Pipe jacking tunnel inlet stop water device

A technology for water-stopping and tunneling at the entrance, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of unsatisfactory water-stopping effect, limited use and failure, etc. The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

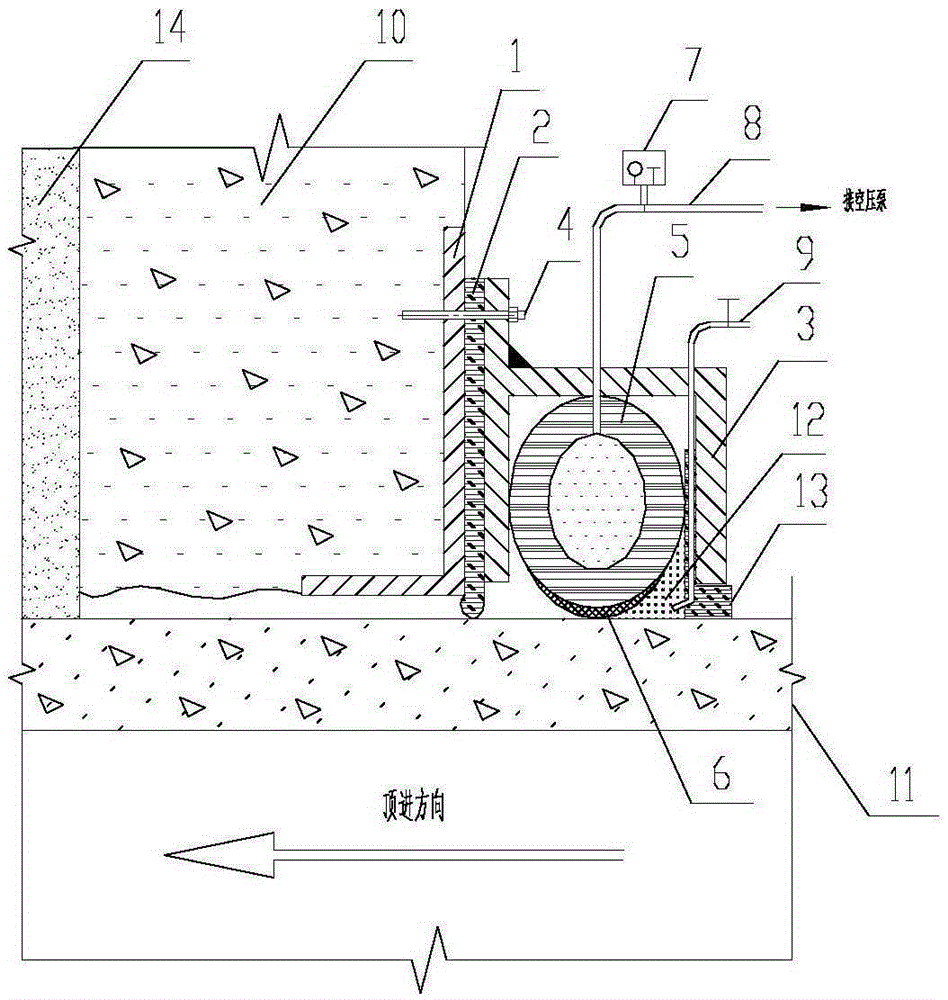

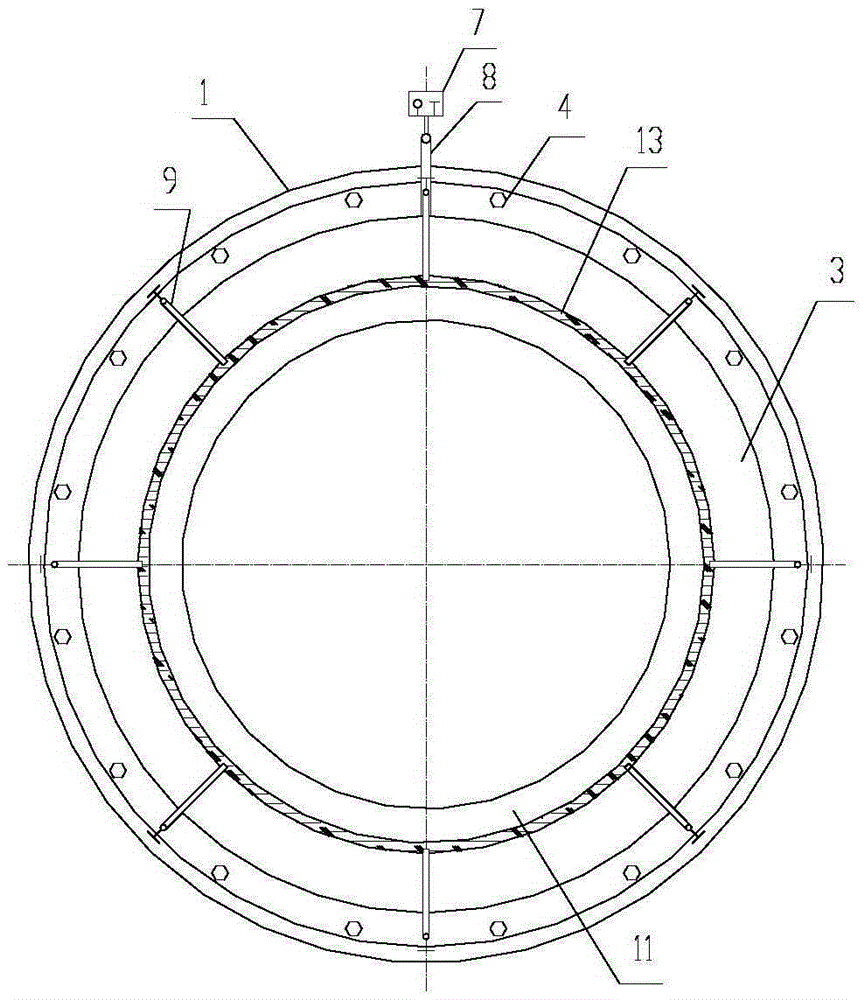

[0028] as attached figure 1 And attached figure 2 As shown, a water stop device at the entrance of a pipe jacking tunnel includes an inflatable rubber water stop ring installation groove 3 fixedly arranged on the shaft wall 10 of the pipe jacking tunnel entrance, and an installation groove 3 of the inflatable rubber water stop ring The flexible inflatable rubber water-stop ring 5 inside, the air guide tube 8 connecting the inflatable rubber water-stop ring 5 and the ground air compressor is also arranged on the installation groove 3 of the inflatable rubber water-stop ring, and the pipe joint 11 of this embodiment The cross-section is circular, the outer diameter is 2980mm, and the hole diameter is 3020mm. The shape of the inflatable rubber water-stop ring installation groove 3 and the inflatable rubber water-stop ring 5 matches the cross-sectional shape of the pipe joint 11, which is circular .

[0029] The hole is equipped with a pre-embedded installation flange 1, a curt...

Embodiment 2

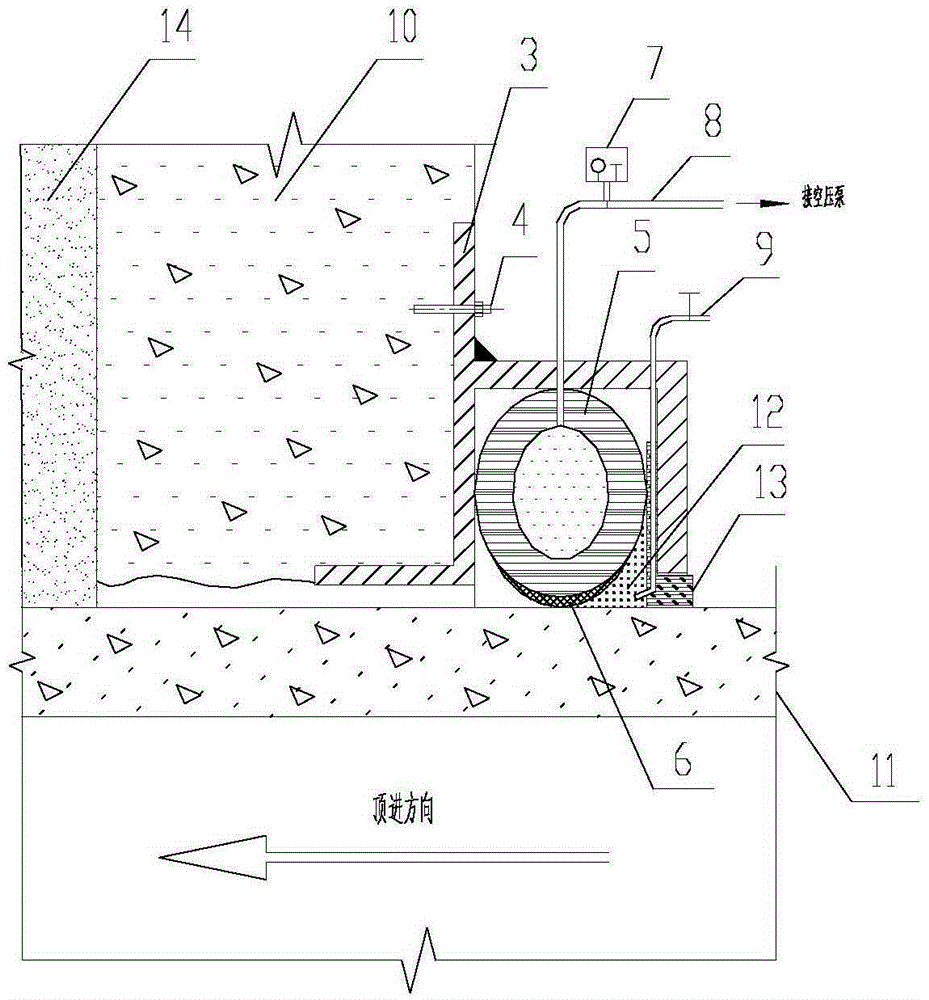

[0040] as attached image 3 And attached Figure 4 As shown, a water stop device at the entrance of a pipe jacking tunnel includes an inflatable rubber water stop ring installation groove 3 fixedly arranged on the shaft wall 10 of the pipe jacking tunnel entrance, and an installation groove 3 of the inflatable rubber water stop ring The flexible inflatable rubber water-stop ring 5 inside, the air guide tube 8 connecting the inflatable rubber water-stop ring 5 and the ground air compressor is also arranged on the installation groove 3 of the inflatable rubber water-stop ring, and the pipe joint 11 of this embodiment The cross section is rectangular, the height × width of the outer circumference of the pipe joint is 3500 mm × 3000 mm, and the wall thickness is 250 mm; the shape of the installation groove 3 of the inflatable rubber water stop ring and the shape of the inflatable rubber water stop ring 5 matches the shape of the cross section of the pipe joint 11 , in a rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com