Baking device for processing and uniformly baking substrate

A substrate, uniform technology, applied in the direction of electric heating devices, furnaces, furnace heating elements, etc., can solve the problems of uneven temperature, not being maintained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present disclosure generally relate to bake apparatus and methods for handling and uniformly baking substrates. These bake apparatuses allow the substrate to be heated to temperatures greater than 50°C without a bend of about 1 mm to about 2 mm from the edge of the substrate to the center of the substrate. These bake apparatuses heat the substrate uniformly or substantially uniformly to improve the quality of the substrate.

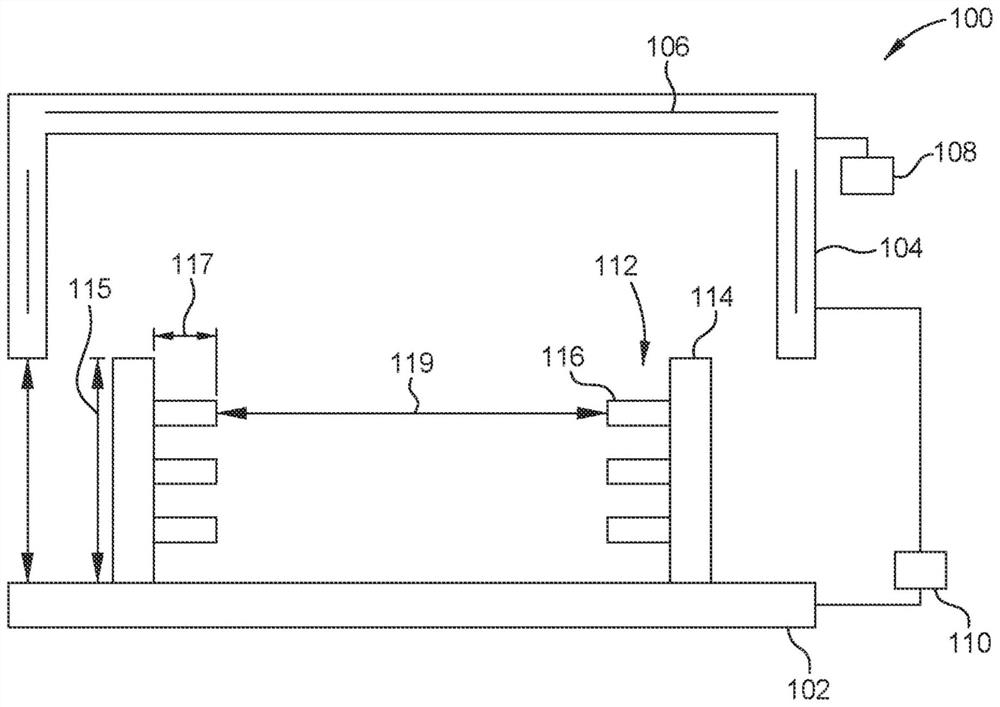

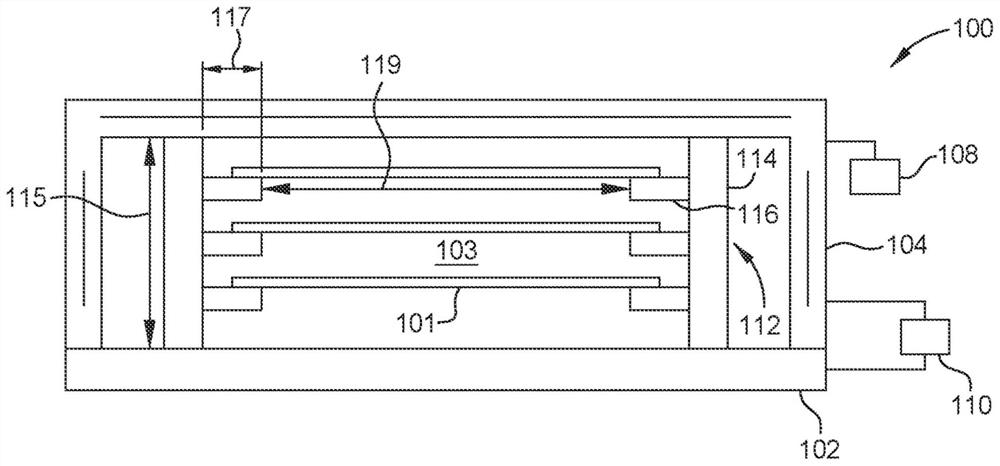

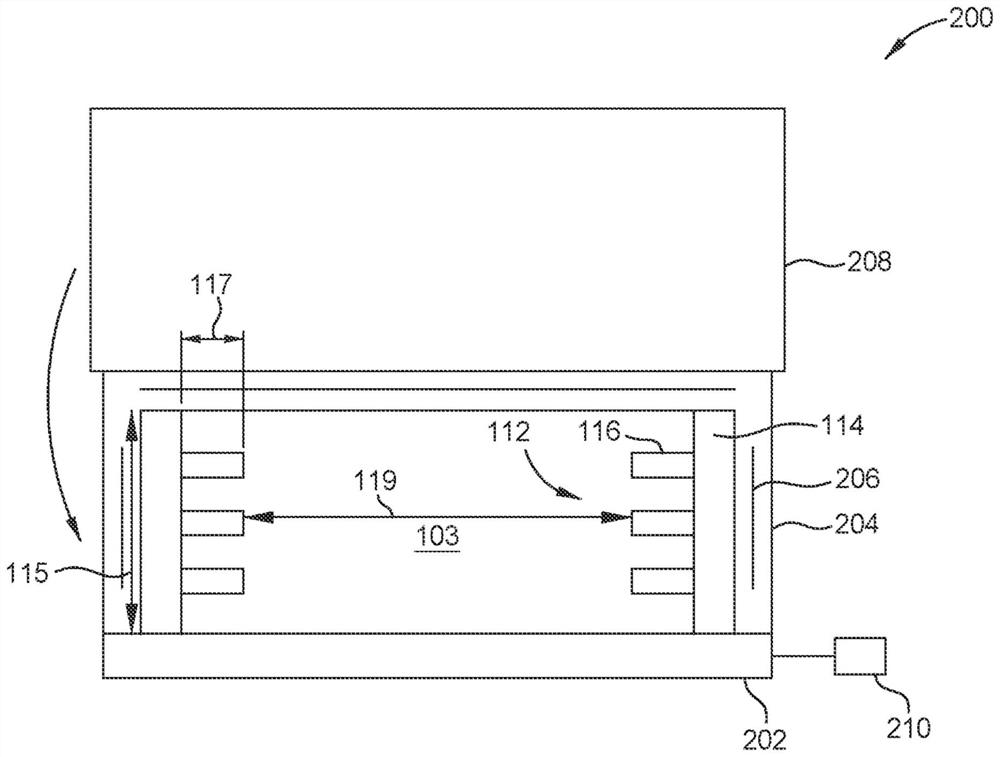

[0021] Figure 1A and 1B is a schematic cross-sectional view of the baking apparatus 100 . Baking apparatus 100 includes base 102 , lid 104 and substrate hold assembly 112 . The substrate support assembly 112 includes two or more shafts 114 having one or more extensions 116 coupled to the two or more shafts 114 . The shafts 114 each have a shaft height 115 . In one embodiment, which may be combined with other embodiments described herein, the shaft height is between about 0.5 inches and about 5 inches.

[0022] The one or m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com