Multiple water stop belt, waterproof structure and construction method of waterproof structure

A technology of waterproof structure and construction method, which is applied in the field of waterproof structure and its construction, and waterproof products. It can solve the problems of upward water seepage of waterstop and concrete shrinkage failure, etc., and achieve the effect of improving waterstop function, simple construction, and ensuring waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

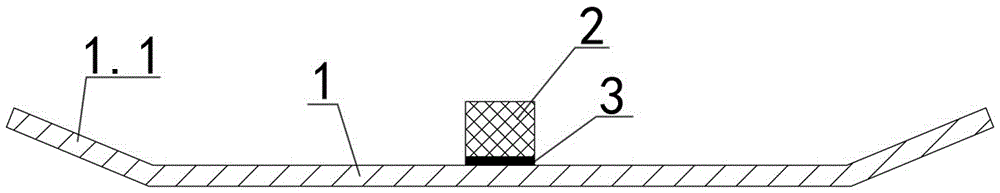

[0053] Embodiment one sees figure 1 As shown, a multiple waterstop, including a metal waterstop 1 and a waterstop strip 2 fixedly connected on the surface of the metal waterstop 1, the waterstop 2 passes along the length direction of the metal waterstop 1 Long setting, the water stop strip 2 is located on the upper side of the metal water stop plate 1 .

[0054] The shape of the metal water stop plate is straight and provided with an upward partial bending 1.1. The local bends 1.1 are located at both ends of the metal water stop plate. The water-stop strip 1 is fixed to the surface of the metal water-stop plate 1 by an adhesive 3 .

[0055]The metal water-stop plate is a steel plate, and in other embodiments may be an aluminum plate, with a thickness greater than 0.2mm.

[0056] The water stop strip is rubber, and in other embodiments, it can be plastic, wood or putty. If the water-stop strip is made of rubber, the surface of the water-stop strip and the metal water-stop p...

Embodiment 2

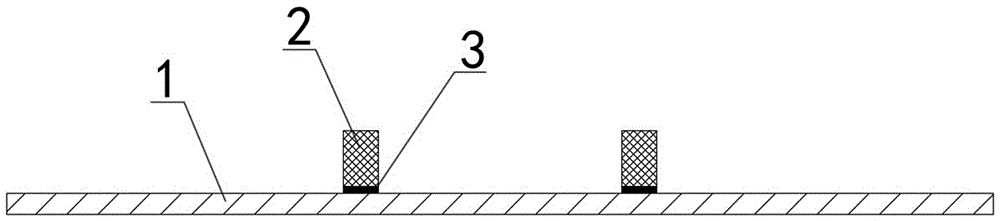

[0057] Embodiment two see figure 2 As shown, a multiple waterstop, including a metal waterstop 1 and two waterstop strips 2 fixedly connected on the surface of the metal waterstop 1, the waterstop 2 is along the length direction of the metal waterstop 1 The overall length is arranged at intervals along the width direction of the metal waterstop 1. The waterstop 2 includes a concrete waterstop 2.1 poured first and a concrete waterstop 2.2 poured later. The poured concrete water stop strips 2.2 are all located on the upper side of the metal water stop plate 1.

[0058] The shape of the metal water-stop plate is straight, and the water-stop strip 1 is fixed to the surface of the metal water-stop plate 1 by an adhesive 3 .

Embodiment 3

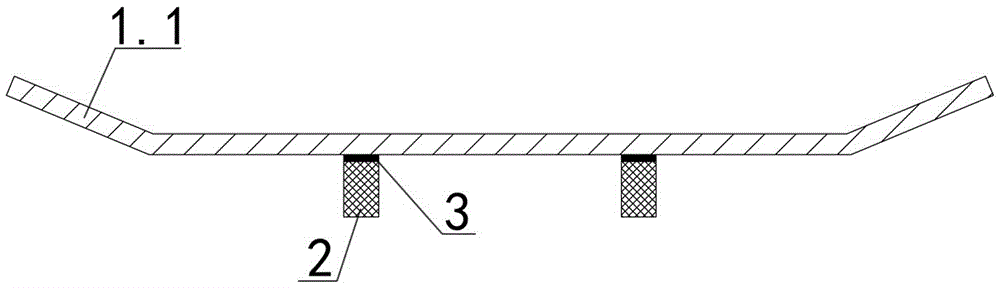

[0059] Embodiment three see image 3 As shown, a multiple waterstop, including a metal waterstop 1 and two waterstop strips 2 fixedly connected on the surface of the metal waterstop 1, the waterstop 2 is along the length direction of the metal waterstop 1 The overall length is arranged at intervals along the width direction of the metal waterstop 1. The waterstop 2 includes a concrete waterstop 2.1 poured first and a concrete waterstop 2.2 poured later. The poured concrete water stop strips 2.2 are all located on the lower side of the metal water stop plate 1 .

[0060] The shape of the metal water stop plate is straight and provided with an upward partial bending 1.1. The local bends 1.1 are located at both ends of the metal water stop plate. The water-stop strip 1 is fixed to the surface of the metal water-stop plate 1 by an adhesive 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com