Construction method for pit-in-pit profile steel interior support of super high-rise building

A layered pit and super-elevation technology, applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of super-high-rise pit-in-pit construction period, tight foundation pit safety and stability, etc., to solve the inconvenience of installation and recycling, and ensure The effect of closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

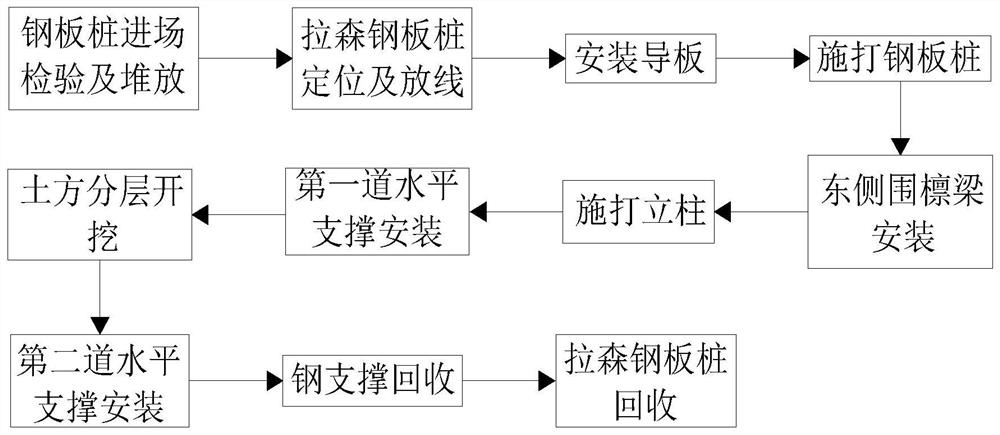

[0025] The invention provides a technical solution: a super-high-rise pit-in-pit-shaped steel internal support construction method, which includes the following steps:

[0026] S1. Carry out site inspection and stacking of the steel sheet piles used: for Larsen steel sheet piles, there are generally material inspections and appearance inspections, so as to correct the unqualified sheet piles and reduce difficulties in the piling process. Appearance inspection: including surface defects, length, width, thickness, height, end square ratio, straightness and lock shape; when stacking, attention should be paid to the order, position, direction and layout of the stack, etc., which should be considered in the future The construction is convenient. The sheet piles shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com