Prefabricated assembly type pier column and top cap connecting structure and construction method thereof

A prefabricated assembly and connection structure technology, applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problems affecting the safety and reliability of assembly connections, affecting the durability of splicing seams, and insufficient shear resistance. It achieves the effects of convenient leveling and elevation adjustment, fast construction speed and reduced residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

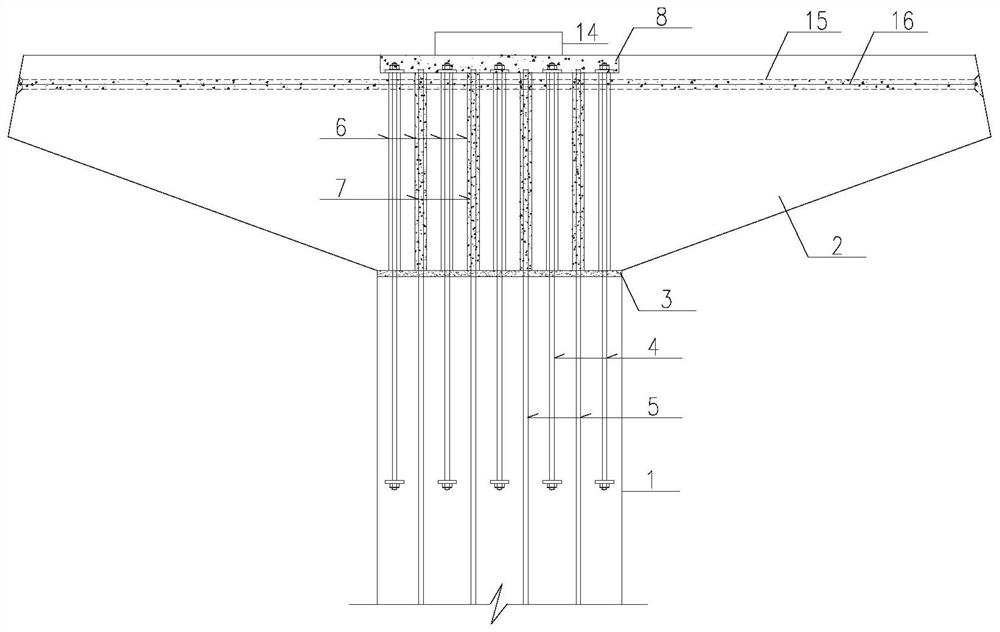

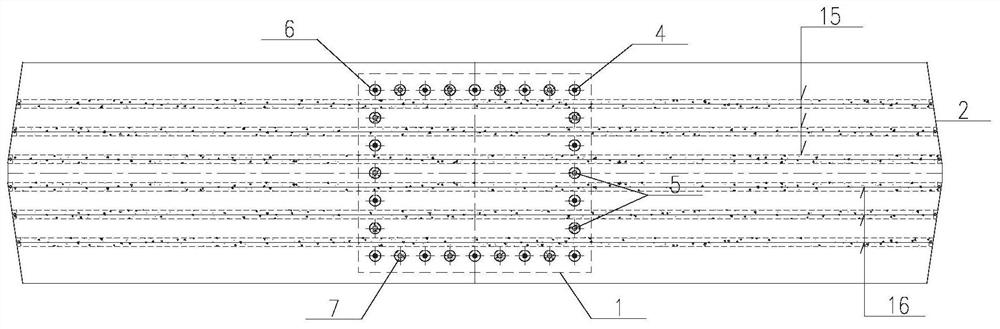

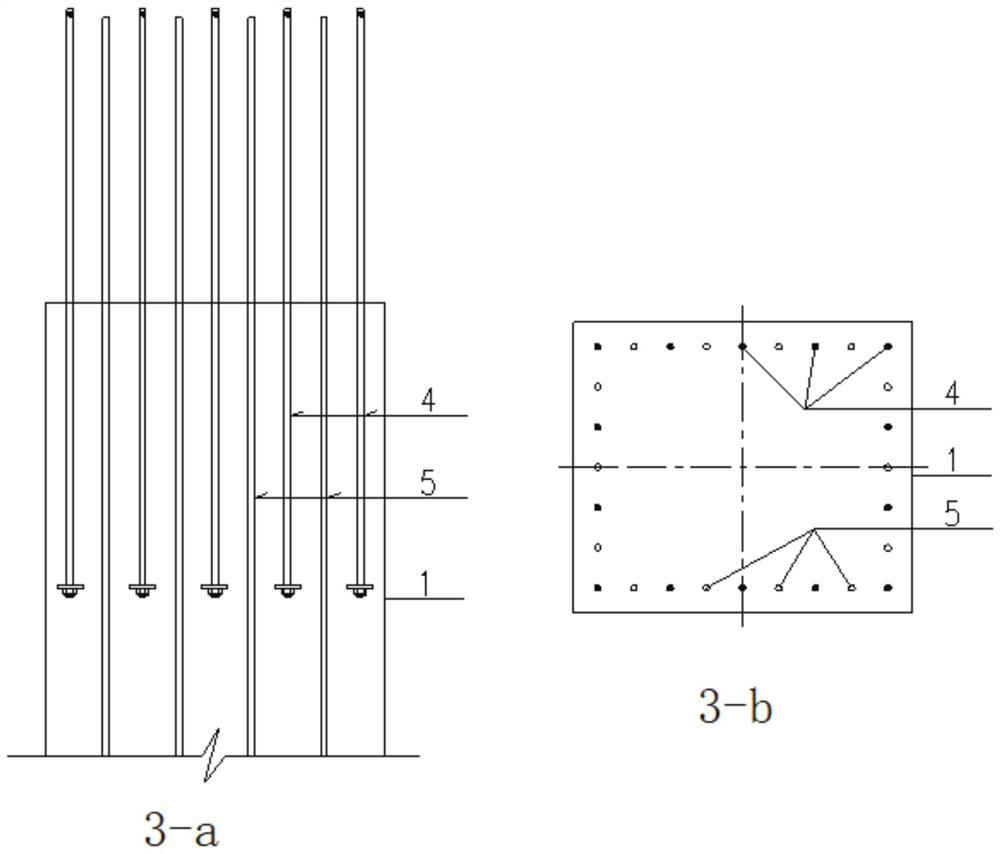

[0053] Embodiment one: if Figure 1-4 As shown, a connection structure between a prefabricated assembled pier and a top hat, including a prefabricated pier 1 and a prefabricated top hat 2, the section of the prefabricated pier 1 is rectangular or circular, and on the section of the prefabricated pier 1 Several prestressed tendons 4 and connecting steel bars 5 are arranged in a staggered manner, and several pre-embedded corrugated pipes 6 are arranged in the prefabricated top hat 2, and channels are reserved in the pre-embedded corrugated pipes 6, and the channels and The prestressed tendons 4 correspond to the connecting reinforcing bars 5 one by one, and the diameter of the tunnel is 2-5 cm larger than the prestressing tendons 4 and the connecting reinforcing bars 5, which is convenient for the latter to penetrate. During prefabrication, part of the prestressed tendons 4 and connecting steel bars 5 are pre-embedded in the prefabricated pier column 1, and a part protrudes from...

Embodiment 2

[0069] Embodiment two: if Figure 6-7 As shown, it is suitable for span-line frame bridge piers and consists of two prefabricated pier columns and a prefabricated top hat. There are two identical connection structures between the prefabricated pier columns and the prefabricated top hat. The specific implementation process is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com