Assembled monolithic multilayer long-span bidirectional multi-span building with space steel grid box-type structures

A box-type structure and steel grid technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of large amount of concrete and steel, high cost, reduced steel consumption in construction civilization, etc., and shorten the construction schedule. , the effect of improving lateral stiffness and improving construction civilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with the examples, the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

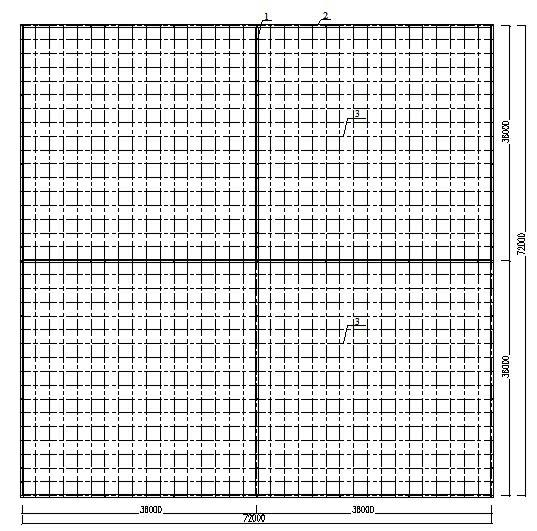

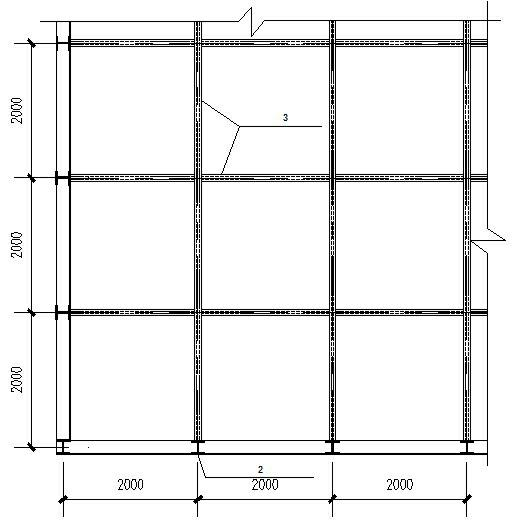

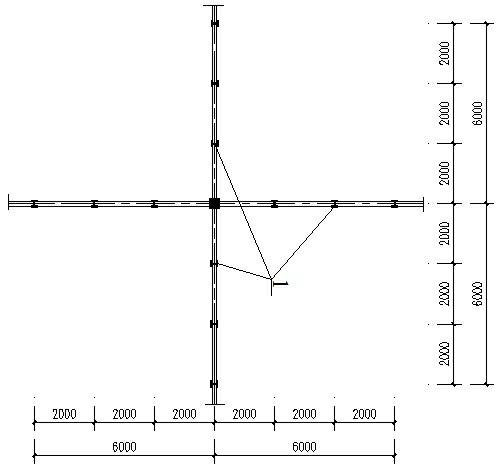

[0028] see figure 1 , figure 2 , image 3 , what this embodiment provides is an assembled integral four-story, orthogonal two-way double-span, the span is 36m×36m, and each floor is divided into four 36m×36m=1296m 2 The space of the hall is a building with a steel grid box structure. The four halls on each floor are separated by a central cross-shaped steel grid wall frame 1. Connected by high-strength bolts, each floor is surrounded by a central cross-shaped steel grid wall frame 1 and a single-layer steel mesh-style outer wall frame 2. The upper part is connected with a steel hollow sandwich plate floor frame 3, thus forming Four space steel grid box structures, each layer of a single space steel grid box struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com