Method of co-producing activated carbon in a circulating fluidized bed gasification process

a fluidized bed and gasification process technology, applied in the direction of inorganic chemistry, combustible gas production, chemistry apparatus and processes, etc., can solve the problems of limited removal of pollutants, significant risk to public health, and recent determination of mercury emissions from coal-fired power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

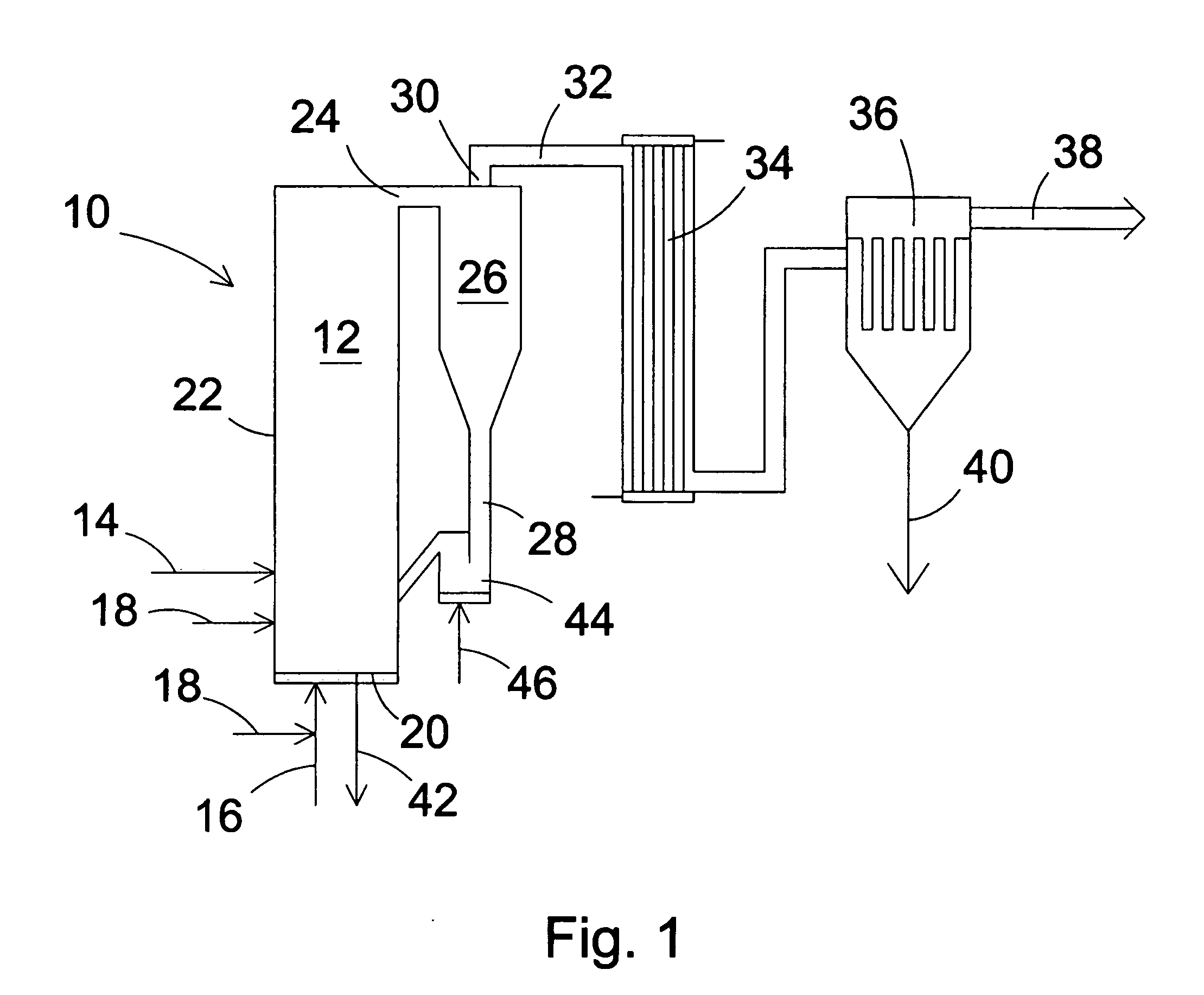

[0023]FIG. 1 schematically illustrates a circulating fluidized bed (CFB) gasifier 10 which can be used in a preferred embodiment of a gasification process in accordance with the present invention. The CFB gasifier 10 comprises a reaction chamber 12 with a fuel supply 14 for feeding carbonaceous fuel to a particle bed formed in the reaction chamber 12. The chamber 12 also comprises an oxidizing gas supply 16 for feeding oxidizing gas (usually air), and an activating agent supply 18 for feeding activation agent, steam, and / or carbon dioxide, at controlled rates into the reaction chamber 12. The activation agent supply 18 may be fed to the reaction chamber 12 through the bottom grid 20, possibly premixed with the oxidizing gas (the lower instance of activation agent supply 18 in FIG. 1), and / or at higher elevations through a side wall 22 of the reaction chamber 12 (the upper instance of activation agent supply 18 in FIG. 1).

[0024] The fuel and other particulate solids in the bed are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com