Steel cylinder with wide tongue and groove fitting

A wide tongue and groove, steel cylinder technology, applied in the field of steel cylinders, can solve the problems of tearing or damage of sealing mudguard strips, affecting the water-stop effect of enclosure structures, and the impact of artificial island construction environment, etc., to achieve mud entry Smooth, full and thorough perfusion, and enhanced soil-breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

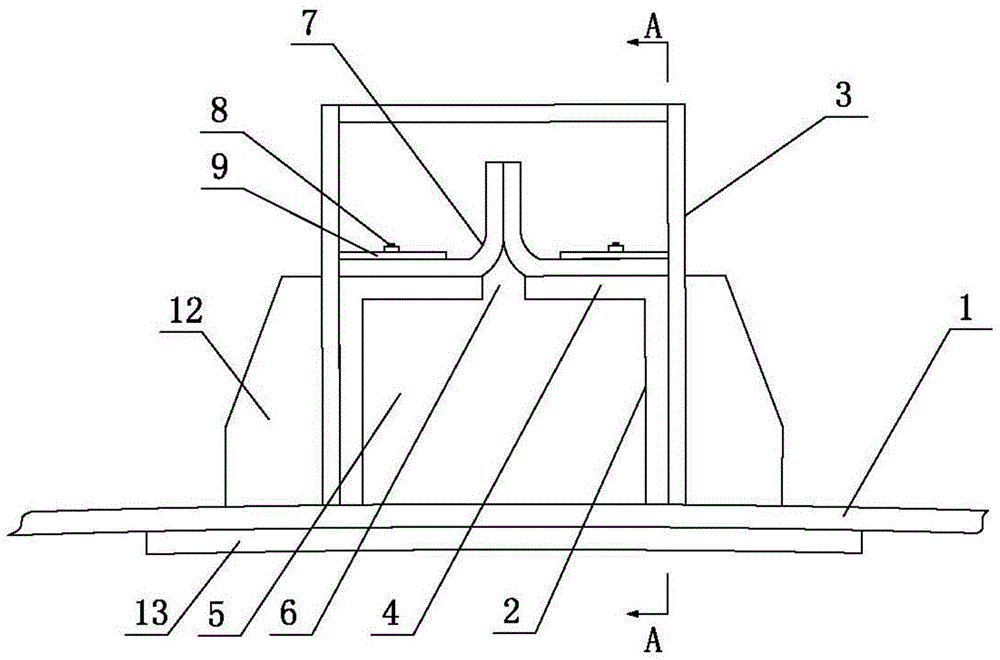

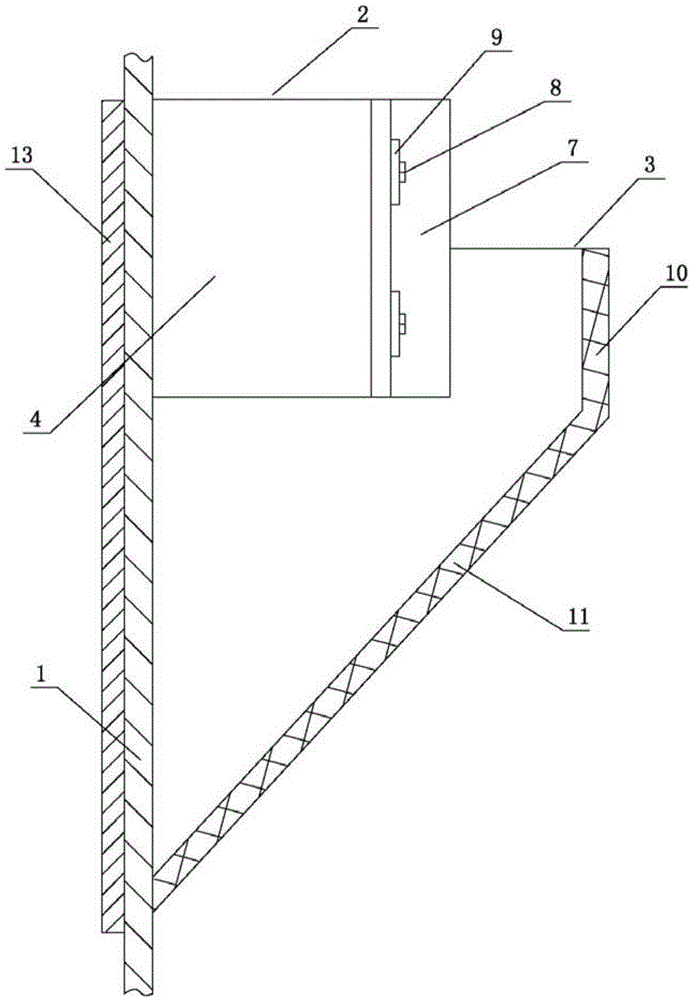

[0017] see figure 1 , figure 2 As shown, a steel cylinder with a wide tenon and groove device of the present invention includes a cylinder body 1 on which a wide tenon and groove device is provided, and the wide tenon and groove device includes a The wide mortise 2 of the arc plate and the protective cover 3 arranged outside the wide mortise for protecting the wide mortise. In this embodiment, the protective cover is integrally arranged outside the wide mortise, and the upper part of the wide mortise protrudes from the wide mortise, so as to facilitate the insertion of the secondary steel arc plate.

[0018] The wide tongue and groove described in this embodiment includes a groove body 4 with an open upper end, a bottom plate 5 is provided at the bottom of the groove body, one side of the groove body is connected with the cylinder body, and a tensioning port 6 is provided on the other side , to facilitate the insertion of the secondary grid steel arc plate, a sealing mudgua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com