Patents

Literature

38results about How to "Low compression heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

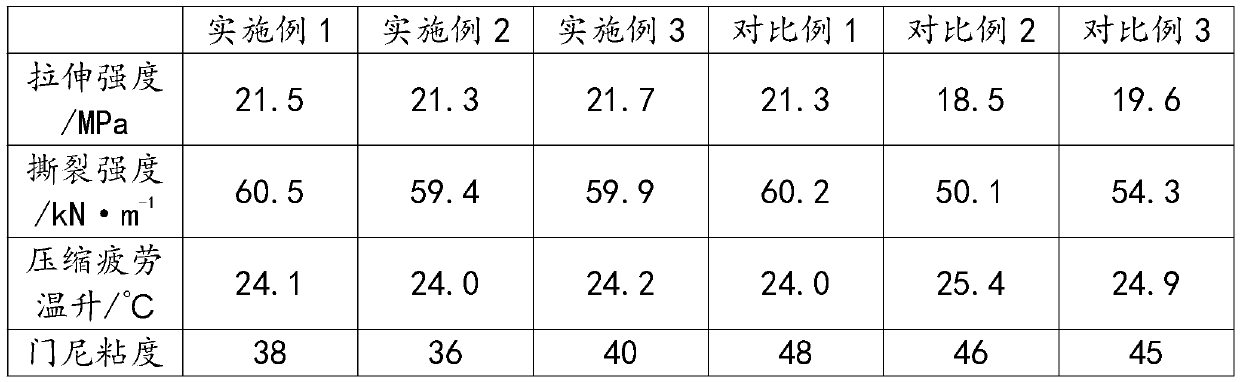

Rubber anti-recovery agent and preparation thereof

The invention discloses a rubber anti-sulfuration recovery agent, which comprises the following components according to the percentage by weight: 50-55% of zinc fatty acid, 23-28% of aromatic acid zinc, 17-22% of poly zinc carbonate with branched chains. The invention also discloses a preparation method for poly zinc carbonate. The invention discloses a preparation method for the rubber anti-sulfuration recovery agent. The rubber anti-sulfuration recovery agent not only has anti-sulfuration recovery function on vulcanized rubber, but also can reduce the Mooney viscosity of gross rubber, improves the sizing processing performance and can reduce dynamic heat build-up of tread rubber of tyre. The preparation method of the rubber anti-sulfuration recovery agent is different from other simple mixed methods adopted for preparing general multicomponent mixtures. The rubber anti-sulfuration recovery agent is prepared by using the method that organic acid and zinc oxide directly reacts; and the reaction process has no pollution.

Owner:JIANGSU KAOU CHEM

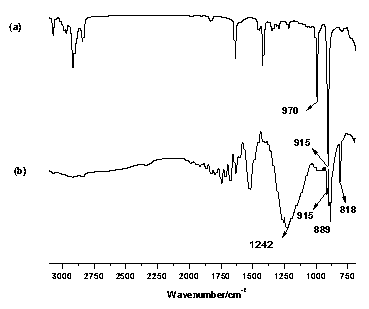

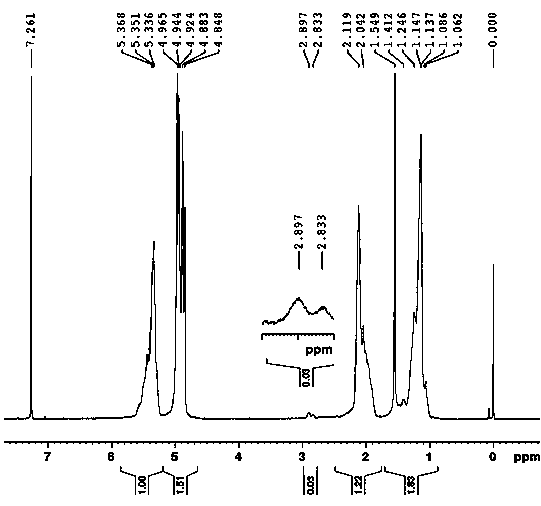

Preparation method of epoxidized 1, 2-polybutadiene

The invention relates to a preparation method of a polymeric material, in particular to a preparation method of epoxidized 1, 2-polybutadiene. Preparation steps of the preparation method are as follows: composition A and composition B are added to a reaction flask and stirred by magnetic force at the temperature of 65 DEG C until the composition A is dissolved; composition C and composition D are added to the reaction flask and stirred fully and uniformly; quantitative composition E is added to a system and reacted for a period at the constant temperature; after the reaction is finished, a product is poured out; absolute ethyl alcohol is added for precipitating a solid, sedimentation is performed for a period, suction filtration is performed, and a sodium bicarbonate solution and distilled water are used for washing a product solid for a plurality of times respectively; and the washed product solid is put into an oven for vacuum drying for 12 h at the temperature of 60 DEG C, and a product is obtained. The invention provides a synthesis method for epoxidizing 1, 2-polybutadiene. The prepared epoxidized 1, 2-polybutadiene can be used for toughening modification of other high polymer materials (such as nylon, epoxy resin and the like).

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Rubber composition with low compression heat and small rolling resistance

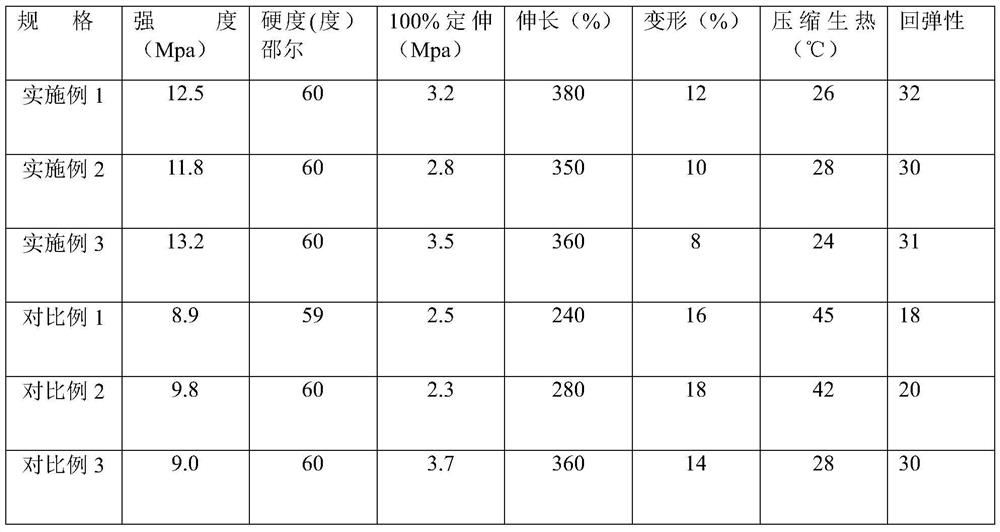

ActiveCN102675701AImproved mixing and extrusion processabilityLow compression heatSilane couplingButadiene-styrene rubber

A rubber composition with low compression heat and small rolling resistance is prepared by taking synthetic rubber as a raw material and carbon black or white carbon black as a reinforcing agent sequentially carrying out plastication, mixing and vulcanization processes of rubber. In the mixing process of the rubber, silicon carbide micro powder is adopted to replace part of reinforcing agent and a silane coupling agent is added; 100 parts by weight of rubber raw material, 45-70 parts by weight of carbon black or white carbon black, 5-50 parts of silicon carbide micro powder and 0.4-2.45 parts of silane coupling agent are added in the mixing process of the rubber; and the synthetic rubber is butadiene styrene rubber of which the content of bound styrene is 15-50 percent and the Mooney viscosity is 30-90. The processing performances of mixed rubber are improved; the compression heat of vulcanized rubber is reduced, the rolling resistance is remarkably reduced and the wet sliding resistance is improved.

Owner:PINGDINGSHAN YICHENG NEW MATERIAL

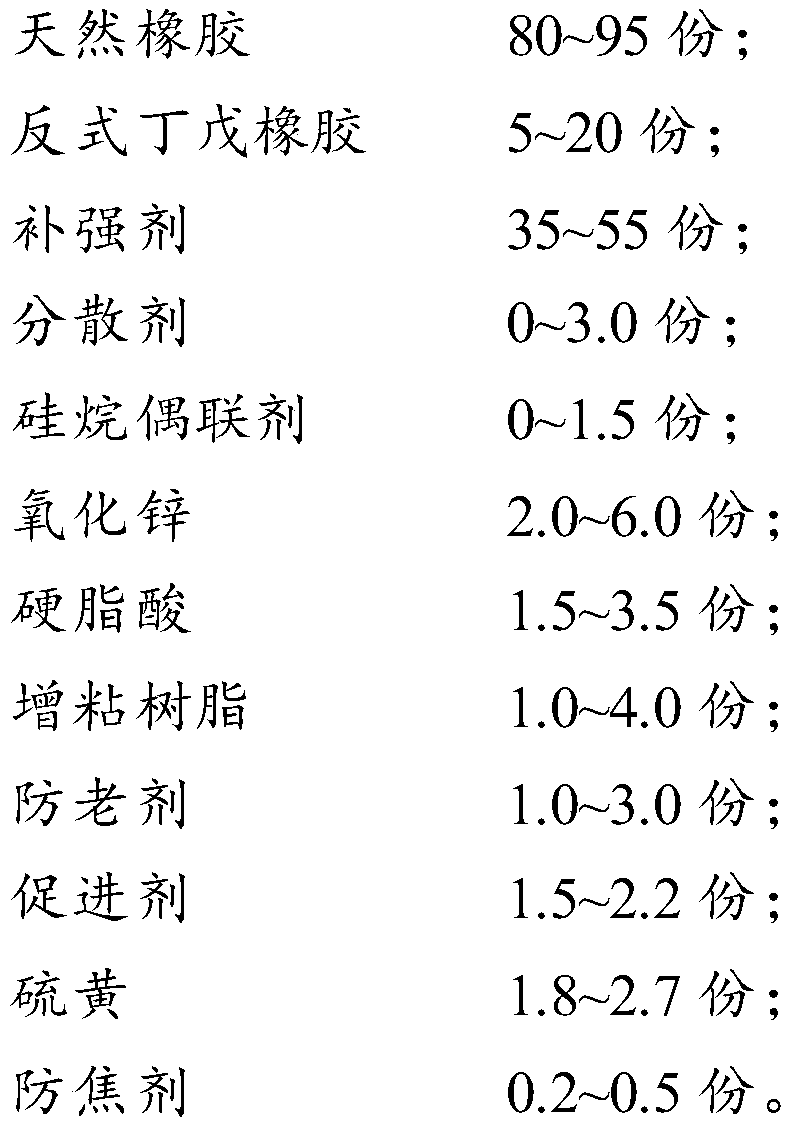

All-steel radial tire shoulder wedge and preparation method thereof

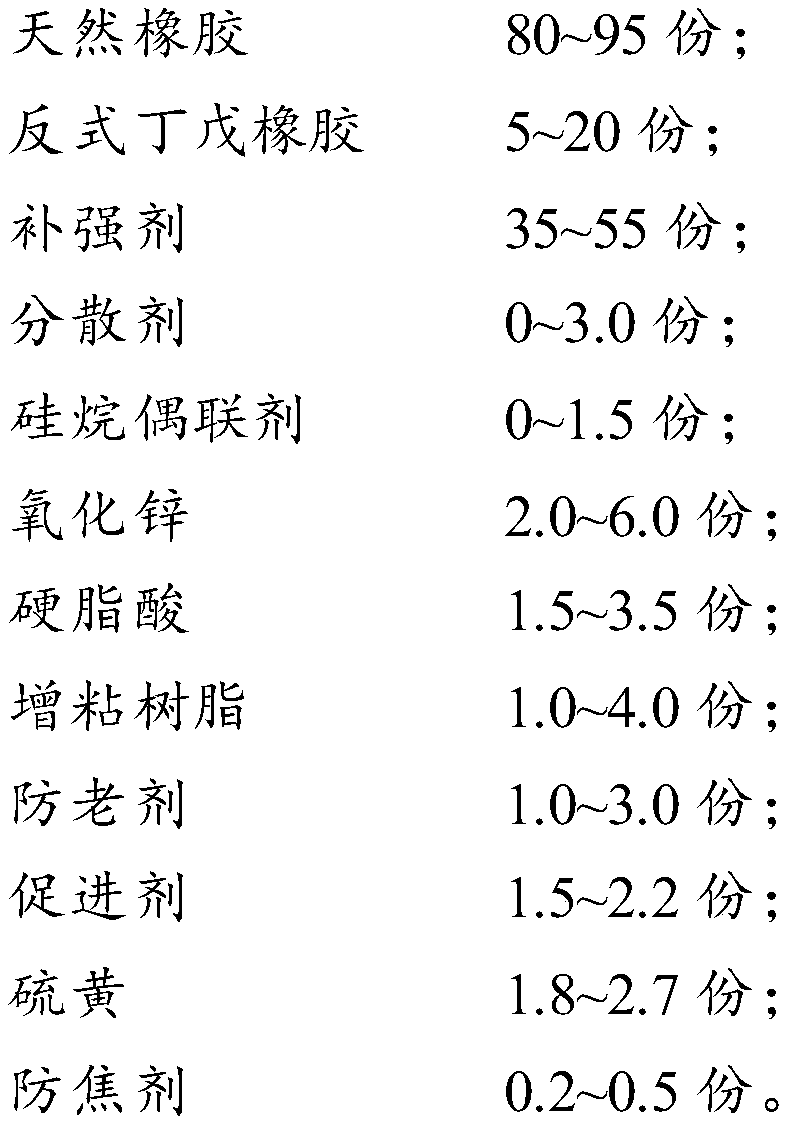

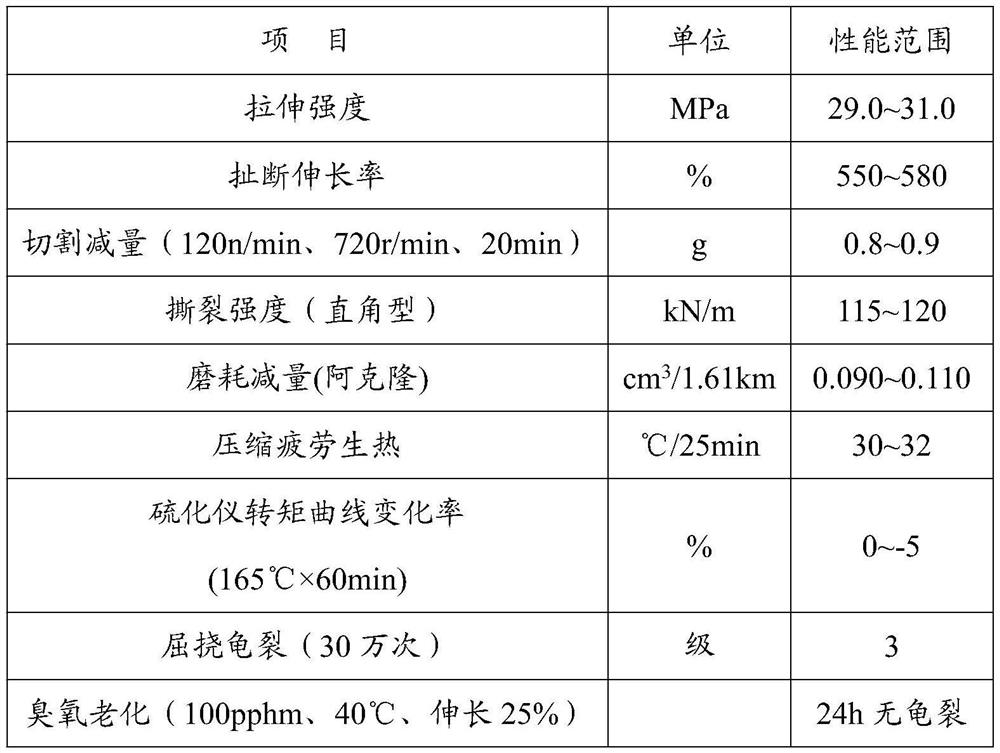

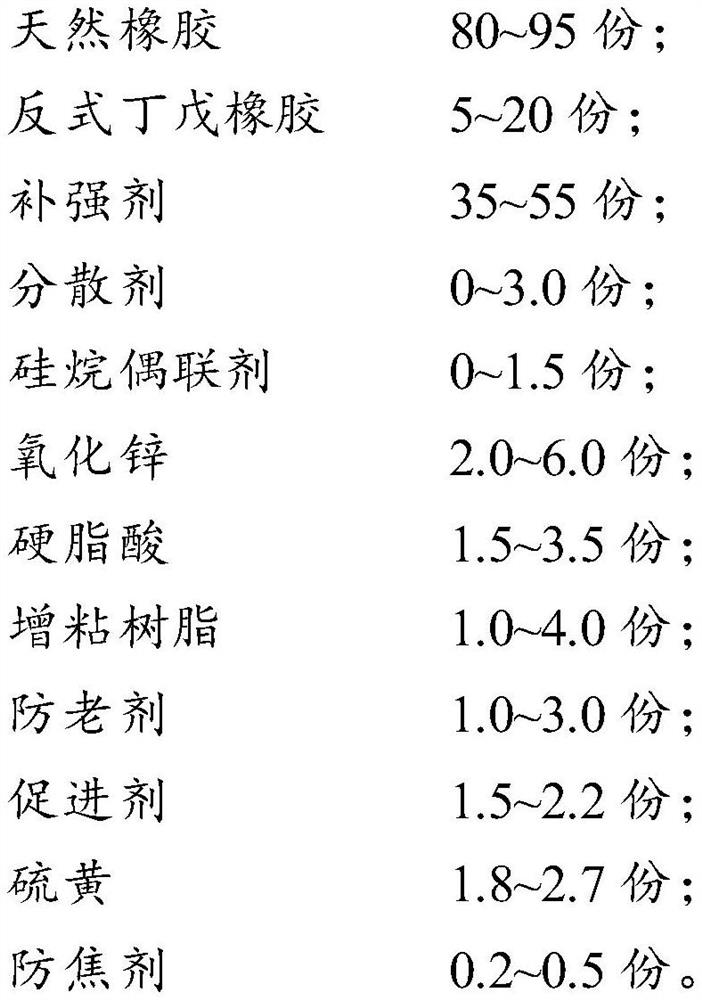

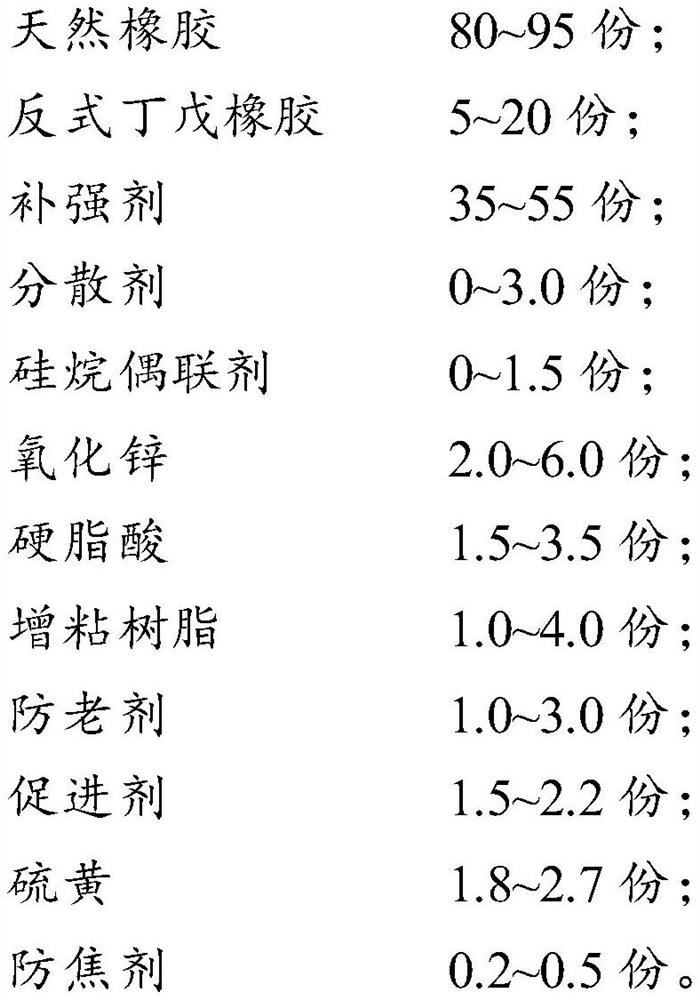

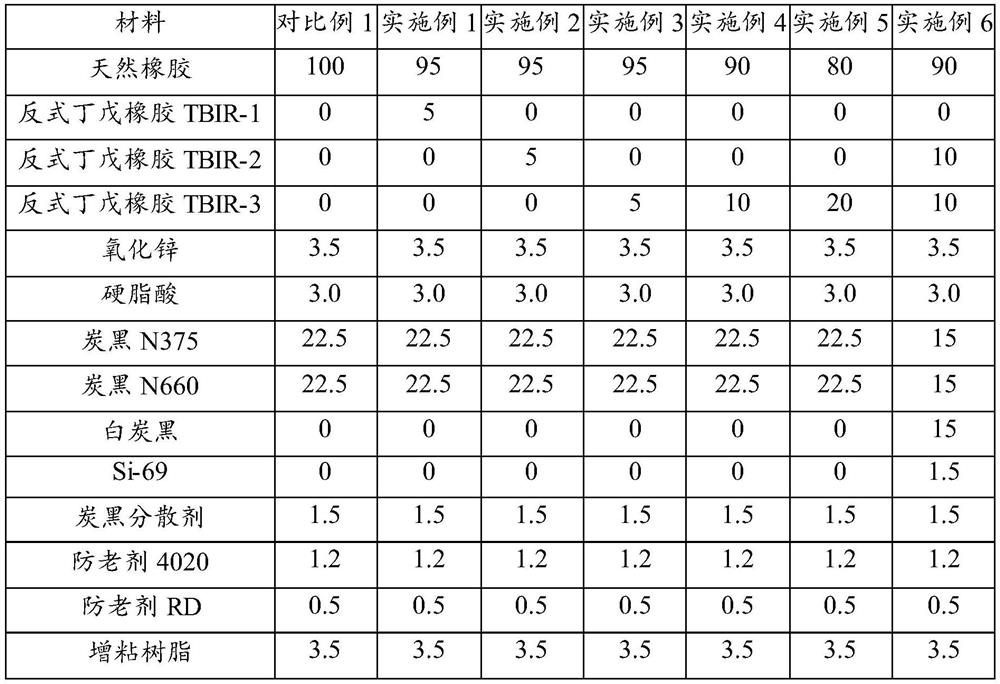

The invention provides an all-steel radial tire shoulder wedge and a preparation method thereof. The all-steel radial tire shoulder wedge provided by the invention is prepared from the following raw materials in parts by mass: 80-95 parts of natural rubber, 5-20 parts of trans-butadiene-isoprene rubber, 35-55 parts of a reinforcing agent, 0-3.0 parts of a dispersant, 0-1.5 parts of a silane coupling agent, 2.0-6.0 parts of zinc oxide, 1.5-3.5 parts of stearic acid, 1.0-4.0 parts of tackifying resin, 1.0-3.0 parts of an anti-aging agent, 1.5-2.2 parts of an accelerant, 1.8-2.7 parts of sulfur,and 0.2-0.5 part of an anti-scorching agent. According to the all-steel radial tire shoulder wedge provided by the invention, on the basis that good vulcanization characteristics and basic physical and mechanical properties of the tire shoulder wedge are ensured, the fatigue resistance can be improved, and the rolling resistance and compression heat generation can be reduced.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

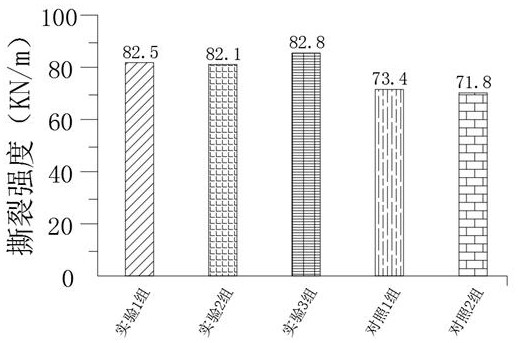

Aircraft tire tread rubber as well as preparation method and application thereof

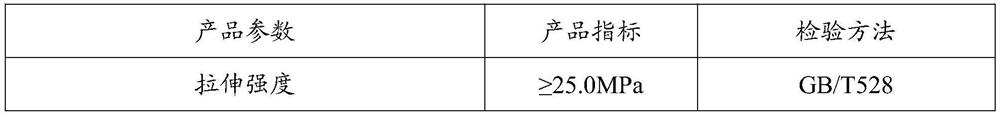

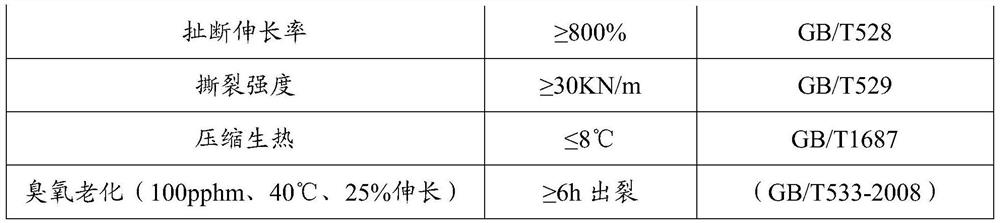

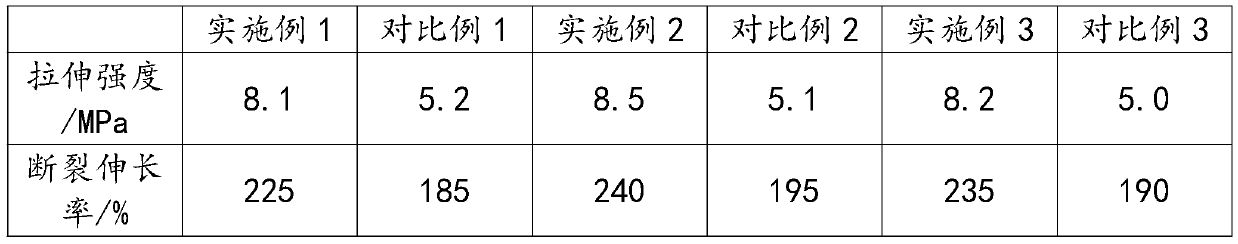

The invention relates to the technical field of aircraft tires, in particular to aircraft tire tread rubber as well as a preparation method and application thereof. The aircraft tire tread rubber is prepared from the following preparation raw materials in parts by mass: 88-92 parts of natural rubber, 46-50 parts of medium-super wear-resistant carbon black, 12-18 parts of white carbon black wet rubber, 2-3 parts of a silane coupling agent, 1-2 parts of a heat stabilizer, 0.5-1 part of an anti-reversion agent, 1-3 parts of a multifunctional vulcanization activator, 1.5-2.0 parts of tear-resistant resin, 3-5 parts of zinc oxide, 2-5 parts of an anti-aging agent, 2.1-2.3 parts of insoluble sulfur, 1.0-1.1 parts of an accelerator and 1-2 parts of multiwalled carbon nanotubes. The tread rubber provided by the invention has the advantages of low compression heat generation, high tearing strength, good cutting resistance, good wear resistance, good flexing and cracking resistance, good ozone aging resistance, good thermal stability, high tensile strength, high elongation at break and the like, and can be used for aircraft tires.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Bicycle tire tread rubber

InactiveCN104292514ASmall deformabilityLight in massSpecial tyresRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of tires, and discloses a bicycle tire tread rubber which comprises the following raw materials in parts by weight: 80-90 parts of natural rubber, 10-20 parts of cis-1,4-polybutadiene rubber, 15-30 parts of plasticizer, 25-58 parts of silica white, 1-10 parts of vulcanizing agent, 1-20 parts of accelerator, 1-9 parts of zinc oxide, 0.1-2 parts of calcium carbonate, 1-10 parts of reinforcing agent cb, 0.1-2 parts of stearic acid, 2-5 parts of anti-aging agent aw, 2-5 parts of anti-aging agent 4010, 1-2 parts of paraffin and 1-10 parts of silane coupling agent. The bicycle tire tread rubber has the advantages of tear resistance, fatigue resistance, heat resistance, abrasion resistance, aging resistance, small deformability, light weight, favorable water absorptivity, long service life, low compressive heat generation and dynamic heat generation, small permanent deformation, favorable anti-slip property and small rolling resistance, and can well absorb shock load.

Owner:MINGGUANG RUITAI IND

Rubber composition with low calorification and low rolling resistance

ActiveCN102675695AEasy to processLow compression heatRolling resistance optimizationRubber materialRolling resistance

The invention discloses a rubber composition with low calorification and low rolling resistance. The rubber composition is prepared by successively carrying out plastification, mixing and vulcanization on rubber based on natural rubber as a rubber raw material and carbon black or white carbon black as a reinforcing agent; in the mixing process of the rubber, silicon carbide micropowder is adopted to replace partial reinforcing agent, a silane coupling agent is added, and the added amounts of the rubber material, the reinforcing agent, the silicon carbide micropowder and the silane coupling agent in the mixing process of the rubber are as follows in parts by weight: 100 part of rubber material, 20-45 parts of carbon black or white carbon black, 5-50 parts of silicon carbide micropowder and 0.4-2.45 parts of silane coupling agent; the silicon carbide micropowder is in an alpha or beta crystal form, and the particle diameter of the silicon carbide micropowder is 0..001mu m-50mu m. According to the invention, the processing performance of the mixed rubber is improved, the compression calorification of vulcanized rubber is reduced, the rolling resistance is obviously reduced, and the slip-wet resistance is improved.

Owner:PINGDINGSHAN YICHENG NEW MATERIAL

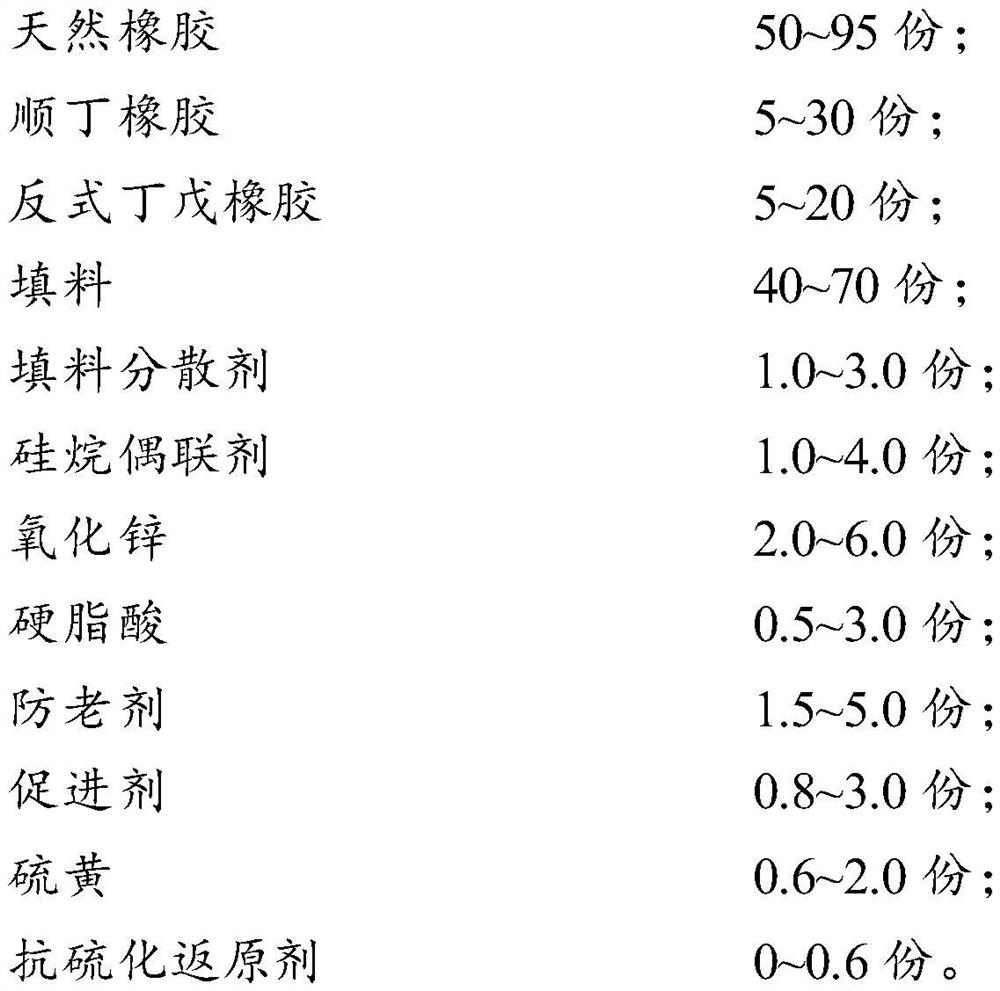

Tread rubber for tire and preparation method thereof

ActiveCN110358156AExcellent wet skid resistanceExcellent abrasion resistanceSpecial tyresRolling resistance optimizationRolling resistancePolymer science

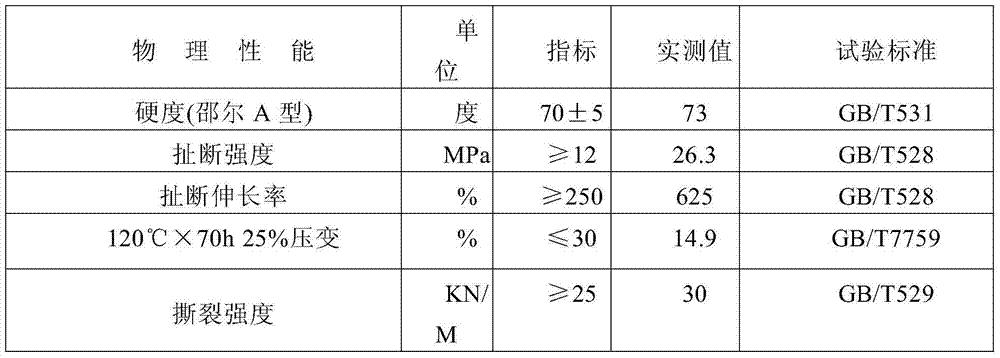

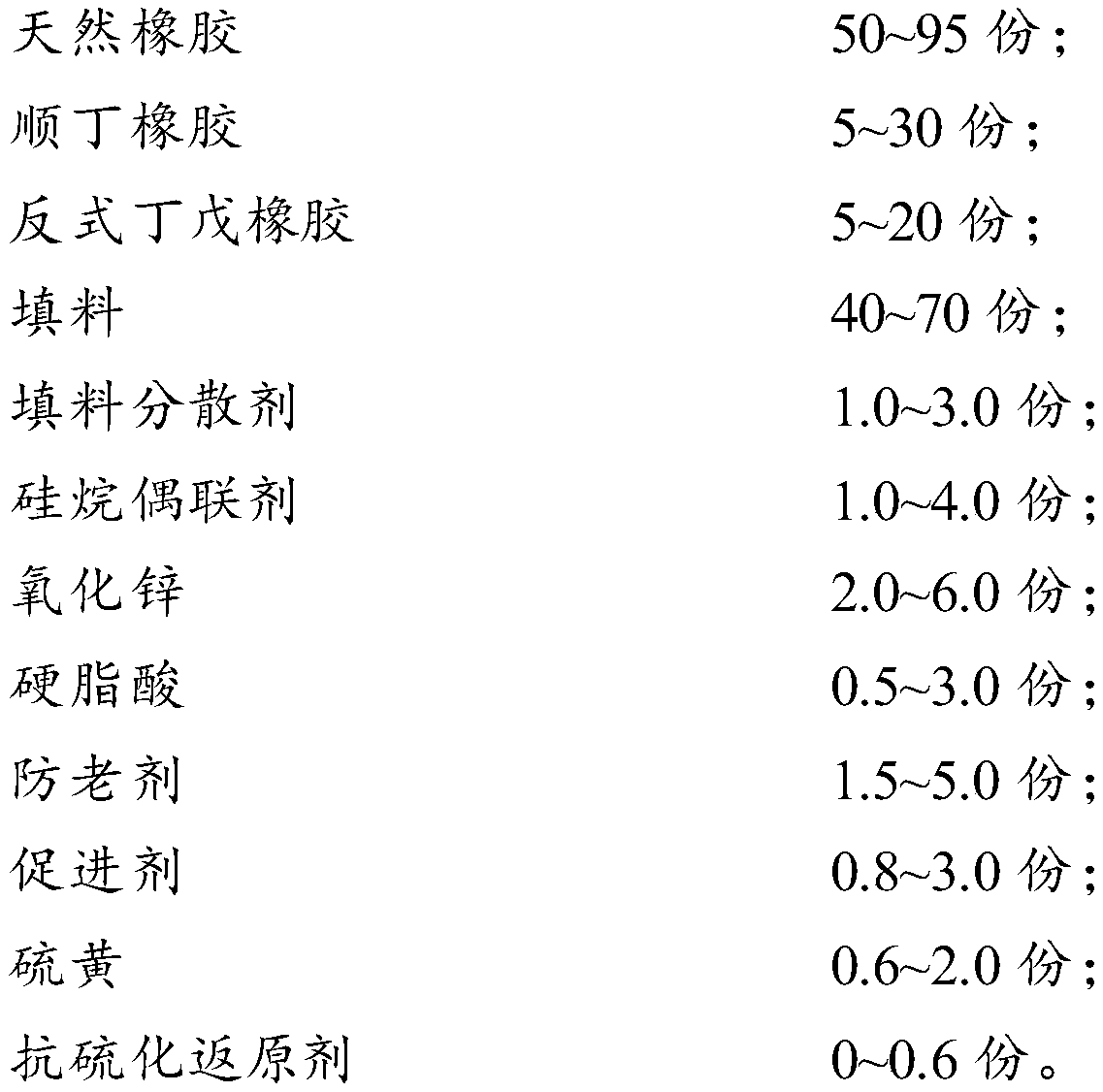

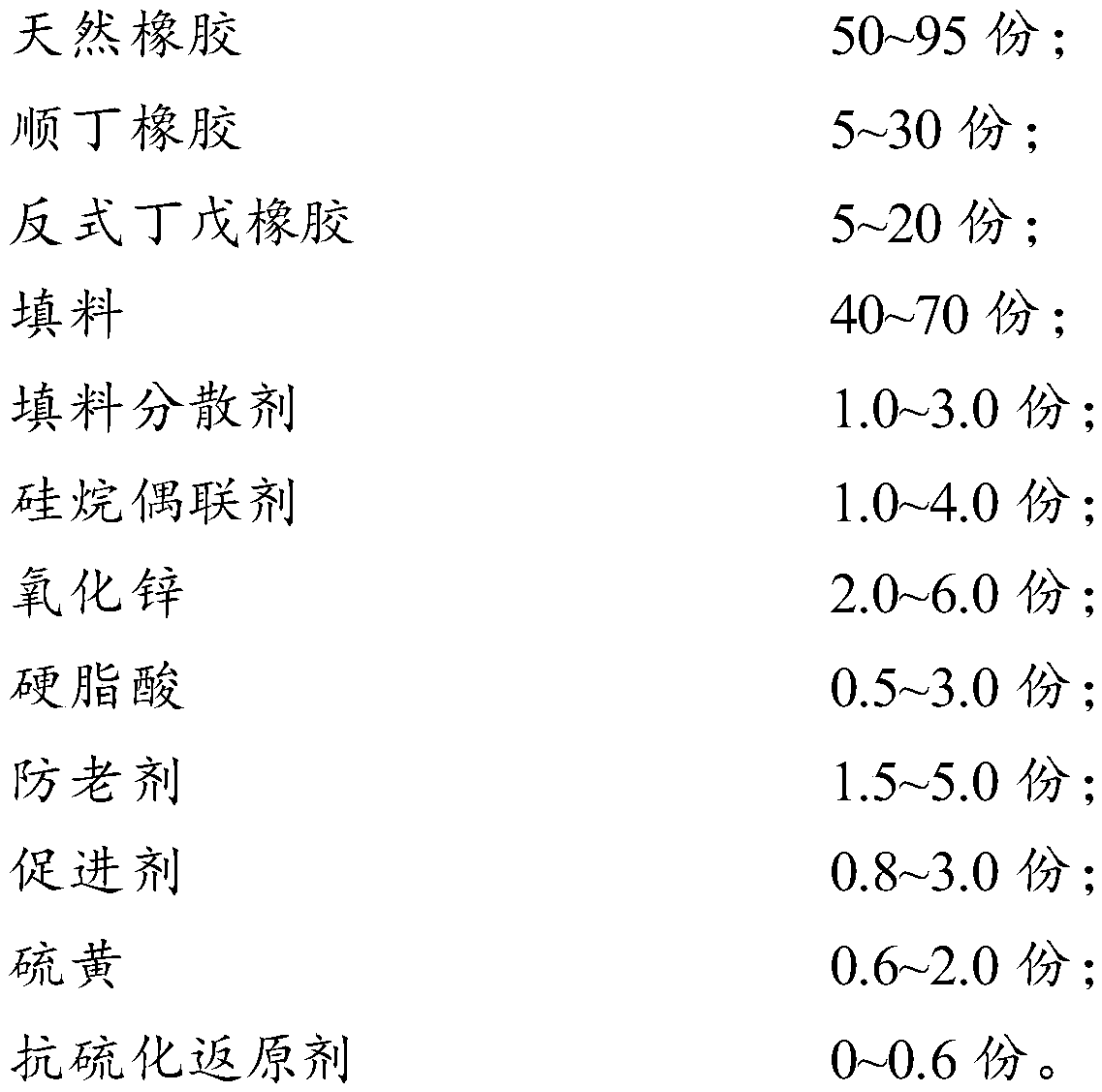

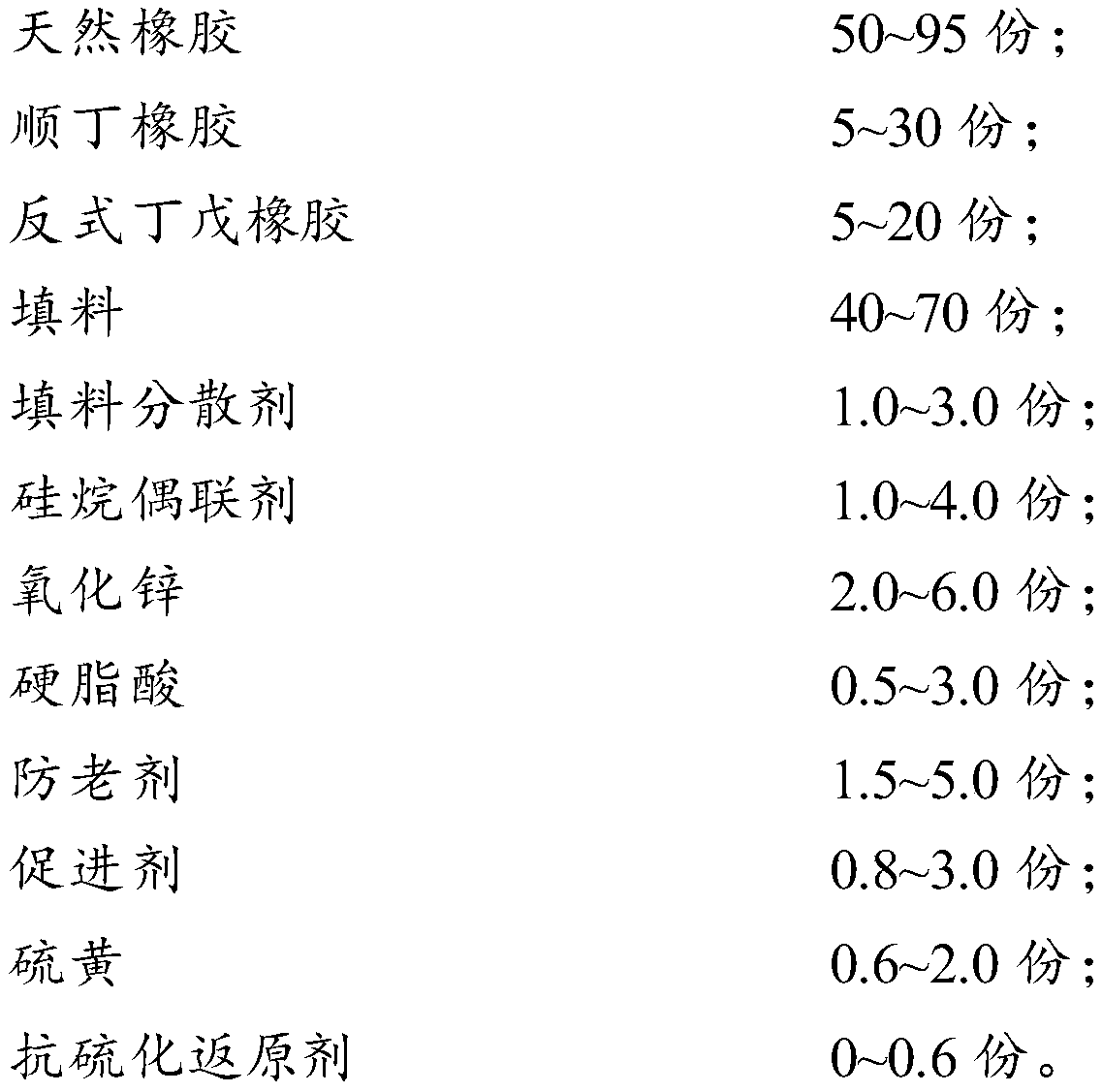

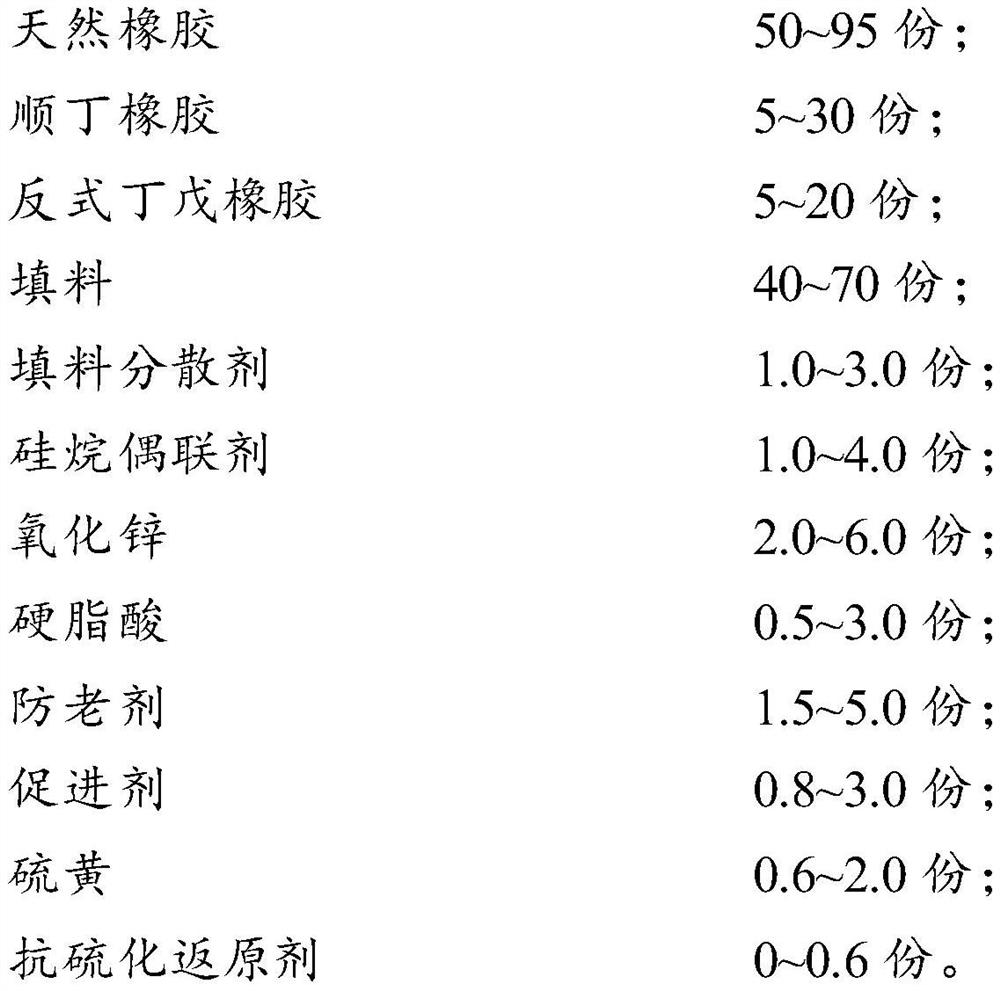

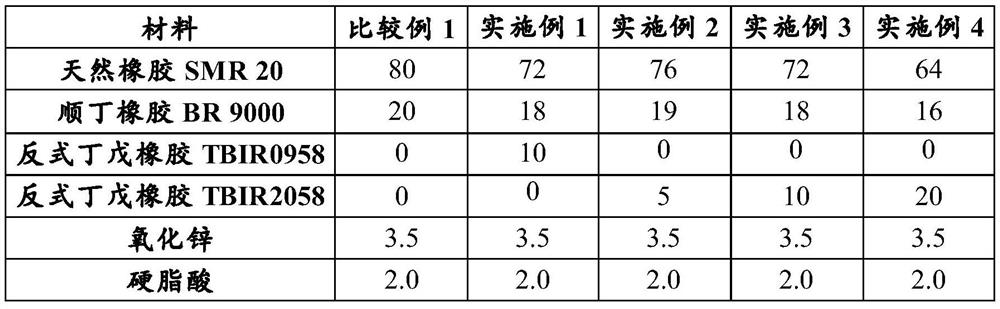

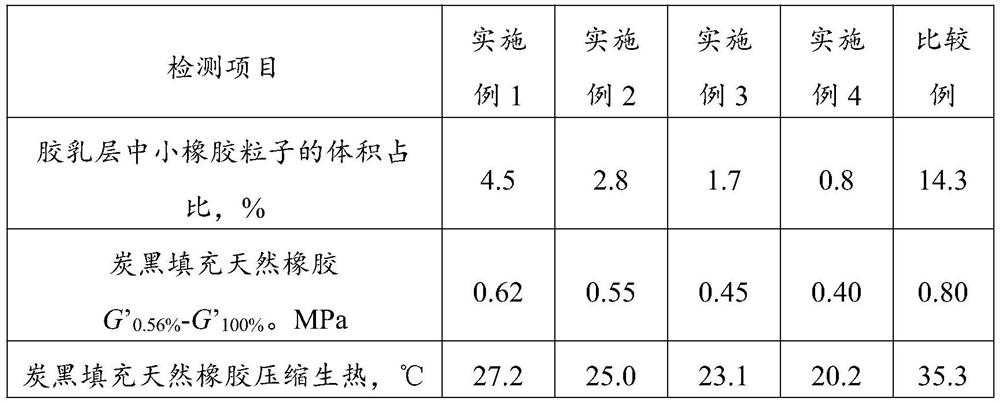

The invention especially relates to tread rubber for a tire and a preparation method thereof, belonging to the field of rubber processing. The tread rubber for the tire comprises, by weight, 50-95 parts of natural rubber, 5-30 parts of butadiene rubber, 5-20 parts of trans-1,4-poly(butadiene-co-isoprene) copolymer rubber, 40-70 parts of a filler, 1.0-3.0 parts of a filler dispersant, 1.0-4.0 partsof a silane coupling agent, 2.0-6.0 parts of zinc oxide, 0.5-3.0 parts of stearic acid, 1.5-5.0 parts of an anti-aging agent, 0.8-3.0 parts of an accelerator, 0.6-2.0 parts of sulfur and 0-0.6 part of an anti-reversion agent. In the tread rubber for the tire provided by the invention, the compatibility and co-vulcanization characteristics of the natural rubber and the butadiene rubber are superior, the filler is uniformly dispersed, and the above components are synergistically reacted with other components, so the finally obtained tread rubber has low rolling resistance and little heat generated by compression on the premise that the wet skid resistance is basically unchanged, and has good wear resistance at the same time.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

Nano hybrid filler reinforced rubber material and preparation process thereof

The invention discloses a nano hybrid filler reinforced rubber material prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 20-30 parts of auxiliary material rubber, 5-7 parts of a hybrid filler, 10-12 parts of white carbon black, 2-3 parts of cerium dioxide, 2-3 parts of asbestos fibers, 35-45 parts of tetrahydrofuran, 11-15 parts of oil, 1-2 parts of stearic acid, 4-6 parts of nano zinc oxide, 0.7-0.8 part of an accelerant, 3-5 parts of sulfur and 0.6-1 part of an anti-aging agent. The invention also discloses a preparation process of the rubber material. The natural rubber and the auxiliary material rubber are used as rubber matrixes, the auxiliary material rubber comprises ethylene propylene diene monomer rubber, nitrile rubber, fluororubber andbutadiene rubber, the auxiliary material rubber plays a complementary role in the natural rubber, and the rubber matrix with excellent performance is obtained; through compounding of the hybrid filler, the white carbon black, the cerium dioxide and the asbestos fibers, the rubber is reinforced, and the mechanical property and the wear resistance of the rubber material are improved, so that the service life of the rubber material is prolonged.

Owner:杭州睿琦化工科技有限公司

Wet-processed carbon masterbatch, as well as preparation method and application thereof

The invention discloses wet-processed carbon masterbatch, as well as a preparation method and application thereof. When a glue solution and carbon black slurry are mixed by utilizing an existing method, the used auxiliary agent reduces the surface activity of filler and influences the interaction between the filler and rubber. The technical scheme is divided into two parts, the carbon black is subjected to surface modification and dispersion in the first part; and in the second part, a carbon black dispersant is mixed with a rubber solution, and the mixture is separated, dried and molded. According to the invention, a surface modification and homodisperse combined method is adopted for carbon black dispersion, and thus the modified carbon black dispersant has high stability. Vulcanized rubber prepared by utilizing the wet-processed carbon masterbatch has good aging resistance, and a tyre prepared from the vulcanized rubber can be used for reducing compression heat, oil consumption and the like.

Owner:ZHEJIANG TRANSFAR SYNTHETIC MATERIAL CO LTD

Low-mooney rubber material applicable to injection vulcanization and preparation method of low-Mooney rubber material

InactiveCN110157106ALower Mooney ViscosityAccelerated vulcanizationRubber materialMicrocrystalline wax

The invention discloses a low-Mooney rubber material applicable to injection vulcanization. The low-Mooney rubber material is prepared from the following raw materials in parts by weight: 80-100 partsof an ethylene-propylene-diene monomer, 60-80 parts of white carbon black, 4-5 parts of zinc oxide, 1-2 parts of stearic acid, 0.5-1 part of a flowing agent, 1-2 parts of an anti-aging agent, 0.8-1 part of a microcrystalline wax, 20-25 parts of paroline, 2-3 parts of an accelerant and 1-2 parts of aids. The invention furthermore discloses a preparation method of the rubber material. Due to adoption of a softening agent, namely the paroline, in rubber materials, and due to process adjustment the preparation process, the property that a rubber material is rapidly vulcanized can be met; meanwhile, the dispersibility of the white carbon black can be improved, and the tension and wearing resistance of the rubber material can be improved; and the rubber material which is low in mooney viscosityand high in vulcanization efficiency and is applicable to an injection process can be prepared.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

Maintenance-free tire rubber material and preparation method thereof

ActiveCN111777806ALow compression heatIncrease elasticitySpecial tyresRolling resistance optimizationRubber materialStearic acid

The invention discloses a maintenance-free tire rubber material. The tire rubber material is prepared from the following components in parts by weight: 30-70 parts of natural rubber, 70-30 parts of ethylene propylene diene monomer, 5-25 parts of carbon black, 45-35 parts of white carbon black, 2-3 parts of zinc oxide, 1-1.5 parts of stearic acid, 0.5-1.5 parts of an anti-aging agent, 0.1-0.6 partof an accelerant, 0.5-1.0 part of sulfur, 2-3.0 parts of a foaming agent, 1.0-1.5 parts of a foaming aid and super silane accounting for 5 to 8% of white carbon black, wherein the sum of the use amounts of natural rubber and ethylene propylene diene monomer is 100 parts. The tire rubber material has the advantages of low compression heat generation, better rebound resilience and smaller abrasion;by adopting the raw materials with low heat generation, high grip and low rolling resistance and a reasonable formula, the hidden danger to a processor and a user in the production and use process isgreatly reduced, and the safety, the economy and the adaptability of the product are wider.

Owner:SICHUAN YUANXING RUBBER

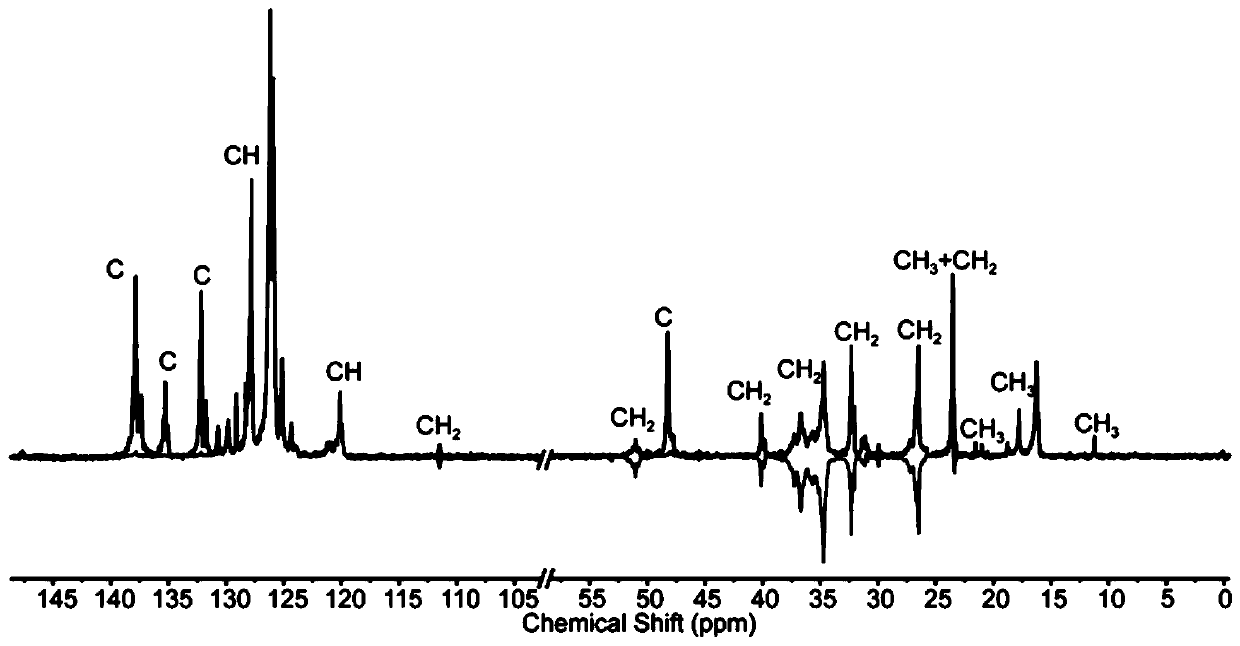

Sulfur-containing high-trans elastomers with adjustable content of trans-1,4-structure and preparation method of elastomers

The invention provides sulfur-containing high-trans elastomers with an adjustable content of a trans-1,4-structure and a preparation method of the elastomers, and belongs to the technical field of functional polymer materials. The elastomers comprise a series of sulfur-containing functionalized high-trans solution-polymerized styrene-butadiene, styrene-isoprene and styrene-isoprene-butadiene rubber with an adjustable content of the trans-1,4-structure. The method provided by the invention is based on an anionic system and has mild reaction conditions, the elastomers can be conveniently synthesized in a hydrocarbon solvent, a partially-alternated multi-block copolymer can be synthesized by adjusting a dosing amount of MTAE and the usage amounts of comonomer styrene, butadiene and isoprene without adding a metal regulating agent, and therefore regulation and control of a content of a diene trans-1,4-structure and the glass transition temperature Tg of the copolymer can be realized; and the high-trans-structural diene polymer has very dynamic properties, such as low rolling resistance and compression heat generation and excellent flexing resistance, and is an ideal rubber compound fordeveloping high-performance tires.

Owner:辽宁科之镁新材料研究有限公司

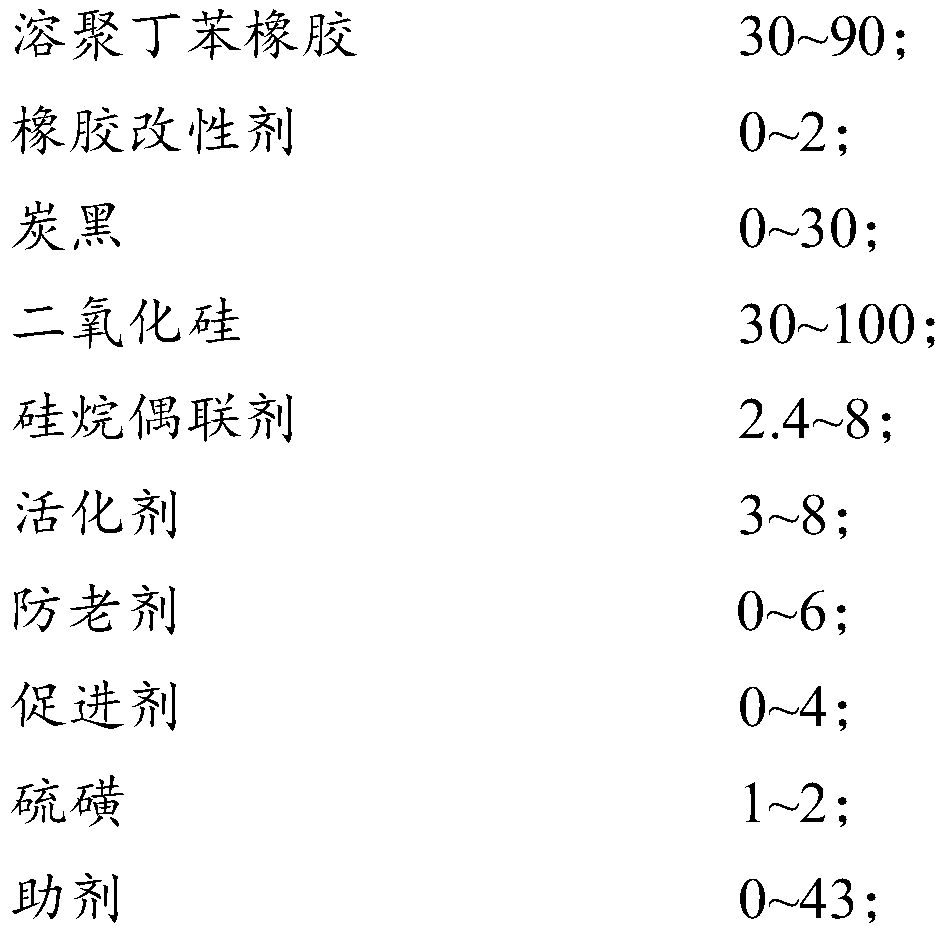

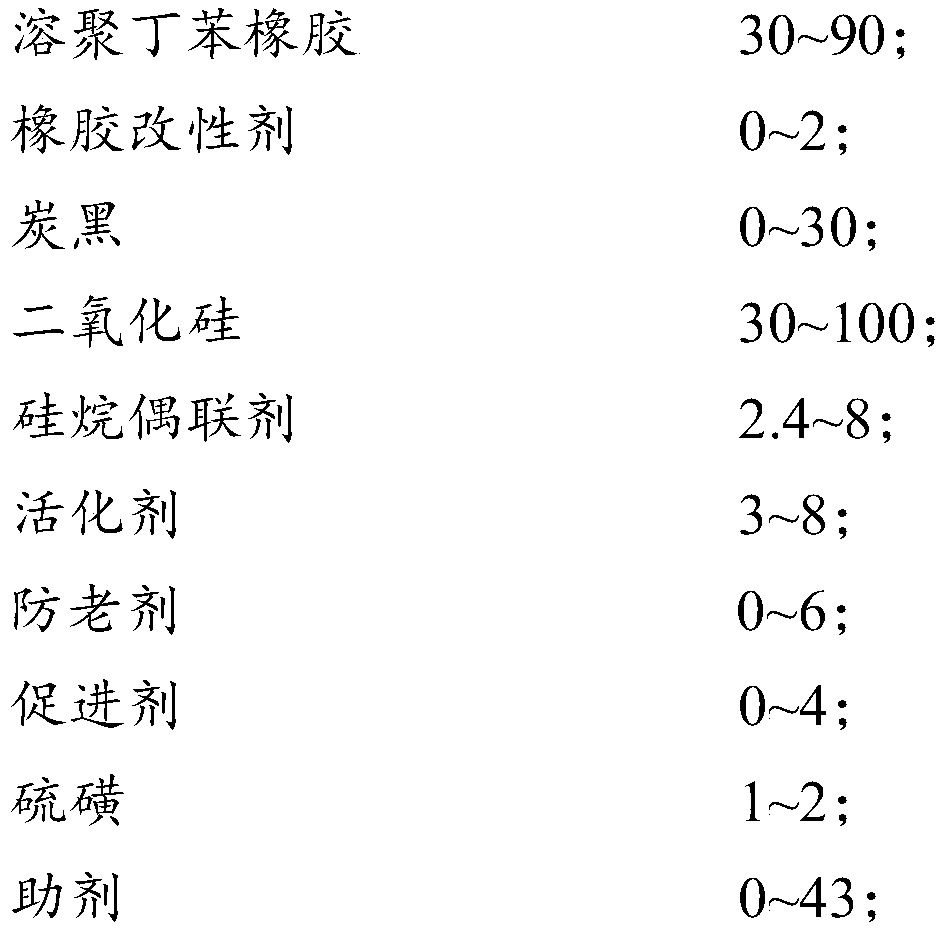

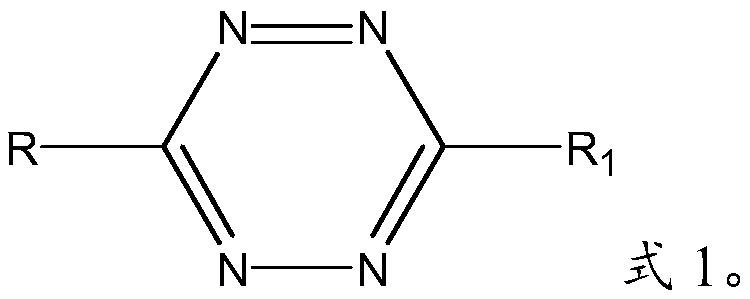

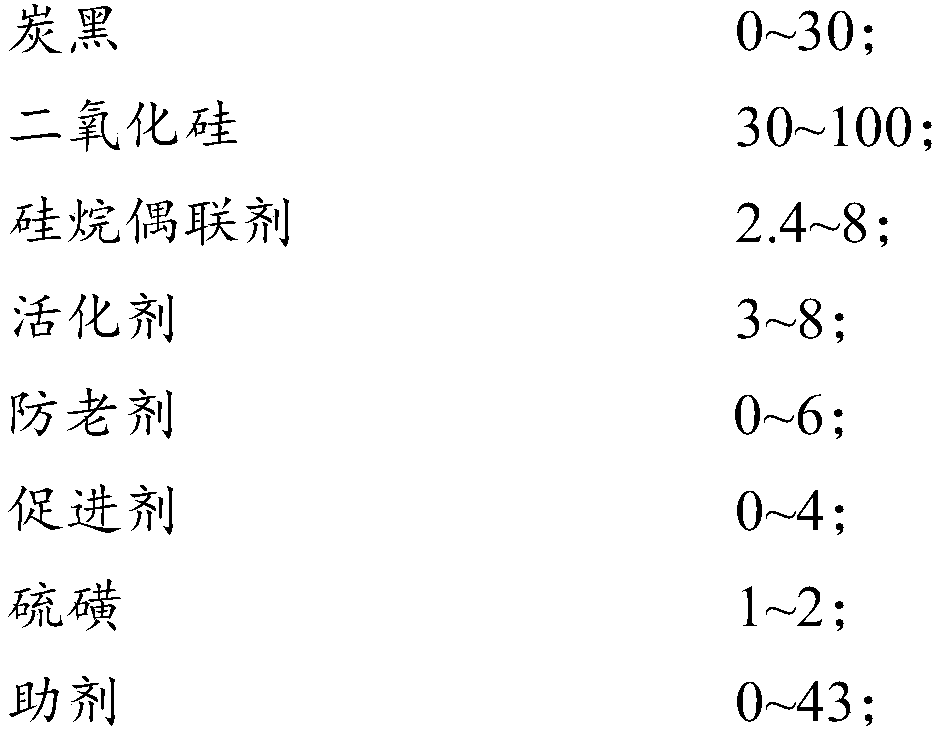

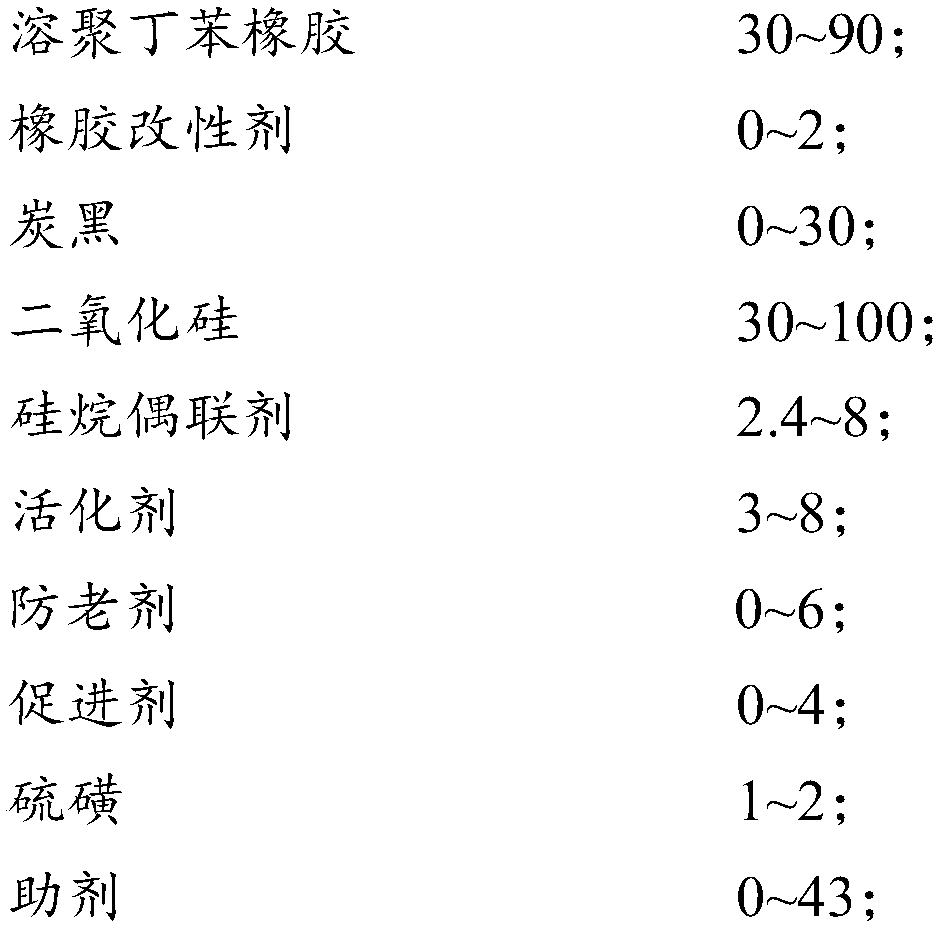

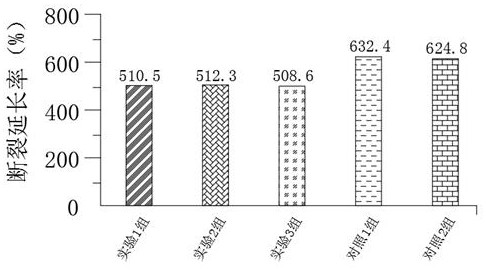

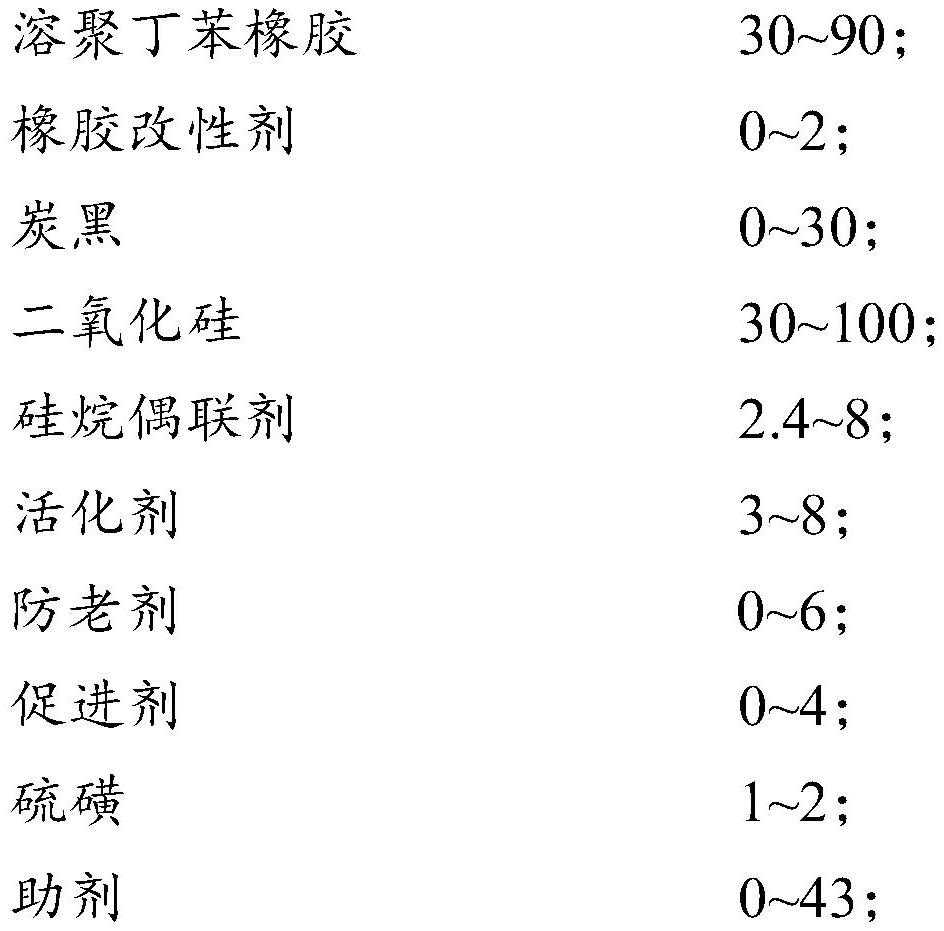

In-situ modified rubber composition for tire, tire and preparing method of tire

ActiveCN109824952AReduce rolling resistanceReduce lossSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention belongs to the technical field of tire manufacturing, and particularly relates to an in-situ modified rubber composition for a tire, the tire and a preparing method of the tire. The in-situ modified rubber composition for the tire comprises a modified solution polymerized styrene-butadiene rubber polymer, second carbon black, a silane coupling agent, silicon dioxide, an activating agent, an anti-aging agent, an accelerant, sulphur and an auxiliary, wherein the modified solution polymerized styrene-butadiene rubber polymer is formed by mixing solution polymerized styrene-butadienerubber, a rubber modifier and first carbon black. The tire prepared by means of the in-situ modified rubber composition for the tire has the advantage of being low in rolling resistance.

Owner:GUANGZHOU FENGLI RUBBER TIRE

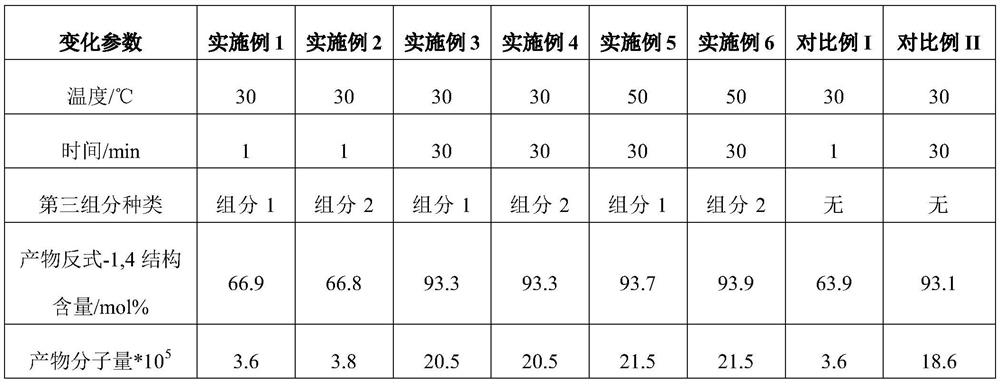

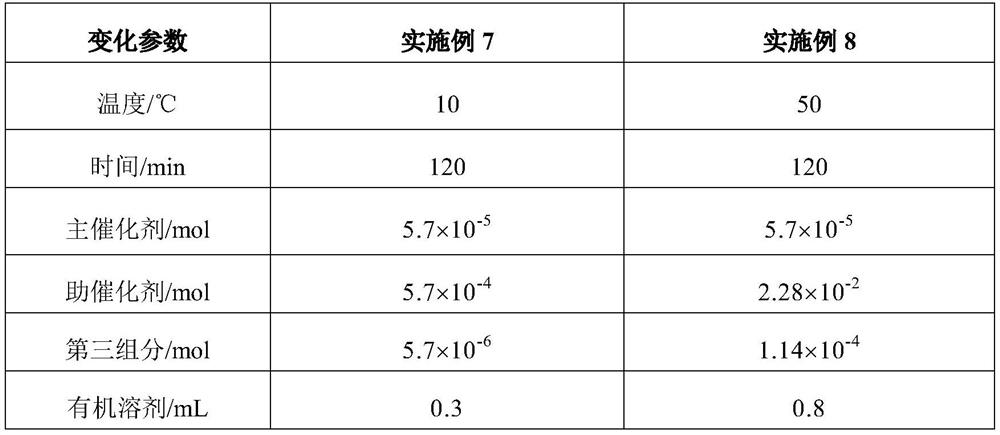

Catalyst for synthesizing high trans-1,4 polybutadiene-isoprene rubber material and catalytic synthesis method thereof

The invention relates to the technical field of synthesis of high-trans-1,4-polybutadiene-isoprene rubber materials, in particular to a catalyst for synthesizing a high-trans-1,4-polybutadiene-isoprene rubber material and a catalytic synthesis method of the catalyst. The catalyst comprises a main catalyst, a cocatalyst and a third component, wherein the third component is an alkoxy silane external electron donor. The method comprises the following steps: pumping, discharging and replacing a reactor, sequentially adding a butadiene / isoprene mixed monomer, a cocatalyst, a third component and a main catalyst / organic solvent mixture to form an active center to initiate monomer polymerization, and conducting reacting at 10-50 DEG C for 1-120 minutes to obtain the trans-1,4-polybutadiene-isoprene rubber material. The external electron donor is introduced into the catalyst, the charging sequence of the monomer, the cocatalyst, the electron donor and the main catalyst is adopted during polymerization, the external electron donor can effectively activate an active center, an active center with higher trans-1,4 steric selectivity is formed, and the steric selectivity of the catalyst is improved.

Owner:JINING UNIV +1

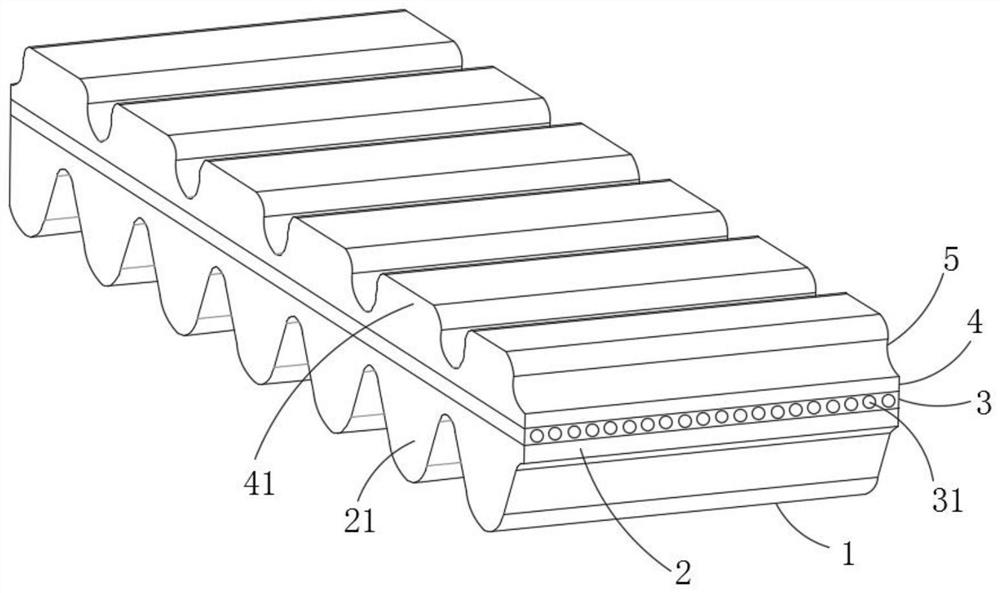

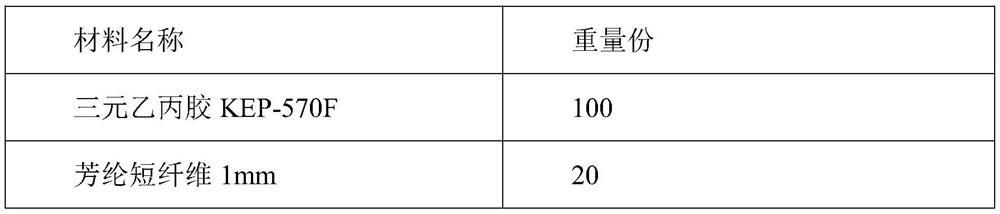

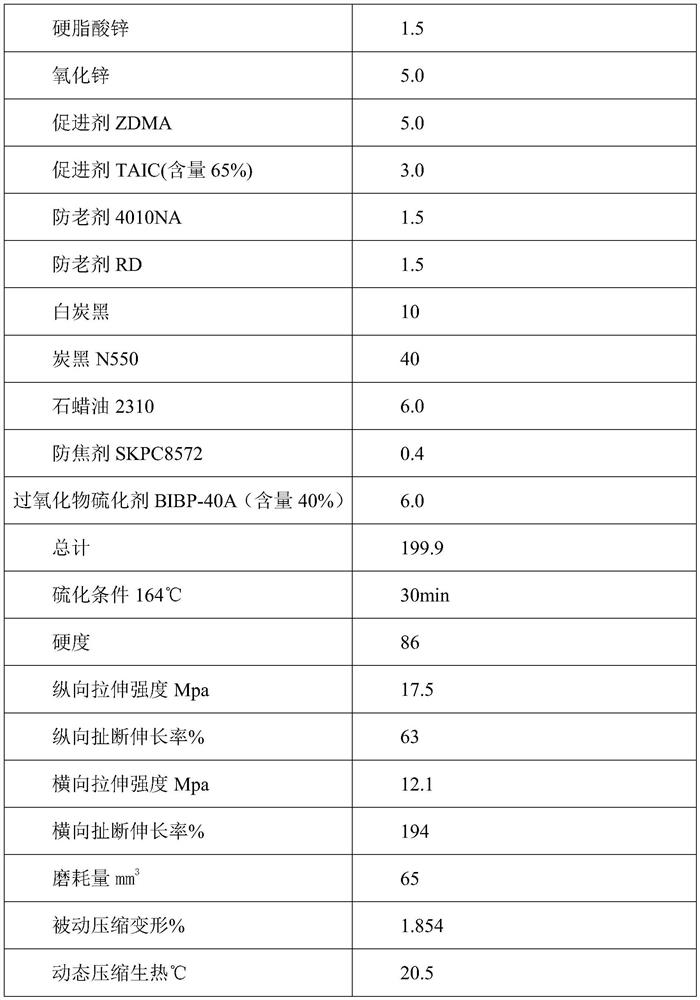

Beach buggy belt as well as formula and processing method thereof

ActiveCN111761885ASolve aging resistanceImprove wear resistanceBeltsRubber layered productsStructural engineeringConveyor belt

The invention discloses a beach buggy belt, and relates to the technical field of transmission belts. A bottom cloth layer, bottom rubber, a framework layer, top rubber and a top cloth layer are sequentially arranged from inside to outside; bottom teeth are arranged on the bottom rubber; top teeth are arranged on the top rubber; aramid fiber ropes are arranged on the framework layer in the direction of the belt; and aramid fibers are arranged in the bottom rubber in the direction perpendicular to the belt. The invention further discloses a formula and a processing method of the beach buggy belt. The temperature resistance, the transverse rigidity and the low-compression heat generation performance of the belt are well considered.

Owner:浙江保尔力橡塑股份有限公司

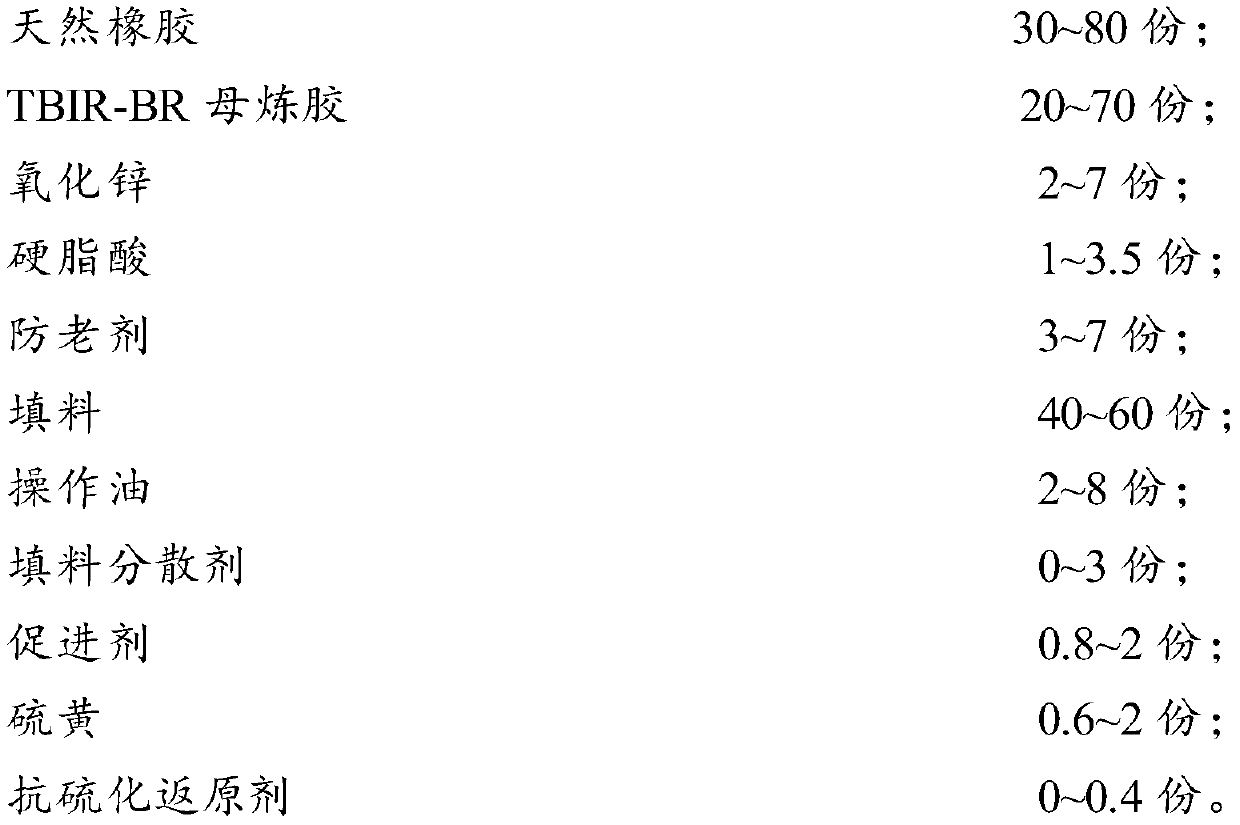

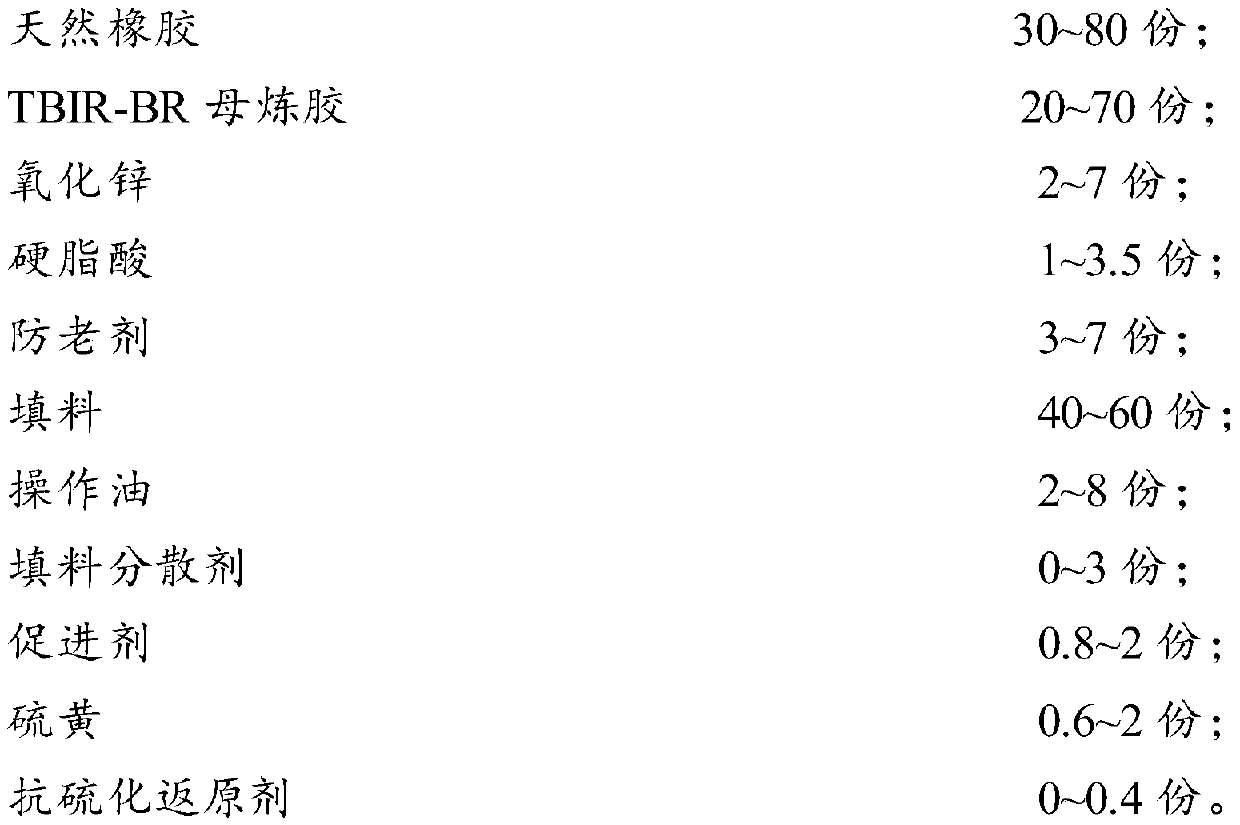

Tire sidewall rubber and preparation method thereof

ActiveCN110283365AImprove fatigue resistanceReduce rolling resistanceSpecial tyresRolling resistance optimizationMasterbatchVulcanization

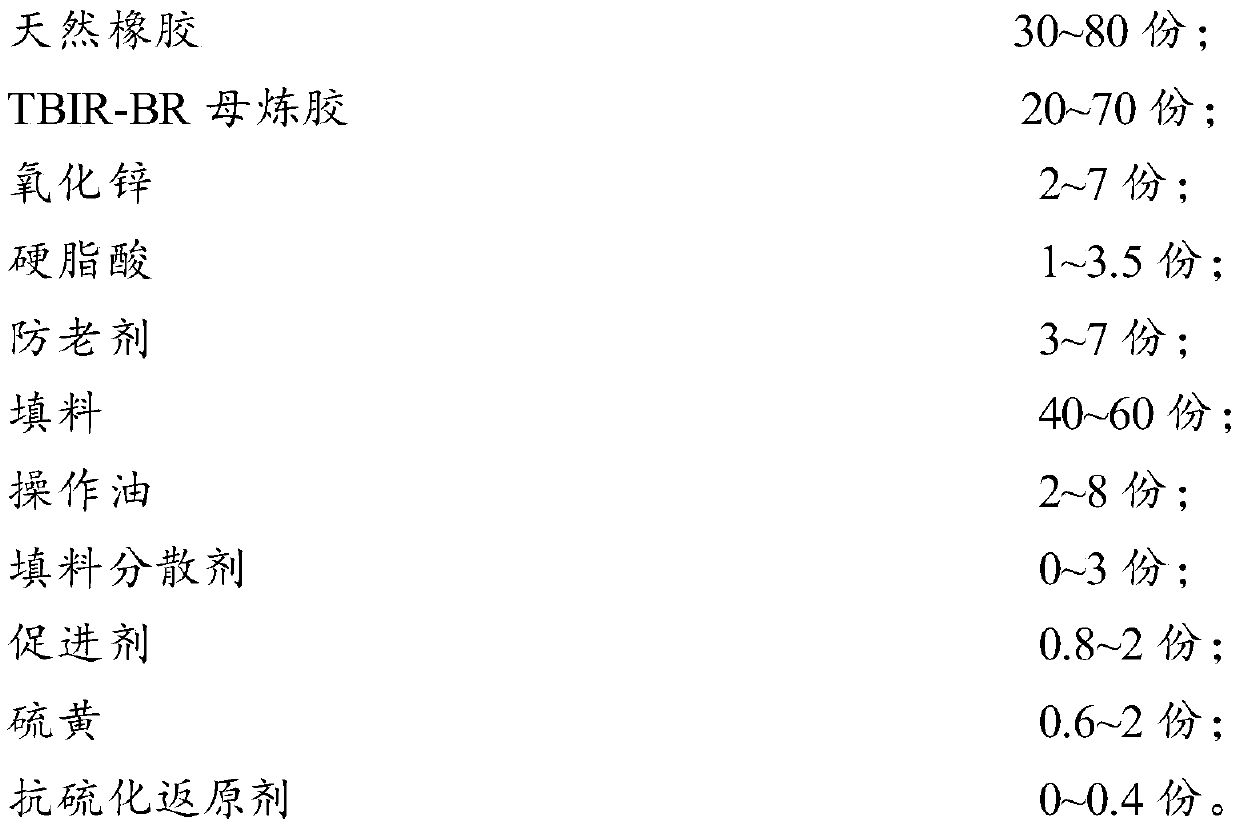

The invention relates to the field of rubber processing, in particular to tire sidewall rubber and a preparation method thereof. The tire sidewall rubber is prepared from the following components in parts by weight: 30-80 parts of natural rubber, 20-70 parts of TBIR-BR masterbatch, 2-7 parts of zinc oxide, 1-3.5 parts of stearic acid, 3-7 parts of an anti-aging agent, 40-60 parts of filler, 2-8 parts of operating oil, 0-3 parts of a filler dispersant, 0.8 -2 parts of an accelerator, 0.6-2 parts of sulfur, and 0-0.4 part of an anti-reversion agent. According to the tire sidewall rubber and the preparation method thereof provided by the invention, the natural rubber and the TBIR-BR masterbatch are matched with other components to achieve a synergistic effect, so that the compatibility and co-vulcanization characteristics of the natural rubber and butadiene rubber are further improved; the filler is more uniformly distributed in the natural rubber and the butadiene rubber; finally, the obtained tire sidewall rubber is relatively good in fatigue resistance, and relatively low in rolling resistance and compression heat generation.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

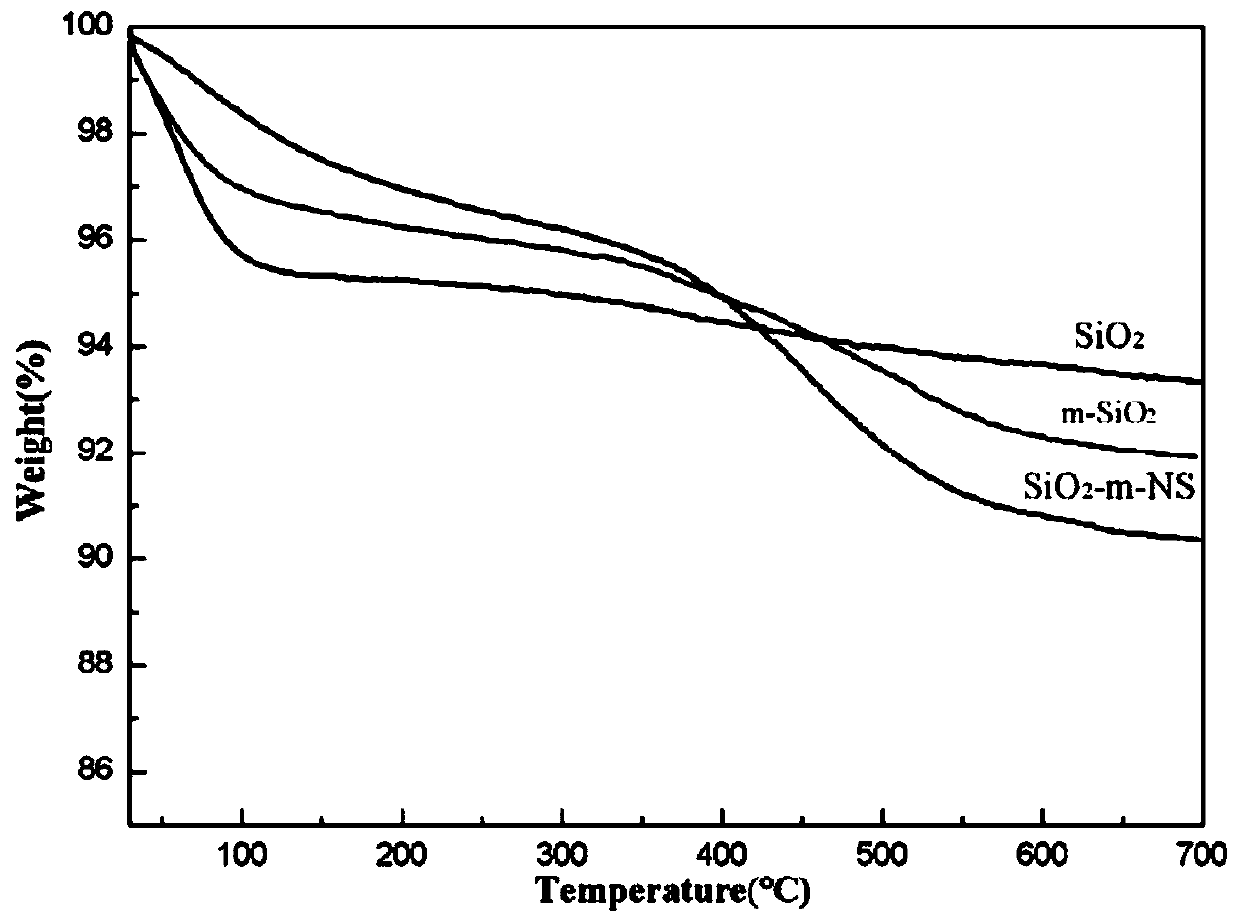

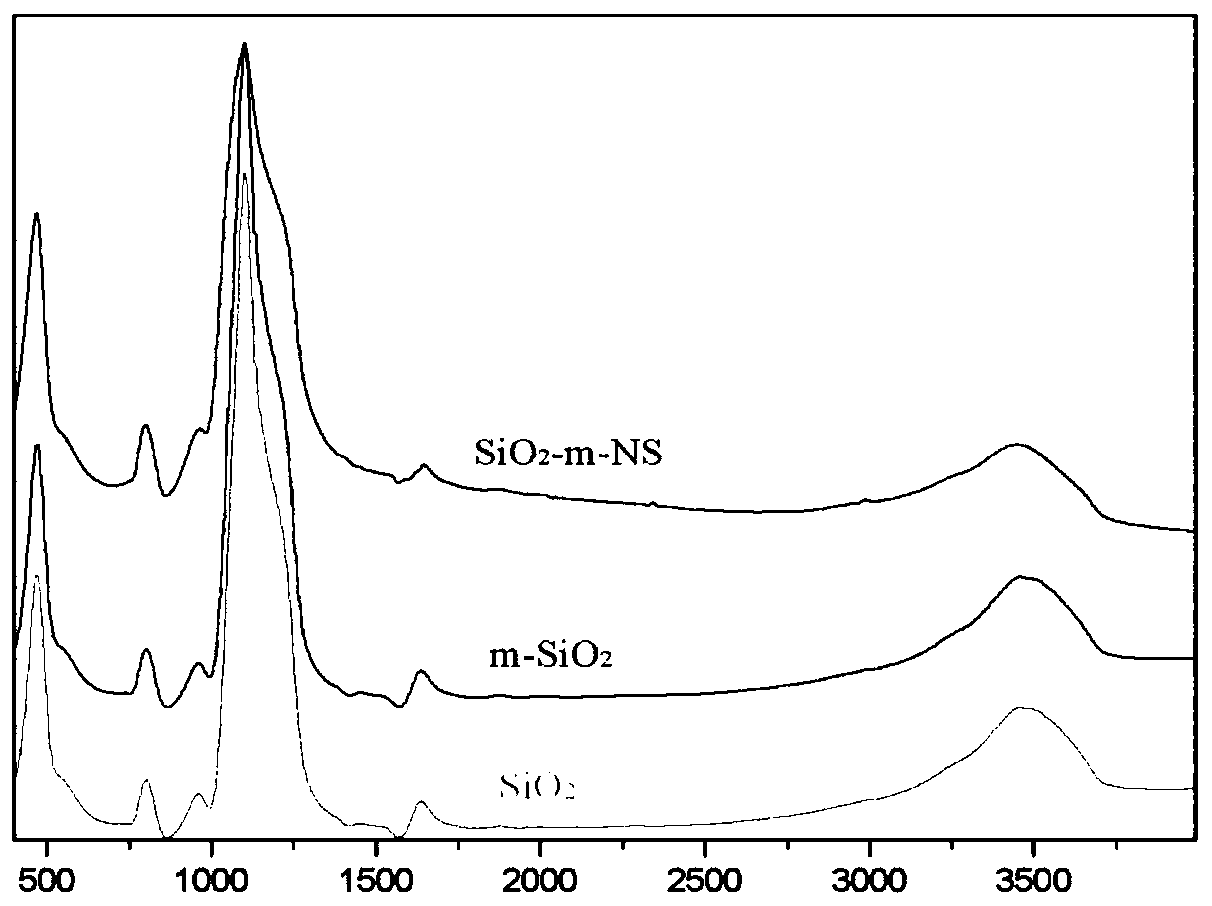

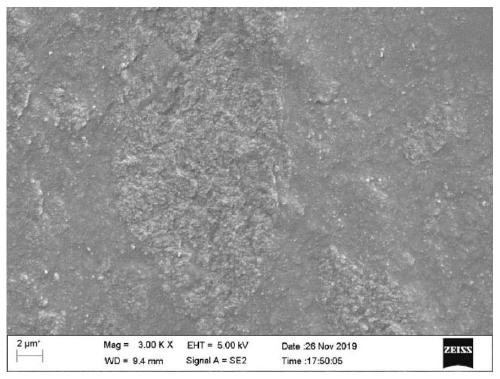

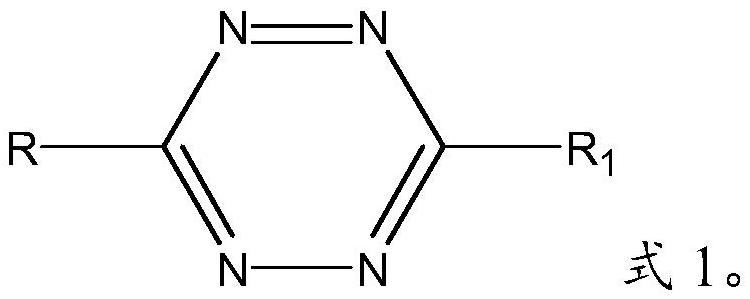

Environmentally-friendly rubber accelerator modified filling material,, and preparation method and application thereof

InactiveCN111303489AReduce rolling resistanceInhibit migrationRolling resistance optimizationVulcanizationOrganic solvent

The invention discloses an environmentally-friendly rubber accelerator modified filling material, and a preparation method and an application thereof. The preparation method comprises the following steps: allowing a silane coupling agent, namely gamma-glycidoxypropyltrimethoxysilane (KH560) to react with a filling material dispersed in an organic solvent under stirring at 40-60 DEG C under the protection of nitrogen, then adding an accelerator NS, and carrying out a reaction at 60-80 DEG C under the protection of nitrogen; and carrying out suction filtration on a product, and carrying out washing and vacuum drying so as to obtain the environmentally-friendly rubber accelerator modified filling material. The surface of the environmentally-friendly rubber accelerator modified filling material is grafted with an organic micromolecule accelerator, so the surface performance of the filling material is improved, and the filling material can be more uniformly dispersed in rubber; meanwhile, the effects of reinforcing and promoting vulcanization are achieved, and the rolling resistance of a tire can be obviously reduced. The environmentally-friendly rubber accelerator modified filling material can reduce the problem of migrating and blooming of micromolecules in rubber products, is an environmentally-friendly rubber auxiliary agent, and has good application and use prospects in the rubber industry.

Owner:SOUTH CHINA UNIV OF TECH

High-elasticity low-heat-generation environment-friendly reclaimed rubber material and preparation method thereof

The invention discloses a high-elasticity low-heat-generation environment-friendly reclaimed rubber material and a preparation method thereof. Reclaimed rubber is prepared from 100 parts of waste rubber powder, 5-15 parts of a softener, 0.20-0.50 part of an activator, 0.10-0.15 part of water, 0.30-0.50 part of rosin or resin and 9-11 parts of environment-friendly naphthenic oil through a high-temperature dynamic desulfurization method. The high-temperature dynamic desulfurization condition is high-pressure steam of 1.30-1.40 Mpa, and the temperature reaches 220-230 DEG C and is kept for 2.0-3.0 hours. The reclaimed rubber is prepared by adopting a high-temperature dynamic desulfurization method, more liquid isoprene rubber LIR30 is used as a softener, a proper amount of environment-friendly naphthenic oil is matched with a small amount of activating agent, rosin and water, other components are not needed for modification, the performance of the reclaimed rubber is improved, the reboundresilience of the reclaimed rubber is remarkably improved, and the compression heat generation of the reclaimed rubber is remarkably reduced.

Owner:SICHUAN YUANXING RUBBER

In-situ modified rubber composition for tire, tire and preparation method of tire

InactiveCN109181039AReduce rolling resistanceReduce lossSpecial tyresRolling resistance optimizationRolling resistancePolymer science

The invention belongs to the technical field of tire manufacturing, and in particular, relates to an in-situ modified rubber composition for a tire, the tire and a preparation method of the tire. Theinvention provides the in-situ modified rubber composition for the tire, wherein the in-situ modified rubber composition includes a modified soluble polymerized styrene-butadiene rubber polymer, a second part of carbon black, a silane coupling agent, silica, an activator, an anti-aging agent, an accelerator, sulfur and an auxiliary agent; the modified soluble polymerized styrene-butadiene rubber polymer is obtained by mixing soluble polymerized styrene-butadiene rubber, a rubber modifier and a first part of carbon black. The tire prepared by the in-situ modified rubber composition for the tirehas the advantage of low rolling resistance.

Owner:GUANGZHOU FENGLI RUBBER TIRE

Rubber mixing method, rubber compound and application

InactiveCN114425823AEvenly dispersedReduce mixing energy consumptionPolymer scienceRolling resistance

The invention relates to the technical field of rubber mixing, in particular to a rubber mixing method, mixed rubber and application. According to the invention, the mixing uniformity of the rubber compound is improved, the physical and mechanical properties of the rubber compound are improved, the dynamic properties of the rubber compound can be improved, heat generation and rolling resistance are reduced, the fatigue resistance and crack resistance of the rubber compound are improved, and the service life of a tire is prolonged; the composite material has enough rigidity, and also has enough flex resistance, tear resistance and low heat generation performance.

Owner:山东万达宝通轮胎有限公司 +1

A kind of in-situ modified rubber composition for tire, tire and preparation method thereof

ActiveCN109824952BReduce rolling resistanceReduce lossSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The invention belongs to the technical field of tire manufacturing, and in particular relates to an in-situ modified rubber composition for tires, tires and a preparation method thereof. The invention provides an in-situ modified rubber composition for tires, comprising: modified solution-polymerized styrene-butadiene rubber polymer, second carbon black, silane coupling agent, silicon dioxide, activator, anti-aging agent, accelerator agent, sulfur and additives; wherein, the modified solution-polymerized styrene-butadiene rubber polymer is obtained by mixing solution-polymerized styrene-butadiene rubber, rubber modifier and the first part of carbon black. The tire prepared from the in-situ modified rubber composition for tires provided by the invention has the advantage of low rolling resistance.

Owner:GUANGZHOU FENGLI RUBBER TIRE

A kind of tire tread rubber and preparation method thereof

ActiveCN110358156BExcellent wet skid resistanceExcellent abrasion resistanceSpecial tyresRolling resistance optimizationPolymer scienceVulcanization

The invention relates to the field of rubber processing, in particular to a tire tread rubber and a preparation method thereof. The tire tread rubber comprises, in parts by weight: 50-95 parts of natural rubber; 5-30 parts of butadiene rubber; 5-20 parts of trans-butadiene rubber; 40-70 parts of filler; 1.0-3.0 parts of filler dispersant silane coupling agent 1.0-4.0 parts; zinc oxide 2.0-6.0 parts; stearic acid 0.5-3.0 parts; anti-aging agent 1.5-5.0 parts; accelerator 0.8-3.0 parts; sulfur 0.6-2.0 parts; Dose 0-0.6 parts. In the tire tread rubber provided by the present invention, the compatibility and co-vulcanization characteristics of natural rubber and butadiene rubber are better, and the filler is evenly dispersed. Under the premise that the wet skid resistance is basically unchanged, the rolling resistance and compression heat generation are lower, and at the same time, the wear resistance is better.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

Large rubber particle natural latex and preparation method thereof, carbon black filled natural rubber and preparation method and application thereof

ActiveCN114213557AAvoid the problem of high dynamic heat generationIncreased dynamic service lifeRolling resistance optimizationPolymer scienceLatex rubber

The invention relates to the technical field of carbon black filled natural rubber, in particular to a preparation method of large rubber particle natural latex, carbon black filled natural rubber and a preparation method and application thereof. The preparation method of the large rubber particle natural latex provided by the invention comprises the following steps: centrifuging a natural latex diluent to obtain upper latex which is the large rubber particle natural latex; and the centrifugal separation factor during centrifugation is greater than or equal to 8340. The preparation method provided by the invention can effectively realize separation of small rubber particles in natural latex, and the volume percentage content of the small rubber particles in the obtained large rubber particle natural latex is less than or equal to 5%. The large rubber particle natural latex is used as a raw material to prepare the carbon black filled natural rubber, and the dynamic heat generation of the obtained carbon black filled natural rubber is obviously reduced.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

A kind of all-steel radial tire shoulder pad rubber and preparation method thereof

The invention provides an all-steel radial tire shoulder pad rubber and a preparation method thereof. The all-steel radial tire shoulder pad rubber provided by the invention is prepared from raw materials comprising the following components by mass: 80-95 parts of natural rubber; 5-20 parts of trans-butadiene rubber; 35-55 parts of reinforcing agent; 0-3.0 parts of agent; 0-1.5 parts of silane coupling agent; 2.0-6.0 parts of zinc oxide; 1.5-3.5 parts of stearic acid; 1.0-4.0 parts of tackifying resin; parts; 1.8-2.7 parts of sulfur; 0.2-0.5 parts of anti-scorch agent. In the all-steel radial tire shoulder pad rubber provided by the present invention, on the basis of ensuring good vulcanization characteristics and basic physical and mechanical properties of the tire shoulder pad rubber, it can also improve its fatigue resistance, reduce rolling resistance and compression heat generation.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

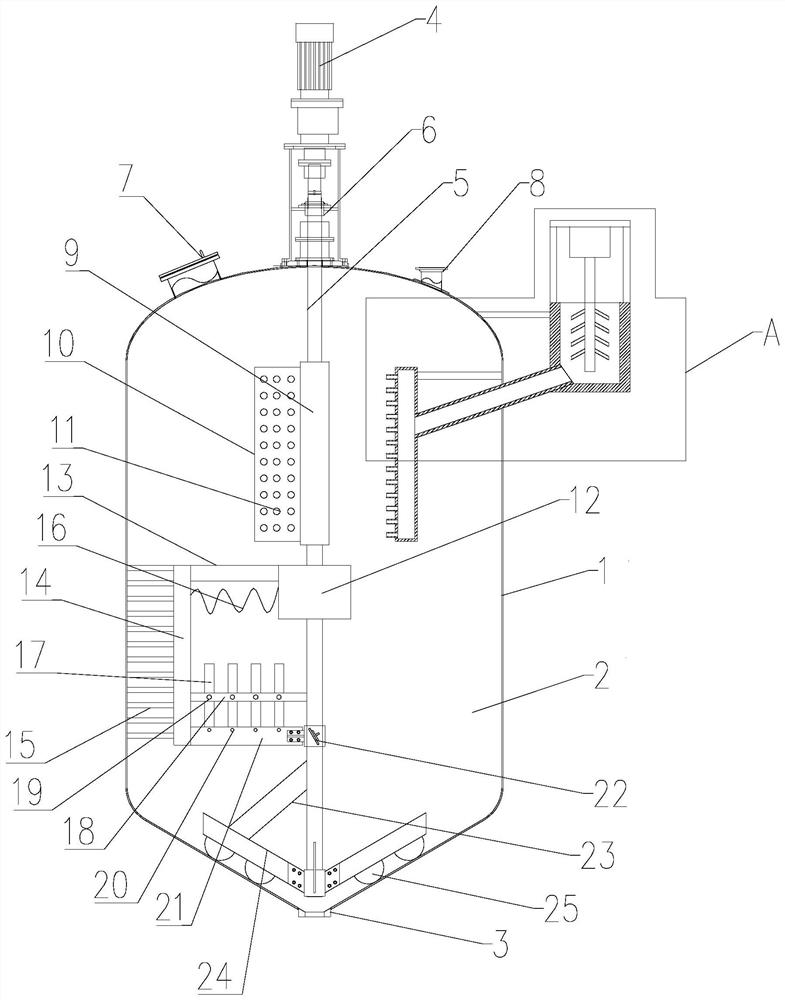

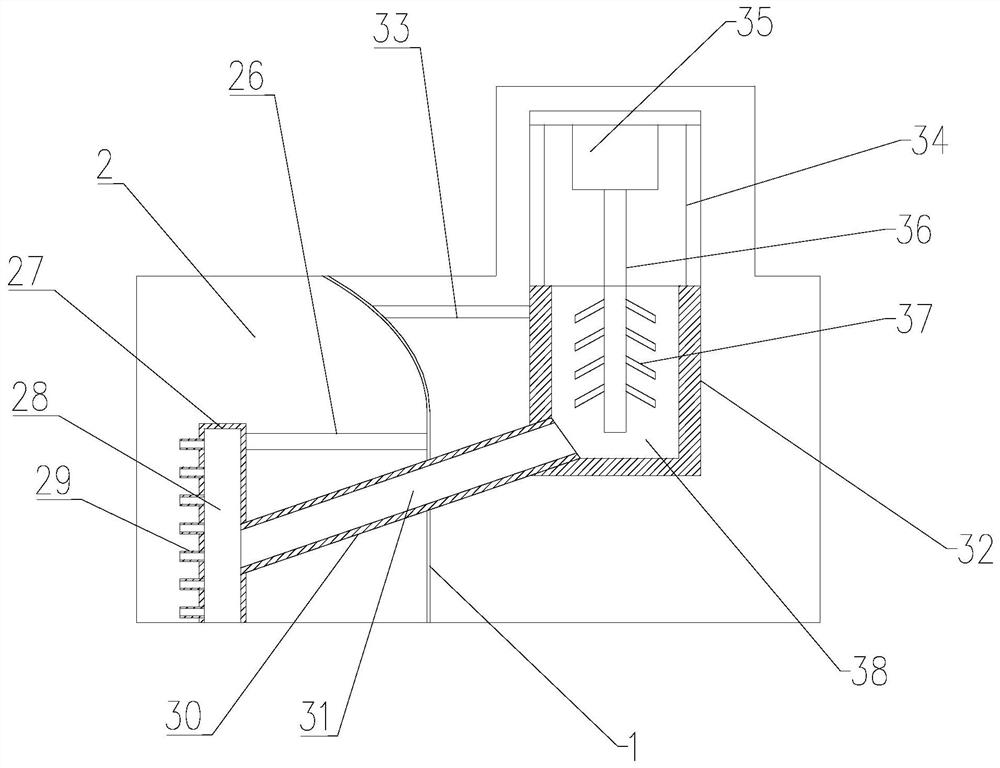

Preparation method and processing equipment of bio-based modified low-heat-generation reinforcing agent

InactiveCN113337073AImprove surface activityGood processing technologyRotary stirring mixersMixer accessoriesHexamethylenetetramineKaolin clay

The invention relates to a preparation method of a bio-based modified low-heat-generation reinforcing agent, which comprises the following steps: S1, pounding a non-metallic mineral material, desanding, grinding, adding the non-metallic mineral material into a first stirring kettle, adding sodium chloride and a calcium carbonate solution into the first stirring kettle, stirring, heating, adding a silane coupling agent Si-69 and stearic acid, mixing, continuously stirring at a high speed and heating; adding zinc oxide and phenolic resin to obtain modified kaolin; S2, putting the modified biomass, lignin, petroleum resin and urotropine into a second stirring kettle, and stirring and mixing to obtain the bio-based modified low-heat-generation reinforcing agent. The invention further provides equipment used in the method. The reinforcing agent disclosed by the invention is high in surface activity, easy to mix into a rubber sizing material, good in processing technology, capable of effectively reducing compression heat generation of the sizing material, improving the bonding effect of a tire body and a belt ply cord fabric sizing material with a steel wire, improving physical and mechanical properties such as aging resistance of the sizing material and the like, and capable of partially replacing carbon black and white carbon black.

Owner:ZHEJIANG WEIXIANG TECH GRP CO LTD

A kind of production method of n330 carbon black

ActiveCN106189377BIncrease resistanceLow compression heatPigmenting treatmentTemperature controlCombustion

The invention provides an N330 carbon black production method. The process is simple and practical, and produced carbon black is better in performance. A hard carbon black reaction furnace is used for production, and the volume ratio of air to natural gas entering the reaction furnace is (18-19):1, so that more redundant air is generated to take participation in secondary combustion in a reaction chamber; raw oil enters the reaction chamber according to the spray amount of 440 kg / h; each kilogram of raw oil needs 2-3 m<3> of mixed gas composed of air and natural gas; the temperature of secondary combustion in the reaction chamber is controlled to be 1500-1600 DEG C; a plurality of gas inlets are evenly formed in a spray burner in the radial direction, and natural gas enters the gas inlets in a radial surrounding and axial mode so as to improve combustion efficiency; a first quenching section and a second quenching section are arranged at an outlet of the reaction furnace, the temperature of the first quenching section is controlled to be 900-950 DEG C, the temperature of the second quenching section is controlled to be 700-950 DEG C, and accordingly reaction time is prolonged; after carbon black is subjected to wet granulation, mixed gas composed of tail gas generated after carbon black production and air is introduced to dry the carbon black at the temperature of 300 DEG C; the tail gas and the air are mixed according to the volume ratio of (1.5-1.6):1.

Owner:山西永东化工股份有限公司

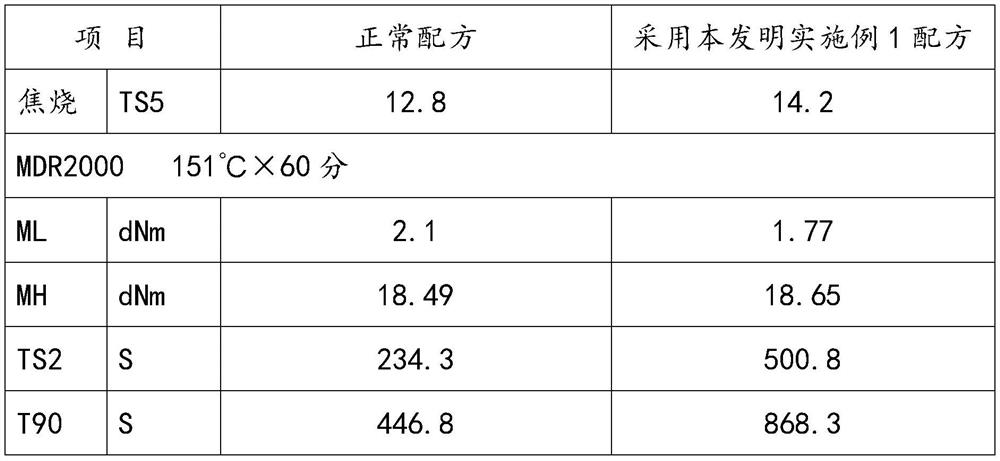

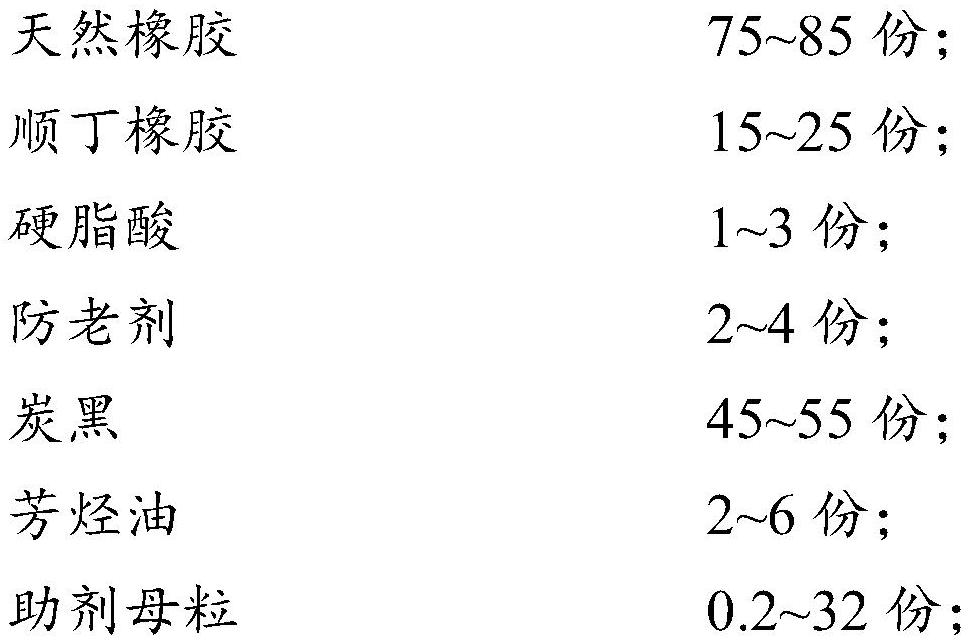

Pre-dispersed rubber auxiliary master batch as well as preparation method and application thereof

The invention relates to the technical field of rubber synthesis and application, in particular to a pre-dispersed rubber additive master batch as well as a preparation method and application thereof. The pre-dispersed rubber auxiliary master batch is prepared from raw materials including a low Mooney trans-1, 4-alkadiene copolymer and a rubber auxiliary; the mass ratio of the low Mooney trans-1, 4-diene copolymer to the rubber auxiliary agent is (20-50): (50-80). The pre-dispersed rubber auxiliary master batch contains a reactive plasticizer low Mooney trans-1, 4-alkadiene copolymer, so that the rubber auxiliary is more uniformly dispersed in a formula system and participates in a cross-linking reaction during vulcanization, and meanwhile, the low Mooney trans-1, 4-alkadiene copolymer is added into the pre-dispersed rubber auxiliary master batch, so that the low Mooney trans-1, 4-alkadiene copolymer is added into the pre-dispersed rubber auxiliary master batch. Due to the introduction of the 1, 4-diene copolymer, the use of non-reactive plasticizer environment-friendly aromatic hydrocarbon oil can be reduced under a formula system, and the performance of the prepared vulcanized rubber is obviously better. Vulcanized rubber prepared from the pre-dispersed rubber auxiliary master batch is relatively low in rolling resistance and compression heat generation and relatively excellent in wear resistance.

Owner:SHANDONG HUAJU POLYMER MATERIALS CO LTD

Rubber composition with low calorification and low rolling resistance

ActiveCN102675695BEasy to processLow compression heatRolling resistance optimizationRubber materialRolling resistance

Owner:PINGDINGSHAN YICHENG NEW MATERIAL

A kind of maintenance-free tire compound and preparation method thereof

ActiveCN111777806BLow compression heatIncrease elasticitySpecial tyresRolling resistance optimizationRolling resistanceFoaming agent

The invention discloses a maintenance-free tire compound, which is composed of the following components measured by weight: natural rubber: 30-70 parts, EPDM rubber: 70-30 parts, carbon black: 5-25 parts, white Carbon black: 45-35 parts, zinc oxide: 2-3 parts, stearic acid: 1-1.5 parts, anti-aging agent: 0.5-1.5 parts, accelerator: 0.1-0.6 parts, sulfur: 0.5-1.0 parts, foaming Agent: 2‑3.0 parts, foaming aid: 1.0‑1.5 parts, super silane: 5‑8% of white carbon black. The sum of the consumption of natural rubber and EPDM is 100 parts. The tire rubber compound of the present invention has the advantages of low compression heat generation, better resilience, and less wear; the present invention uses low heat generation, high grip, and low rolling resistance raw materials, coupled with a reasonable combination of component design, greatly The hidden dangers caused to processors and users in the process of production and use are reduced, and the safety, economy and adaptability of the product are wider.

Owner:SICHUAN YUANXING RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com