Environmentally-friendly rubber accelerator modified filling material,, and preparation method and application thereof

A rubber accelerator and an environmentally friendly technology, which is applied in the field of modified fillers and preparations of environmentally friendly accelerators, can solve the problems of easy aggregation of accelerators and low vulcanization rate, and achieve the effects of reducing agglomeration, improving interface properties, and weakening interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 15g of precipitated silica into a 1000ml three-necked flask, then add 600ml of absolute ethanol, stir evenly under nitrogen protection, add 5ml of silane coupling agent γ-glycidyl etheroxypropyltrimethoxysilane (KH560), in React for 13 hours under nitrogen protection at 50°C. suction filtration, washing, and vacuum drying to obtain silane coupling agent modified white carbon black. Add 2g of accelerator NS, add 0.2g of NaOH, and react at 60°C for 9 hours under the protection of nitrogen. The product is filtered, washed, and dried in vacuum to obtain the environmental accelerator modified filler SiO 2 -s-NS.

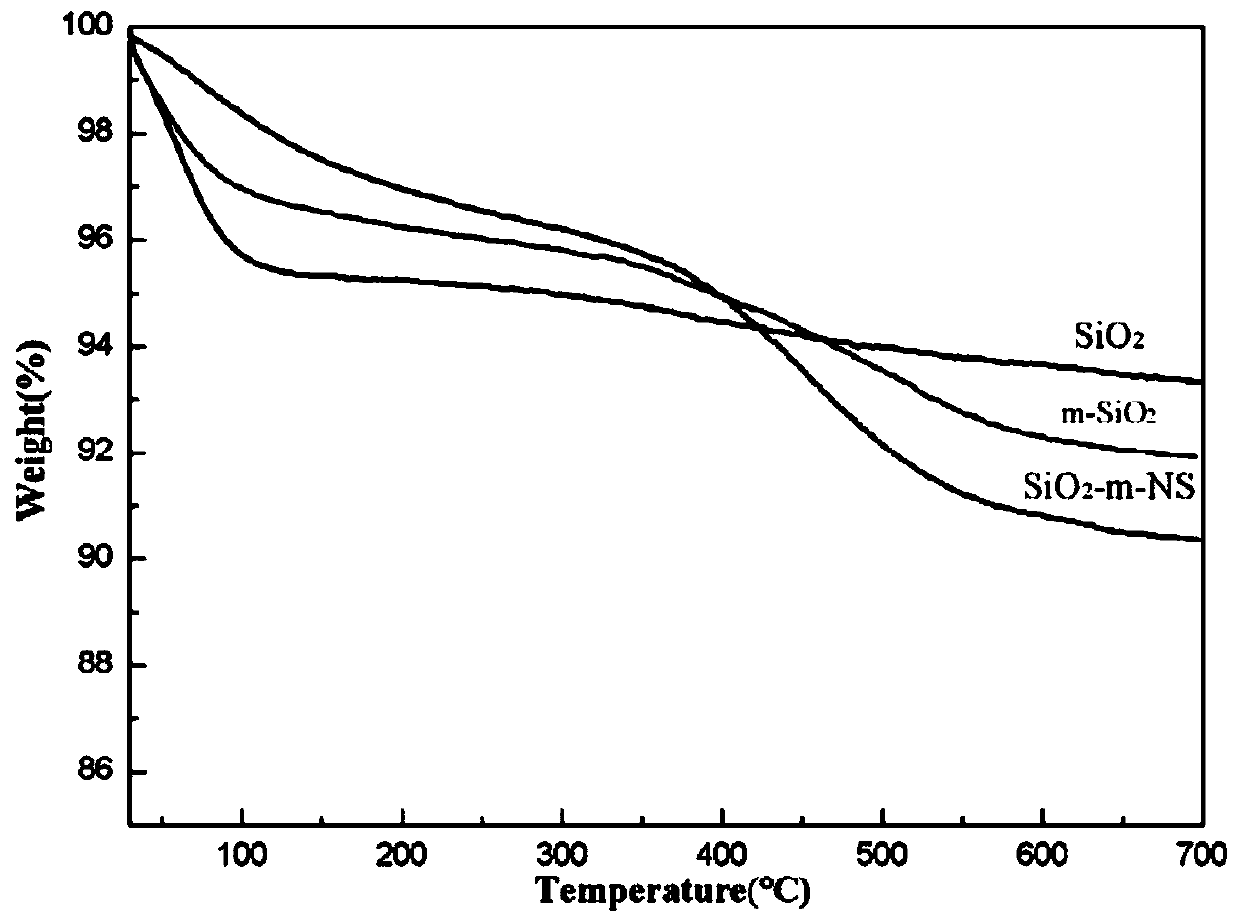

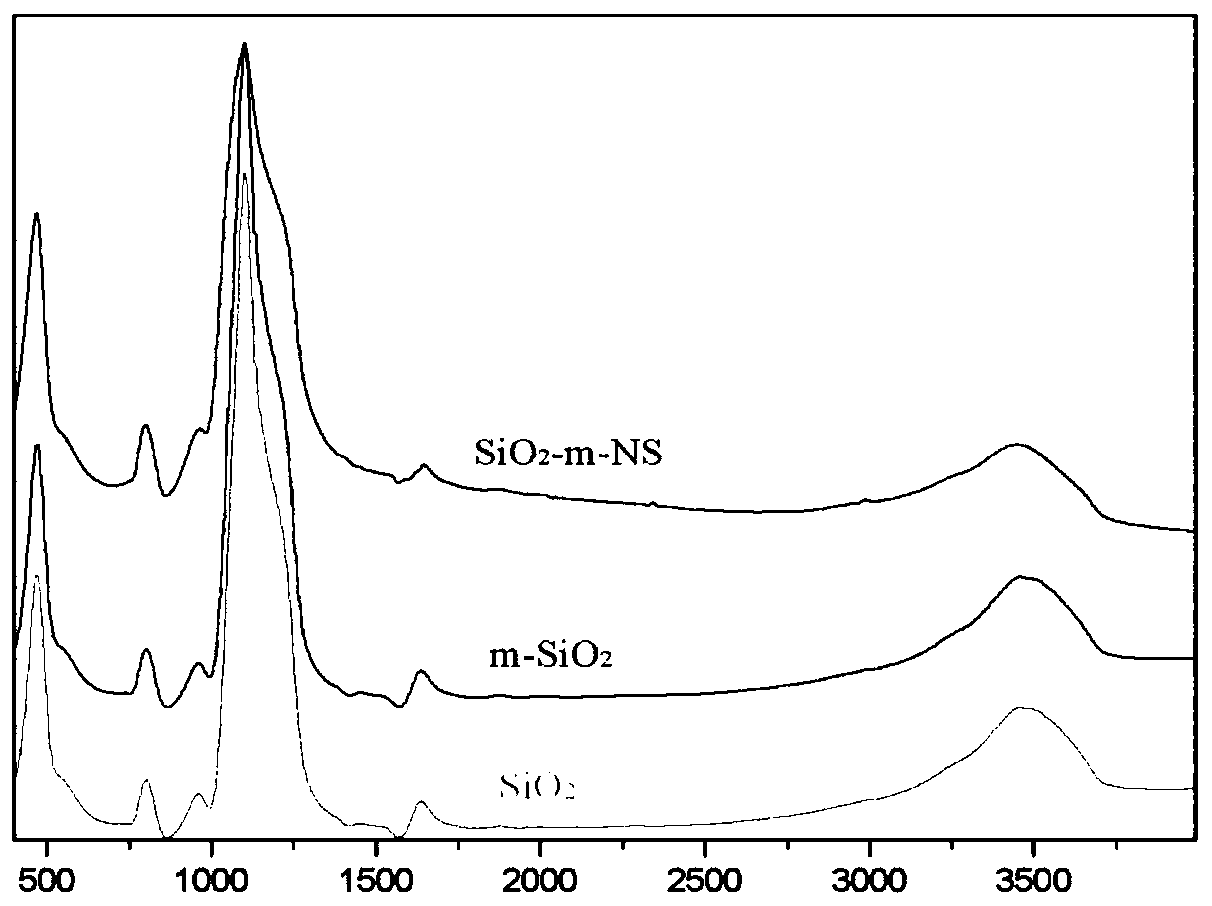

[0038] The above-mentioned environmental accelerator modified filler SiO 2 -s-NS infrared spectrum (see figure 1 ) shows that at 2890cm -1 A new absorption peak appeared at 1231cm -1 The absorption peak at is obviously broadened, indicating that the accelerator NS has been grafted on the surface of the filler through the silane coupling agent. Thermograv...

Embodiment 2

[0042] Disperse 10g of montmorillonite in 500ml of petroleum ether solvent, add 1ml of γ-glycidyl etheroxypropyl trimethoxysilane (KH560), stir at 40°C for 3 hours under the protection of nitrogen, wash with suction, and put in Drying in a vacuum oven at 50° C. for 24 hours to obtain silane coupling agent-modified montmorillonite (m-MMT). Then the obtained MMT was dispersed in petroleum ether, 2 g of N-tert-butyl-2-benzothiazole sulfenamide was added, and stirred at 70° C. for 13 hours under the protection of nitrogen. After suction filtration, washing, and drying in a vacuum oven at 50°C for 24 hours, the environmental accelerator modified montmorillonite (MMT-s-NS) was obtained.

[0043] The obtained product was confirmed to be the target product through elemental analysis and infrared spectrum analysis. The weight loss rate was determined to be 2.17% through thermogravimetric analysis.

[0044] Using the montmorillonite (MMT-s-NS) modified by the environmental protection ...

Embodiment 3

[0046] Disperse 10g of halloysite nanotubes (HNTs) in 300ml of absolute ethanol, slowly add 2.5ml of γ-glycidyl etheroxypropyltrimethoxysilane (KH560) dropwise at 60°C, and stir to react 8 Hours, after suction filtration and washing, drying in a real power oven at 50°C for 13 hours to obtain silane coupling agent-modified halloysite nanotubes (m-HNTs), the obtained silane coupling agent-modified halloysite nanotubes The tube (m-HNTs) was dispersed in 300ml of petroleum ether, 3g of N-tert-butyl-2-benzothiazole sulfenamide was added, and reacted at 80°C for 5 hours under the protection of nitrogen, and the obtained product was filtered, washed, The environment-friendly promoter-modified halloysite nanotubes (HNTs-s-NS) were obtained by drying in a vacuum oven at 50°C for 24 hours.

[0047] Infrared spectrum and nuclear magnetic resonance showed that the synthesized product was the Japanese standard product HNTs-s-NS. Thermogravimetric analysis showed that the mass fraction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com