Rubber mixing method, rubber compound and application

A technology of rubber mixing and rubber mixing, which is applied in the field of rubber mixing, which can solve problems such as tire damage and increased heat generation of components, and achieve the effects of prolonging service life, reducing rolling resistance, and reducing energy consumption for mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

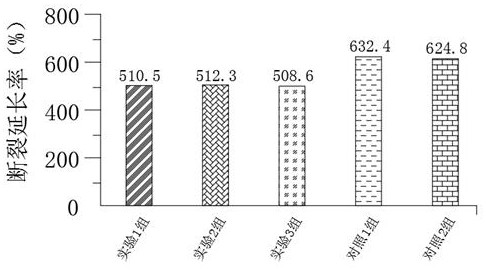

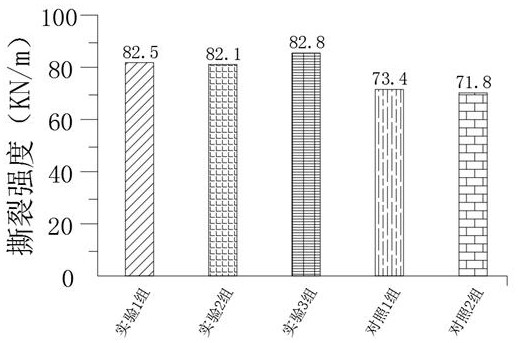

Examples

Embodiment 1

[0041] The invention provides a kind of rubber mixing method, comprises the following steps:

[0042] (1) Mastication: Weigh natural rubber and environment-friendly peptizer and place them in an open mill for plastication to obtain natural plasticized rubber.

[0043] (2) One-stage mixing: put natural plastic rubber and rare earth butadiene rubber into the internal mixer, and under the condition of the speed of internal mixer at 50rpm, mix the rubber to 140°C and lift the top bolt floating weight for 90s, and then put it into Mo The stone fiber, white carbon black, silane coupling agent and 2 / 3 of the carbon black are in the internal mixer, under the condition of the internal mixer speed of 60rpm, and under the condition of 150°C, lift the top bolt to float After 80 seconds, adjust the speed of the internal mixer to 60rpm and lower it to 130°C for mixing. After the mixed material is unloaded, pressed into tablets and cooled, it is crushed and sieved to obtain a section of mixe...

Embodiment 2

[0055] A kind of rubber mixing method, rubber compound and application provided in this embodiment are roughly the same as in Example 1, the main difference being:

[0056] Including the following raw materials by weight: 60 parts of natural rubber, 2 parts of environmental peptizer, 40 parts of rare earth butadiene rubber containing nearly 98% cis-1,4 structure content, 22 parts of white carbon black, silane coupling agent 2.4 parts, 35 parts of carbon black, 7 parts of active agent, 2 parts of microcrystalline wax, 2 parts of anti-aging agent 6PPD, 2 parts of anti-aging agent TMQ, 1 part of microcrystalline paraffin, 2 parts of insoluble sulfur, 3 parts of mullite fiber, aromatic 4 parts of fiber staple, 1.8 parts of accelerator TBBS, 1 part of accelerator DPG, 0.1 part of anti-scorch agent CTP;

[0057] The silane coupling agent is vinyltrimethoxysilane;

[0058] In step (2), put the natural plasticized rubber and rare earth butadiene rubber into the internal mixer, and un...

Embodiment 3

[0065] A kind of rubber mixing method, rubber compound and application provided in this embodiment are roughly the same as in Example 1, the main difference being:

[0066] Including the following raw materials in parts by weight: 80 parts of natural rubber, 3 parts of environmentally friendly peptizer, 60 parts of rare earth butadiene rubber containing nearly 98% cis-1,4 structure content, 30 parts of white carbon black, silane coupling agent 3 parts, 40 parts of carbon black, 10 parts of active agent, 2 parts of microcrystalline wax, 2 parts of anti-aging agent 6PPD, 2 parts of anti-aging agent TMQ, 1.5 parts of microcrystalline paraffin, 2.2 parts of insoluble sulfur, 4 parts of mullite fiber, aromatic 6 parts of fiber staple, 2.2 parts of accelerator TBBS, 1.5 parts of accelerator DPG, 0.2 parts of anti-scorch agent CTP;

[0067] The silane coupling agent is vinyltrisilane;

[0068] In step (2), put the natural plasticized rubber and rare earth butadiene rubber into the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com