Construction technology for deep water foundation pile foundation

A technology for deep water foundation and construction technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as frequent drill sticking, poor hole expansion effect, and hammer head wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

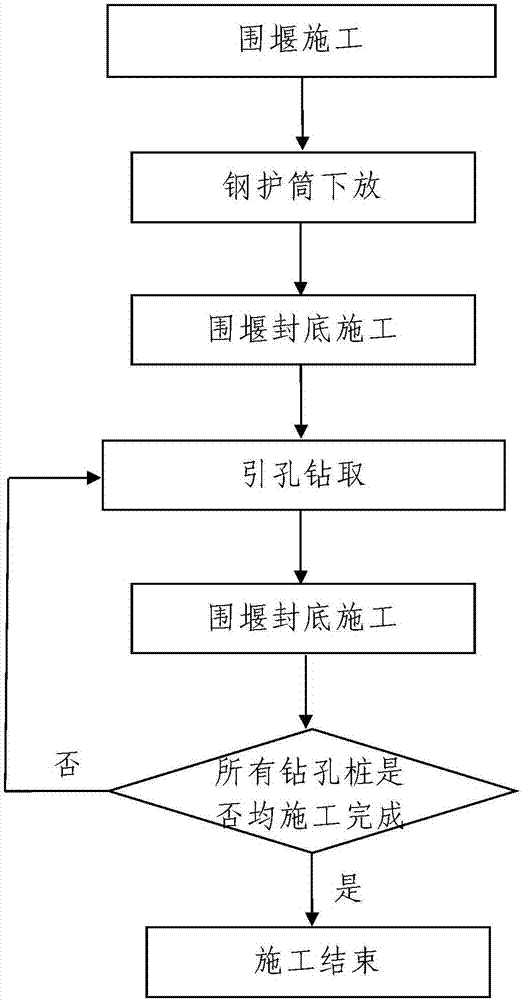

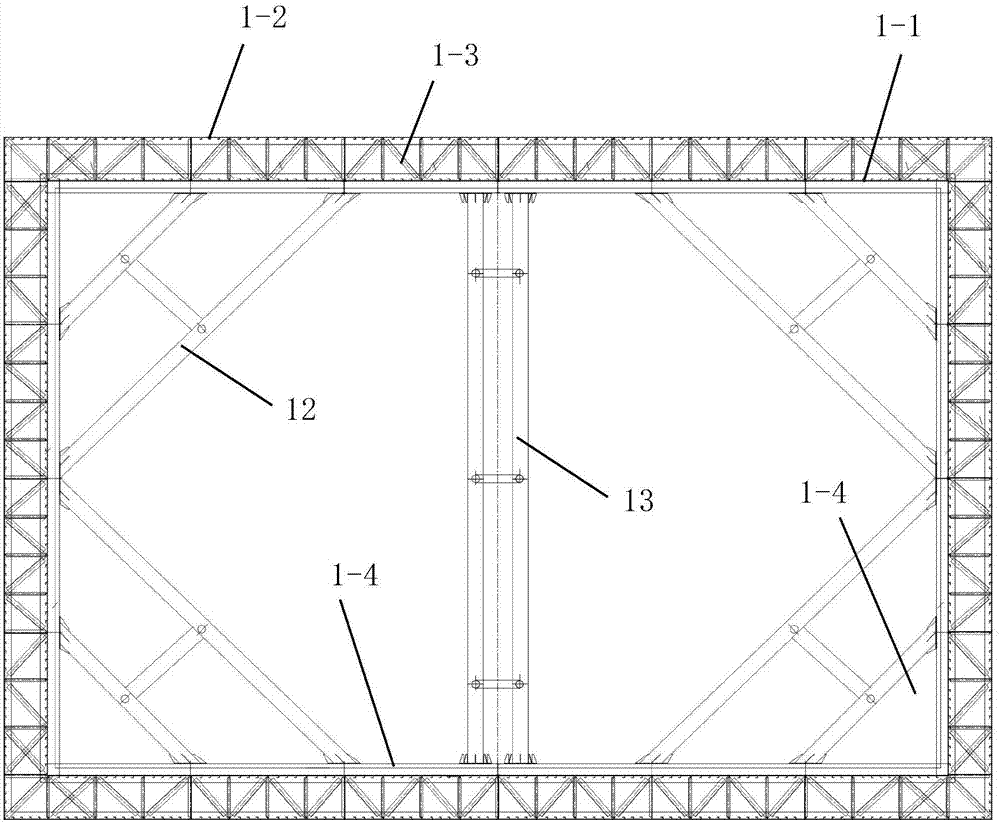

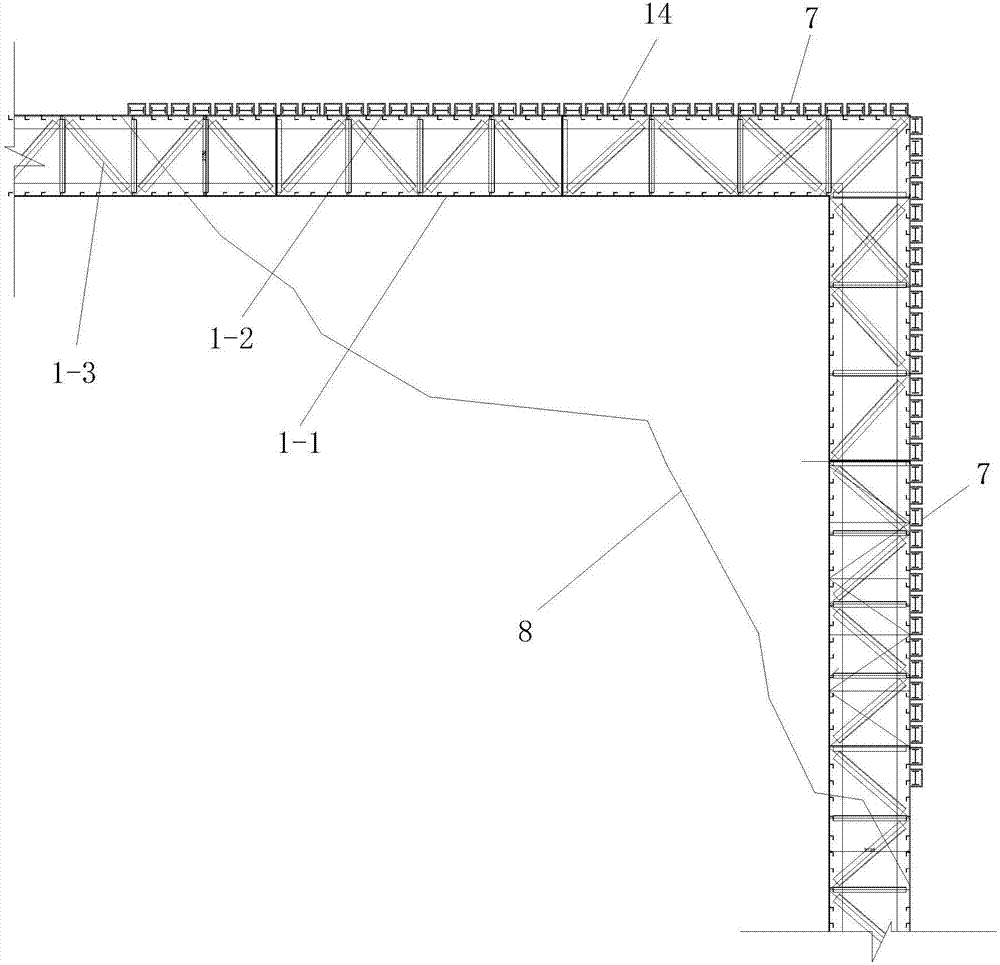

[0083] Such as figure 1 A deep water foundation pile foundation construction technology shown, combined with Picture 1-1 , Figure 8 and Figure 9 , the constructed deep-water foundation pile foundation includes a plurality of bored piles 17 supporting the caps in the water, and the caps in the water are reinforced concrete caps formed by adopting steel cofferdams 1-4; the steel cofferdams 1 -4 Supported on the rocky riverbed 5, the bored pile 17 is a reinforced concrete pile positioned below the horizontal cap and arranged vertically, and the bored pile 17 is on the hard rock 18 in the rocky riverbed 5 ;

[0084] When constructing the deep water foundation pile foundation, the process is as follows:

[0085] Step 1, cofferdam construction: according to the conventional cofferdam sinking construction method, the steel cofferdam 1-4 is sunk from top to bottom to the construction position of the cap in the water, and the steel cofferdam 1-4 is supported on On the rocky riv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com