Water-seal structure with expansion joint and spraying and filling construction method for forming same

An expansion joint and water-stop technology, which is applied in water conservancy projects, sea area engineering, construction, etc., can solve the problems that materials do not meet the engineering durability and deformation, the durability of expansion joints is difficult to guarantee, and the simple operability is not satisfied. Achieve superior water-stop performance, improve water-stop effect, and good stretching and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

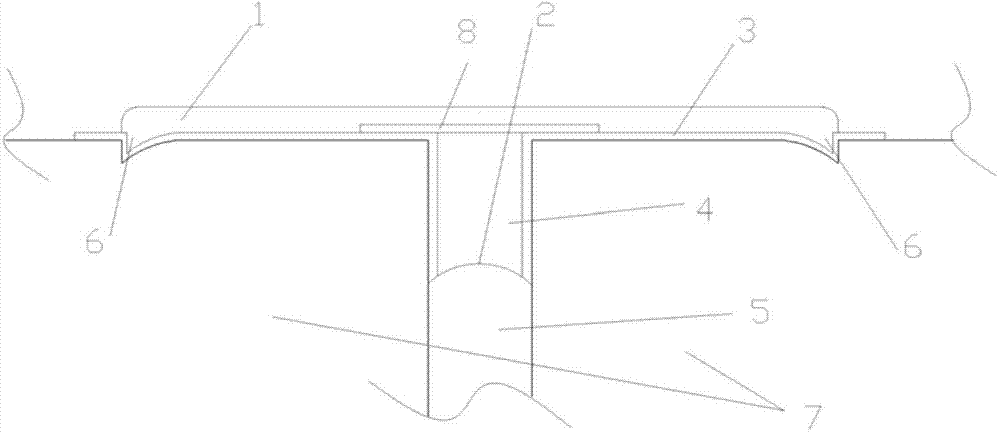

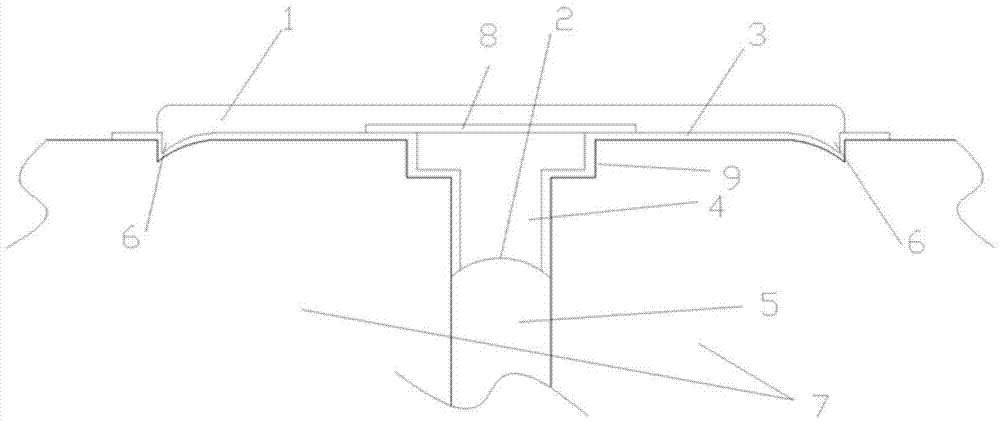

[0016] Such as figure 1 As shown in the water-stop structure of this expansion joint, a primer layer 3 is provided on the side wall and upper edge of the expansion joint 5, an elastic waterproof filler 4 is filled in the expansion joint, and polyurea elastic is sprayed on the upper edge of the expansion joint. Body waterproof coating1. Expansion joints may be formed from concrete 7 .

[0017] Preferably, the elastic waterproof filling body is arranged at the upper part of the expansion joint in the water-facing direction. Because the elastic waterproof filling body is only arranged on the upper part of the water-facing direction, and does not need to be arranged at other positions, the material used for the elastic waterproof filling body is very small, thereby reducing the cost well.

[0018] Preferably, the bottom 2 of the elastic waterproof filling body is in an upward concave shape. This not only changes the stress-bearing structure, but also saves more materials than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com