Rotary dynamic metal corrosion testing device and using method thereof

A rotary dynamic, metal corrosion technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of complex devices, liquid metals are easily polluted, and the number of samples loaded is limited, so as to avoid The device is complex, realizes the change of relative motion rate, and ensures the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

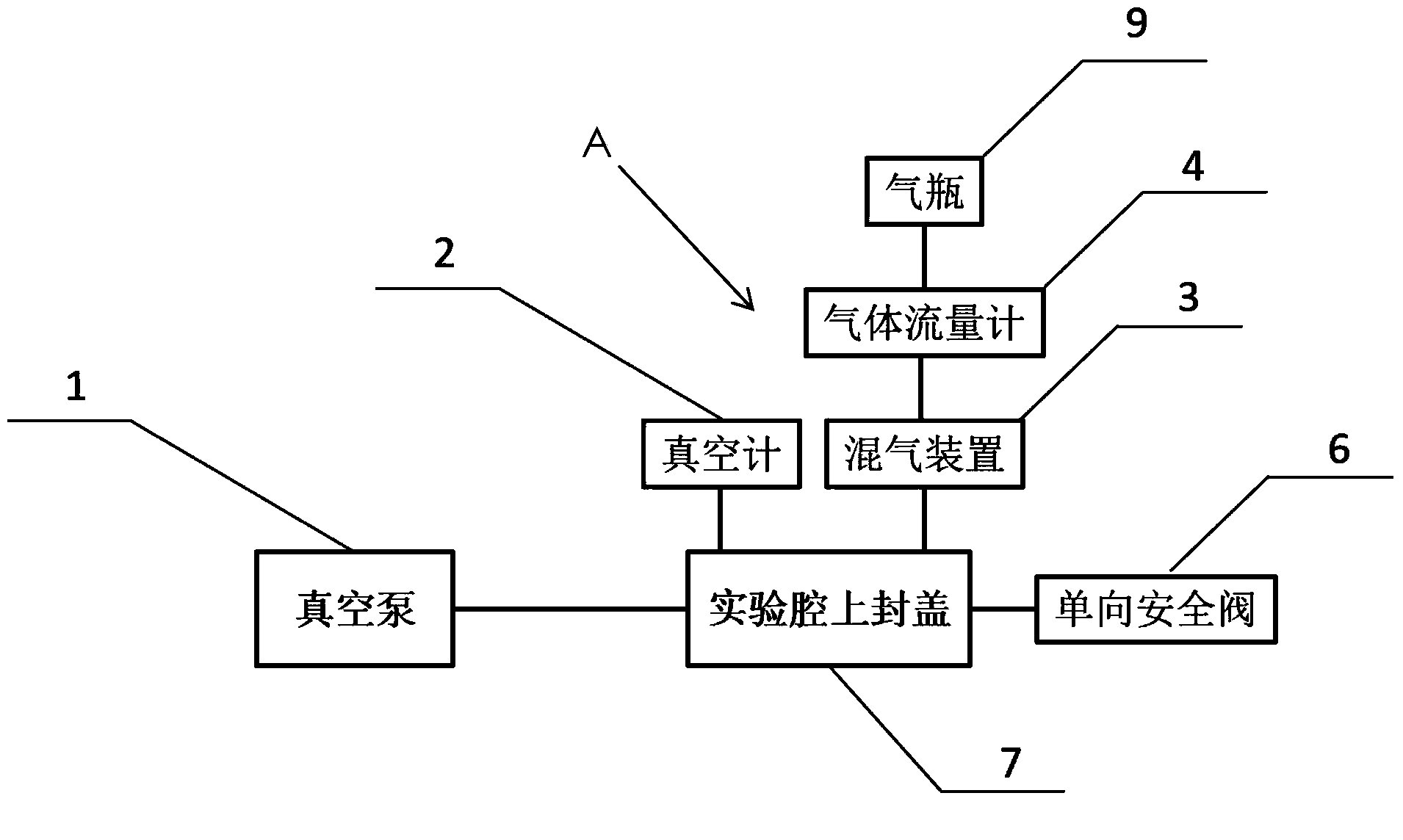

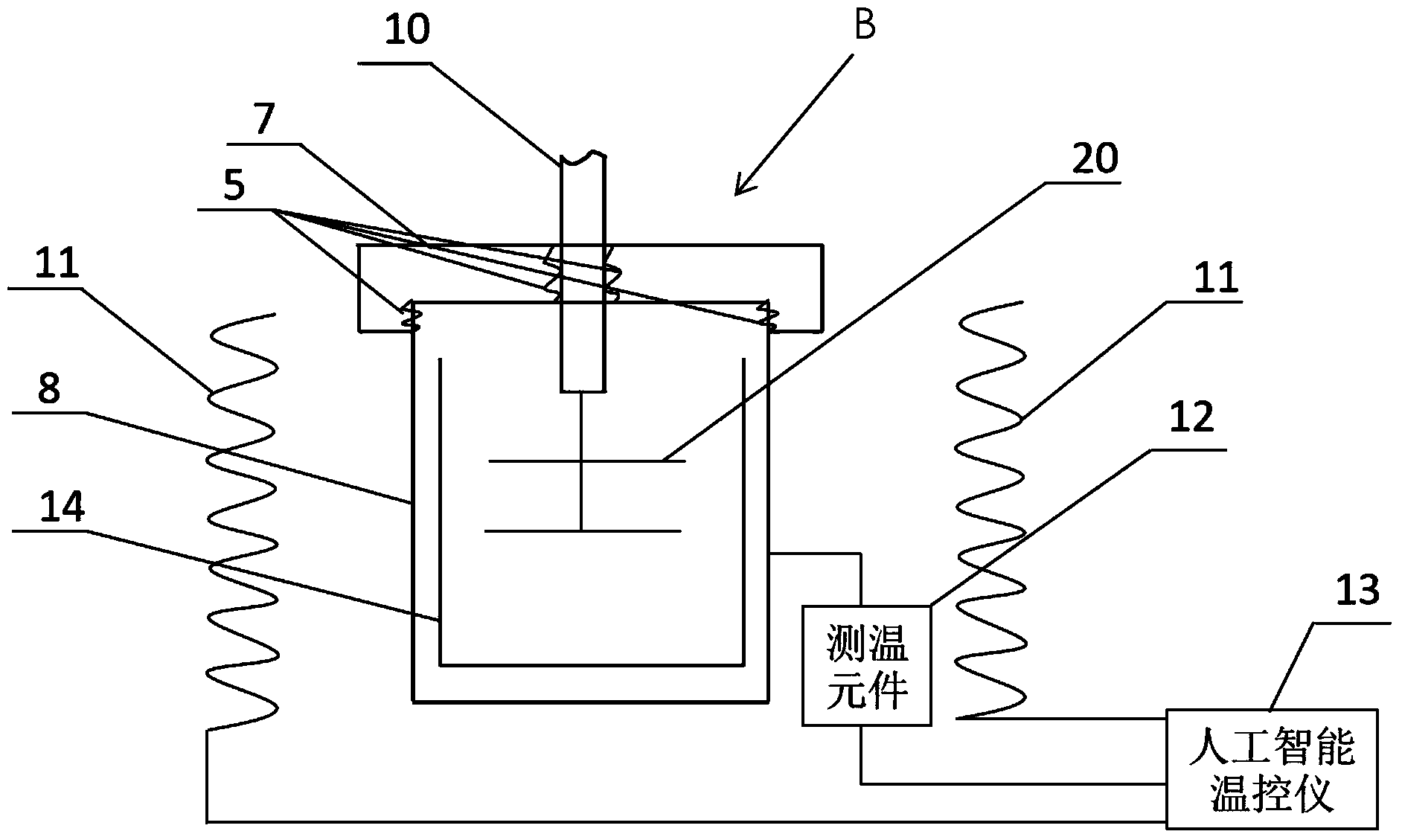

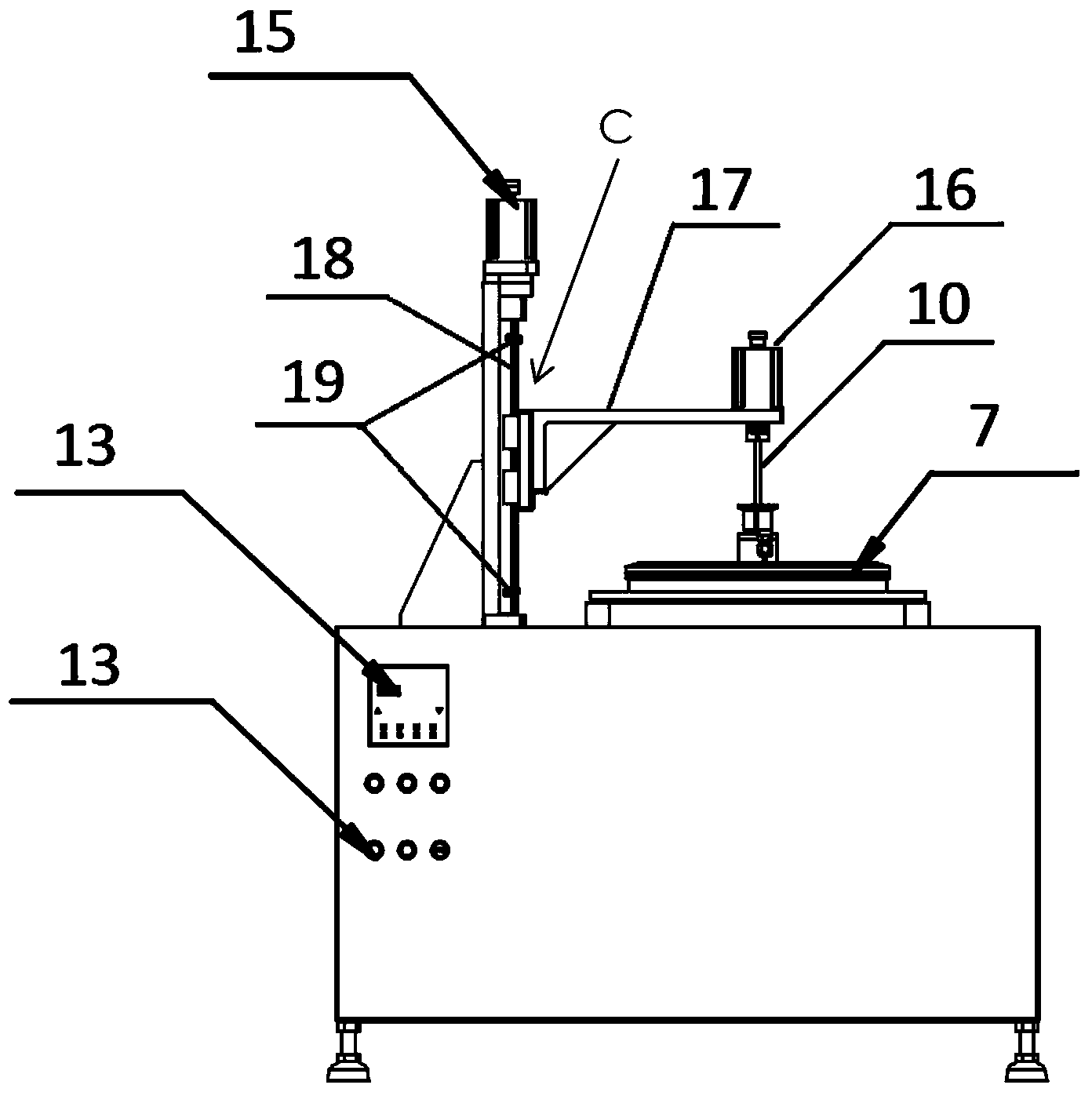

Method used

Image

Examples

Embodiment 1

[0059] Use the device mentioned in the invention to test the corrosion behavior of martensitic heat-resistant steel P91 in a dynamic lead-bismuth (Pb-Bi) eutectic alloy at 550 °C, and proceed as follows:

[0060] 1) Put the glass lining into the experimental chamber, and use corundum powder to fill the gap between the glass lining and the experimental chamber, and put about 20kg of Pb-Bi eutectic alloy into the glass lining;

[0061] 2) Put the extruded sealing metal frame and high-temperature rubber ring in the center hole of the upper cover of the experimental chamber, and pass the rotating rod through the central hole of the upper cover of the experimental chamber;

[0062] 3) Connect the sample holder with the rotating rod that passes through the upper cover of the experimental chamber, and at the same time clamp the φ5×10mm round rod-shaped P91 sample on the sample holder, and use the lifting motor to lift the sample holder and the sample to the height above the glass lin...

Embodiment 2

[0070] Use the device mentioned in the invention to test the corrosion behavior of martensitic heat-resistant steel P91 in a dynamic lead (Pb) alloy at 600 °C, and proceed as follows:

[0071] 1) Put the glass lining into the experimental cavity, and use corundum powder to fill the gap between the glass lining and the experimental cavity, and put about 25kg of Pb alloy into the glass lining;

[0072]2) Put the extruded sealing metal frame and high-temperature rubber ring in the center hole of the upper cover of the experimental chamber, and pass the rotating rod through the central hole of the upper cover of the experimental chamber;

[0073] 3) Connect the sample holder to the rotating rod that passes through the upper cover of the test chamber, and at the same time, clamp the 40mm×20mm×5mm sheet-shaped P91 sample on the sample holder, and use the lifting motor to place the sample holder and the test chamber. The sample is lifted to a height higher than the glass lining.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com