A kind of all-steel radial tire shoulder pad rubber and preparation method thereof

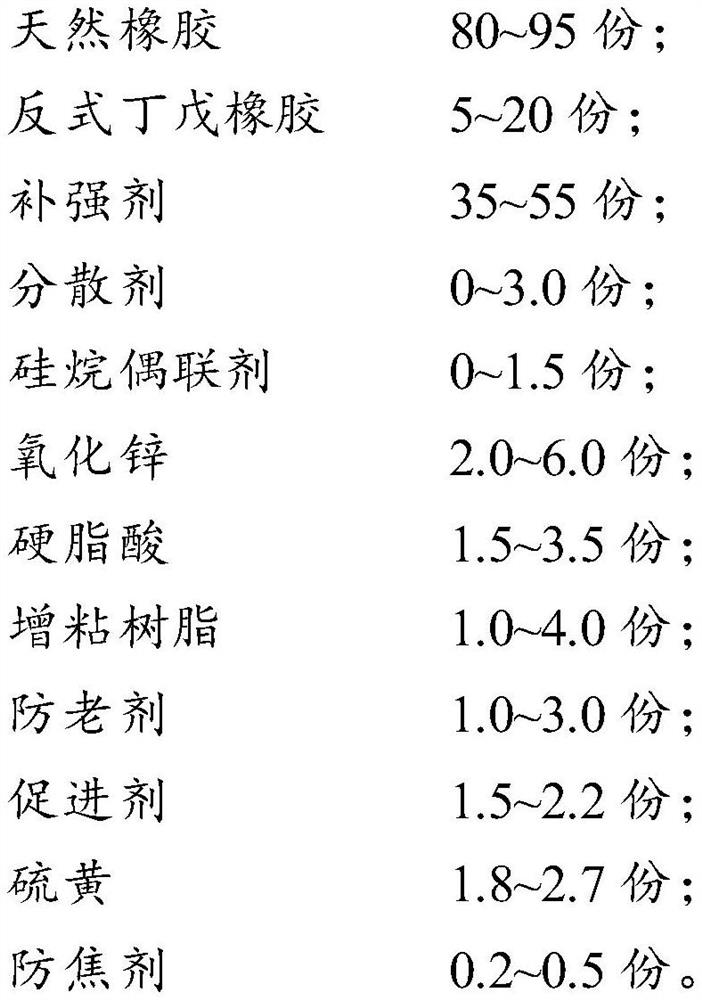

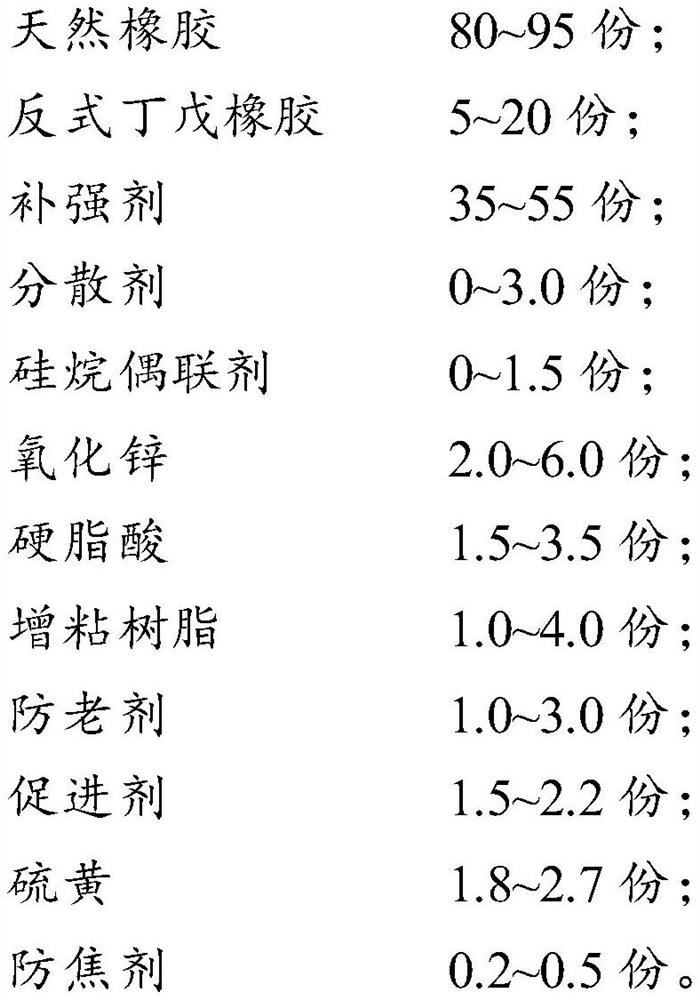

A technology for radial tires and shoulder pads is applied in the field of all-steel radial tire shoulder pads and their preparation, which can solve the problems of reduced vulcanization rate, reduced heat generation by compression of shoulder pads, slow vulcanization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the all-steel radial tire shoulder pad rubber described in the above technical solution, comprising the following steps:

[0044] a) banburying natural rubber, trans-butadiene rubber, zinc oxide, stearic acid, anti-aging agent, reinforcing agent, dispersant, tackifying resin, accelerator, sulfur, anti-scorch agent and silane coupling agent, to obtain Mixed rubber;

[0045] b) kneading the banbury rubber to obtain the final rubber mix;

[0046] c) vulcanizing the final rubber mix to obtain shoulder pad rubber.

[0047] Wherein, the types and types of natural rubber, trans-butadiene rubber, zinc oxide, stearic acid, anti-aging agent, reinforcing agent, dispersant, tackifying resin, accelerator, sulfur, anti-scorch agent and silane coupling agent Consumption etc. are all consistent with described in the above-mentioned technical scheme, do not repeat them one by one here.

[0048] In the present invention, said...

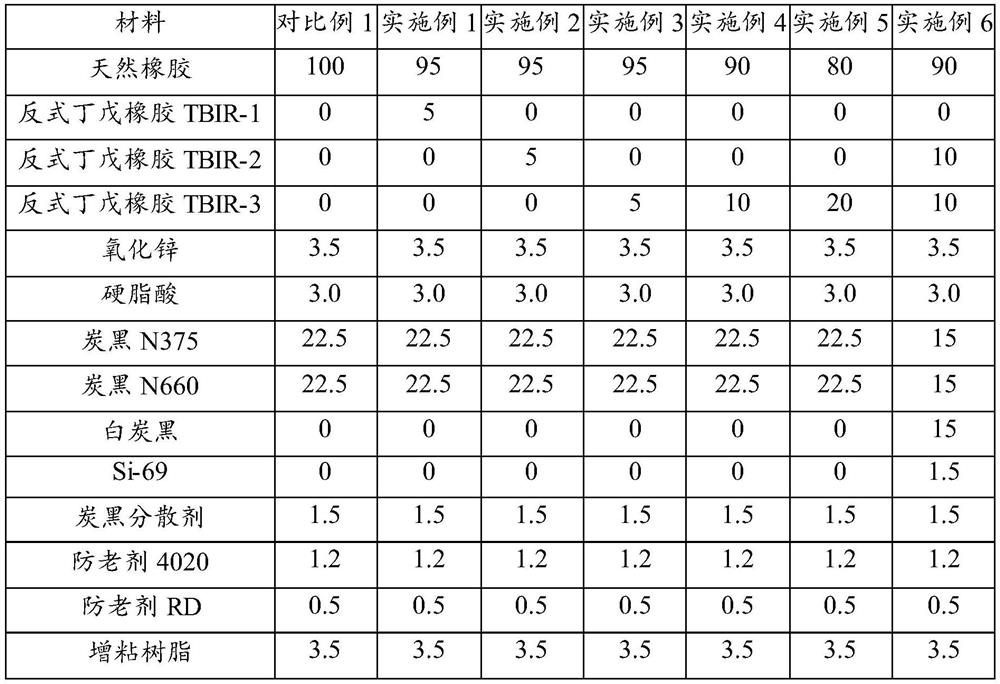

Embodiment 1

[0059] 1.1 Raw material

[0060] 95 parts of natural rubber SCR WF, 5 parts of trans-butylene rubber TBIR-1, 3.5 parts of zinc oxide, 3.0 parts of stearic acid, 45 parts of carbon black (22.5 parts of carbon black N375+22.5 parts of carbon black N660), 1.5 parts of carbon Black dispersant Adhesive AR-105, 1.7 parts of anti-aging agent (1.2 parts of anti-aging agent 4020+0.5 part of anti-aging agent RD), 3.5 parts of phenolic tackifying resin, 1.8 parts of accelerator TBBS, 2.25 parts of sulfur, 0.4 parts of anti-scorch agent CTP.

[0061] 1.2 Preparation:

[0062] S1. One stage of internal refining:

[0063] The initial temperature of the internal mixer is 70°C, the rotational speed of the internal mixer is 70rpm, and the feeding coefficient is 0.75.

[0064] The natural rubber and trans-butadiene rubber were banburyed for 1 minute, and active agents such as zinc oxide and stearic acid, anti-aging agent, reinforcing agent and dispersant were added to continue banburying for...

Embodiment 2

[0075] According to the raw materials and preparation of Example 1, the difference is that the trans-butadiene rubber TBIR-1 is replaced by trans-butadiene rubber TBIR-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com