Large rubber particle natural latex and preparation method thereof, carbon black filled natural rubber and preparation method and application thereof

A technology of natural rubber latex and rubber particles, which is applied in the fields of large rubber latex and its preparation, carbon black filled natural rubber and its preparation, and can solve the problems of internal temperature rise, service life of rubber products, and carbon black filled natural rubber. Obvious issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

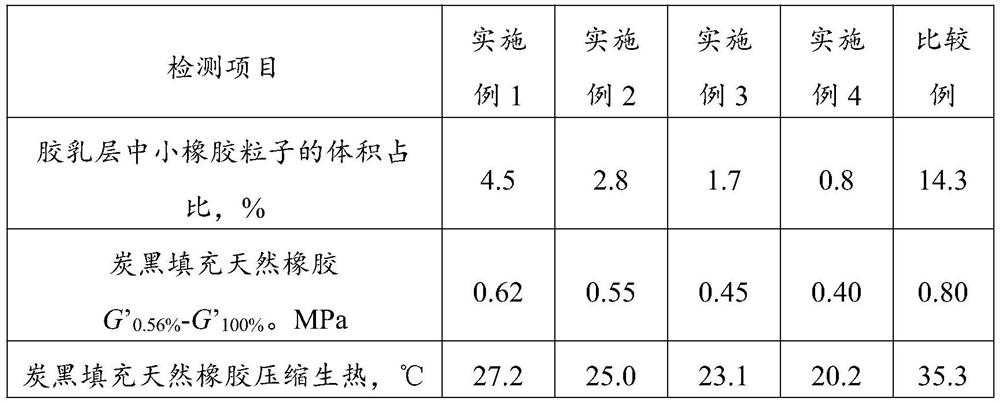

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of large rubber particle natural latex, comprises the following steps:

[0023] The natural latex dilution is centrifuged, and the upper latex layer obtained is natural latex with large rubber particles; the centrifugal separation factor during the centrifugation is ≥8340.

[0024] In the present invention, the natural latex dilution is obtained by diluting collected fresh natural latex with a solvent.

[0025] The present invention has no special requirements on the source of the fresh natural rubber latex.

[0026] In the present invention, the natural latex diluent preferably includes natural rubber and a solvent, and the mass percentage of the natural latex diluent is preferably 20-30%.

[0027] In the present invention, the solvent is preferably water.

[0028] In the present invention, the mass percentage of the natural latex diluent is preferably 20 to 30%, and in a specific embodiment of the present invention...

Embodiment 1

[0075] Get freshly collected natural latex 5kg, add water to dilute, add 25% ammoniacal liquor 0.04kg, obtain natural latex dilution, natural rubber content is 20%, adopt high-speed refrigerated centrifuge centrifugal, natural latex dilution temperature is 4 ℃ during centrifugal, The separation factor is set to 8340, the centrifugation time is 30min, and the upper layer of latex layer and the lower layer of latex layer are obtained by centrifugation, and the latex layer is taken to obtain the natural latex of large rubber particles;

[0076] The large rubber particle natural rubber latex is diluted with water to 30% of the natural rubber percentage. Take 3kg of natural rubber latex, add 1kg of 2wt% formic acid to coagulate it, and after aging for 16 hours, the curd is creped three times, and the granules are torn off, and the granules are dried at 110°C to obtain natural rubber raw rubber. Using the carbon black standard test formula, referring to the mixing and vulcanization ...

Embodiment 2

[0079] Get freshly collected natural latex 5kg, add water to dilute, add 25% ammoniacal liquor 0.04kg, obtain natural latex dilution, natural rubber content is 25%, adopt high-speed refrigerated centrifuge centrifugal, natural latex dilution temperature is 4 ℃ during centrifugal, The separation factor is set to 10600, the centrifugation time is 40min, and the upper latex layer and the lower latex layer are obtained by centrifugation, and the latex layer is taken to obtain the natural latex of large rubber particles;

[0080] The large rubber particle natural rubber latex is diluted with water to 30% of the natural rubber percentage. Take 3kg of natural rubber latex, add 600g of Lactobacillus bacteria liquid to coagulate, and after the curd is matured for 16 hours, it is creped three times, and the particles are torn off, and the rubber particles are dried at 110°C to obtain natural rubber raw rubber. Using the carbon black standard test formula, referring to the mixing and vul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com