Kettle-tower integrated waste oil regeneration device

A technology of waste oil regeneration and kettle tower integration, which is applied in the petroleum industry, hydrocarbon oil treatment, and only multi-stage serial refining process treatment, etc., which can solve the problem of high energy loss in the kettle tower, low energy efficiency utilization rate, and large floor area and other problems, to achieve the effect of reducing pipeline connections, improving energy efficiency and reducing pipe clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

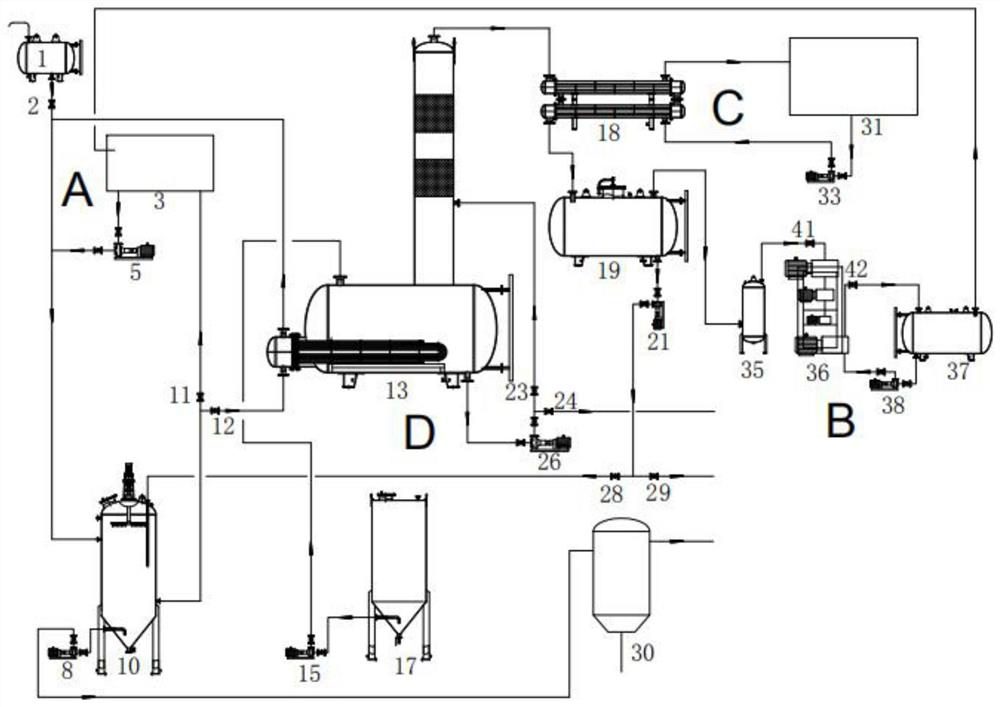

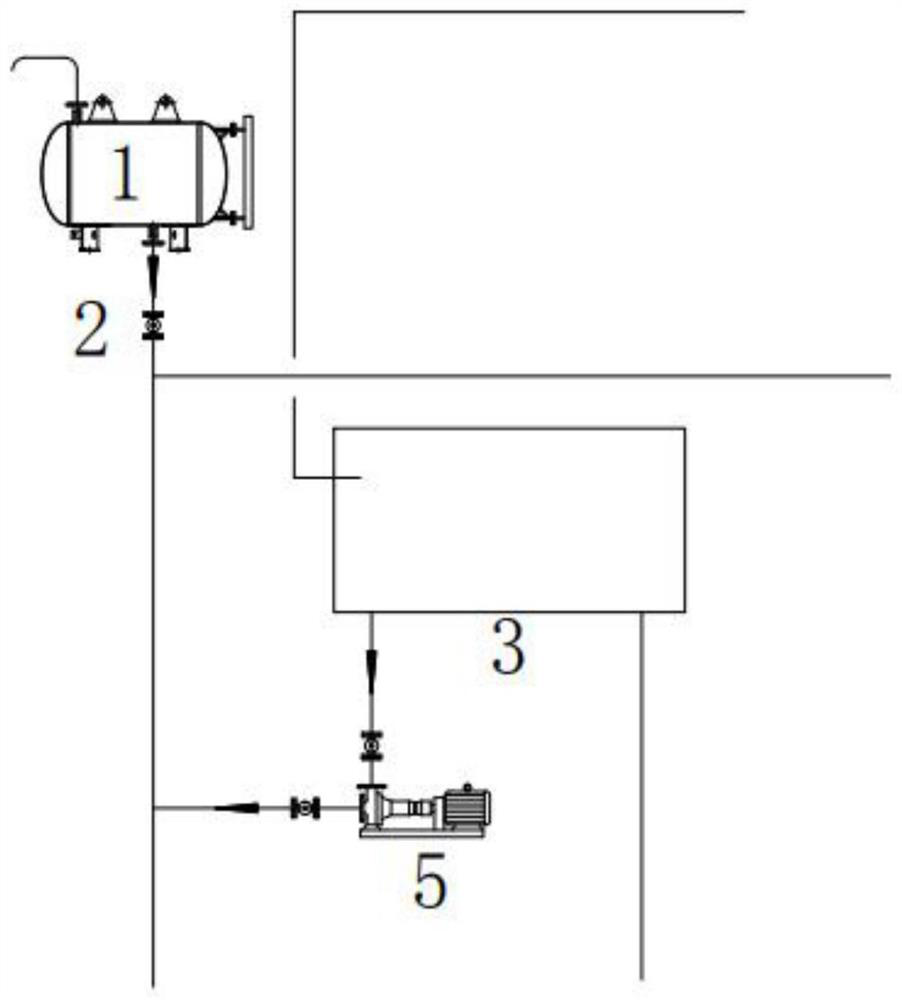

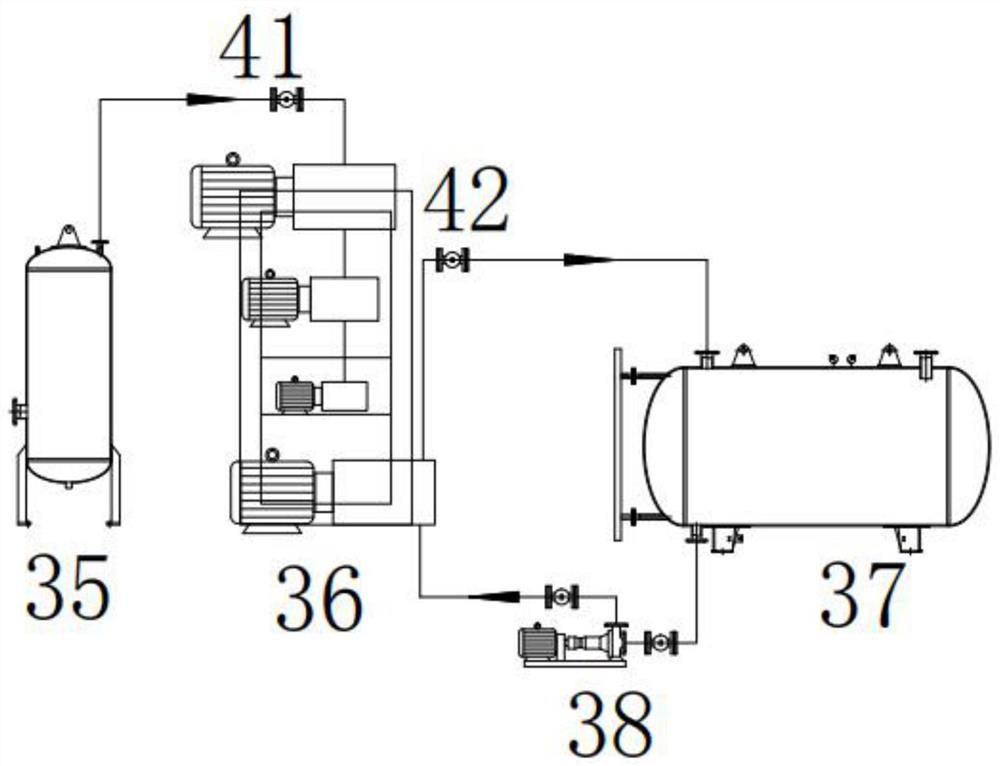

[0019] combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , still-tower integrated waste oil regeneration device, comprising a raw material tank 17, the lower end of the raw material tank 17 is connected with a feed pump 15 through a pipeline, and the other end of the feed pump 15 is connected with a still tower 13 through a pipeline, Above the kettle tower 13, a condenser 18 is communicated with a pipeline, and a buffer tank 19 is communicated with a buffer tank 19 below the condenser 18, and an output pump 21 is communicated with a pipeline below the buffer tank 19. A semi-refined oil valve 29 is provided on the pipeline connected to the other end of the pump 21, and a refining valve 28 is provided on the side of the pipeline communicating between the output pump 21 and the semi-refined oil valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com