Energy-saving type grain microwave insect preventing and mould-proof method and special equipment

A kind of anti-mildew technology for grains, which is applied in the direction of trapping or killing insects, application, preservation of seeds through radiation/electrical treatment, etc., can solve the problems of tarnish and beauty, high cooling speed, surface cracks, etc. The effect of enhanced thermal effect, improved heat transfer efficiency, and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 (Examples of basic test methods and equipment):

[0041] 1. Test materials and equipment

[0042] The grains used in the experiment were paddy and rice produced in China (variety Jinyou 207, provided by Hunan Jinjian Rice Co., Ltd.). Common storage insects are rice elephants, saw-valley pirates, and red pseudo-valley pirates, gifted by Henan University of Technology. The analytical testing instrument is a near-infrared grain quality analyzer (Perten 9100 / 01, produced in Germany).

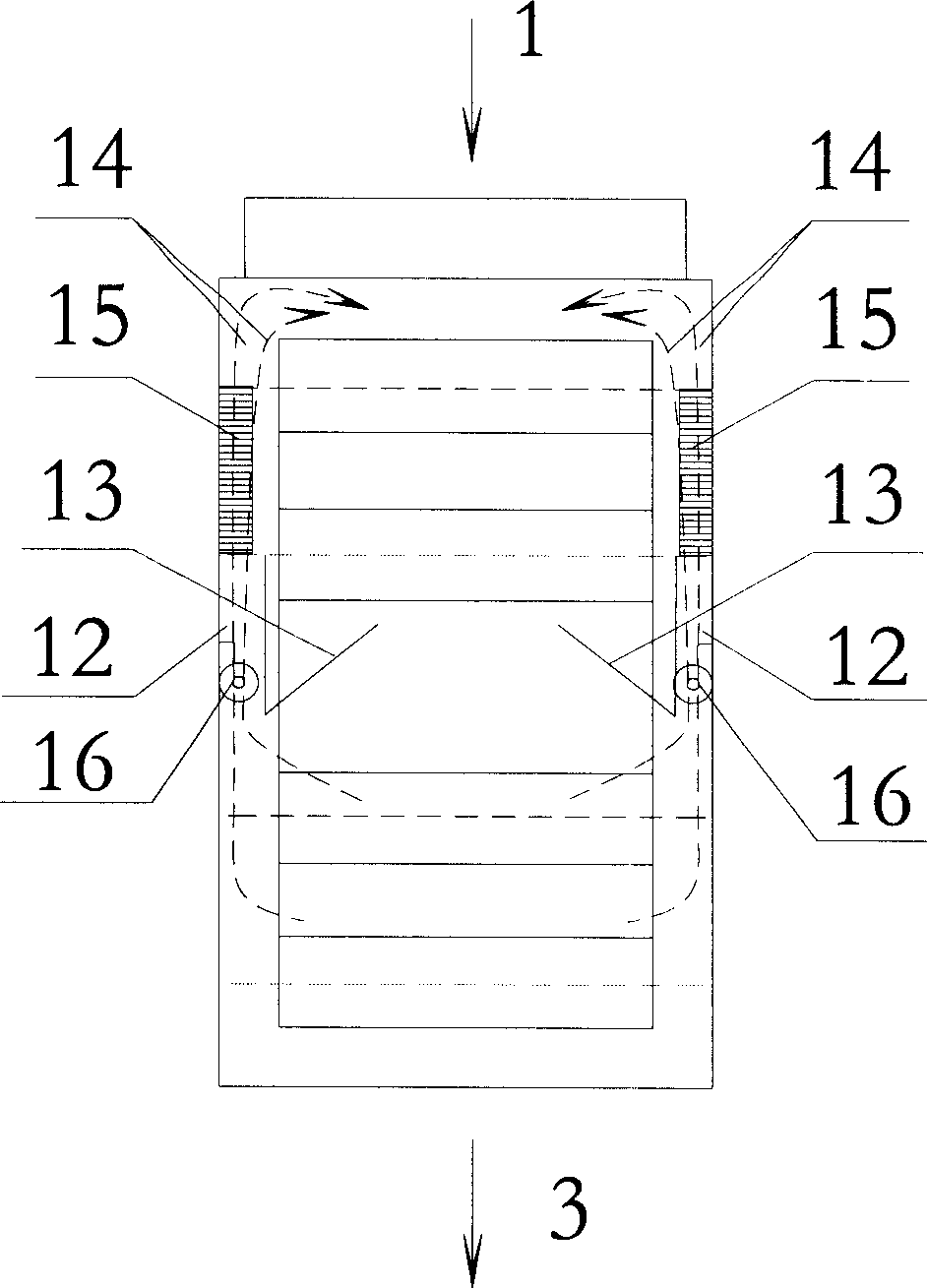

[0043] The microwave oven of the present invention adopts industrial microwave oven, model: QW-15HM, 2450MHz, output power 24KW, produced by Guangzhou Kewei Microwave Energy Co., Ltd. The effective size (the accumulation volume of rice in the microwave oven) is 4680mm×600mm×60mm (length×width×height).

[0044] 2. Test method:

[0045] (1) Sample preparation

[0046] 1) Put 20 live and robust test insects (Rice Elephant, Sawgrass Pirate, Red Grain Pirate) into 200g rice samples (which ha...

Embodiment 2

[0072] Example 2 (Examples of special equipment and process parameters of the present invention):

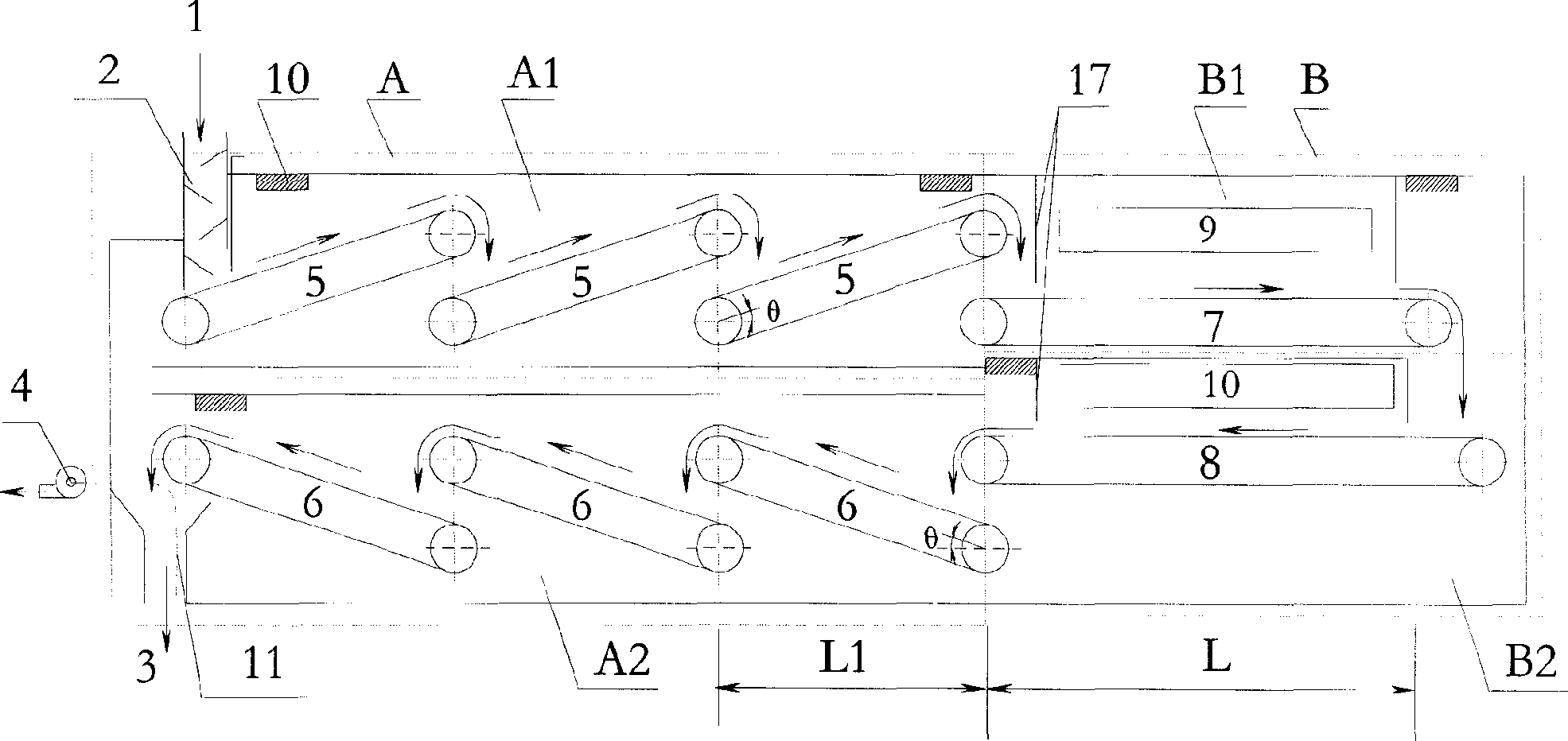

[0073] By the attachment figure 1 , 2 As shown, the processing equipment of the present invention includes processing units A and B, wherein the belt conveyors (5) and (6) in the processing unit A have a projection length L1=2m, and an actual length of 2.263m. The belt width is 600mm, the number is 3, and the inclination angle θ=20°. The speed of belt conveyors 5 and 6 is 399 rpm, and the residence time of rice in A1 and A2 is 8 min respectively.

[0074] The belt conveyor (7) in the processing unit B has a length L=3m and a width of 600mm; the belt conveyor (8) has a length of 3.3 meters and a width of 600mm. The speed of the belt conveyors (7) and (8) is 375 rpm. The total time of microwave treatment (B1 and B2) is 5 min. The microwave output power is 13.125kw;

[0075] The total length of the microwave device is 9.8m, the total width is 0.7m, and the total height is 3m.

[0076] ...

Embodiment 3

[0083] Embodiment 3 (example of the effect of the invention):

[0084] In order to obtain the best implementation of the present invention, the applicant designed a series of 1#-17# tests. After reagent tests and tests, the main technical parameters are as follows:

[0085] Microwave output power: P=13.125kw;

[0086] The rice flow rate is 820kg / h; the irradiation mass is 85.3kg (rice) and 71.6kg (rice);

[0087] The specific heat of rice is 1.96kJ / kg·℃; the heat loss is 5%; the microwave dose (power) is 0.15kw / kg;

[0088] The initial temperature of rice is 38℃; the thickness of the material is 50±2mm; the width of the material is 500±2mm;

[0089] The total length L used for the irradiation treatment in the experimental microwave oven is 7.2m; when the speeds of the belt conveyors (7) and (8) are 300, 375, and 400 rpm, the corresponding microwave treatment time is 4, 5, and 6 min, respectively.

[0090] Table 1 shows the preheated air temperature 45℃-50℃, time 8-12min, make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com