Method for water stopping in on-vehicle electric wires

A treatment method and wire technology, applied to circuits, electrical components, insulated cables, etc., can solve the problems of easy pressure loss, complicated management of vehicle-mounted wire operations, and large pressure loss, and achieve high water-stop performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

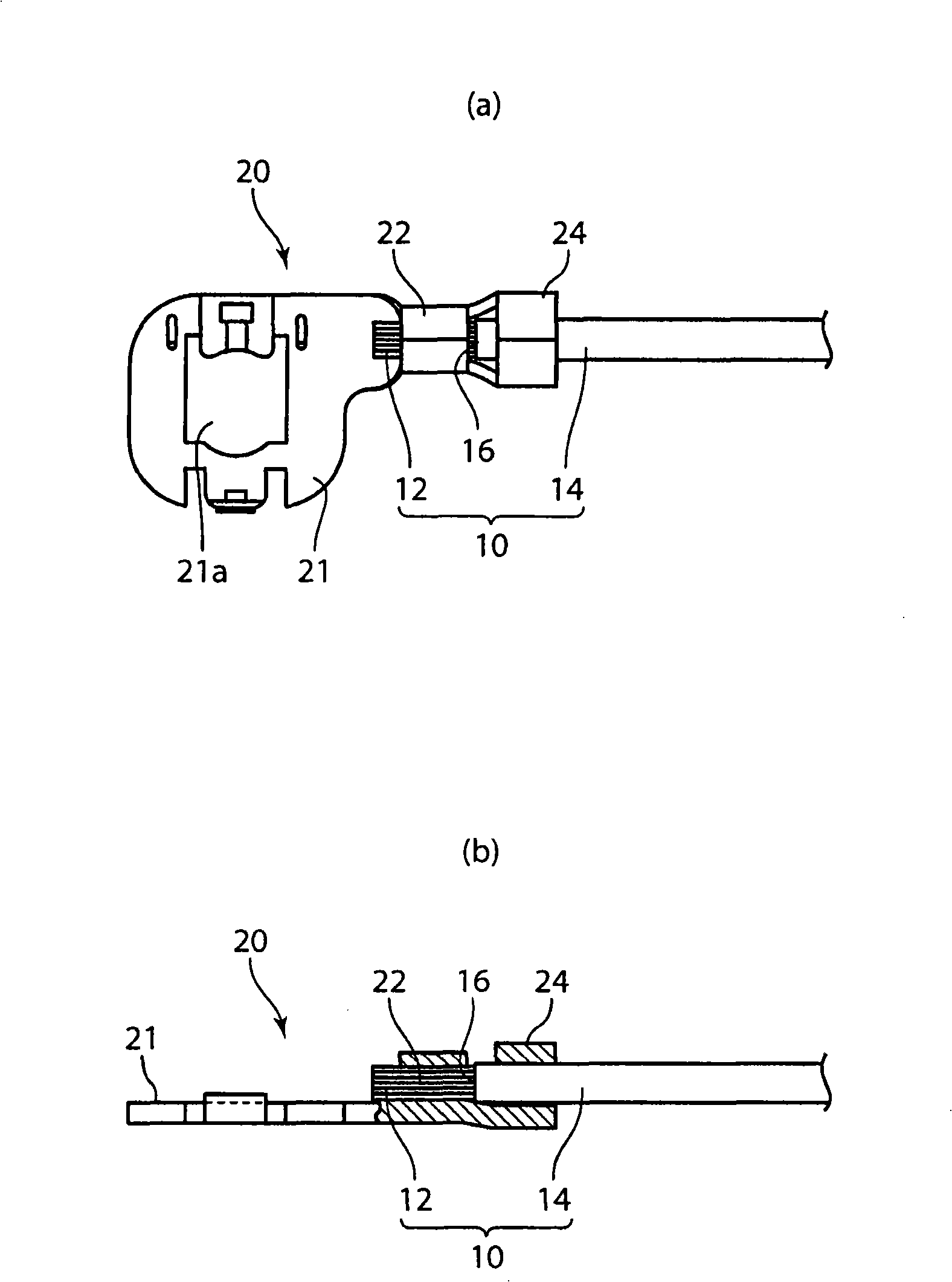

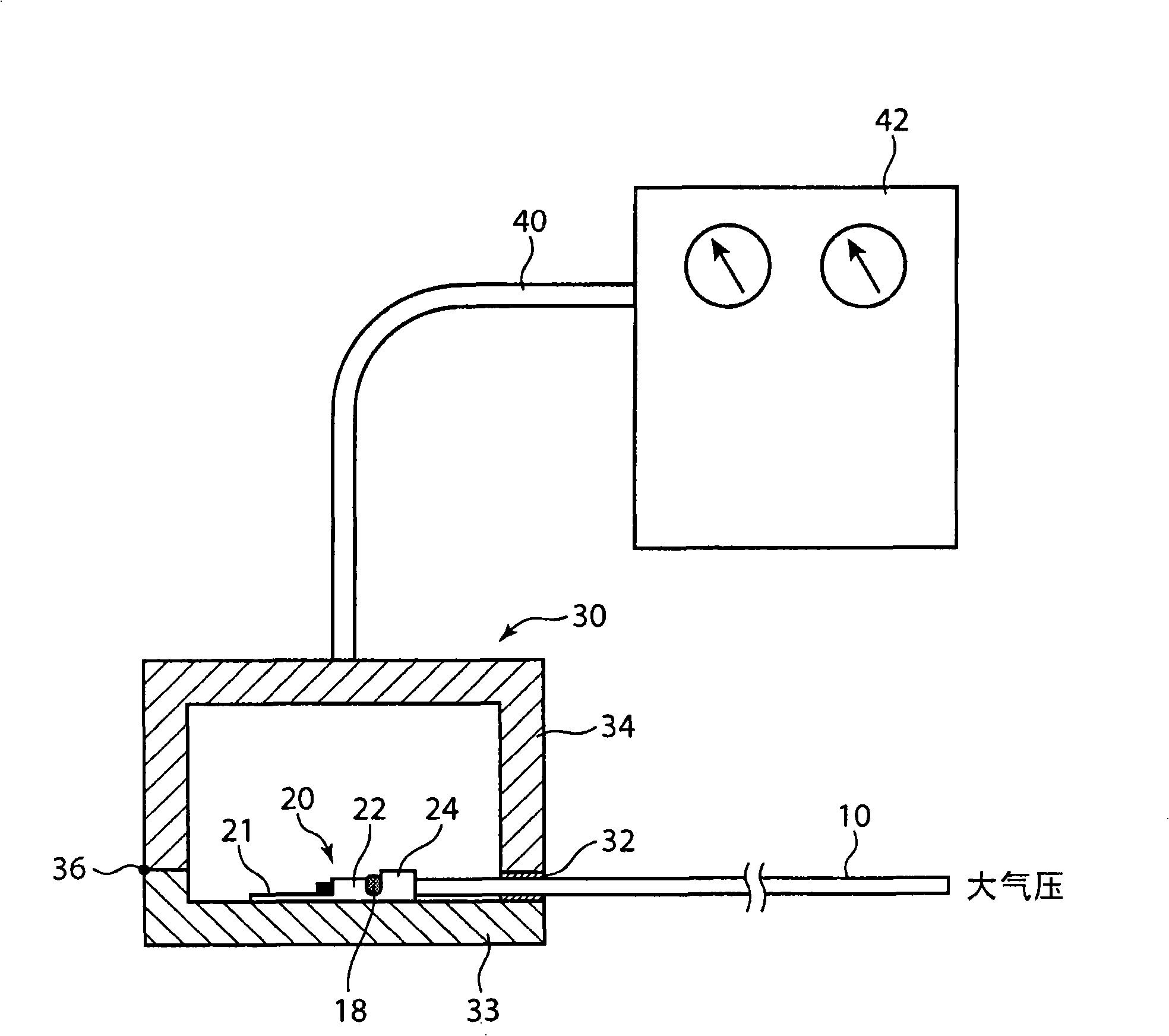

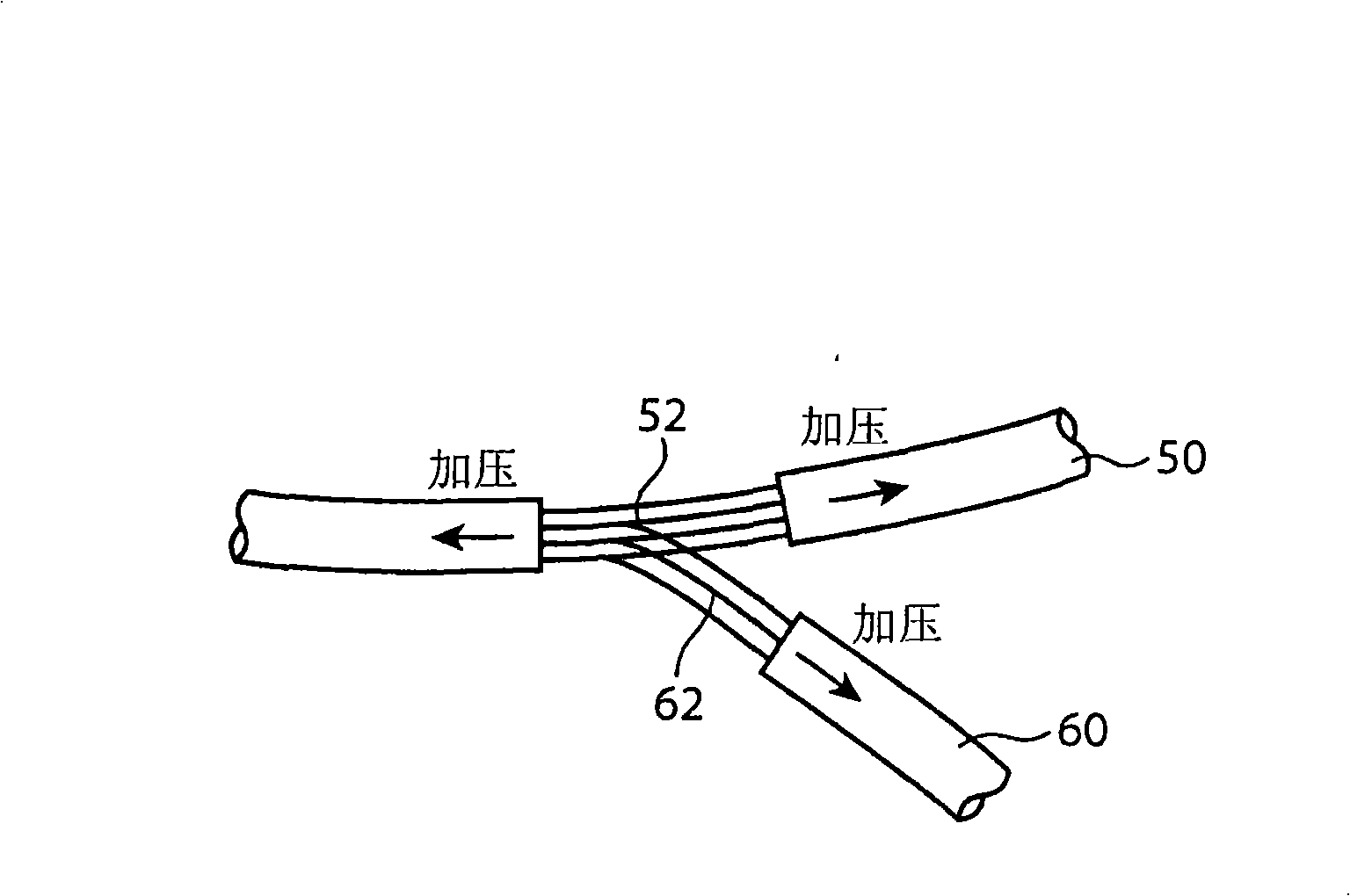

[0052] Use the above figure 1 as well as figure 2 In the method shown, under the following conditions, the operating pressure is appropriately changed and the water stop treatment is performed.

[0053] ·Wire length……1m

[0054] ·The cross-sectional area of the wire……0.85mm 2

[0055] ·Water stop agent used...silicone rubber (viscosity 0.6Pa·S)

[0056] ·Drip volume of water stop agent……10~20mg

[0057] ·Operation pressure (gauge pressure)...a) Pressurize the processing side terminal 16 to 300 kPa, b) Pressurize the processing side terminal 16 to 200 kPa, and c) Reduce the opposite side terminal of the processing side terminal 16 Three methods of pressure to -70kPa (previous method) to stop water treatment

[0058] ·Processing time……10~20sec

[0059] Figure 5 Indicates the result of this water stop treatment. Figure 5The "penetration distance" in is the maximum value of the distance from the end position of the coating material 14 to the deepest penetration position of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com