Opening treatment method for pipe-roofing continuous perforation

A treatment method and tube curtain technology, which are applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of heavy workload, inapplicability, and cumbersome water-stop treatment, so as to strengthen the water-stop effect and reduce the impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] The method for processing the opening of the continuous opening of the pipe curtain of the present invention, the specific steps are:

[0018] 1. Pre-buried water-stop rubber plates and grouting pipelines on the underground structure

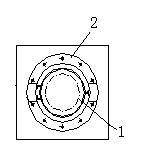

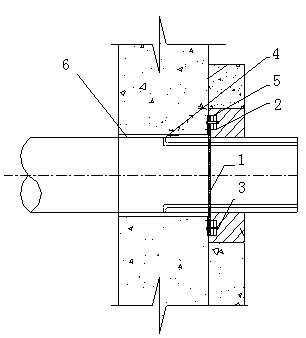

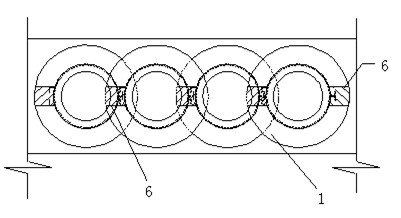

[0019] Before the steel pipe jacking of the pipe curtain is carried out, the construction of the underground structure simultaneously pre-embeds the water-stop rubber plate 1 at the corresponding pipe curtain position, and uses the ring and fan-shaped rubber pressure plate 2 to connect with the underground structure wall through the expansion bolt 3 or the pre-embedded anchor bars and bolts. After the construction of the underground structure is completed, the water-stop rubber plate 1 is buried, and the lap joints between adjacent water-stop rubber plates 1 are cut to form a whole; Slurry pipeline 4;

[0020] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com