Prefabricated continuous box girder bridge with saddle shell bottom and its construction method

A prefabricated and saddle technology, which is applied in erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of difficult tension and anchorage of prestressed steel bars in the lower part, large consumption of wooden formwork, and large workload of concrete, so as to achieve assembly and construction The effect of fast speed, no support construction, and convenient anchor construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

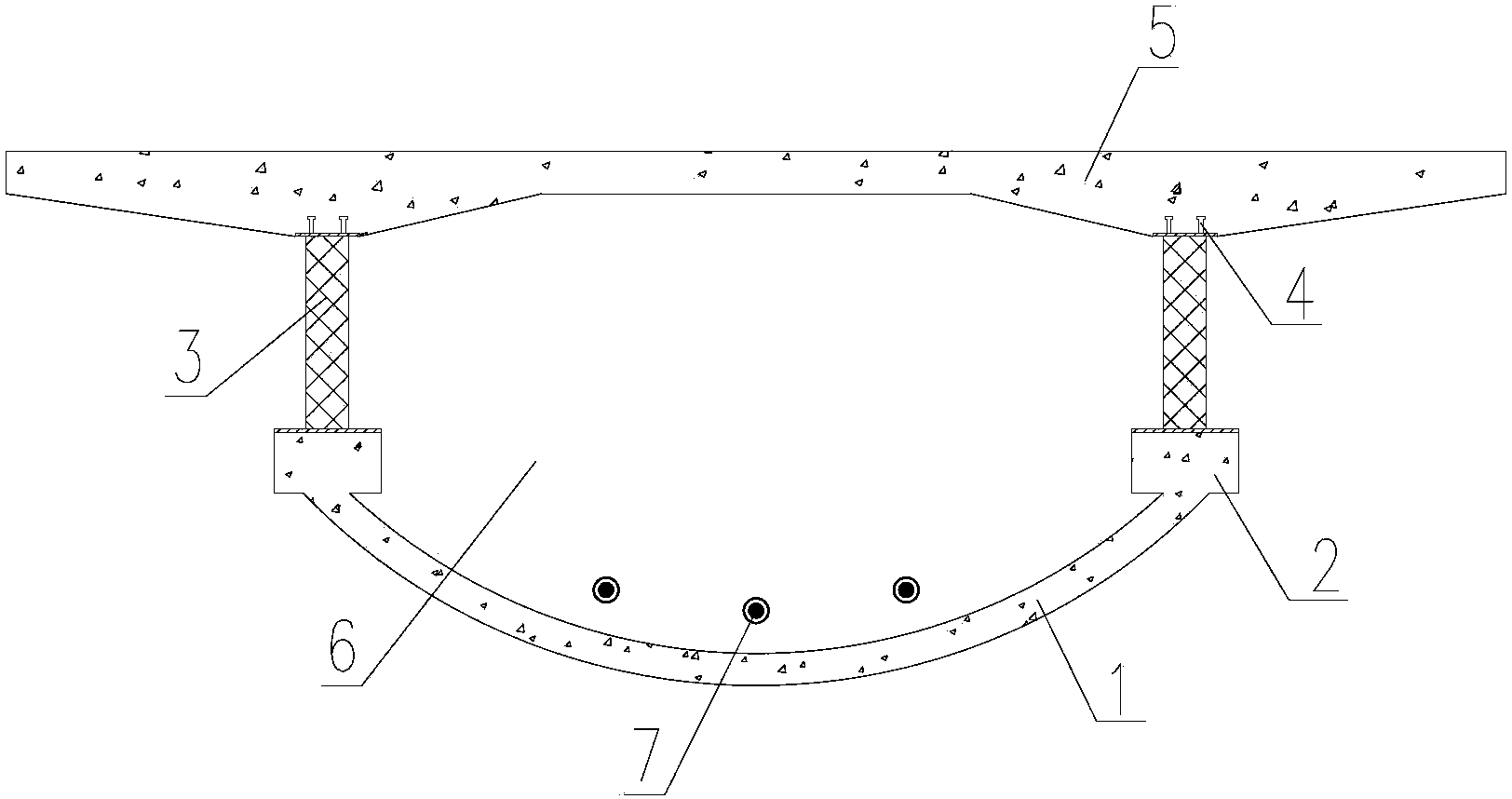

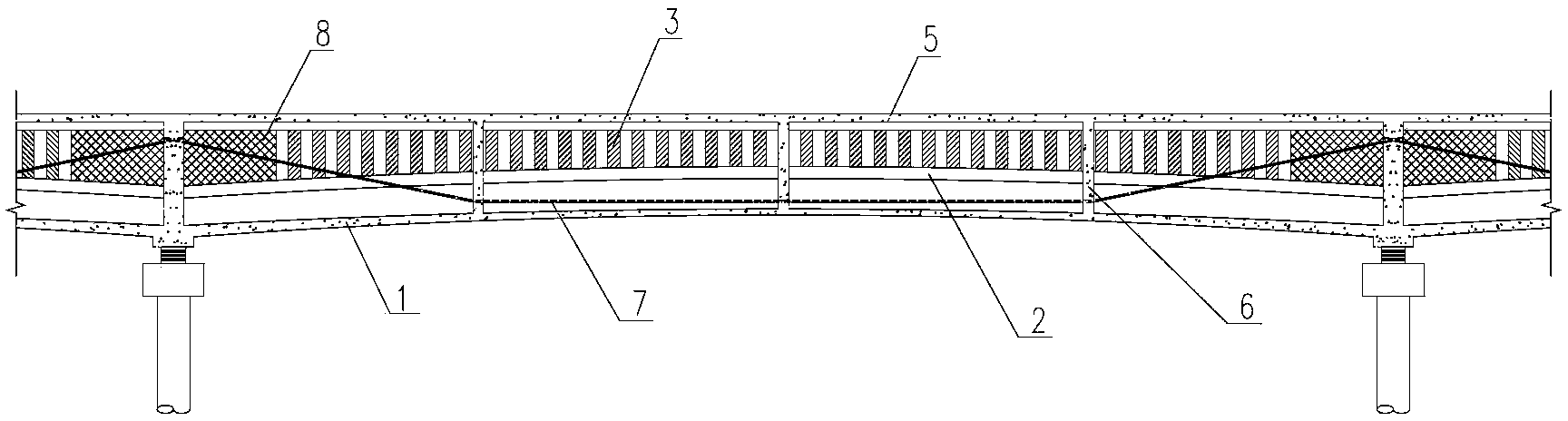

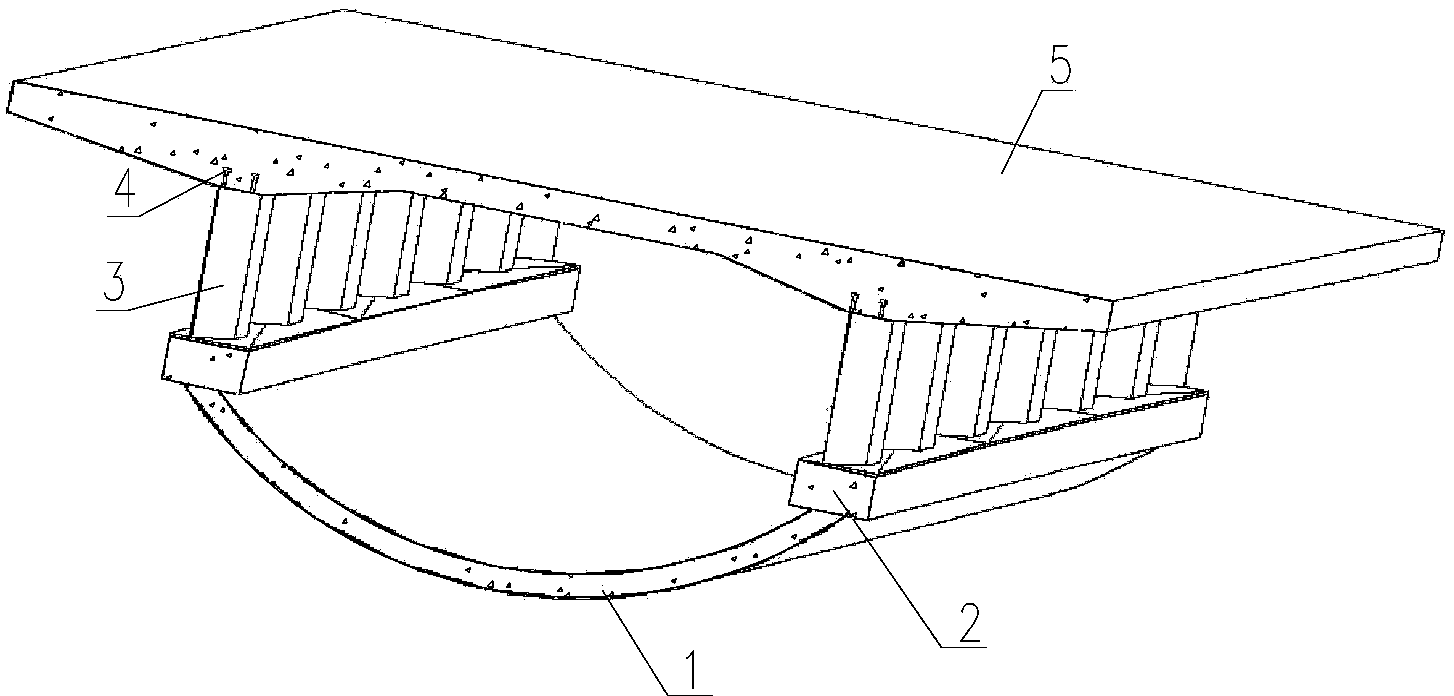

[0035] The assembled saddle shell-shaped bottom plate continuous box girder bridge of the present invention consists of a saddle shell-shaped plate 1, a top ring beam 2, a corrugated steel web 3, a column stud 4, a prestressed concrete top plate 5, a concrete diaphragm 6, and an in vitro The prestressed tendons 7 and the zero segment 8 of the concrete box girder are formed. The saddle shell bottom plate 1 is a prefabricated pre-tensioned high-efficiency prestressed concrete saddle shell plate. The upper sides of the saddle shell bottom plate 1 are respectively connected to a top ring beam 2 at both ends in the transverse direction, and are used as the bottom plate member of the continuous box girder bridge. A corrugated steel web 3 is arranged between the top of the crimping ring beam 2 and the prestressed concrete roof 5, the lower end of the corrugated steel web 3 is connected to the top of the crimping ring beam 2, and the upper end is connected to the prestressed concrete r...

Embodiment 2

[0037] A method for building a continuous box girder bridge with an assembled saddle shell-shaped bottom plate, comprising the following steps:

[0038] The first step is to pour concrete piers on site, install the pot bearings of the continuous box girder bridge, hoist the factory-fabricated saddle shell-shaped bottom plate 1 with topping ring beams 2 to the pier, and use several steel brackets to temporarily support the saddle shell Shaped bottom plate 1, the reserved reinforcement at the end of saddle shell shaped bottom plate 1 at the welding connection support, pouring concrete at the joint;

[0039] The second step is to hoist the corrugated steel web 3 into place, firmly weld the lower ends of the left and right corrugated steel webs 3 to the pre-embedded steel plate on the top of the top ring beam 2, and firmly weld the double row of columnar studs 4 to the corrugated steel web On the top surface of the upper flange of 3, a temporary transverse steel support is install...

Embodiment 3

[0044] A rail transit viaduct is composed of multiple continuous girder viaducts with seven spans and one connection. It adopts a prestressed concrete continuous girder structure of 7 spans × 30 meters. The box girder adopts a single-box single-chamber cross-section. , using the fabrication method of continuous box girder bridge with saddle shell bottom plate. The width of the box girder floor is 4 meters, the width of the bridge deck is 7 meters, the beam height is 2.5 meters, and the vehicle load is road-I class. The pre-tensioned prestressed concrete saddle slab is selected as the bottom plate of the box girder. The prefabricated saddle slab is poured with C60 concrete. The thickness of the middle plate is 150mm, the thickness of the plate at the support is 350mm, the height of the parabola of the shell plate is 400mm, and 36 7φ5 steel strands are arranged inside. The cross-section of the saddle plate topping ring beam is rectangular, with a section of 300×500mm. The toppi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com