Spot welding device for battery cap and tab

A technology of spot welding device and cap, which is applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., which can solve the problems that the product qualification rate is difficult to reach the ideal standard, difficult product quality consistency, large human resources, etc. , to achieve the effects of simplified processing equipment, simple overall structure and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions and beneficial effects of the present invention will be apparent through the detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings.

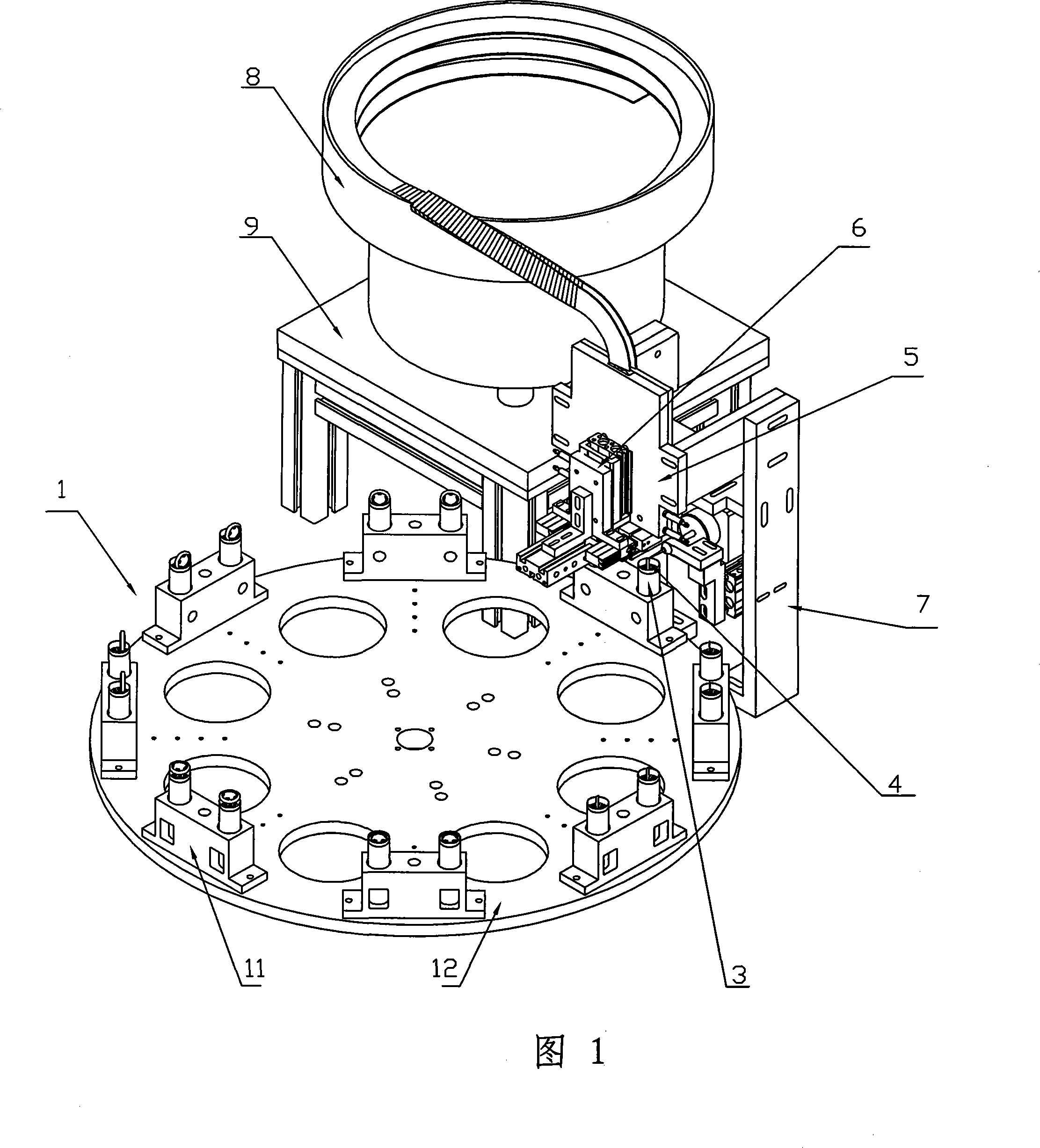

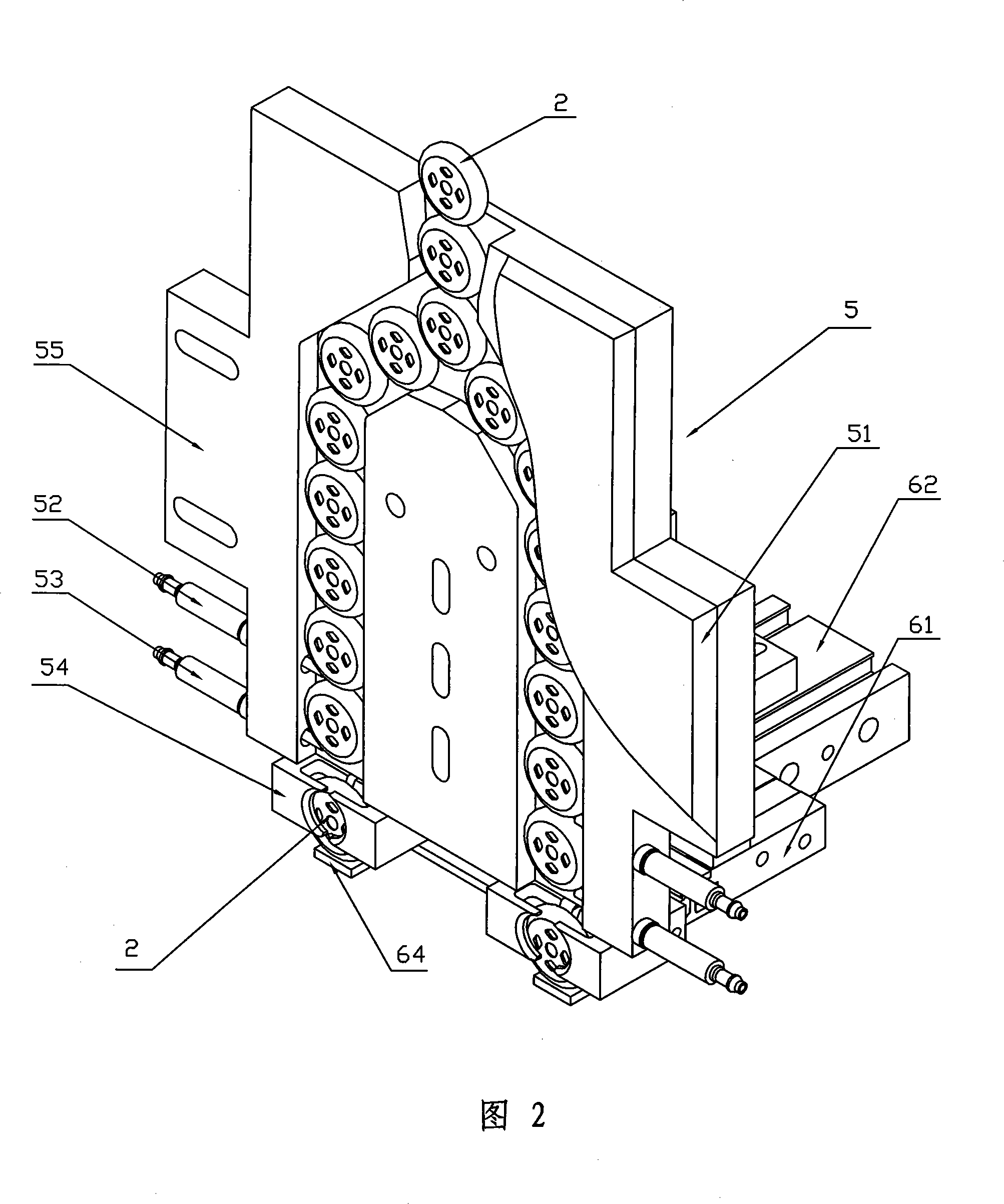

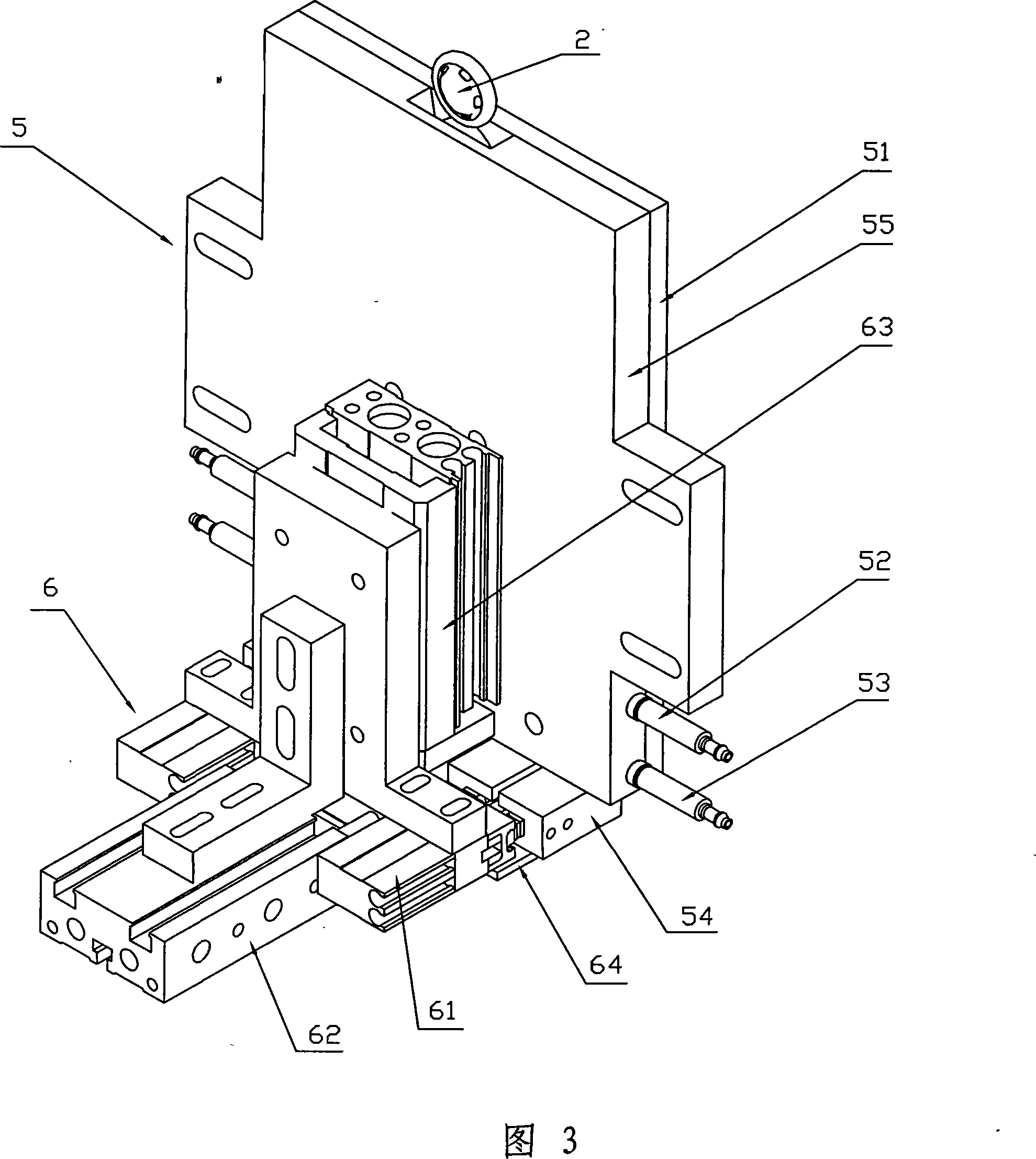

[0048] Such as figure 1 As shown, the present invention includes a battery feed mechanism 1, a cap material guide mechanism 5, a cap feed mechanism 6, a laser spot welding mechanism 7 and a control system (not shown) that controls the actions of the above-mentioned mechanisms. The battery feed mechanism 1 It is used to send the battery 3 to be processed into the spot welding welding station. The cap feeding mechanism 5 can introduce the caps 2 transported thereon and automatically arrange and advance them in sequence. The cap feeding mechanism 6 and the cap guiding mechanism The feeding mechanism 5 is matched and connected, and placed above the battery feeding mechanism 1, it can accept the cap 2 sent by the cap material guide mechanism 5, and send ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com