Nitroglycerin-containing waste water neutralizing treatment process

A technology of nitroglycerin and treatment process, applied in the field of explosives, can solve the problems of long treatment time, large equipment investment and treatment space, etc., and achieves the effects of good mixing effect, flexible use mode and reduced treatment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

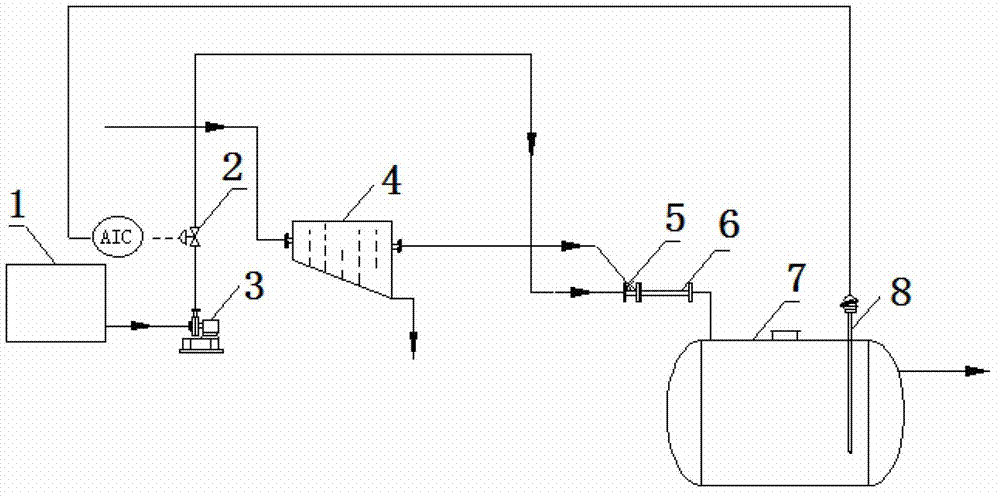

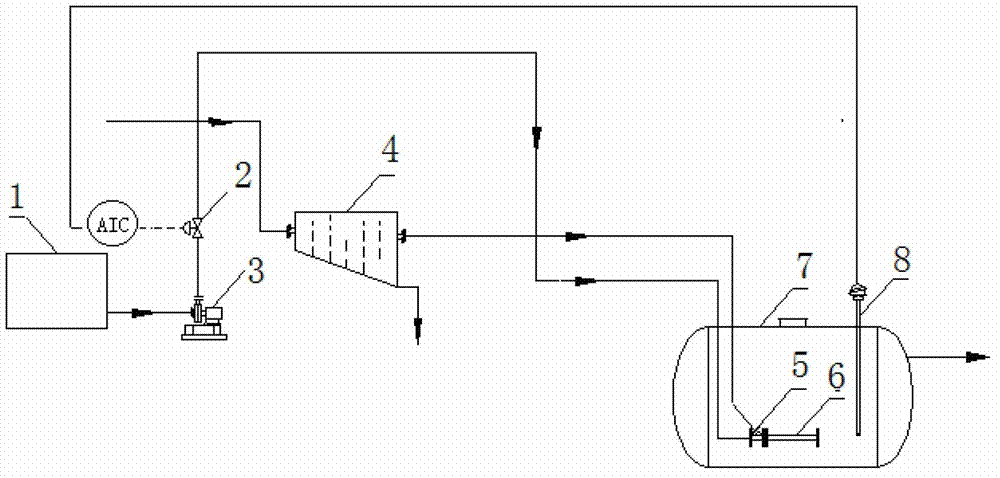

Image

Examples

Embodiment

[0027] Implementation example: The applicant uses the nitroglycerin-containing wastewater neutralization treatment process of the above-mentioned static mixer external type to continuously process nitroglycerin-containing wastewater. The height of the wastewater outlet of the bender 4 from the static mixer 6 is 500mm, and the wastewater discharge standard is pH The value is equal to 8.5. The nitroglycerin-containing wastewater with a volume flow rate of 4m3 / h first flows into the bender 4, and due to the effect of the baffle in the bender 4, the flow rate of the nitroglycerin-containing wastewater is relatively slow, so that most of the free state nitrification in the wastewater Glycerin settles to the bottom of the bender. Afterwards, the waste water containing nitroglycerin flows into the mitered pipe 5 through a height difference of 500 mm, and flows into the static mixer 6 together with the lye injected by the pump 3 through the mitered pipe 5 . Under the action of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com