Process for lengthening long anchor bar pile on high slope

A technology for anchor-reinforced piles and slopes, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as difficulty in guaranteeing construction quality, lack of standardized methods for lengthening anchor-reinforced piles, and prominent construction safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of technology of high slope long anchor reinforcement pile lengthening is as follows:

[0020] 1) First use CM351 high wind pressure down-the-hole drilling rig to drill the anchor piles, use the surveying and mapping total station to arrange the hole positions, and correct the deviation in time during the drilling stage. The deviation angle does not exceed 3°;

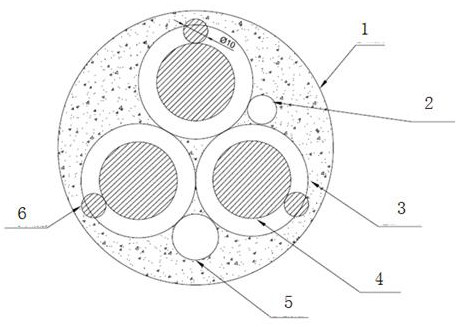

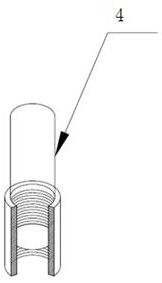

[0021] 2) Prefabricate the B32 steel bar 4 with a length of 3m with a steel bar cutting machine, tap the end of the steel bar with a straight thread rolling machine to process it into a steel bar with wires, and use the national standard B32 straight thread sleeve for the straight thread sleeve 3;

[0022] 3) Assembly: Bind and connect 3 B32 steel bars with wires and 3 A10 centering steel bars 6 to form an equilateral triangle (the position of the steel bars is fixed), and tie a grout return pipe 2 on the right side of the wire steel bars , the lower side is tied with a grout pipe 5 to form the overall s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com