Ultra-long concrete wall body structure and method for controlling structural cracks by constructing wall body

A concrete wall and concrete technology, which is applied to underwater structures, building structures, infrastructure engineering, etc., can solve the problems of affecting the use function, poor control of structural cracks, and many construction steps, so as to reduce the number and density , Eliminate harmful cracks, and the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

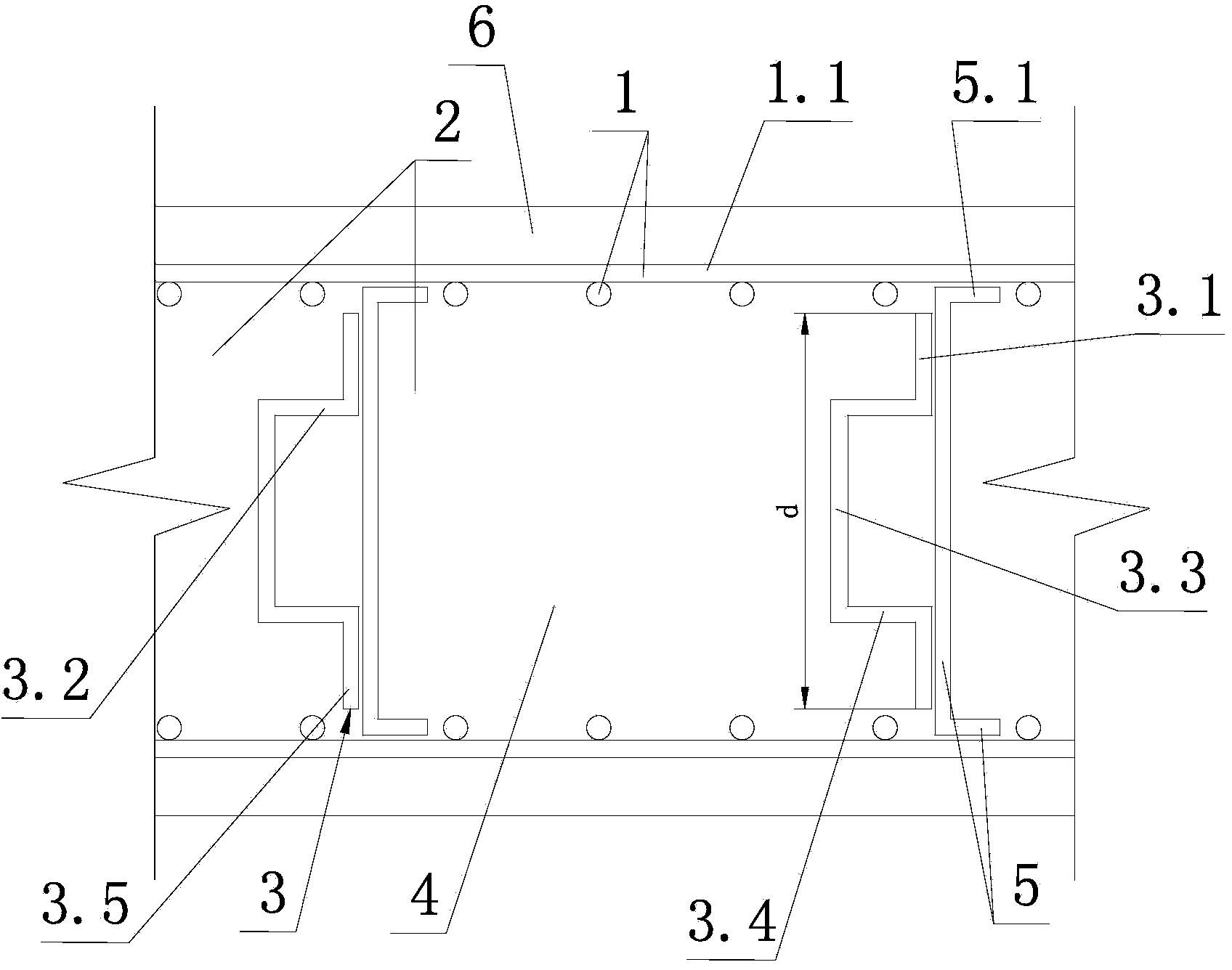

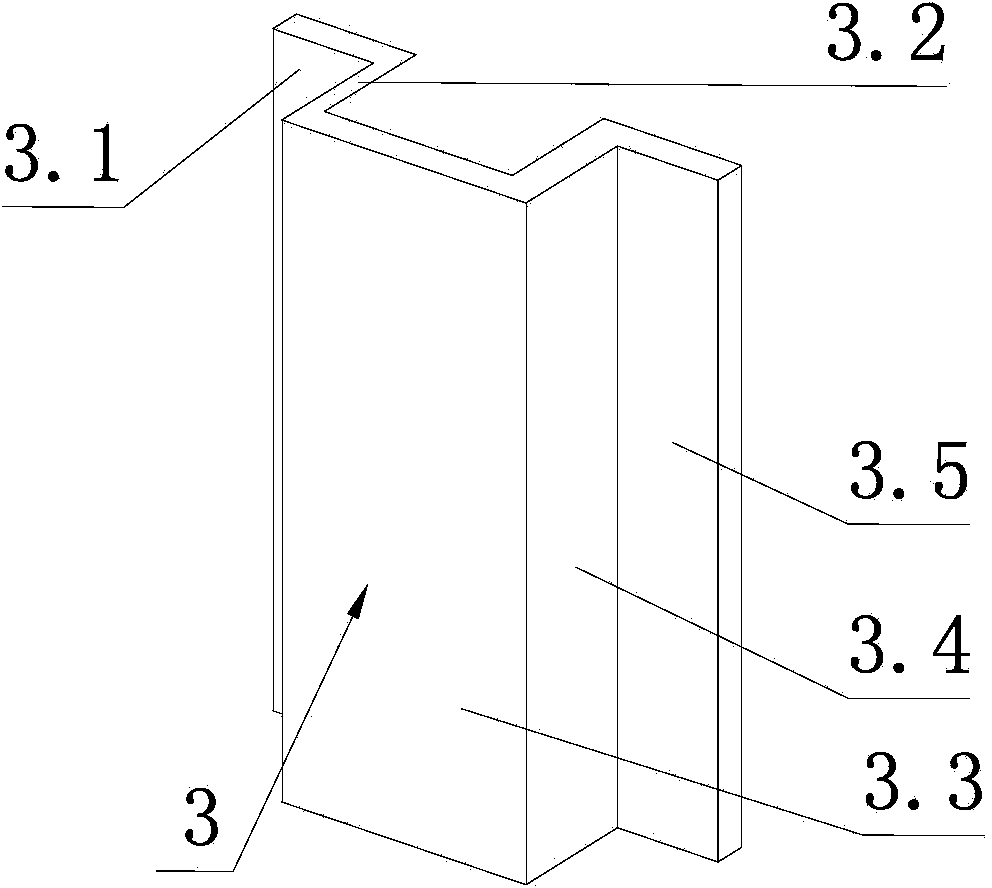

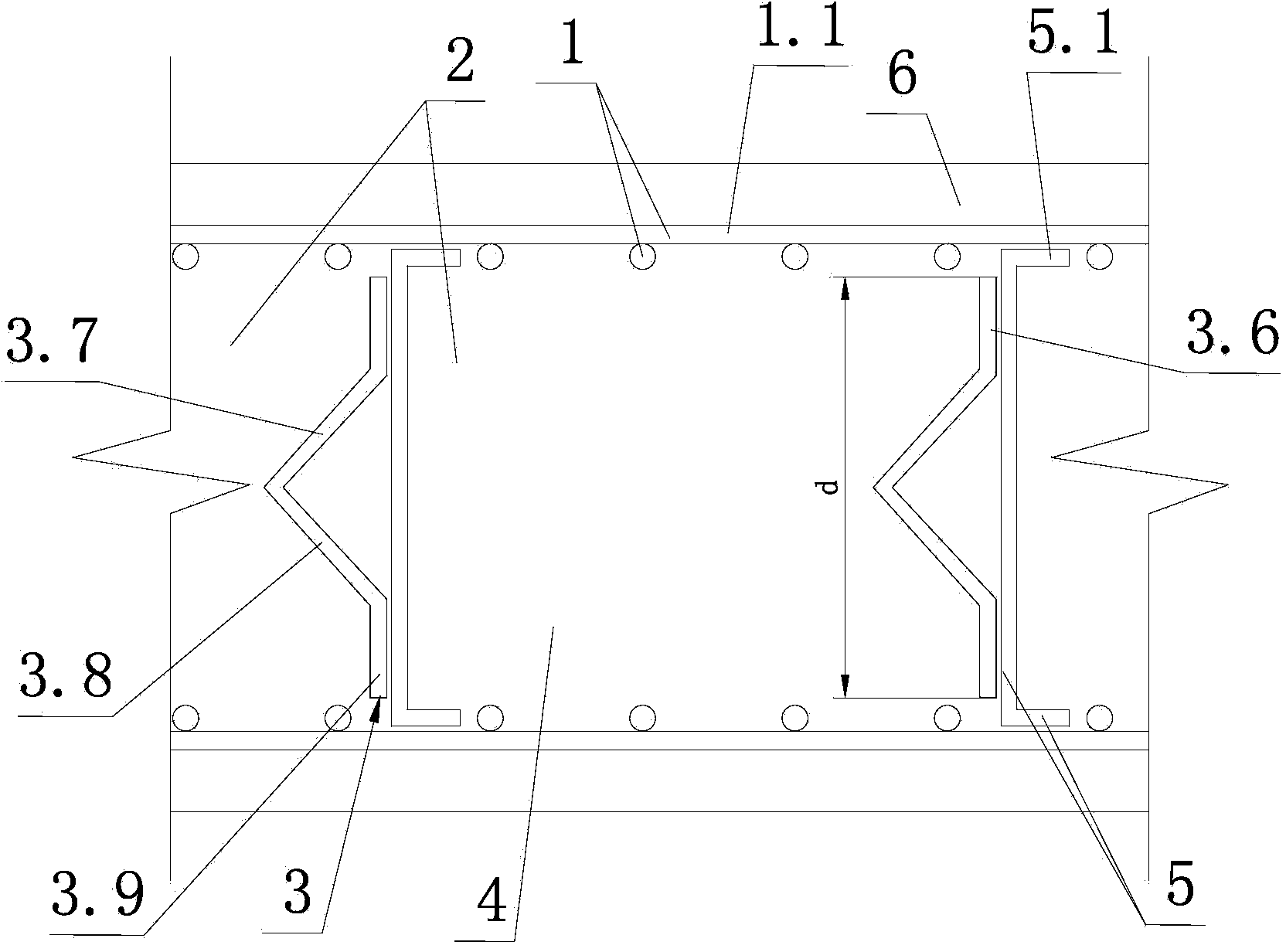

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the superlong concrete wall structure of the present invention, it comprises the body of wall, and two layers of reinforcement mesh 1 are anchored in the wall body. The concrete core layer 2 between the two layers of steel mesh 1 of the wall body is provided with a cutting steel plate 3 at regular intervals along the length direction of the wall, and the cutting steel plate 3 cuts the continuous concrete core layer between the two layers of steel mesh 1 Layer 2 is cut into concrete core units 4 . There are many horizontal connecting steel bars 5 of different heights welded on each cutting steel bar 3, and the two ends of each connecting steel bar 5 are provided with a bending section 5.1, and the two bending sections 5.1 of each connecting steel bar 5 are connected with two l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com