Large depth underground continuous wall water-stop joint device

An underground diaphragm wall and joint device technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve problems such as failure to bury the waterstop, difficult to dismantle as a whole, loss of waterproofing, etc., and achieve reform of construction technology, installation and dismantling. Simplify and avoid the effect of mud skin generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

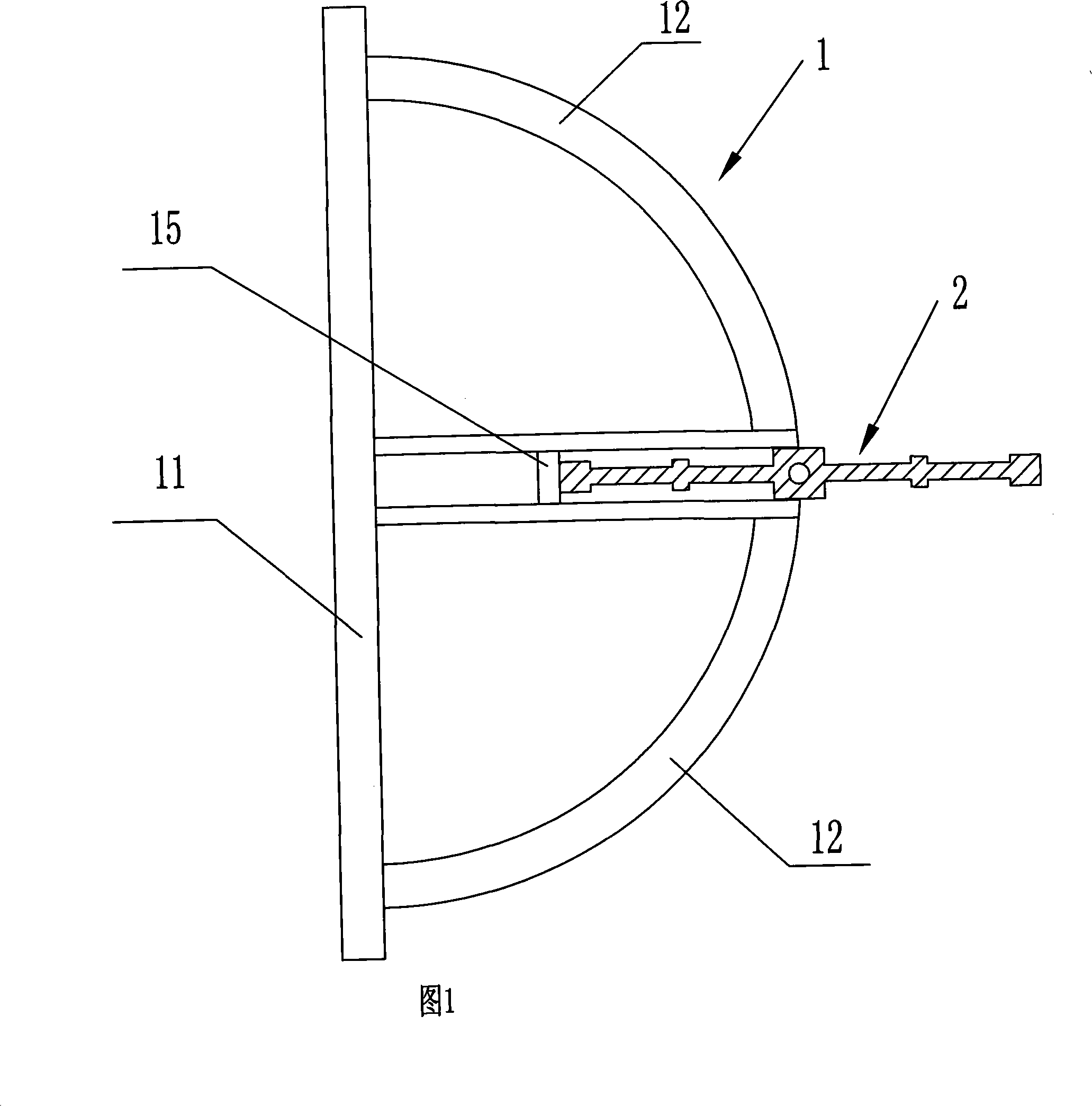

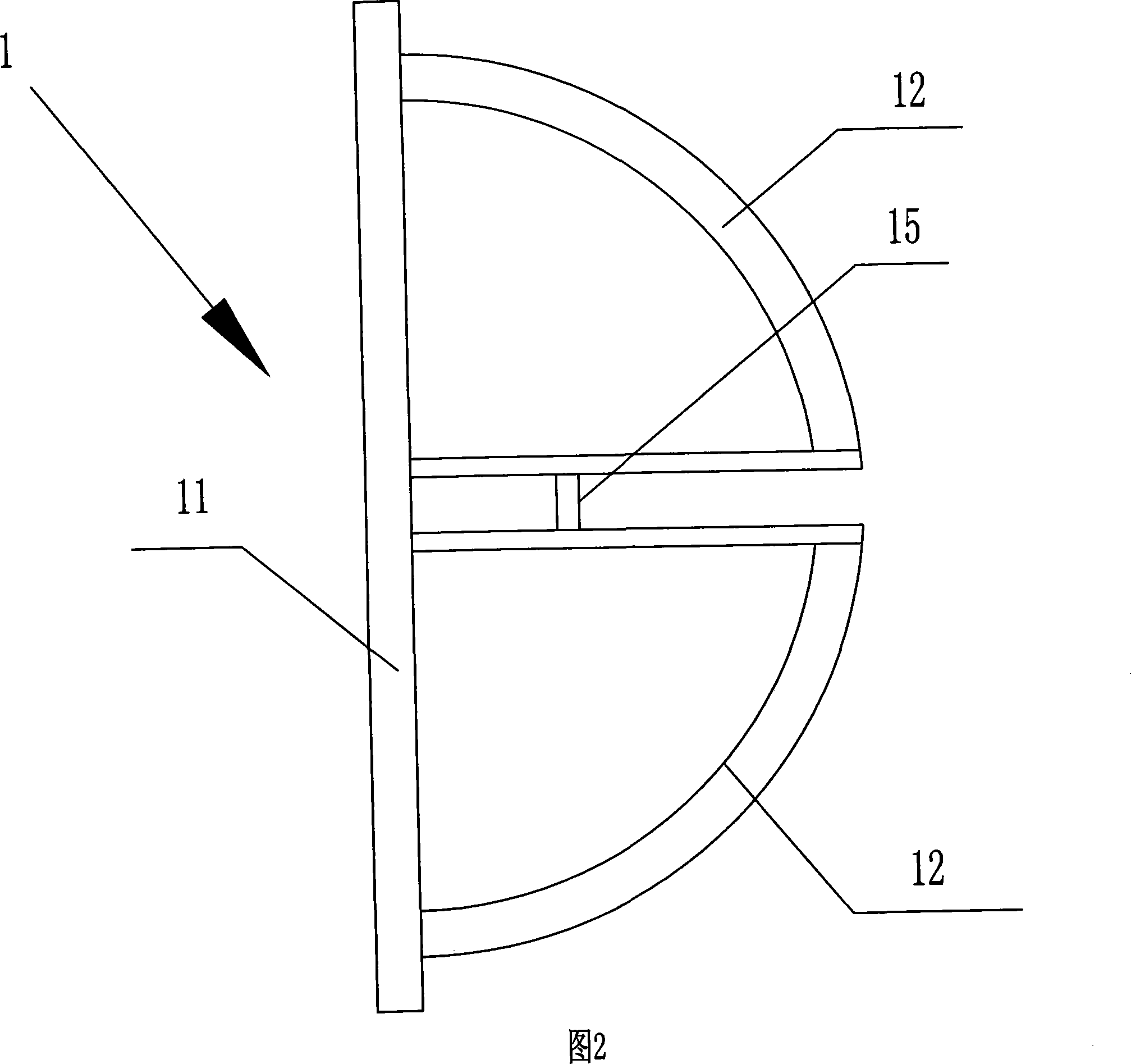

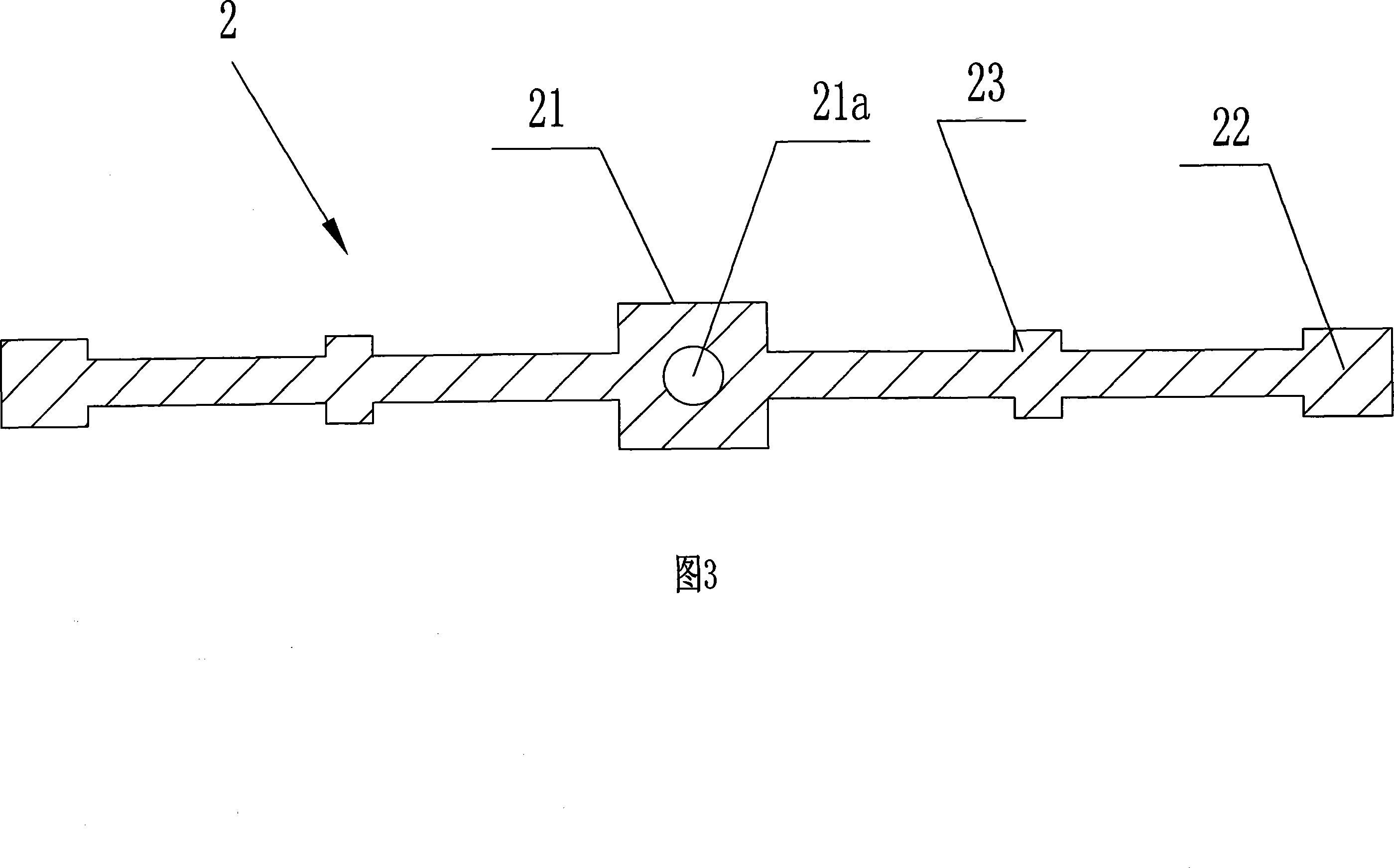

[0054] Referring to Figures 1, 2, and 3, and referring to Figures 4, 5, and 6 for cooperation, the water-stop joint device for a large-depth underground diaphragm wall of the present invention mainly includes a water-stop joint plate 1, and a rubber water-stop seal embedded in the water-stop joint plate 1 with 2.

[0055] 1. Waterproof joint plate

[0056] The water-stop joint plate 1 of the present invention is a steel structural member, including joint side plates 11, two arc-shaped plates 12, H-shaped groove plates 15, upper and lower end plates 13, 14, which are fixed and connected in sequence;

[0057] Two arc-shaped plates 12 are set opposite to each other along the plate width of the joint side plate 11; the H-shaped groove plate 15 is centrally arranged between the two arc-shaped plates 12; the two open ends of the H-shaped groove plate 15, the two ends of one end The outer sides are fixedly connected with two arc-shaped plates 12 respectively, and the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com