Two-way pneumatic control valve

A technology of pneumatically controlling valves and valve stems, which is applied in the direction of lifting valves, valve details, valve devices, etc., which can solve the problems of easy backflow of liquids, lax functions, and loss of control, etc., so as to improve reliability, prevent springs from sticking, and improve The effect of job reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

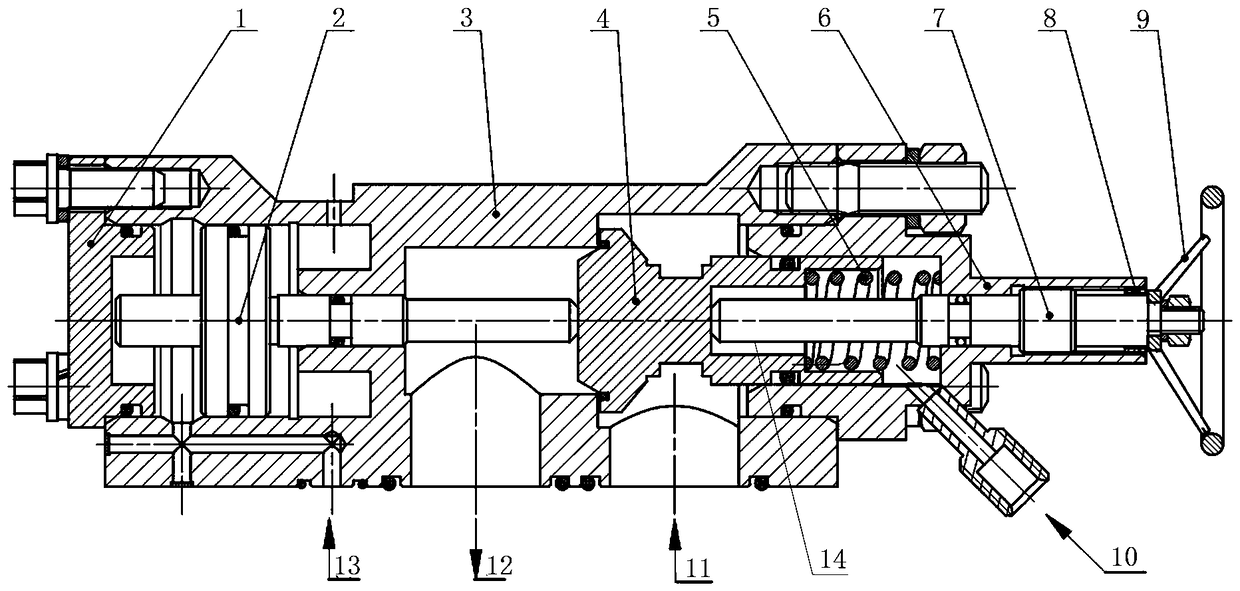

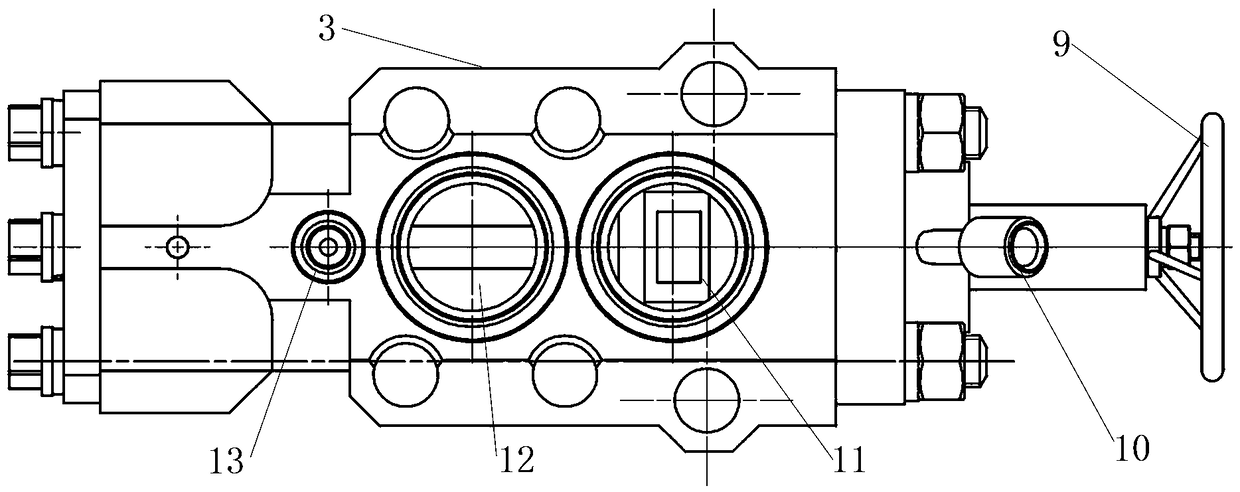

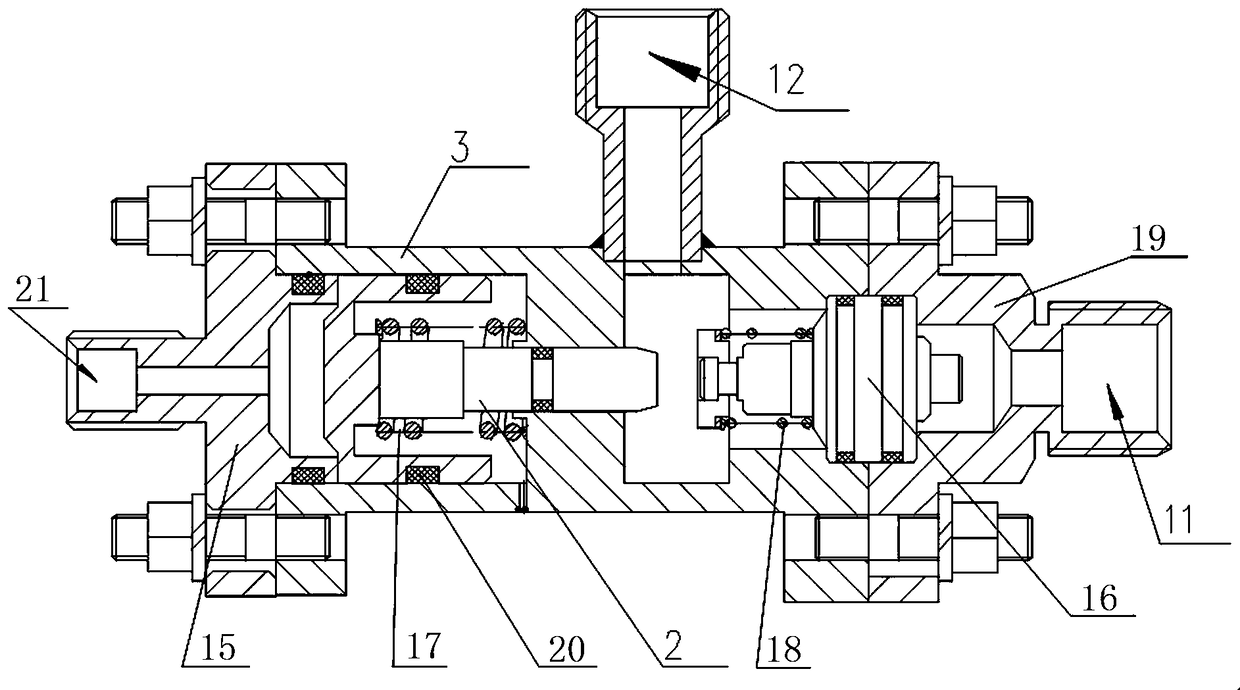

[0022] A two-way pneumatic control valve, comprising a housing 3 with a liquid inlet 11 and a liquid outlet 12, a plunger 2 arranged in the housing 3, and a valve core 4 matched with the plunger 2 for opening and closing the liquid inlet 11; The front end of the spool 4 is used to open and close the liquid inlet 11. A cavity is formed between the end of the spool 4 and the housing 3. The housing 3 has a first control air inlet 10 connected to the valve. The cavity formed by the end of the core 4 and the housing 3; the end of the valve core 4 is provided with a valve rod 14, the front end of the valve rod 14 is opposite to the end of the valve core 4, and the end of the valve rod 14 slides on the housing 3, The valve stem 14 is sheathed with a return spring 5 which is in contact with the end of the valve core 4 ; the housing 3 is also provided with a second control air inlet 13 for inputting external air to control the movement of the plunger 2 .

[0023] A locking pin 7 whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com