Aircraft tire tread rubber as well as preparation method and application thereof

A technology for aviation tires and tread rubber, which is applied to special tires, tire parts, transportation and packaging, etc., to achieve the effects of good puncture resistance, high tear strength and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention provides the preparation method of aviation tire tread rubber described in above-mentioned scheme, comprises the following steps:

[0056] Mix the plasticized rubber of natural rubber. When the mixing temperature rises to 90-95°C, add multi-walled carbon nanotubes, multi-functional vulcanization activator and heat stabilizer to continue mixing. When the mixing temperature rises from 90-95°C When 95°C rises to 100-105°C, add Zhongchao wear-resistant carbon black, white carbon black wet-process adhesive and silane coupling agent to continue mixing. When the mixing temperature rises from 100-105°C to 140-145°C, add The obtained mixture is lowered, cooled and parked to obtain a section of mixed rubber;

[0057] Mix the first-stage compound rubber, tear-resistant resin, zinc oxide and anti-aging agent. When the temperature of the mixing rises to 120-125°C, the obtained mixture is lowered, cooled and parked to obtain the second-stage rubber compound;

...

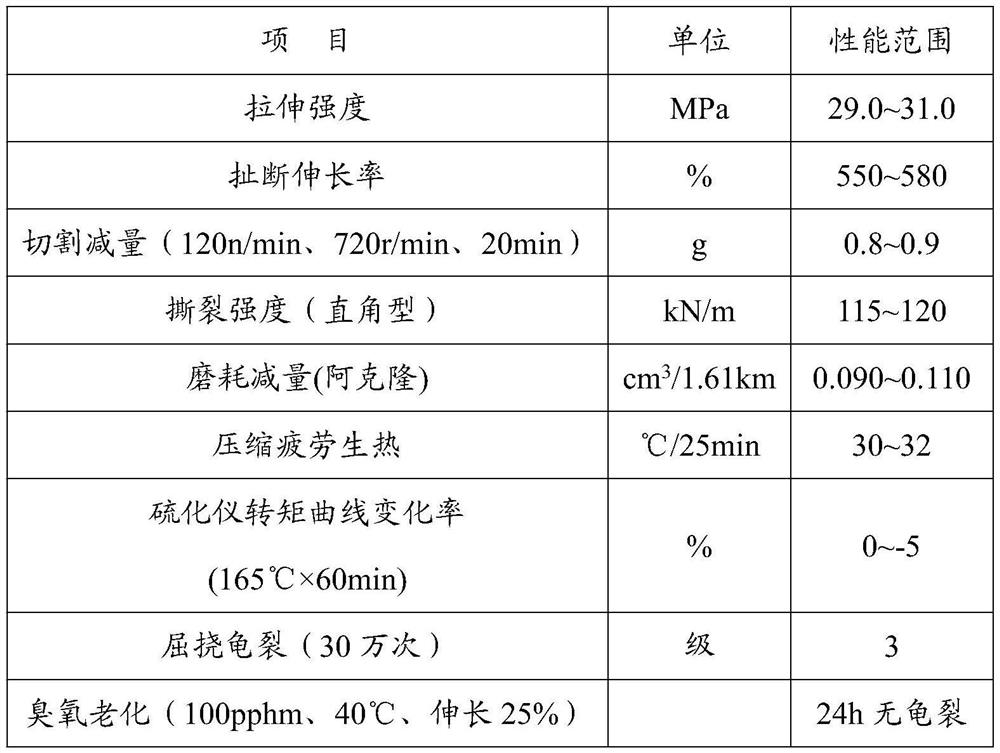

Embodiment 1~3

[0067] The preparation raw materials of Examples 1-3 are shown in Table 4.

[0068] The preparation method of aviation tire tread rubber is as follows:

[0069] One section of mixing:

[0070] Put the natural rubber plastic compound into the internal mixer, and the mixing temperature is raised from 80°C to 90°C; put the multi-walled carbon nanotubes, multi-functional vulcanization activator, and heat stabilizer into the internal mixer according to the proportion, mix and internally knead, The mixing temperature is raised from 90°C to 100°C; put Zhongchao wear-resistant carbon black, white carbon black wet-process glue, and silane coupling agent into the internal mixer according to the proportion, mix and banbury, and the mixing temperature is raised from 100°C to 140°C; when the mixing temperature reaches 140°C, the mixture is discharged from the internal mixer to the tablet press, cooled, and parked for 16 hours to obtain a section of mixed rubber.

[0071] Two stage mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com