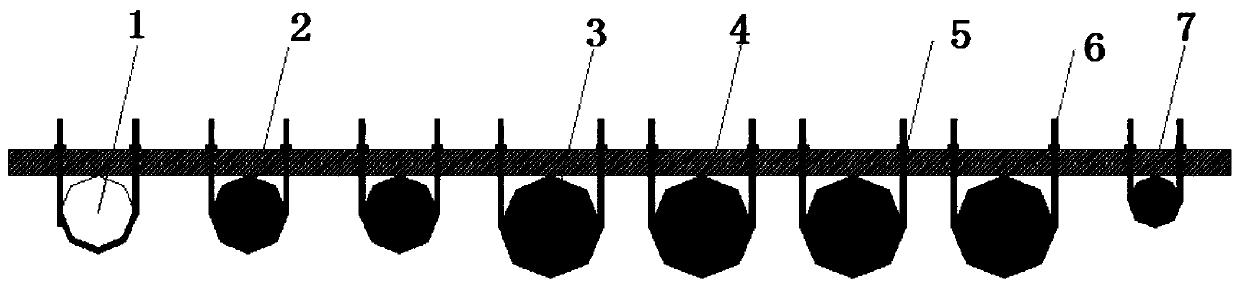

Substrate processing apparatus

ActiveCN105793959ASymmetrical even distributionEasy to cleanSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

The present invention relates to a substrate processing apparatus comprising: a chamber allowing a substrate to enter and exit on one side thereof and having a first space therein; an inner chamber arranged in the first space inside the chamber and having a second space therein; a substrate support, arranged in the interior of the inner chamber, for supporting the substrate; and a gas sprayer for spraying gas on the substrate support, wherein the inner chamber comprises: a first body fixed on the upper part of the interior of the chamber; a second body arranged below the first body, being capable of moving vertically and having an exhaust hole in the central part of the bottom surface thereof; and an exhaust body connected to the exhaust hole and having a gas exhaust path in the interior thereof.

Owner:CHARM ENG CO LTD

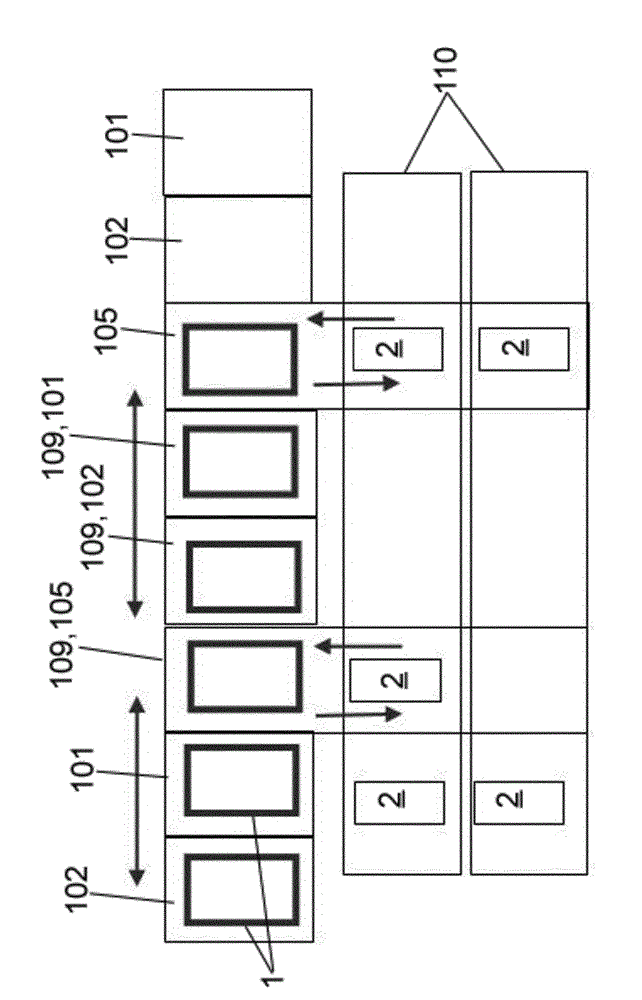

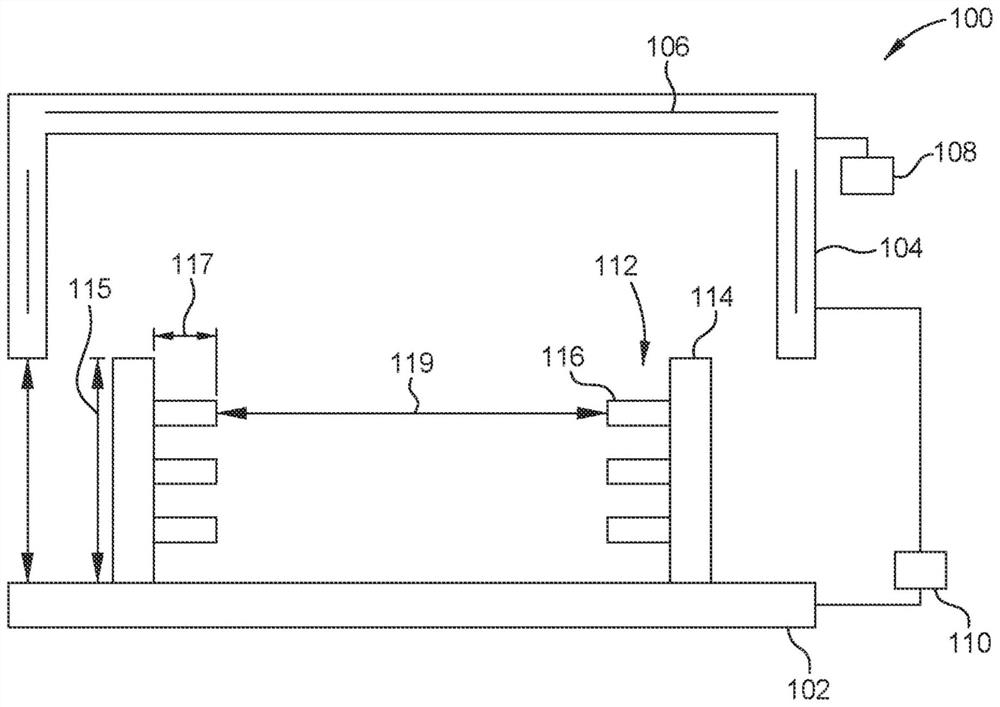

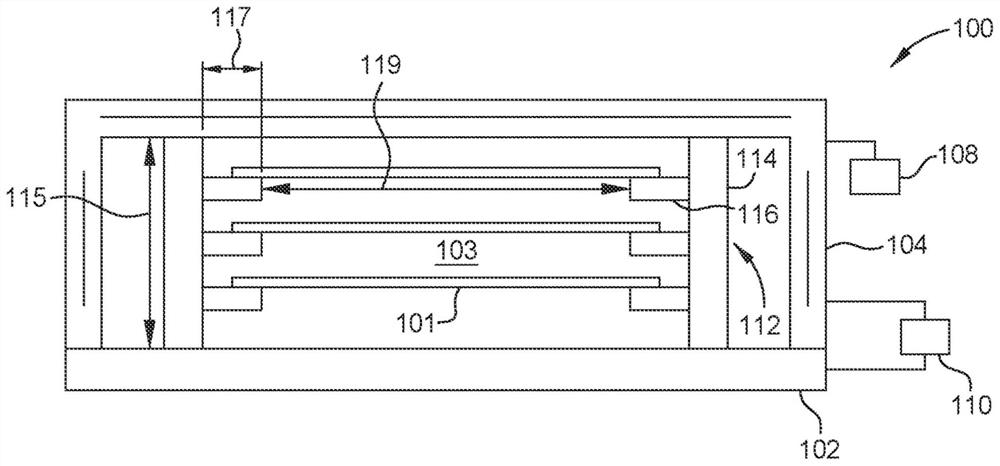

System and method for processing substrates

ActiveCN104937706AReduce wearSimple structureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal radiationCooling Units

The present invention relates to a system for processing coated substrates, having the following features: at least one evacuable process box for accommodating at least one substrate with a gas-tightly sealable housing, which forms a hollow space, wherein the housing comprises at least one housing section, which is implemented such that the substrate is thermally treatable by incident electromagnetic thermal radiation, wherein the housing has at least one housing section coupleable to a cooling device for its cooling and at least one housing section not coupled to the cooling device, wherein the hollow space is divided by at least one separating wall into a process space for accommodating the substrate and an intermediate space, wherein the separating wall has one or a plurality of openings and is arranged between the substrate and the housing section coupled to the cooling device, and wherein the housing is provided with at least one sealable gas passage that opens into the hollow space, for evacuating and introducing gas into the hollow space; a cooling device for cooling the process box housing section coupleable to the cooling device; at least one loading / unloading unit for loading and / or unloading the process box; at least one heating unit for heating the substrate in the process box; at least one cooling unit for cooling the substrate in the process box; at least one pumping-out device for draining the hollow space of the process box; at least one gas supply device for supplying the hollow space of the process box with at least one gas; at least one transport mechanism, which is implemented for the purpose of executing a relative movement between, on the one hand, the process box and, on the other, the heating, cooling, and loading / unloading unit.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

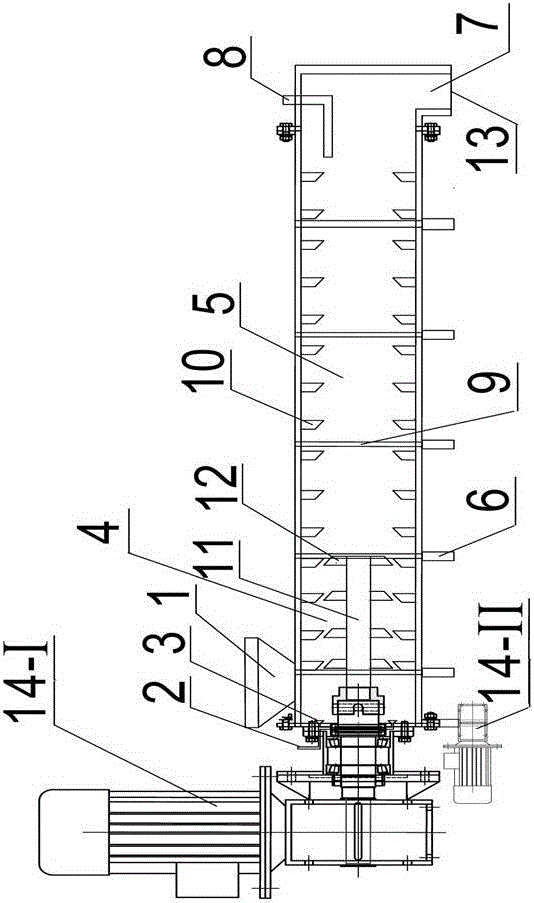

Municipal solid waste bag-breaking and fermentation integrated device and application

ActiveCN106378349AEffective pollution controlLow viscosityTransportation and packagingSolid waste disposalEnvironmental engineeringOrganic matter

The invention provides a municipal solid waste bag-breaking and fermentation integrated device and application. The current household waste recycling process in China comprises the following steps: bag breaking; sorting; fermentation; and recycling. In the above process, organic matters decay during bag breaking treatment, malodorous gas and a large amount of percolate are generated, and the problems about increased material viscosity, difficult sorting, low recycling efficiency, high cost and the like are caused. In order to solve the problems about low recycling efficiency, low cost and environmental pollution, the integrated device and an application method thereof are provided. According to the integrated device, a complex microbial bacterium solution is sprayed into municipal solid waste before bag breaking, and the organic matters are quickly degraded during uninterrupted bag breaking and fermentation, thereby guaranteeing quick transformation of the perishable organic matters during bag breaking and fermentation, and greatly reducing the impact of the malodorous gas on the environment; and meanwhile, the viscosity of residual solids can be greatly reduced during fermentation, the recycling efficiency can be improved by 35% or above, and the recycling cost can be reduced by 10% or above.

Owner:NANKAI UNIV

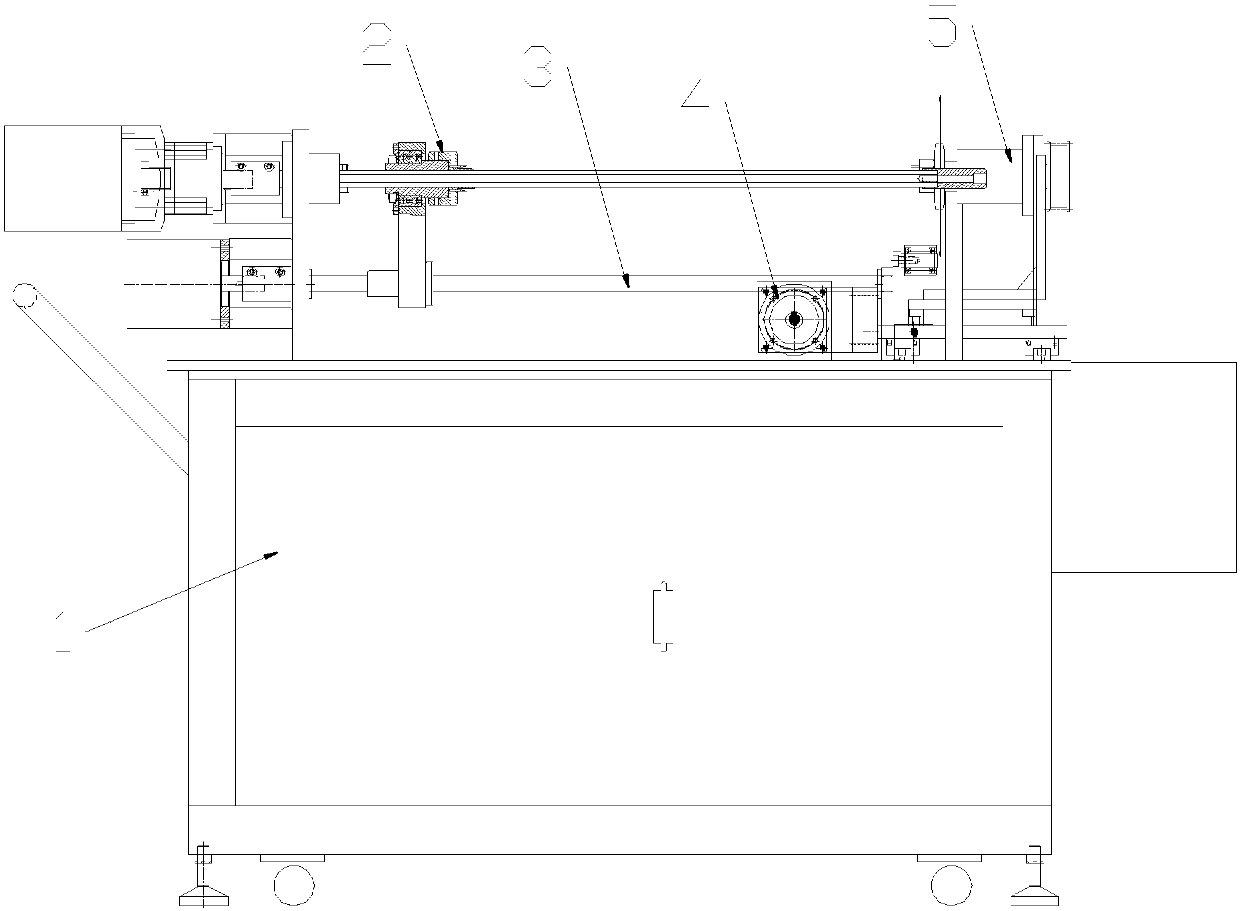

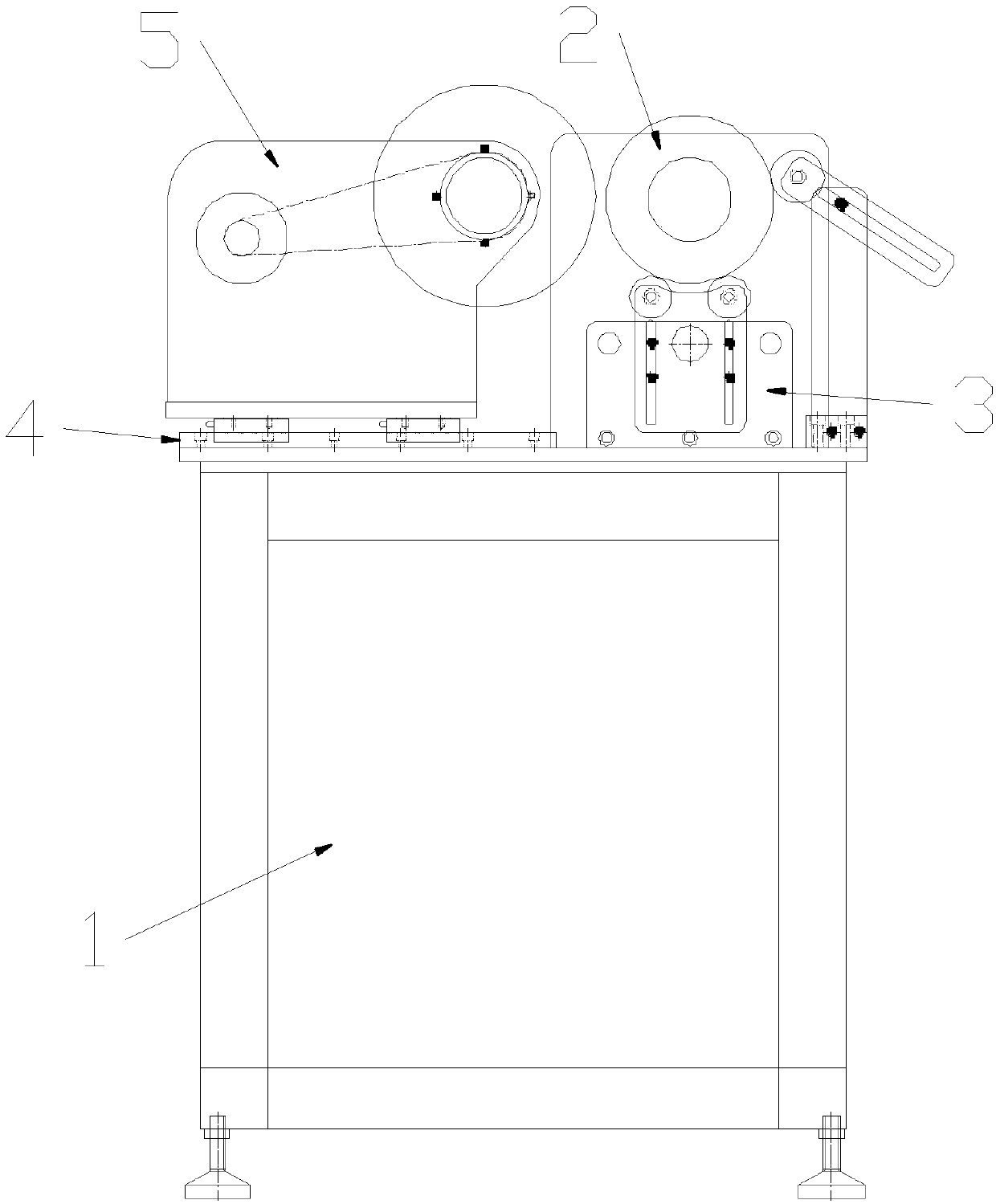

Three-in-one pipe cutting machine

A three-in-one pipe cutting machine comprises a machine platform, a fast replacement chuck device, a feeder, a feed device and a cutter device, wherein the fast replacement chuck device, the feeder, the feed device and the cutter device are arranged on the surface of the machine platform; the fast replacement chuck device comprises a chuck servo motor, a transmission core shaft, a paper core shaftand a paper core bush, the chuck servo motor is in transmission connection with one end of the transmission core shaft, the paper core shaft is in sliding sleeved connection with the transmission core shaft, and the paper core bush is fixedly sleeved with the other end of the transmission core shaft; the feeder drives the paper core shaft to move in the extension direction of the transmission core shaft; and the feed device is arranged at one end of the paper core bush and drives the cutter device to move along the machined coiled material direction and cut machined coiled materials through the cutter device. The paper core shaft is matched with the paper core bush to horizontally fix the machined coiled materials and drive the machined coiled materials to rotate, the feeder drives the paper core shaft to slide to obtain the cutting length, the feed device drives the cutter device to complete cutting, for different materials, what is only needed is to replace the paper core shaft andthe paper core bush, use convenience is realized, replacement is fast, and one machine can achieve multiple purposes.

Owner:SHENZHEN REBORN PRECISION MACHINERY CO LTD

Process for manufacturing dry degreased veneer by one-step low-temperature dewatering and degreasing

A process for manufacturing a dry degreased veneer by one-step low-temperature dewatering and degreasing includes the steps of a, directly conveying a wet veneer into an extraction tank, closing the extraction tank and performing vacuuming to -0.09 Mpa to extract air in the extraction tank; b, injecting dimethyl ether into the extraction tank for soaking and extracting, and extracting dimethyl ether out of the extraction tank after soaking and extracting for 20-40 minutes, wherein weight ratio of dimethyl ether to the wet veneer is 1-1.2:1 and extraction temperature is 30-50 DEG C; and c, repeating the step b for two to four times, extracting dimethyl ether in the extraction tank in vacuum, and finally taking out the wet veneer from the extraction tank to obtain a dewatered degreased dry veneer. The process for manufacturing the dry degreased veneer is simple, quick, high in efficiency, low in cost and free of pollutants in production process and has promising development prospect.

Owner:陈智存 +1

Collecting device for scrap iron on bottom of turning machine tool

InactiveCN111420748AAvoid scratching the scalpSave processing spaceGrain treatmentsMaintainance and safety accessoriesEngineeringCrusher

The invention discloses a collecting device for scrap iron on a bottom of a turning machine tool. The collecting device comprises a base body, wherein a crushing cavity with an upward opening is arranged in the base body; a crushing mechanism is arranged in the crushing cavity; the right side of the crushing cavity is provided with a drive cavity; the rear side of the drive cavity is provided witha rectangular slot; a stacking cavity which communicates with the crushing cavity is arranged below the crushing cavity; a turnover mechanism is arranged in the stacking cavity; the rear side of thestacking cavity is symmetrically provided with return cavities which communicate with the stacking cavity left and right; the rear sides of the return cavities are provided with belt wheel cavities; the rear sides of the belt wheel cavities are provided with rotary cavities; the right sides of the rotary cavities are provided with movable cavities; moving mechanisms are arranged in the movable cavities; intermittent cavities are arranged above the movable cavities; intermittent mechanisms are arranged in the intermittent cavities; a dropping cavity which communicates with the stacking cavity is arranged below the stacking cavity; and a compressing mechanism is arranged in the dropping cavity.

Owner:TAIZHOU JIAOJIANG MENFA MASCH TECH CO LTD

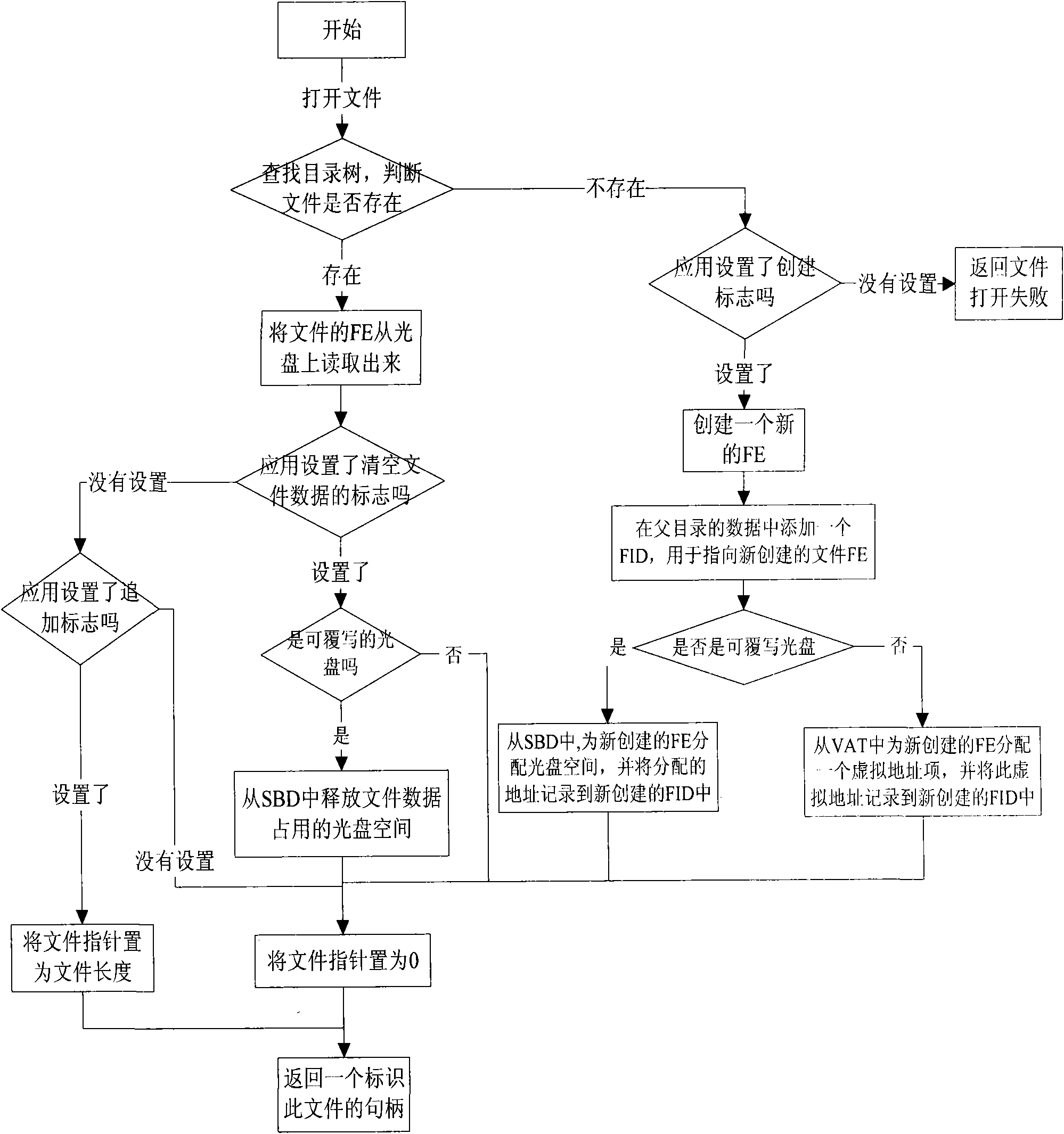

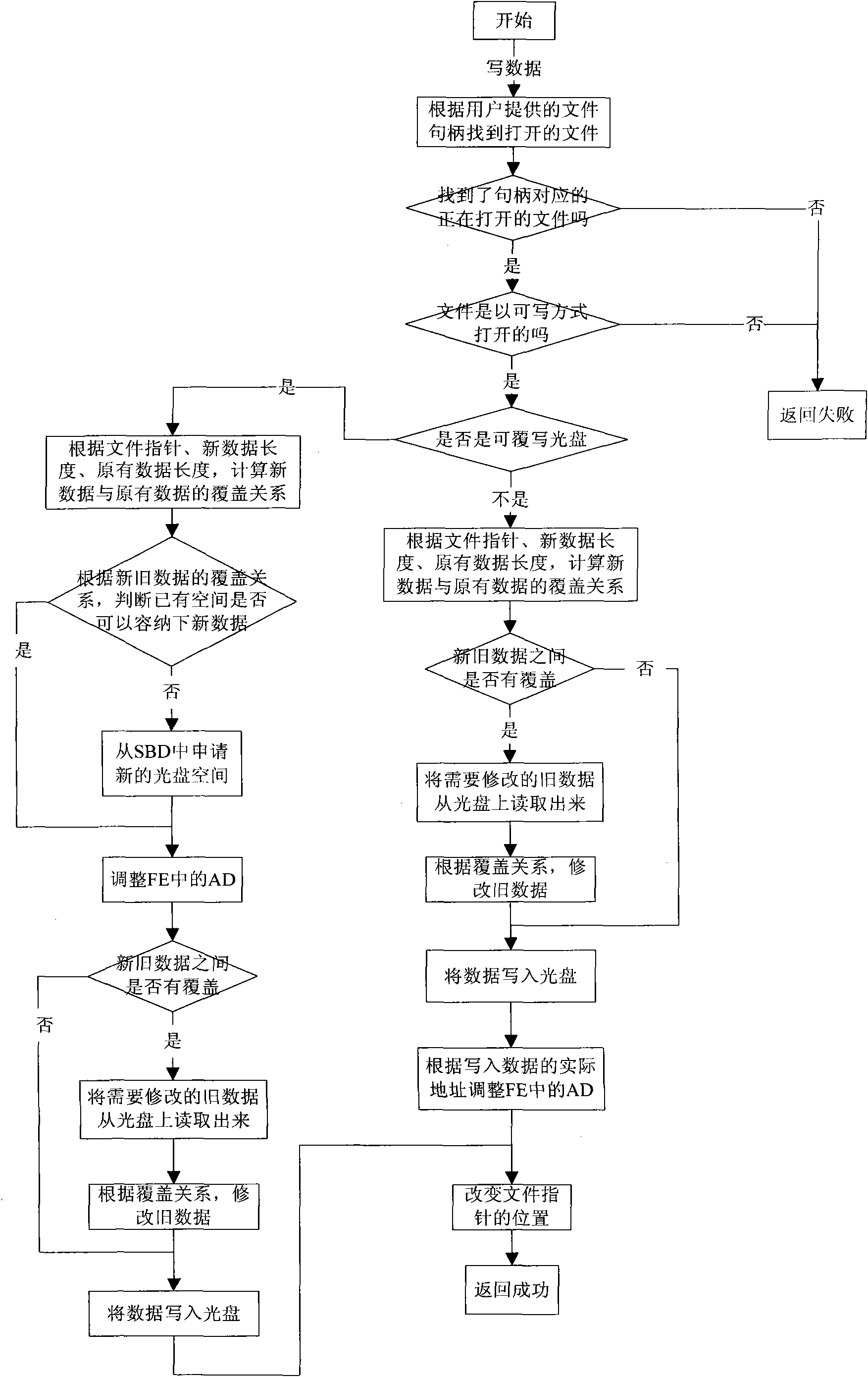

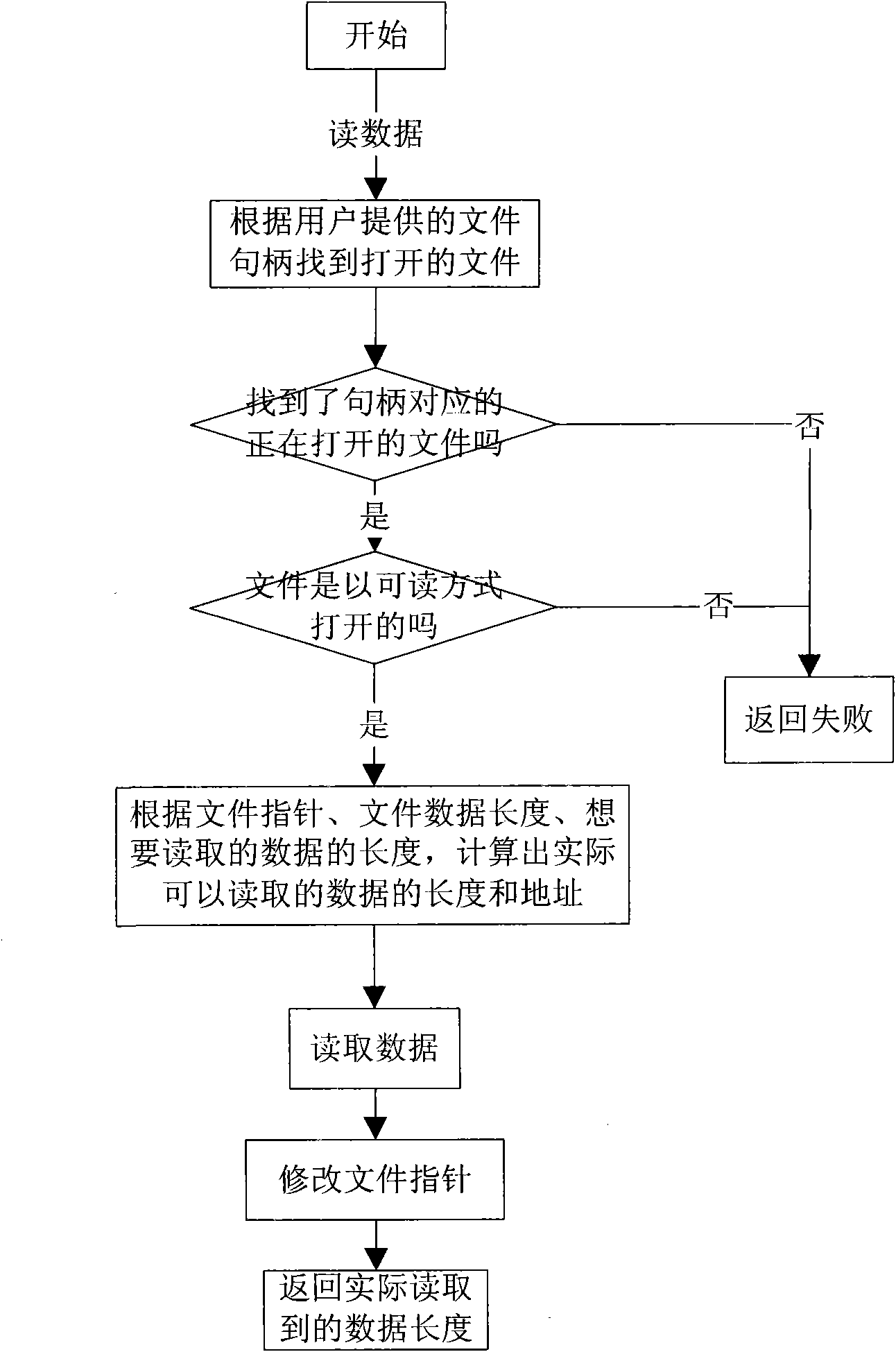

Method for realizing editable CD file data

InactiveCN101527152AImprove editing efficiencySave processing time and space overheadElectronic editing digitised analogue information signalsUsing detectable carrier informationData needsDatabase

The invention discloses a method for realizing editable CD file data. A process of writing file data comprises the following steps: 11) according to file pointers, the length of new file data needing to be written, as well as the length of original file data, figuring out covering relation between new data and original data; 12) according to the covering relation, determining used space of a CD; 13) modifying old data by use of new data, or directly writing the new data into the CD; and 14) modifying the corresponding file pointers. Due to the proposal, the method can directly modify, replace, cover, add and delete the file data on the CD, and no longer needs to record a whole file again in order to modify only a small part of the data of one file. Therefore, the method has the advantages of greatly improving the efficiency of editing CD data, saving a large amount of processing time and space overhead and reducing use cost.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Instant kelp vinegar and processing technology thereof

The invention discloses instant kelp vinegar and a processing technology thereof. The instant kelp vinegar comprises the following raw materials in parts by weight: 9-10 parts of mature vinegar and 0.5-1 part of kelp powder. Compared with the prior art, the instant kelp vinegar disclosed by the invention has the advantages of instant property, good mouthfeel, high nutritional value, long preservation time and the like.

Owner:DALIAN SENZE MARINE BIOTECH CO LTD

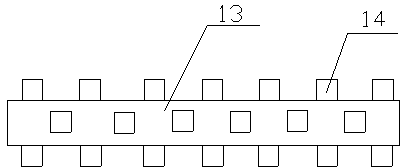

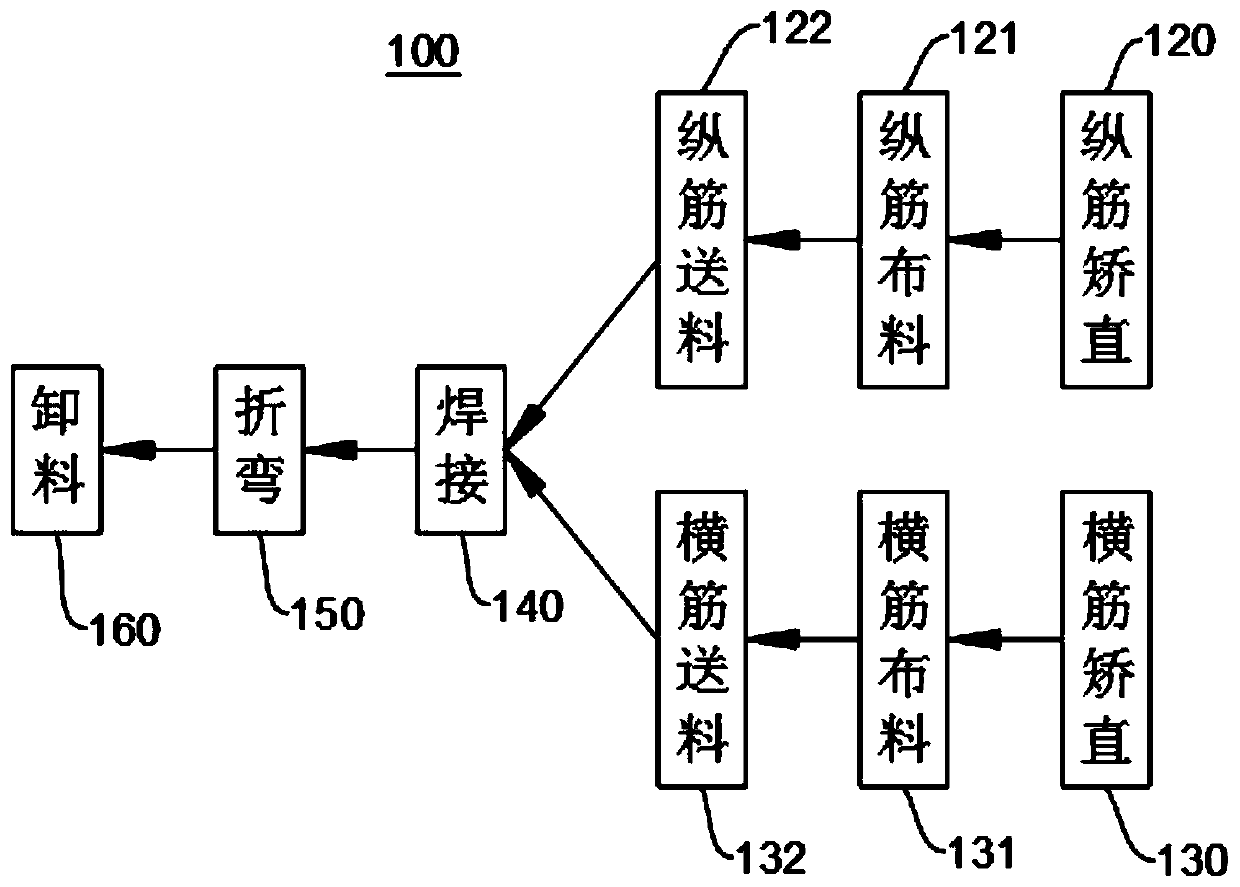

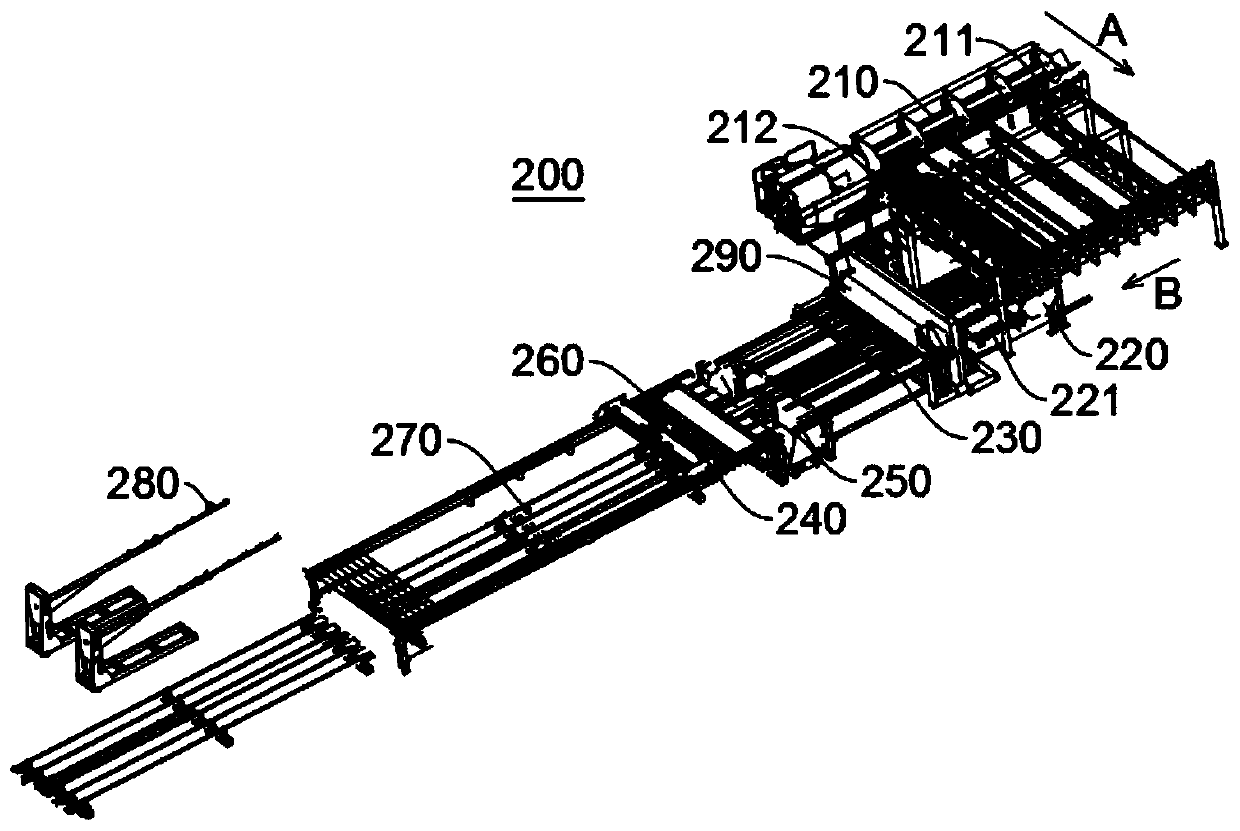

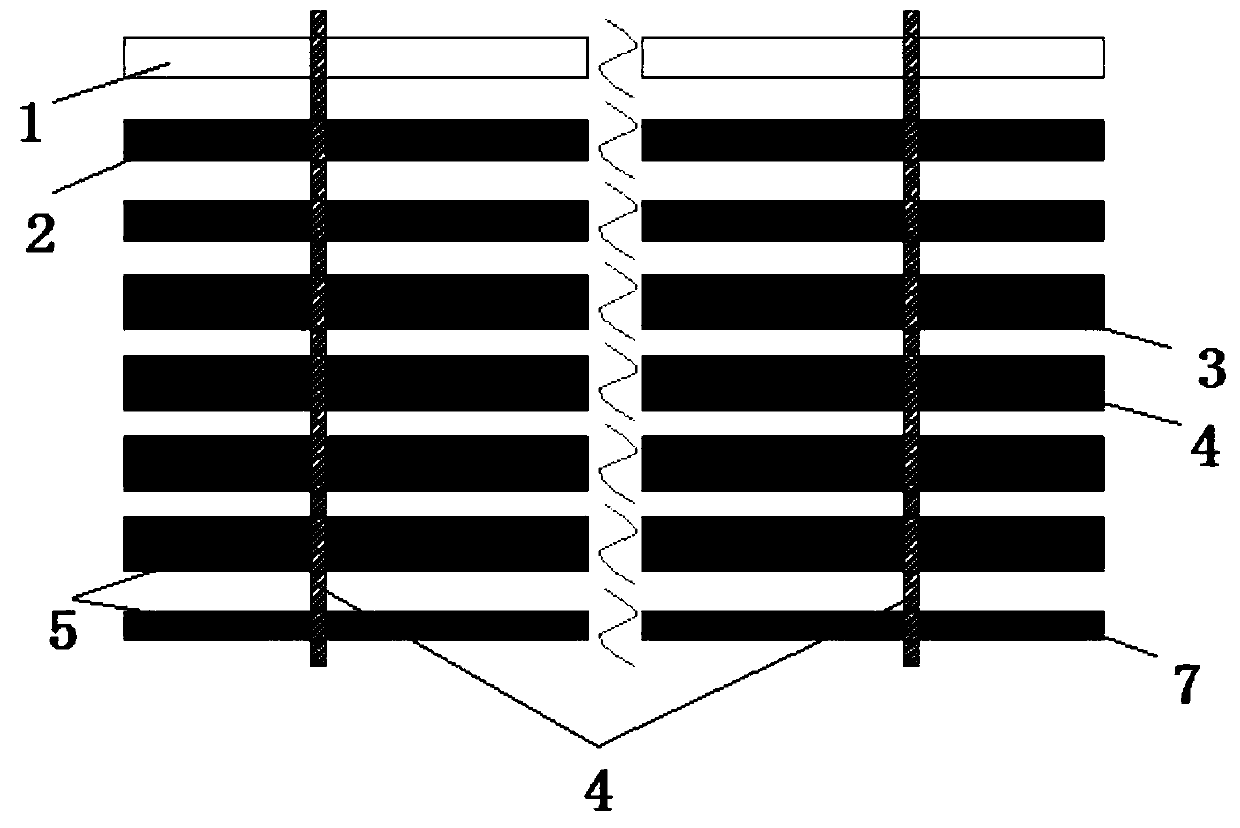

Reinforcing mesh processing method and reinforcing mesh processing equipment

The embodiment of the invention provides a reinforcing mesh processing method and reinforcing mesh processing equipment, and relates to the field of reinforcing mesh processing. Problems that existingreinforcing mesh processing is large in occupied space, and a reinforcing mesh needs to be overturned in a using process so that using cost is increased are solved. The reinforcing mesh processing method comprises the following steps of processing a longitudinal bar above a preset plane, and processing a transverse bar below the preset plane so that the longitudinal bar is located above the transverse bar at a welding station; and welding a crossed position of the longitudinal bar and the transverse bar located at a welding station so as to form the reinforcing mesh with the longitudinal barlocated at a top of the transverse bar. The reinforcing mesh processing equipment comprises a longitudinal bar processing device, a transverse bar processing device and a welding device. In the embodiment, longitudinal bar machining treatment and transverse bar machining treatment are performed in an upper space and a lower space, and a machining treatment space can be saved; the longitudinal barof the reinforcing mesh is arranged above the transverse bar so that overturning equipment or manual overturning is not needed during use, operation is more convenient, and use cost is reduced.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

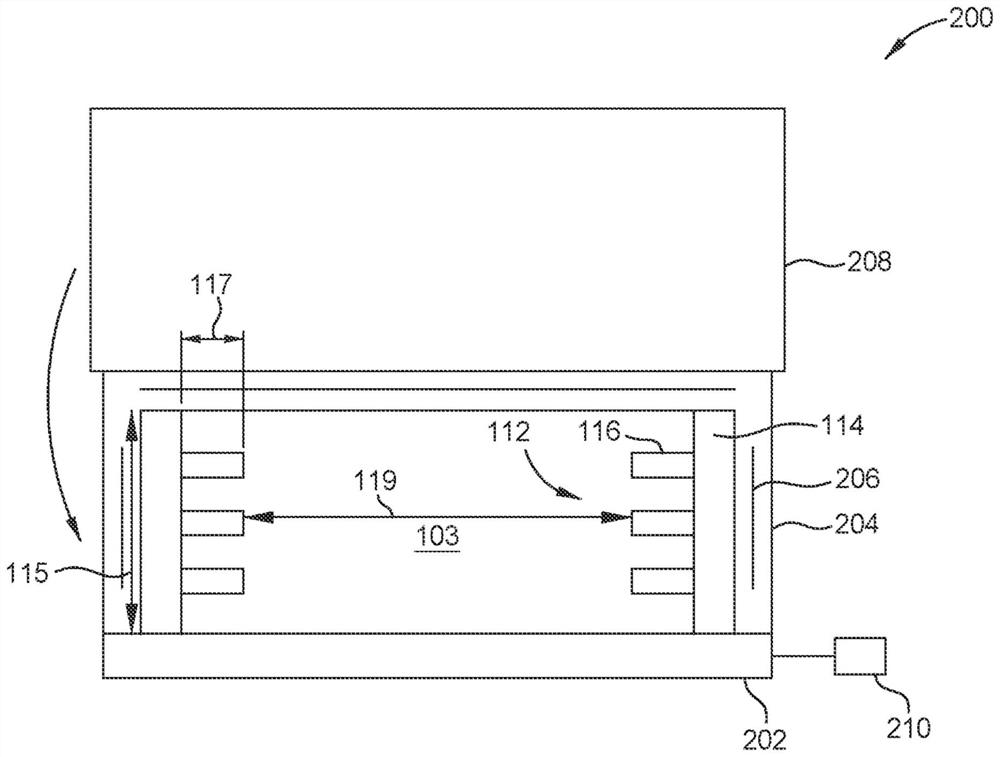

Baking device for processing and uniformly baking substrate

PendingCN114830313ASave processing spaceHeating evenlyCharge supportsSemiconductor/solid-state device manufacturingMechanical engineeringComposite material

Owner:APPLIED MATERIALS INC

Multi-section inflow sewage treatment equipment and treatment process thereof

ActiveCN114477582AClean up in timeSolve cleaning difficultiesWater aerationTreatment involving filtrationTurbine bladeWater flow

The invention relates to the technical field of advanced environmental protection industry, in particular to multi-section type inflow sewage treatment equipment and a treatment process thereof.The multi-section type inflow sewage treatment equipment comprises a treatment barrel, and an efficient cleaning assembly used for filtering sewage and rapidly removing filtered impurities is arranged on the inner wall of the treatment barrel; a collecting assembly for collecting impurities filtered out from the sewage is arranged on the outer wall of the treatment cylinder; the bottom end of the treatment cylinder is provided with a buffer assembly for slowing down the flow velocity of sewage; a sectional treatment assembly for further treating filtered sewage is arranged on one side of the buffer assembly; the efficient cleaning assembly comprises an upper seal head, an outer ring filter screen, an inner ring filter screen, a first motor, turbine blades, a driving wheel and a gear; the turbine fan blades drive water flow to rotate, filtered impurities are discharged through the output port through centrifugal force generated by the water flow, the impurities can be cleaned in time, the impurities are filtered out of sewage in the efficient cleaning assembly firstly, and the situation that after the sewage flows into the aeration tank, the impurities are precipitated at the bottom of the aeration tank, and cleaning is difficult is avoided.

Owner:江苏华太生态环保科技有限公司

Nitroglycerin-containing waste water neutralizing treatment process

InactiveCN102826643ASave processing spaceGood mixing effectWater/sewage treatment by neutralisationTreatment timeStatic mixer

The invention discloses a nitroglycerin-containing waste water neutralizing treatment process. Used equipment comprises a lye tank, a lye-charging regulating valve, a pump, a curved-path device, a miter tube, a static mixer, a neutralization tank and an on-line pH (potential of hydrogen) detector. The process includes the procedures that lye in the lye tank enters the miter tube by passing through the pump and the lye-charging regulating valve, and nitroglycerin-containing waste water flows into the curved-path device by the aid of position differences; the nitroglycerin-containing waste water passing through the curved-path device and the lye flow into the static mixer together via the miter tube, so that the acidic nitroglycerin-containing waste water is sufficiently mixed and reacted with the lye; and the reacted waste water flows into the neutralization tank for further reaction in the same, and the waste water meeting the requirements is discharged from the upper-middle portion of the neutralization tank. The static mixer can be arranged inside or outside the neutralization tank to be applicable to batch treatment and continuous treatment of the nitroglycerin-containing waste water respectively. The process has the advantages of low equipment investment cost, small required space, short treatment time, flexible usage mode, capability of sufficiently recovering nitroglycerin and the like.

Owner:XIAN MODERN CHEM RES INST

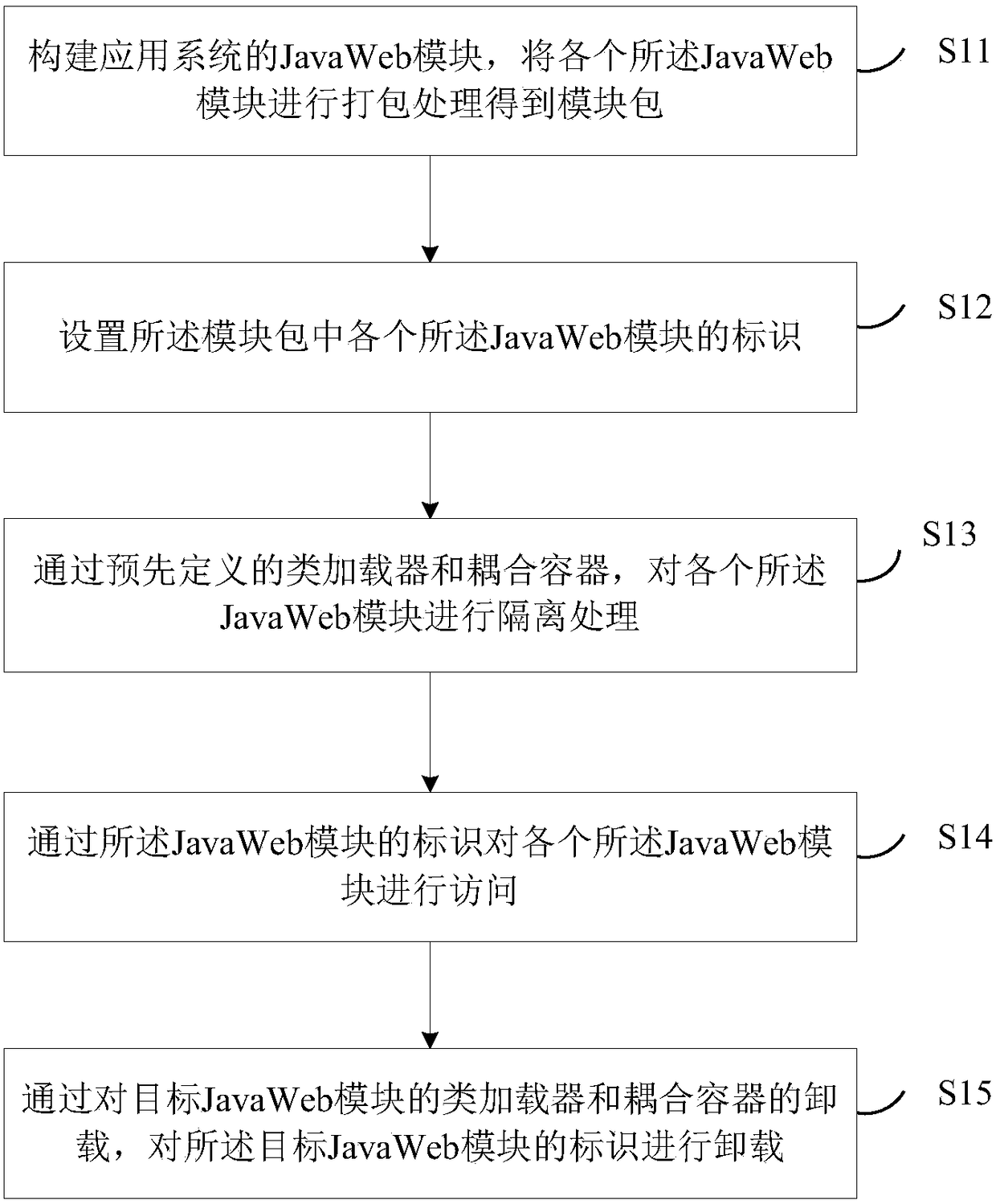

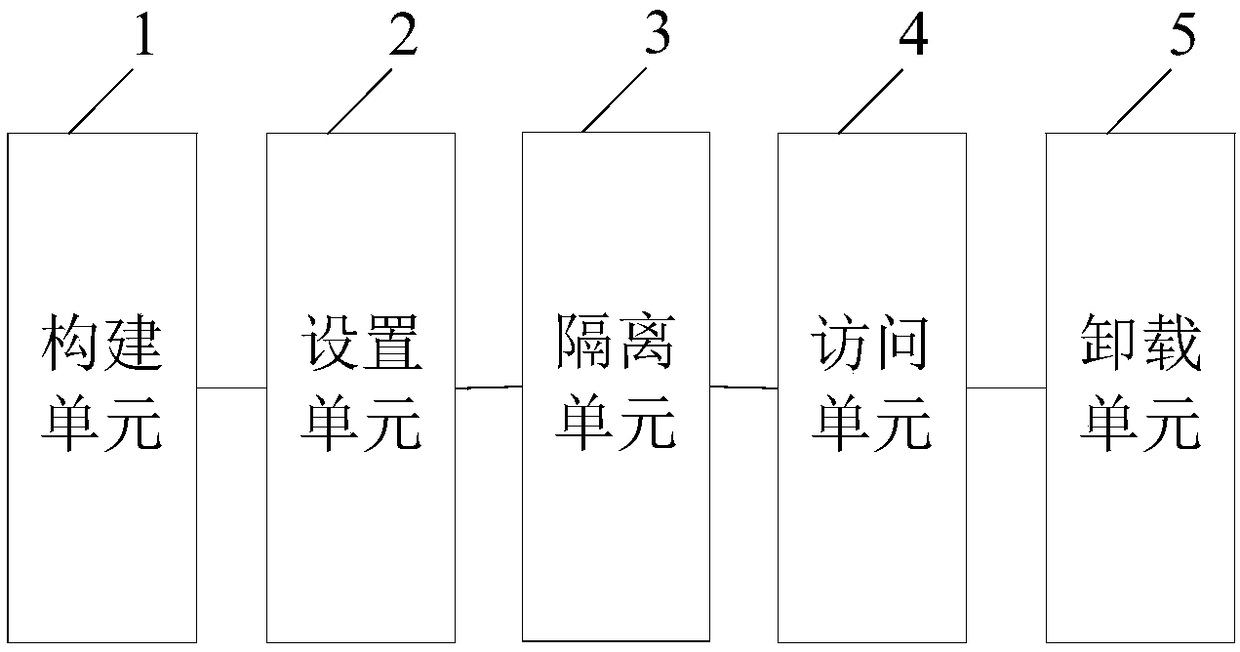

JavaWeb module management method and device

ActiveCN108319482ASave processing spaceEasy managementProgram loading/initiatingTransmissionEngineering

The invention discloses a JavaWeb module management method and device. The method comprises the steps of building JavaWeb modules of an application system and packaging all the JavaWeb modules to obtain a module package; setting identification of all the JavaWeb modules in the module package; through a predefined class loader and a coupling container, isolating all the JavaWeb modules; accessing all the JavaWeb modules through the identification of the JavaWeb modules; by uninstalling the class loader and the coupling container of a target JavaWeb module, uninstalling the identification of thetarget JavaWeb module. The JavaWeb modules are simply and efficiently managed.

Owner:BEIJING FOREVER TECH

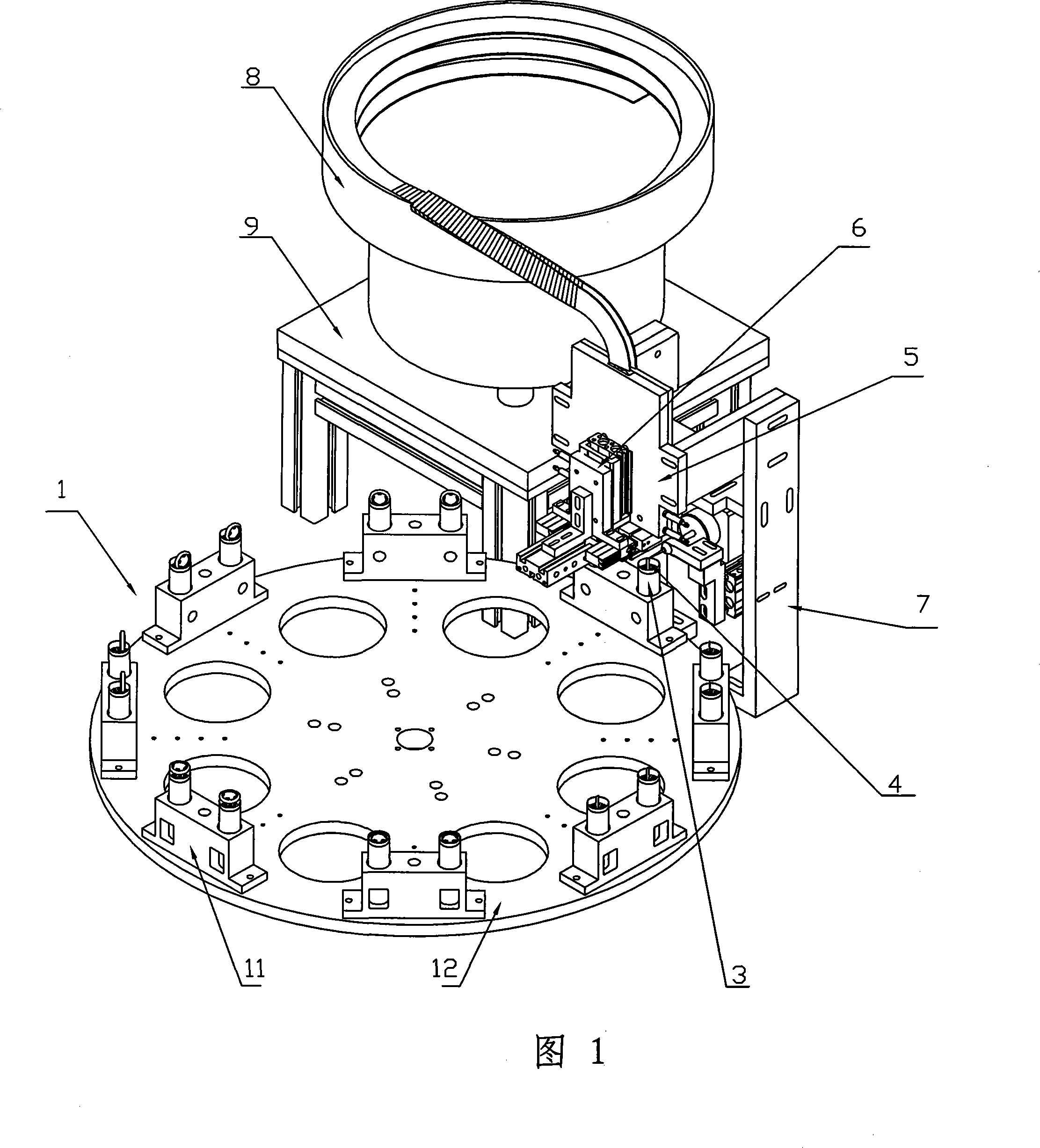

Spot welding device for battery cap and tab

ActiveCN101434008BSimple structureCompact structureWelding/soldering/cutting articlesMetal working apparatusControl systemEngineering

The invention relates to a cell cover and polar ear spot welding device, which comprises a cell feeding mechanism which can send cells to be processed into spot welding stations, a cover guiding mechanism which can lead in covers and automatically and progressively arrange the covers in order, a cover feeding mechanism which accommodates the covers sent by the cover guiding mechanism and sends the covers into the spot welding stations, a laser spot welding mechanism which welds the cell covers and cell polar ears sent into the welding stations, and a control system which can control the motion of various mechanisms, wherein the cover feeding mechanism and the cover guiding mechanism are in matched connection and arranged above the cell feeding mechanism, so that the covers contact upper polar ears of the cells; the laser spot welding mechanism is positioned aside the cell feeding mechanism; and a laser emitting center of the laser spot welding mechanism is in the same line with the contact points of the covers and the upper polar ears of the cells. The invention provides a laser spot welding processing apparatus which can automatically send the cylindrical cells and the covers into the welding stations and perform spot welding connection on the upper polar ears of the cells and the covers.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

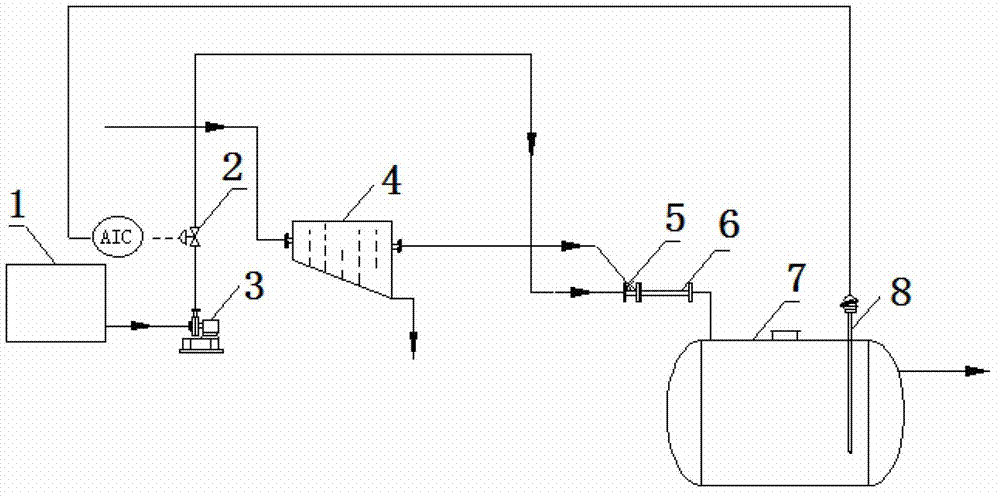

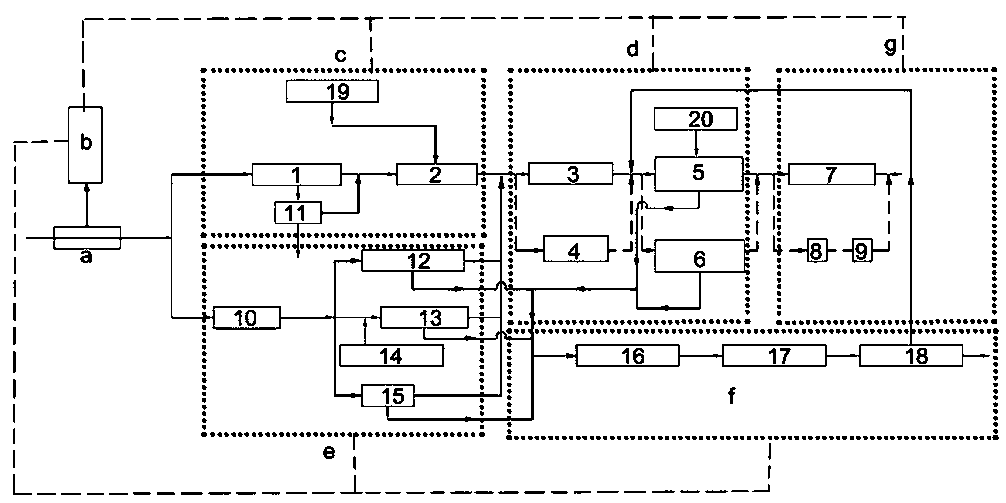

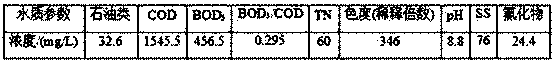

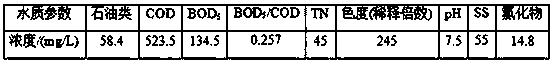

An integrated process system and method for petrochemical industrial wastewater treatment

ActiveCN106830562BSave processing spaceConducive to mutual transformationWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSludgeControl signal

The invention provides a petroleum chemical industrial wastewater treatment integrated process system and method. The system comprises an on-line monitoring and analyzing system, an intelligent feedback control system and a wastewater treatment system, wherein the on-line monitoring and analyzing system is used for monitoring and analyzing the composition of water quality of petroleum chemical industrial wastewater and the composition of water quality of effluent at all treatment links and transferring monitoring and analyzing data to the intelligent feedback control system; the intelligent feedback control system is used for outputting a control signal to the wastewater treatment system after the monitoring and analyzing data are processed; the wastewater treatment system comprises a pre-treatment module, an oil removal module, a biochemistry module, a sludge treatment module and a depth treatment module; the pre-treatment module, the oil removal module, the biochemistry module, the sludge treatment module and the depth treatment module are used for treating the petroleum chemical industrial wastewater according to an instruction of the control signal output by the intelligent feedback control system. According to the method, treated water with stable and qualified indexes of SS, COD, chromaticity and the like is obtained by seven steps.

Owner:海南博士通环境工程有限公司

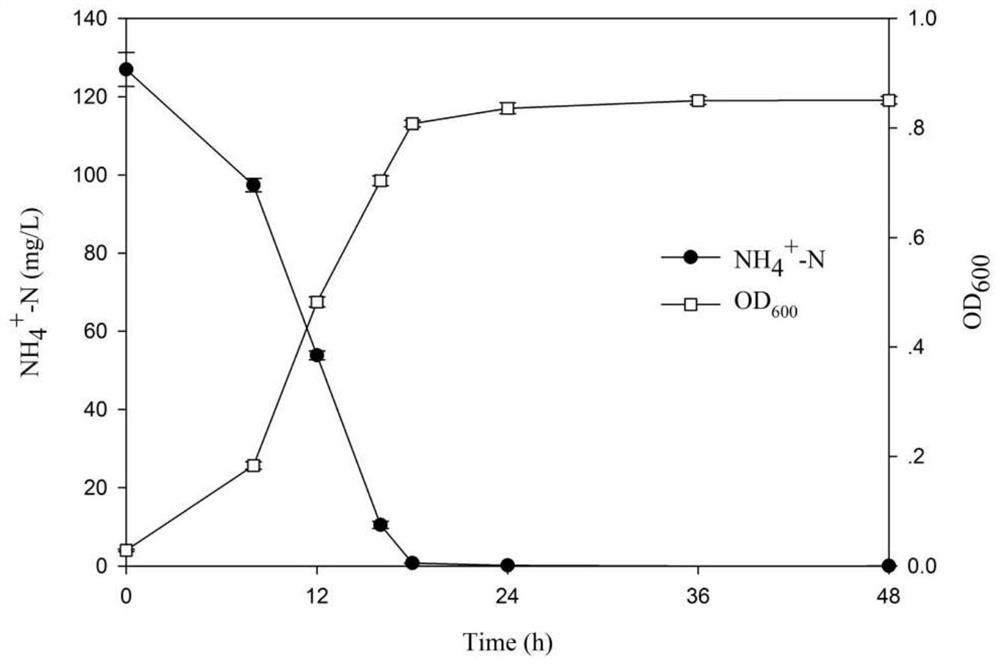

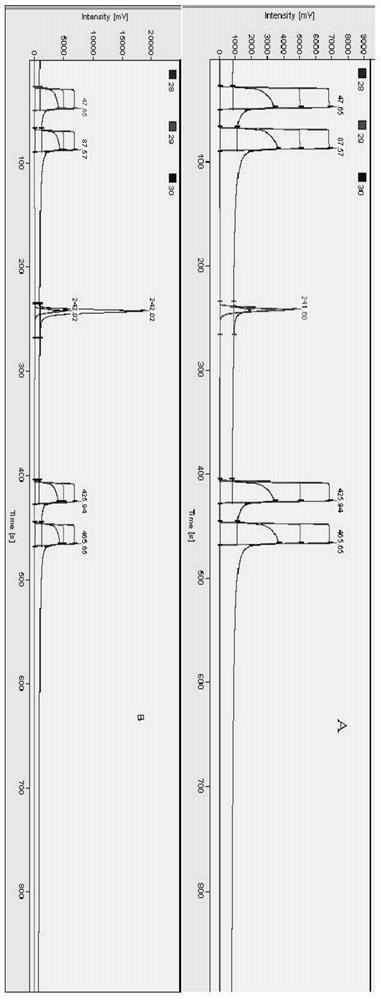

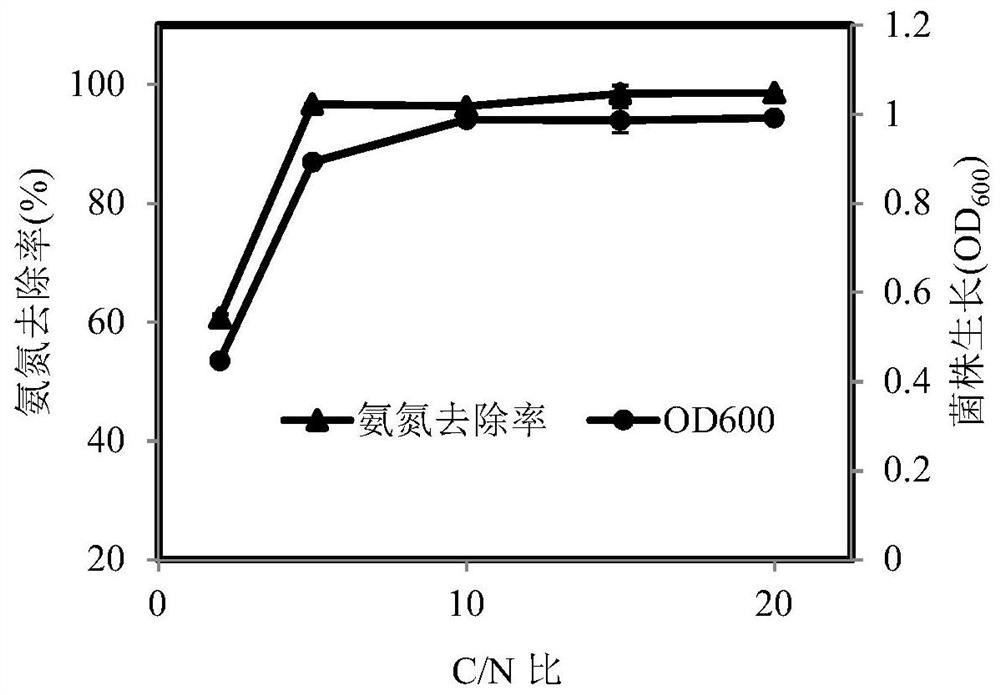

A Alcaligenes strain ho-1 and its application

ActiveCN111218410BEfficient removal abilityEfficient removalBacteriaTreatment using aerobic processesBiotechnologyPig farms

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Substrate processing equipment

ActiveCN105793959BSymmetrical even distributionEasy to cleanSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

The present invention relates to a substrate processing apparatus comprising: a chamber allowing a substrate to enter and exit on one side of the chamber and having a first space in the chamber; an inner chamber arranged inside the chamber in the first space of the internal chamber, and has a second space in the internal chamber; a substrate support arranged inside the internal chamber, the substrate support for supporting the substrate; and a gas injector for the Spraying gas on a substrate support, wherein the inner chamber comprises: a first body fixed on an upper portion of the interior of the chamber; a second body arranged below the first body, the second body being vertically movable and There is an exhaust hole in a central portion of the bottom surface of the second body; and an exhaust body connected to the exhaust hole and having an exhaust path inside the exhaust body. The technical scheme of the invention can manufacture a thin film with uniform thickness on the substrate. It is possible to have properties almost equal to or similar to each other, and the quality of the film can be improved.

Owner:CHARM ENG CO LTD

Production and installation method for outdoor multi-specialty prefabricated pressure pipeline groups

InactiveCN111457157ASave processing spaceAvoid damagePipe supportsPipe laying and repairVirtualizationSoftware

The invention discloses a production and installation method for outdoor multi-specialty prefabricated pressure pipeline groups. The production and installation method comprises the specific followingsteps that the professional drawings of outdoor multi-specialty pipelines are integrated through revit software modeling, and a virtualization model is obtained; a pressure pipeline network in an area is divided into module groups by revit software according to pipeline lengths; the information of the prefabricated pressure pipeline groups is derived through the revit software; and a factory produces the multi-specialty pipelines according to the information, pipeline assembly is carried out in the factory after pipeline production is completed, the multi-specialty pipelines are uniformly placed side by side, square steel is placed in the perpendicular direction of the multi-specialty pipelines, the multi-specialty pipelines are fixed sequentially through round steel U-shaped steel bars,each specialty pipeline is fixed by adopting a connecting mode of the square steel and the round steel U-shaped steel bars at an interval of 1.5m, and each pipeline length is taken as one prefabricated pressure pipeline group. According to the production and installation method, data refinement transmit is realized, the damage to finished products caused by repeated excavation is avoided, the construction period is shortened, the construction difficulty is reduced, and the construction cost is saved.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com