Catalyst for synthesizing high trans-1,4 polybutadiene-isoprene rubber material and catalytic synthesis method thereof

A technology of isoprene rubber and polybutadiene, which is applied in the field of high trans-butadiene rubber material synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of described main catalyst comprises the steps:

[0033] (1) Under an inert gas atmosphere, add a magnesium compound into the ball mill jar, and ball mill at room temperature for 10-48 hours;

[0034] (2) Under an inert gas atmosphere, add titanium halide to the ball milling tank in step (1), and continue ball milling at room temperature for 10-48 hours to obtain a mixture;

[0035] (3) washing the mixture in step (2) with an organic solvent for 2 to 5 times, suction filtering, and drying to obtain a powdery main catalyst;

[0036] Wherein: the mass ratio of the magnesium compound to the titanium halide is 1:0.005-0.200.

[0037] The organic solvent is one or two of anhydrous n-hexane, anhydrous n-heptane, anhydrous cyclohexane, anhydrous toluene, anhydrous chloroform and anhydrous xylene.

[0038] A method for catalyst-catalyzed synthesis of high trans-1,4 polybutadiene-isoprene rubber materials, comprising the following steps: after the reacto...

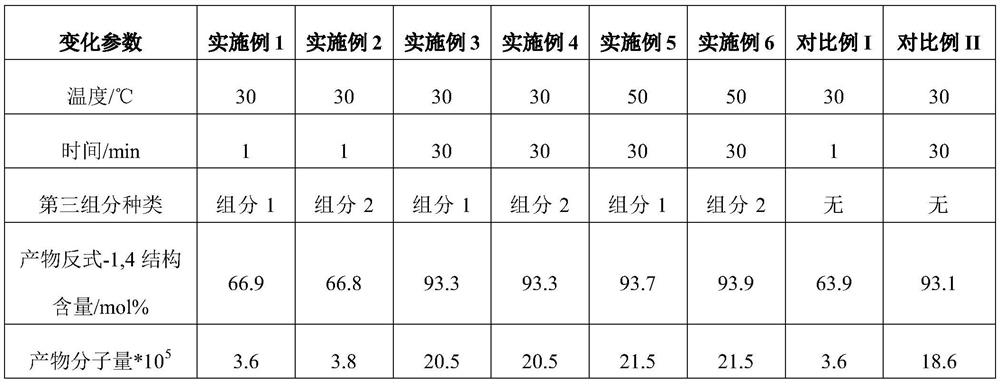

Embodiment 1~ Embodiment 6 and comparative example I~II

[0042] Preparation of the main catalyst: Vacuumize the ball mill tank, replace with nitrogen, pump and replace three times in sequence, add 14.25g (0.15mol) of anhydrous magnesium chloride carrier under nitrogen atmosphere, grind at room temperature for 12h; add 50mL of anhydrous n-heptane / 0.87mL The mixed solution of titanium tetrachloride was ground again at room temperature for 12 hours, and the catalyst was washed twice with a large amount of anhydrous n-heptane, filtered, and vacuum-dried to obtain a powdery main catalyst, which was analyzed by an ultraviolet spectrophotometer, and the Ti content of the main catalyst was It is 1.74wt.%.

[0043] Polymerization: Vacuumize the 100mL round-bottomed flask (containing magnets), replace with nitrogen, pump and replace three times in sequence, add 42.54g of butadiene / isoprene mixed monomer (0.63mol, monomer and The main catalyst molar ratio is 1:9×10 -5 , the molar ratio of butadiene to isoprene is 1:65.7), 1.71×10 -3 mol trii...

Embodiment 7~ Embodiment 8

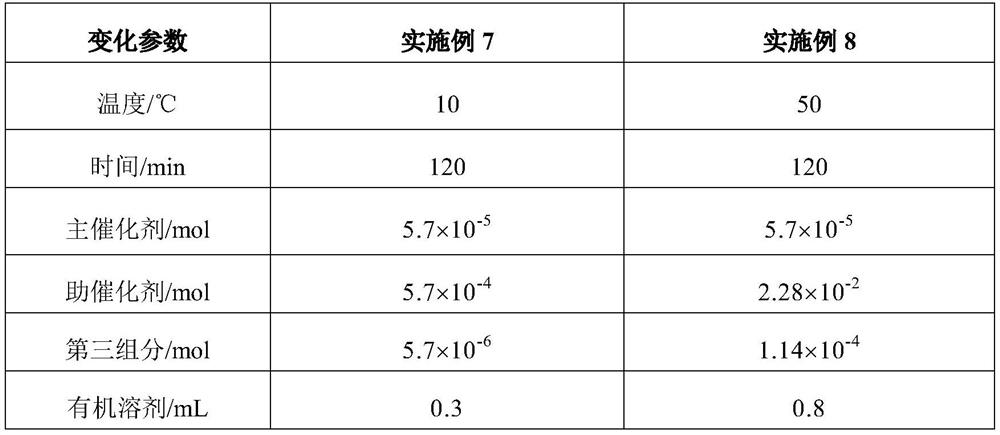

[0053] The preparation method of the main catalyst is the same as in Example 1, and the polymerization reaction uses the same reagents and reaction steps as in Example 1, except that the amount of reagents used and the reaction parameters in Table 2 below are different.

[0054] Table 2. Raw material addition amount and reaction parameters

[0055]

[0056]

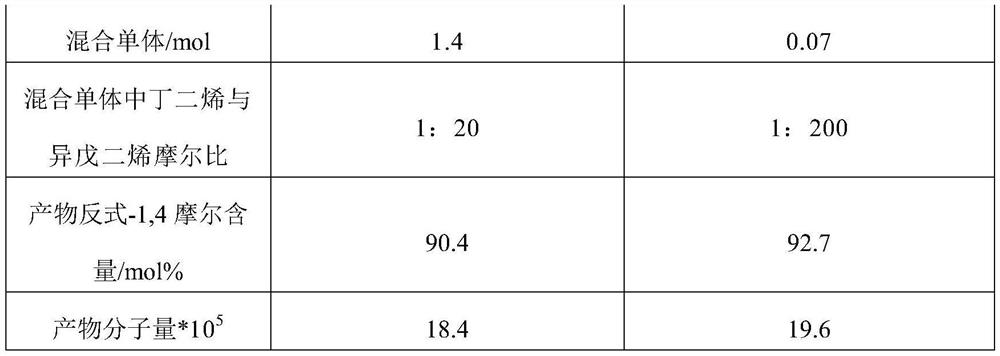

[0057] Comparing Example 7 with Examples 1, 3, and 5, it can be seen that the catalysts of Example 7 of the present invention and Examples 1, 3, and 5 are all made up of a main catalyst, a cocatalyst and an external electron donor, and the external electron donor is two Phenyldimethoxysilane, but embodiment 7 uses a low reaction temperature of 10°C, a low amount of promoter, a low amount of electron donating, and a low ratio of main catalyst to monomer. Example 7 is a 120min polymerization product, characterized by proton nuclear magnetic resonance spectrometer and gel permeation chromatography, it can be seen that:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com