Water stopping construction method for horizontal seam of face rock-fill dam panel

A construction method and technology of face dams, which are applied in water conservancy projects, sea area projects, buildings, etc., to achieve the effects of convenient construction, chemical medium corrosion resistance, and sealing performance resistance to aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

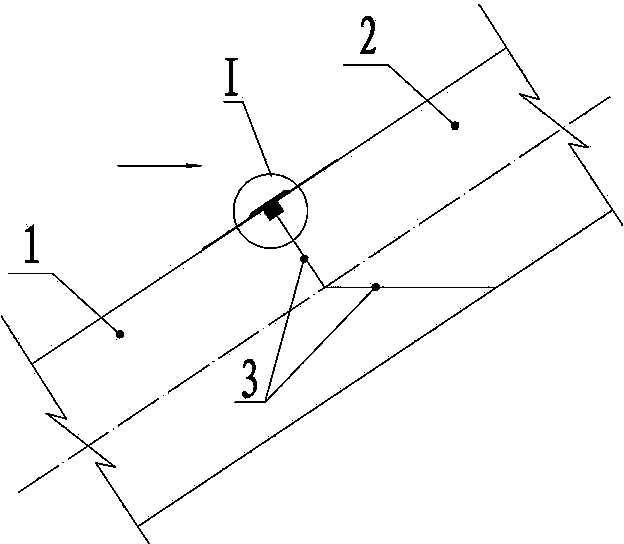

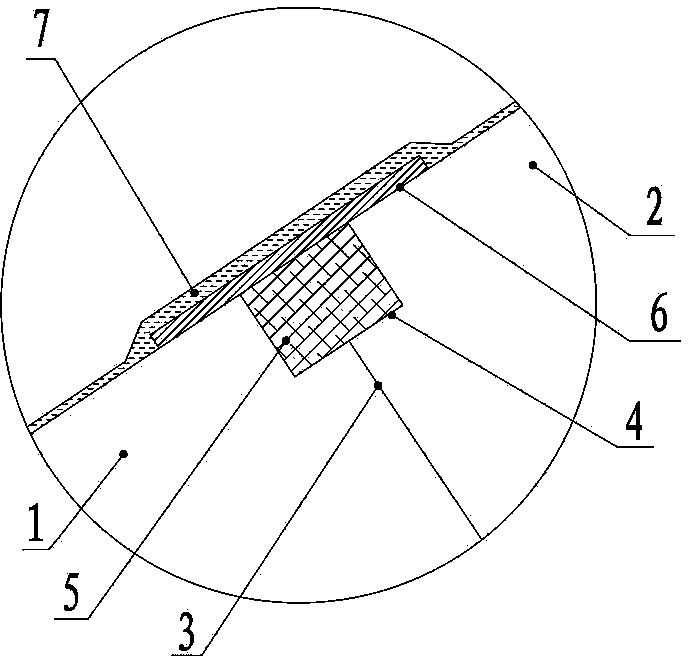

[0019] Such as figure 1 , 2 As shown, the face dam face face horizontal seam waterproofing construction method of the present invention is carried out according to the following steps:

[0020] Step 1: Set the connecting joints 3 of the concrete panels 1 and 2 of the first and second phases in a broken line form composed of oblique joints and horizontal sections perpendicular to the panels;

[0021] Step 2: Open a groove 4 with a rectangular structure perpendicular to the slope of the face dam along the joint 3 of the first-stage and second-stage concrete panels 1 and 2 on the water-facing surface, and carry out construction chiseling treatment; the width of the groove 4 × depth 40mm×30mm respectively;

[0022] The third step: fill the groove 4 with polysulfide sealant water-stop filler 5;

[0023] Step 4: Paste the water stop plate 6 with a width greater than the width of the groove notch at the position of the notch of the groove; the width of the water stop plate 6 is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com