Preparation method of silicon dioxide/graphene modified rubber composite material

A graphene modification, silica technology, applied in the direction of rolling resistance optimization, transportation and packaging, special tires, etc., can solve the problem of antistatic, no significant improvement in thermal conductivity, inability to improve various properties of rubber, self-polymerization compounds Expensive and other problems, to achieve the effect of increasing mechanical properties, avoiding water pollution problems, and reducing mixing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

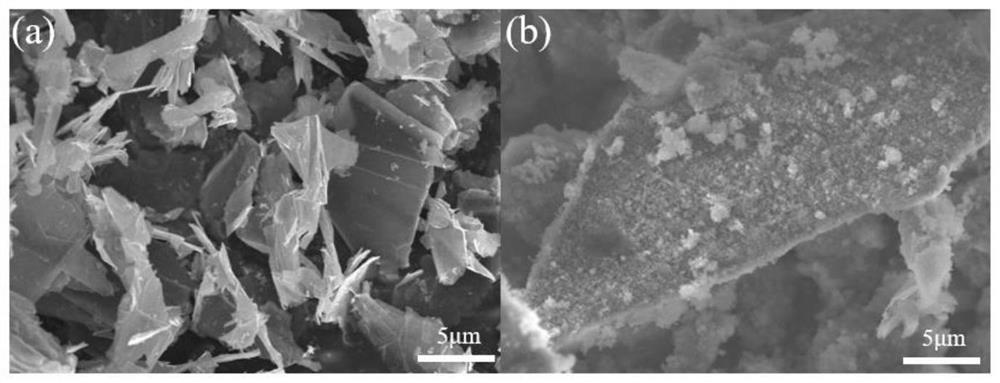

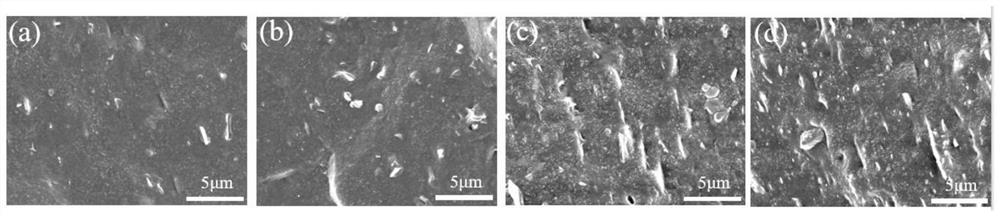

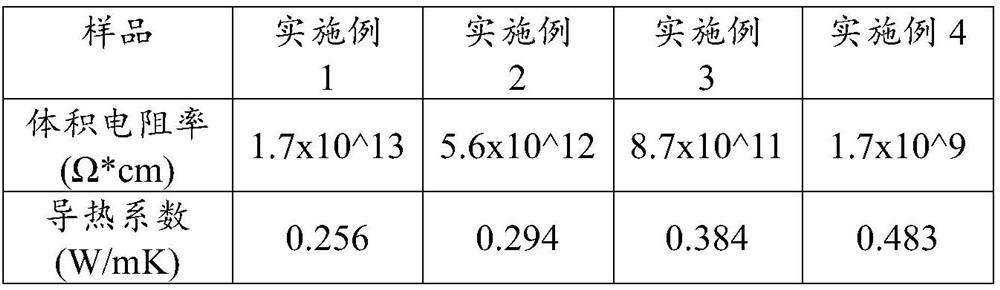

[0041] with graphene dry powder (see figure 1 The content of (a) is 100 phr, take graphene dry powder, 5 phr ethanol, 2 phr polyvinylpyrrolidone, add 3900 phr distilled water, ultrasonically stir for 3 h, perform suction filtration, wash multiple times, and dry to obtain surface-modified polyvinylpyrrolidone. Functionalized graphene, i.e. powdered hydrophilic graphene;

[0042] Based on the functionalized graphene dry powder content of 12 phr, take 1278 phr sodium silicate (n=3.2) and 1566 phr distilled water, heat up to 68 ° C, and stir for 20 min to obtain a graphene-sodium silicate aqueous solution; stir at a rotating speed of 600 rad / min , slowly add dilute sulfuric acid solution (wt = 20%) dropwise to the graphene-sodium silicate aqueous solution until the pH of the solution = 8-9, then heat up to 80 ° C for 3 h, and then slowly add 72phr modifier ( γ-glycidyl ether oxypropyltrimethoxysilane: ethanol=1:1), after the modifier is completely added, the constant temperature ...

Embodiment 2

[0047] Based on the graphene dry powder content of 100 phr, take graphene dry powder, 5 phr ethanol, and 2 phr polyvinylpyrrolidone, add them to 3900 phr distilled water, ultrasonically stir for 3 hours, suction filter, wash multiple times, and dry to obtain the surface modified with polyvinylpyrrolidone. Graphene, namely powdered hydrophilic graphene;

[0048] Based on the functionalized graphene dry powder content of 12 phr, and taking 639 phr of sodium silicate (n=3.2) and 783 phr of distilled water, the temperature was raised to 70 ° C, and after stirring for 20 min, the graphene-sodium silicate aqueous solution was obtained; under the rotating speed of 600 rad / min Stir, slowly add dilute sulfuric acid solution (wt = 20%) to the graphene-sodium silicate aqueous solution until the pH of the solution = 8-10, then heat up to 80 ° C for 3 hours, and then slowly add 36phr modifier to the reaction system (γ-glycidyl ether oxypropyltrimethoxysilane: ethanol=1:1), after the modifi...

Embodiment 3

[0052] Based on the graphene dry powder content of 100 phr, take 5 phr of ethanol and 2 phr of polyvinyl pyrrolidone, add them into 3900 phr of distilled water, and after ultrasonic stirring for 3 hours, suction filtration, multiple washings, and drying to obtain the surface-modified functionalized graphene with polyvinyl pyrrolidone, That is, powdered hydrophilic graphene;

[0053] Based on the content of functionalized graphene dry powder of 12 phr, take 319.5 phr sodium silicate (n=3.2) and 391.5 phr distilled water, heat up to 69 ° C, and stir for 20 min to obtain a graphene-sodium silicate aqueous solution; at a rotating speed of 600 rad / min Under stirring, dilute sulfuric acid solution (wt = 20%) was slowly added dropwise to the graphene-sodium silicate aqueous solution until the pH of the solution = 8-10, then the temperature was raised to 80 °C for 3 h, and then 18phr was slowly added to the reaction system for modification agent (γ-glycidyl ether oxypropyltrimethoxysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com