Fly ash surface modifying material and using method thereof

A technology for surface modification and modification of materials, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of waste, increase the cost of concrete, etc., achieve high fluidity, prolonged setting time, flow sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] For example, the steps are as follows:

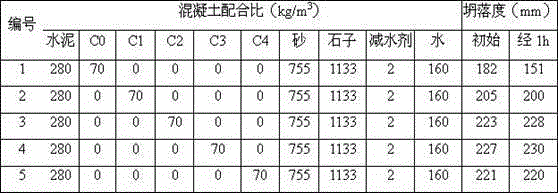

[0021] (1) According to the material formula in Table 1, 4 kinds of materials of the patent invention were respectively formulated, denoted as A1, A2, A3 and A4.

[0022] Table 1 Preparation scheme of fly ash surface modification materials (mass, parts)

[0023] Numbering Sugar Calcium Wood calcium Sodium Gluconate Rosin soap Saponin Sodium Alkyl Sulfonate A11000100 A20100050 A3055002 A4505101

[0024] (2) Dissolve the 4 materials of the invention of the present patent in water, mix and stir them evenly, prepare an aqueous solution of modified materials with a solid content of 30%, denoted as B1, B2, B3, and B4;

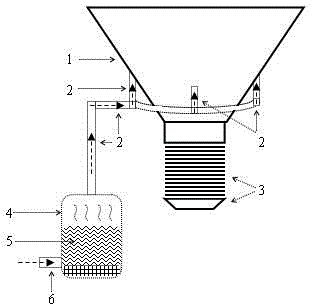

[0025] (2) Use metal or plastic pipe 2 to connect the air outlet of the atomizer with the air inlet at the bottom of the fly ash bin;

[0026] (3) Load the above-mentioned four modified material aqueous solutions B1, B2, B3, and B4 into the atomizer 4, turn on the atomizer, and generate mist containing different modified mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com