Method for erecting slab form with ribbed beam

A technology of floor formwork and rib beams, which is applied in the field of support of ribbed beam floor formwork, can solve the problems of inconsistent heights of load-bearing poles and difficult construction, and achieve the effects of difficult construction, convenient operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

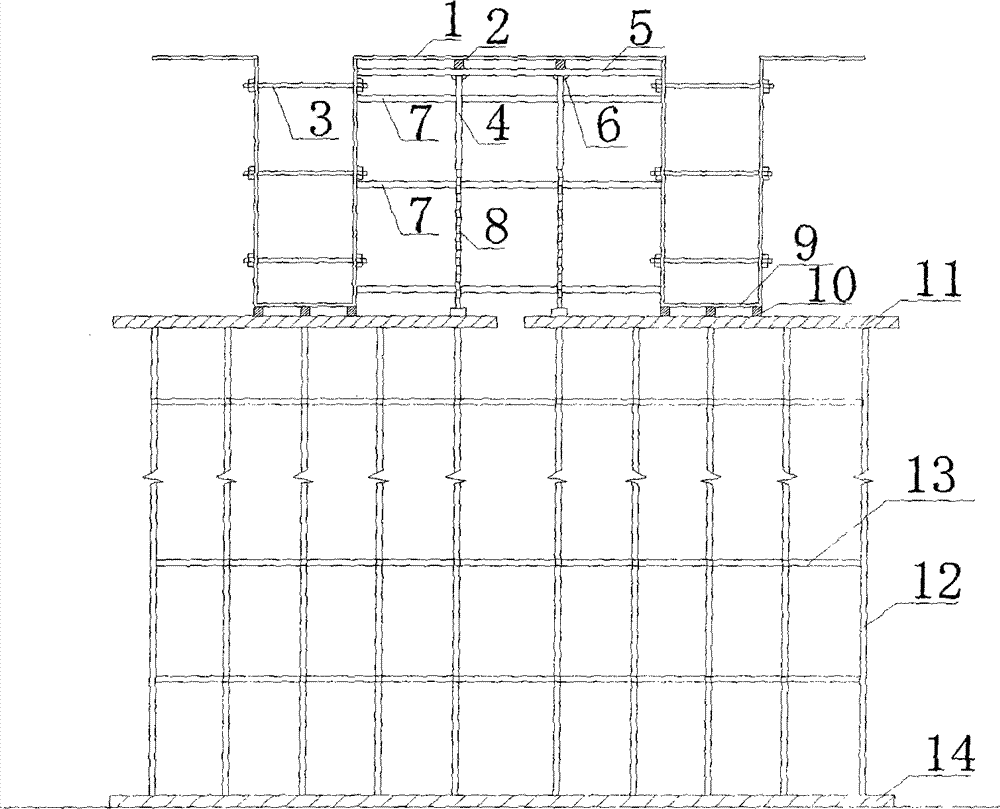

[0008] As shown in the figure, the method for supporting ribbed slab formwork provided by the present invention includes A. setting up the ribbed formwork support system; The wooden square 10 is supported on the wooden square 11 of the rib beam main joist, and the rib beam main joist wooden square 11 transmits the upper load to the back of the ground or the lower floor through the load-bearing vertical pole 12, and the rib beam main joist wooden square 11 is erected on the Slab support system, when erecting the slab support system, the lower end of the support rod composed of the vertical steel pipe 4 and the adjustable support 8 can be supported on the main keel wooden square 11 of the rib beam, and the adjustable support 8 can be supported at the bottom of the rib beam. On the rib beam main keel wooden square 11, the height adjustment range of the adjustable support 8 is 800mm, the horizontal steel pipe 5 is horizontally fastened to the upper end of the vertical steel pipe 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com