Construction method of sludge soil texture deep foundation pit excavation and pumping sand compacted backfilling

A technology for deep foundation pit and silt is applied in the field of foundation pit backfilling construction method, which can solve the problems of insignificant precipitation effect, high construction risk, high construction difficulty, etc., and achieves the solution of cumbersome construction procedures, high safety factor, and shortened construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

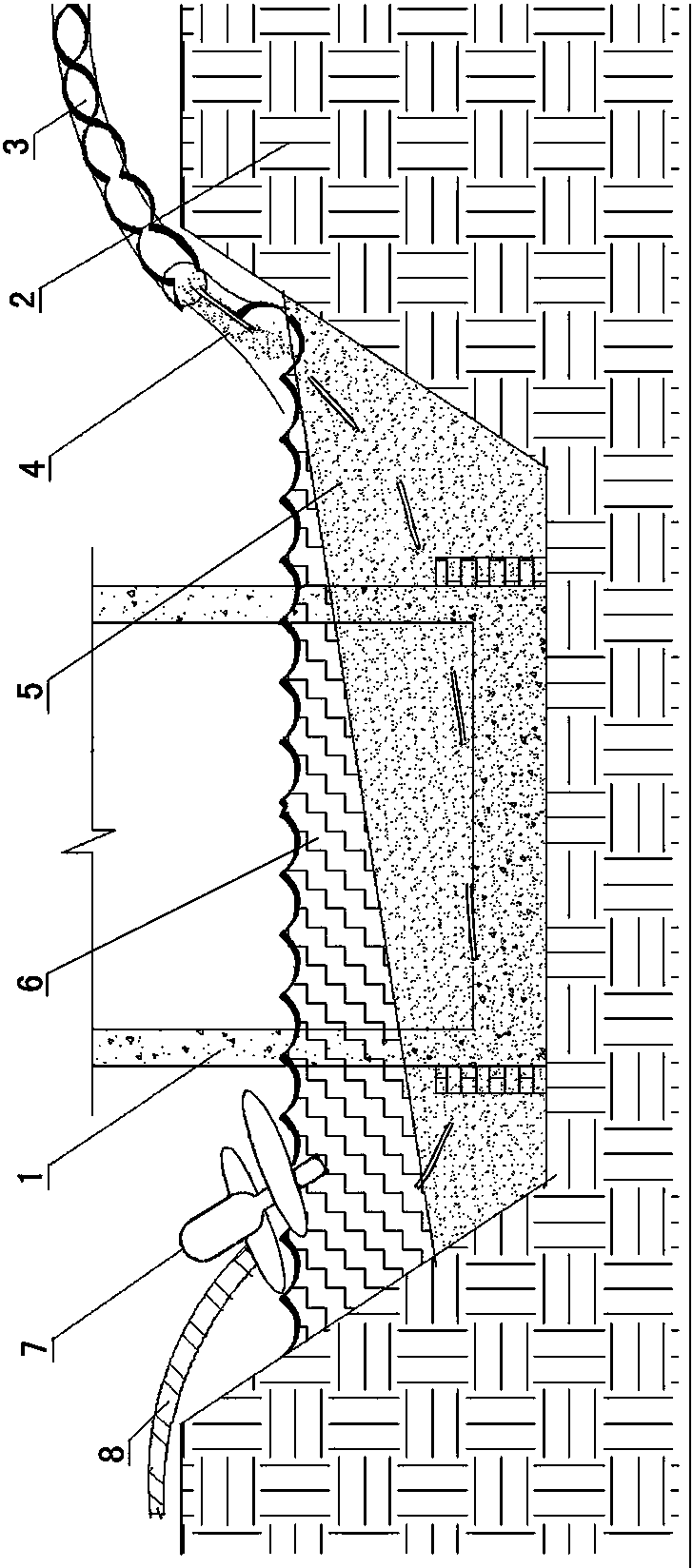

[0023] The construction method of excavating a deep foundation pit of muddy soil and backfilling by pumping and shaking sand has the following steps.

[0024] Step 1, measurement and positioning. Specifically, professional surveyors accurately locate the location and grading of deep foundation pits based on drawings, geological survey reports, and earthwork excavation plans, and the foreman organizes surveyors, quality inspectors, and technicians to jointly check and accept the dimensions of the foundation pit to ensure that The working face meets the construction requirements to prevent secondary costs.

[0025] Step 2. Use manual work to dig a small foundation pit with a diameter of about 1 to 3 meters (depending on the size of the sewage pump and air bag) and a depth of about 300 to 500 mm in the middle of the deep foundation pit to be excavated. The excavated silt is piled up around the deep foundation pit to be excavated to prevent the secondary input of manpower and mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com