Combined box girder and processing method thereof

A processing method and technology of box beams, which are applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., to achieve the effects of cost reduction, high degree of industrialization, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

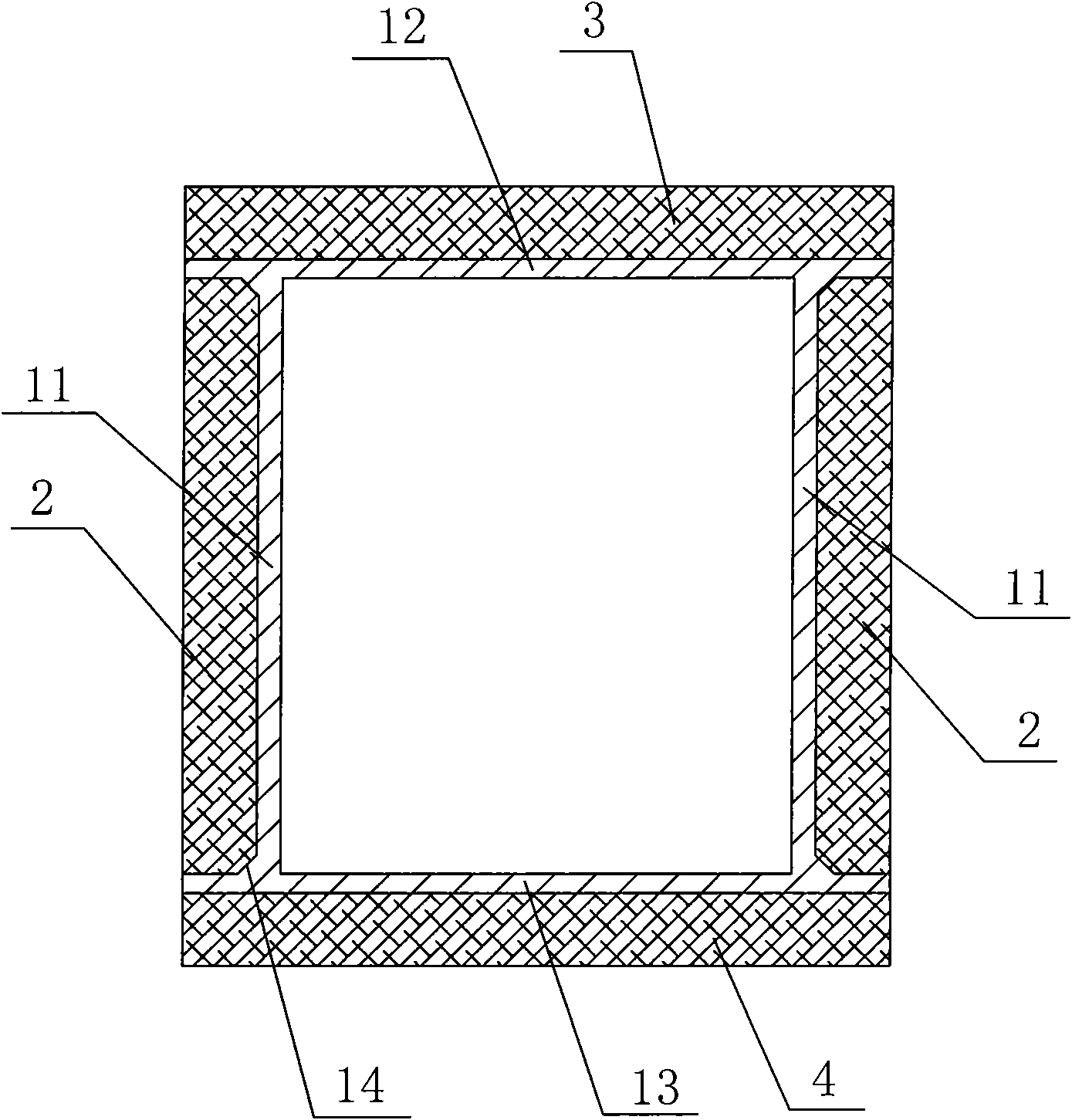

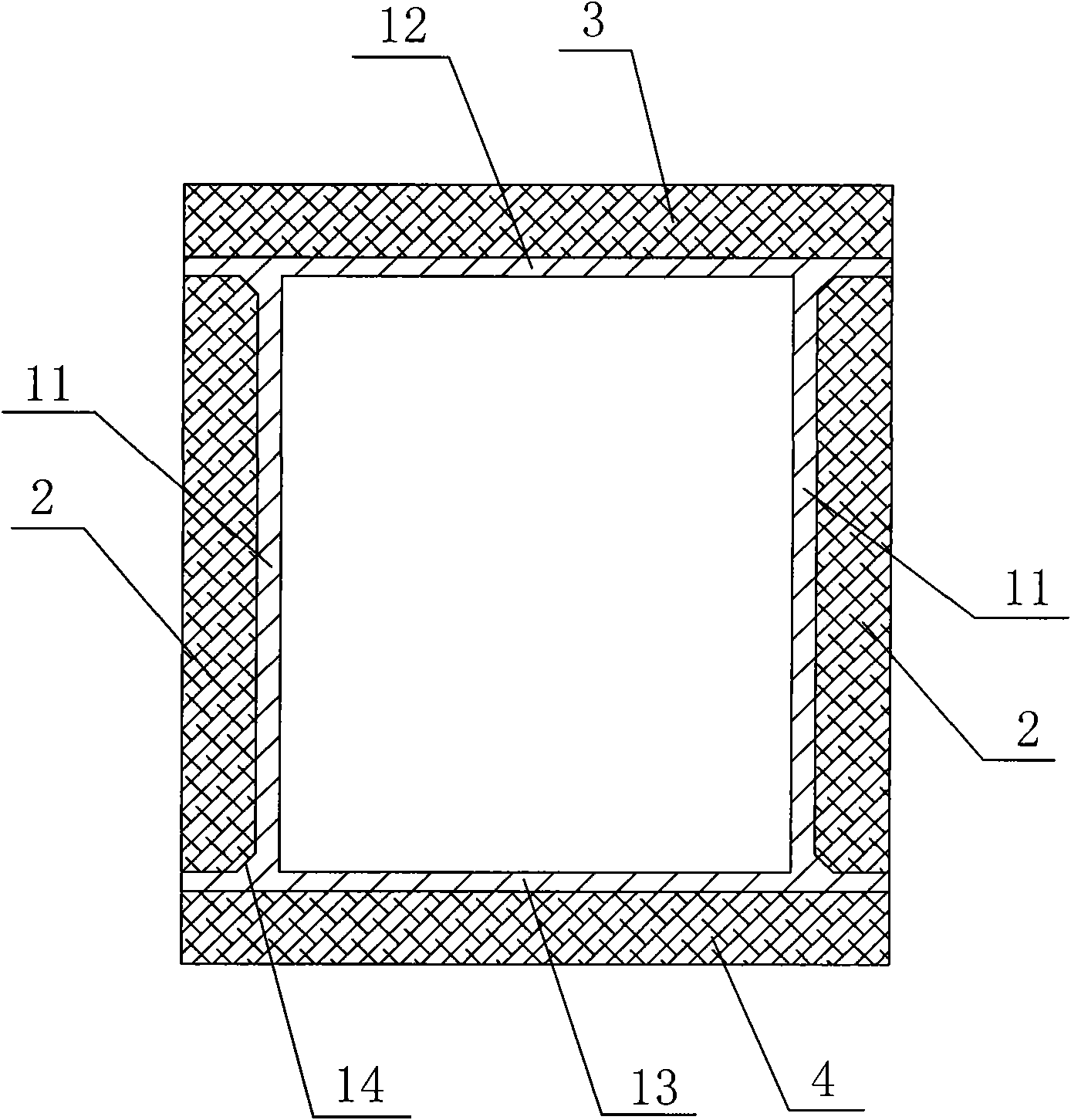

[0020] A method for processing the above composite box girder, it comprises the following steps:

[0021] (1), process the box-shaped steel frame by hot rolling, cold bending, cold rolling or steel plate welding;

[0022] (2) Use a steel wire brush to remove floating rust on the surface of the steel frame, and then use a flat grinding wheel to polish the grooves until the surface of the steel frame has a metallic luster, and wipe the surface of the steel frame with absorbent cotton dipped in acetone;

[0023] (3), get the first bamboo board 2 whose size matches the web 11 of the steel frame, the second bamboo board 3 whose size matches the upper flange 12 of the steel frame, the first bamboo board 3 whose size matches the lower flange 13 of the steel frame Three bamboo boards 4, its paste surface is polished with sandpaper, and its surface is scrubbed clean with acetone;

[0024] (4), adhesive is smeared on the outer side of steel frame web 11 evenly, then the first bamboo bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com